For the past year, the four tawny stalks that NoodleFeet balances upon have remained common pool floaties, 2.5 inches in diameter, hollow, providing nothing more than the obvious support needed to function as legs... but Noodle longs for something greater.

GRIPPING TOES

When Noodle feels threatened, there is little he can do to defend himself. He can beep and perhaps canter away at a slow speed… but he is passive and therefore vulnerable. He isn't equipped to handle the harrowing task of world domination::cough:: I mean, daily life. To fix this, I decided to add another layer of complexity to Noodle’s most important characteristic: RETRACTABLE GRIPPING TOES for his feet.

A while back, I came across a video of a rock drilling probe concept (this is actually a newer video they've made featuring a full robot using their device! So cool!). This neat claw attaches itself to a surface by splaying out a hundred or so mini grappling hooks in all directions, which catch on the rock and help anchor the central cylindrical drill in place. I saw this and thought to myself… Noodle needs four of these, as shoes.

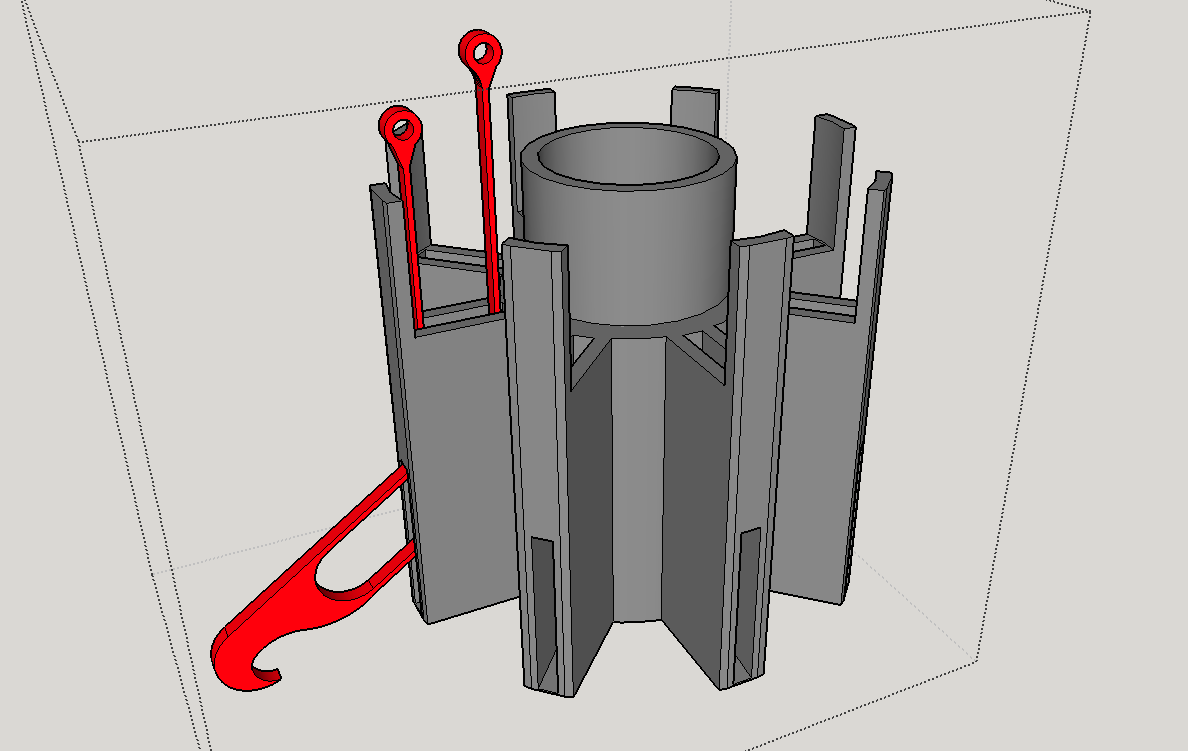

Like a good mother, I started brainstorming how to create said shoes. Originally I designed long claw-like toes that rotated out and back, sort of like switch-blades:

They fit into Noodle's original 2.5" diameter noodle material, and even added stability... but there wasn't enough area to actually install any motors to actuate things.

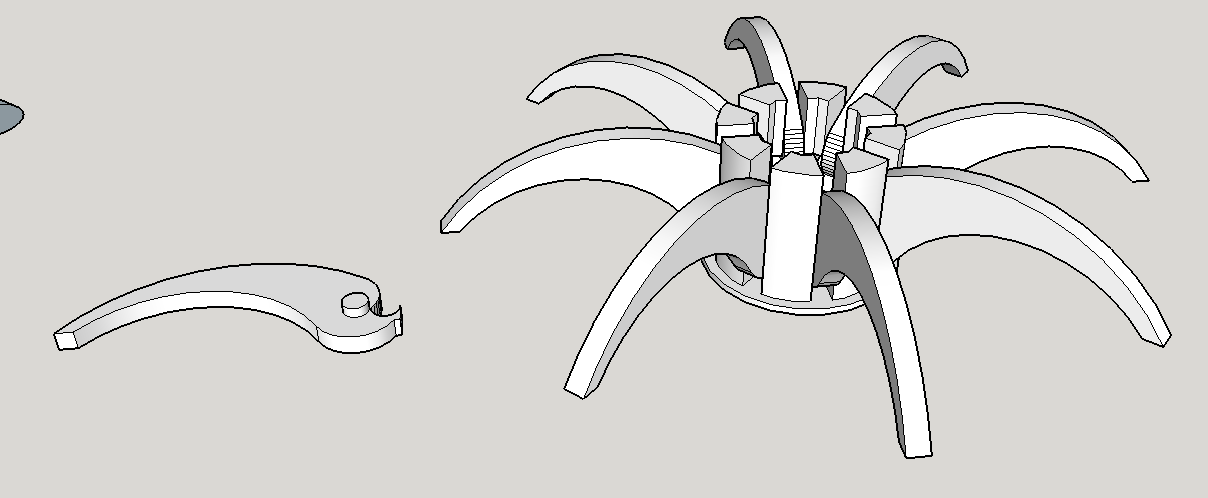

With a little bit of trial and error I rethought the whole design and came up with a solution that made use of 3D printed plastic’s flexibility. This new concept worked more like a cat's retractable claw, and was similar to the drill from the video that had inspired me.

Each individual toe (in red) would be forced through a curved internal channel and out the side via two thin bendable "tendons":

How The "Tendons" Work

An individual toe has two strands of tendon attached to the back. When the tendons are pulled in opposite directions, it causes the toe to torque upwards or downwards.

Why Do the Toes Need to Tilt Back and Forth?

If the toe goes straight back into the sheath the way it came out, it won't unhook from whatever its currently gripping. Also, the tip of the toe will likely snag on the edge of the sheath on its way back in. To properly "detach", the toe should arc upwards slightly as it retracts.

My first prototypes were designed to fit inside the 2.5” diameter noodle material. I was able to make it work, but it didn’t leave much room for the other future functions of his feet (his tongue):

In the end I really needed more space to fit moving parts and hardware. Luckily I have a noodle fairy living with me (Mark) who harvested a larger piece of noodle stock from a pile in his garage. It is 4” in diameter and offers me much more room to play around with! Plus, fatter feet will give Noodle more stability!

4" PRO-TOE-TYPE 1.0

I tweaked my design for the new 4” material and printed my first prototype with a set of eight twinkling magenta toes (I haven't ordered red filament yet).

The reason for the tendons being slightly different in length is so that when they are fixed next to one another, it creates the needed outward/upward tilt:

(so, this is what a toe flower looks like):

I originally planned to connect both tendons of each toe to a common ring piece (above). When the ring is pushed downward towards the sheath, it would force all of the toes through their channels and outward at the same time. I also added a spring and guide rod (a long screw) below the ring to push it up again once downward force is removed:

The first complete 4" prototype worked more or less... It certainly passed the "carpet snagging" test:

I learned right away that I couldn't actually connect both tendons to the same ring and run it through the inside of the sheath without it binding (which now seems pretty obvious). The only way I could get the above demonstration to work was if I left the longer set of tendons sticking...

Read more » Sarah Petkus

Sarah Petkus

Did you consider or try using a solenoid to push the ring connecting the toes down? I was reading one of your blog posts, in which you described putting the toes in a 3.5" foam floatie originally, but the problem was no room for motors. Would a slender solenoid maybe fit in there?