Oasis

Oasis is a open source powder and inkjet (3DP) 3D printer. It is designed to be a hackable platform to experiment with 3DP printing.

Current specs:

- Build size: Ø84mm x 100mm;

- Printhead: HP45;

- Printhead DPI: 600;

- Printhead swatch size: 300 nozzles, 0.5" (12.7mm);

Handy features:

- A cover to keep dust out and powder in. (This may seem mundane, but was seriously lacking in my previous printers).

- A large, flat, unobstructed build area that is easy to clean. (Again, seems mundane, is not mundane).

- An aluminium extrusion frame where parts can easily be bolted on.

- Plenty of room for future additions (It should be able to handle 5 printheads or a 200mm cubed print area).

Logs of interest

- https://hackaday.io/project/86954-oasis-3dp/log/117820-a-bit-of-background

- https://hackaday.io/project/86954-oasis-3dp/log/118433-an-introduction-into-3dp-and-oasis

- https://hackaday.io/project/86954-oasis-3dp/log/123969-a-start-on-the-inkjet-controller

- https://hackaday.io/project/86954-oasis-3dp/log/145601-construction-in-progress

- https://hackaday.io/project/86954-oasis-3dp/log/153322-some-info-on-interfacing-with-the-hp45

- https://hackaday.io/project/86954-oasis-3dp/log/153411-the-color-of-the-day-blue

How 3DP

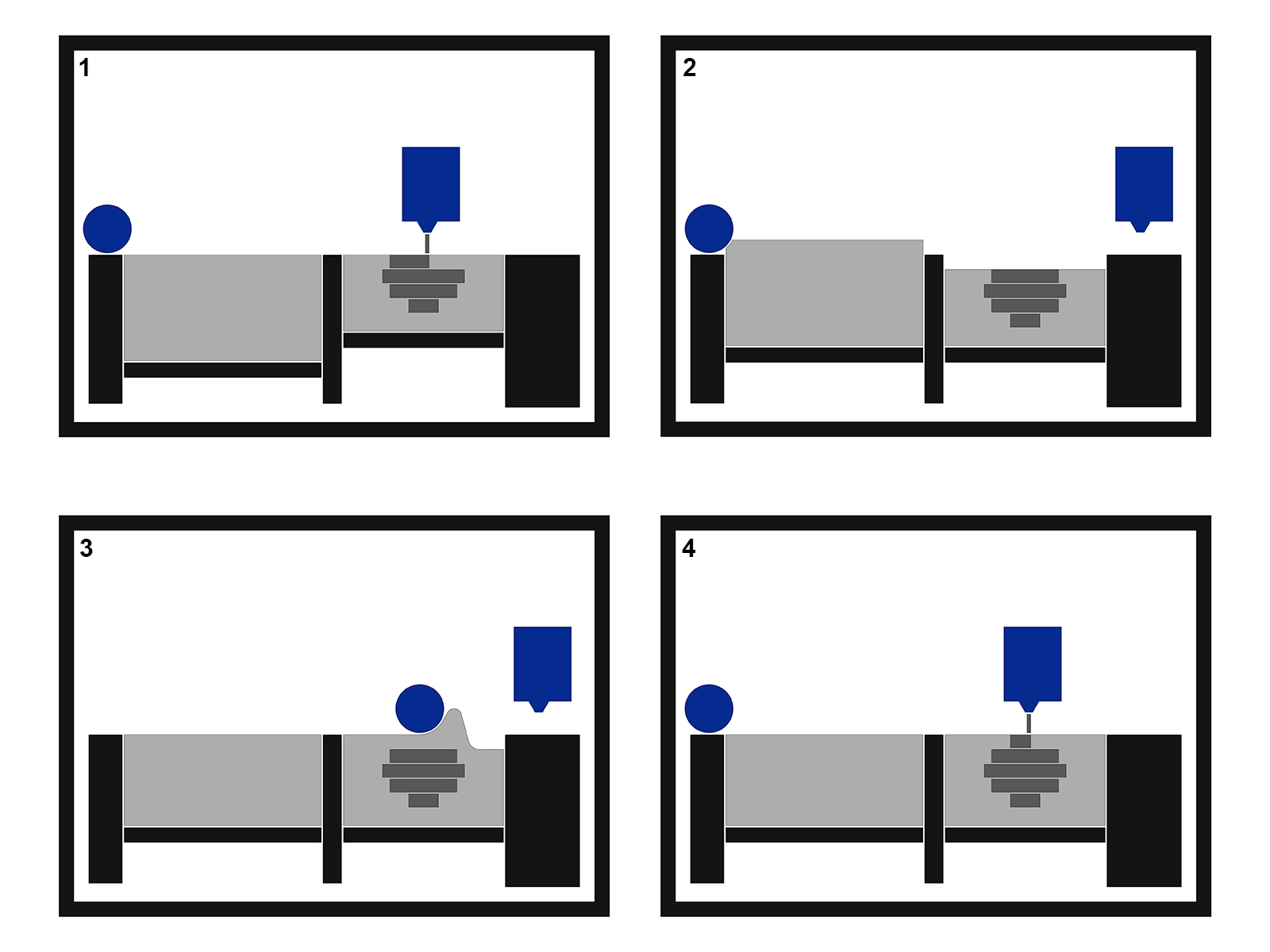

'3DP' also going by the names 'binder jetting' or 'powder and inkjet printing', is a technique that uses inkjet and powder to fabricate parts. 3DP printers consist of a moving inkjet printhead, a build area, and a way to deposit new layers of powder in said build area. The example below uses 2 hoppers and a spreader. The left hopper supplies the powder and is called the 'feed hopper', the part is built in the right 'build hopper'. A spreader can move between these hoppers to transfer powder from one to another. The order of operation for 3DP printing is as follows:

- The inkjet head deposits binder wherever the part needs to be. Where the binder fills the powder, the powder solidifies;

- The build piston lowers by the layer thickness, the feed piston raises enough to fill the build area completely;

- The spreader spreads the powder from the feed hopper to the build hopper;

- The spreader returns and the printer starts at step 1 again. This is repeated until the part is finished.

After this printing, the part is allowed some time to dry. It can then be removed from the printer and gently cleaned. After this the part can either receive further processing, or be used directly.

Why 3DP

3DP is quite unlike FDM and SLA. It's biggest advantages are:

- You do not need support material. The powder is added one layer at a time, and the powder from the previous layers supports the next layers. All the unprinted powder can be reused infinitely.

- A wide range of materials can be printed. While FDM is limited to plastics, and SLA requires light sensitive resins, 3DP can print most materials that come as powders.

- Color can be printed. Because 3DP uses standard inkjet technology, it is possible to add color, simply by printing dye alongside the binder.

3DP is not perfect though, There are some drawbacks that need to be considered:

- Powder printing is inherently messy. Very messy.

- All prints require post processing, ranging from simple cleaning to firing or infiltrating. Untreated parts are very fragile. This also limits maximum size of parts. The part needs to be able to survive post processing.

- All of the print area needs to be filled with powder. While the excess can be reused, a minimum amount of powder is required to print at all.

- 3DP prints only one material at a time.

- Hollow parts need escape holes to drain unprinted powder.

What 3DP

There are a variety of materials 3DP can print. The only thing these materials have in common is that they are powders. In most cases, a glue is added to the powder. Examples of this are PVA, sugar or maltodextrin. The binder is generally an inert liquid, like an alcohol/water mix. I have seen people printing directly with Vodka or Rice wine (Rice wine smells amazing). While I do not posses a full list of possibilities, a range of know materials is provided below.

- Gypsum (with PVA) and a water/glycol/potassium sulfate mix is used on Zcorp machines. The material safety datasheet gives insight into what the powder is. Gypsum allows for full color prints. The printed parts are cleaned and infiltrated with a wax or resin afterwards to give the parts strength. (Powder / Binder)

- Sand (for sand casting molds). ExOne specializes in this. By printing in types of sand with special binders (Furan, Phenolic and silicate binders are mentioned) you can create detailed sand casting molds that can receive metal without special post processing.

- Metal can be printed with a special binder. The part is printed in fine stainless steel with a glue in the binder. After printing the part can be infused with bronze in a kilt, turning it into a full density metal part. ExOne and several others do this technique. (A good example is this video)

- Ceramics can be printed by adding glue to the powder. Most of the available information uses maltodextrin and powdered sugar to make the ceramic powder printable (most recipes 4-1-1 ceramic, sugar, malto). A 10%-20% alcohol/water based binder is then used to bind the part. A site called open 3DP (university of Washington) has some great potential recipes, not only in ceramics. Check the site out if you have time.

- Powdered Sugar was revealed by a company called 'The Sugar Lab' around 2013, but was almost instantly bought by 3D systems. It now lives on as Chefjet. Exact details of how to print sugar are not known, but I suspect printing in pure sugar with water/alcohol should already somewhat work. I will investigate.

License

All software related to the Oasis 3DP printer is licensed under GPL v3. A PDF license can be found in the "files" section.

All CAD files on this page are licensed under the Creative commons - Attribution - ShareAlike license.