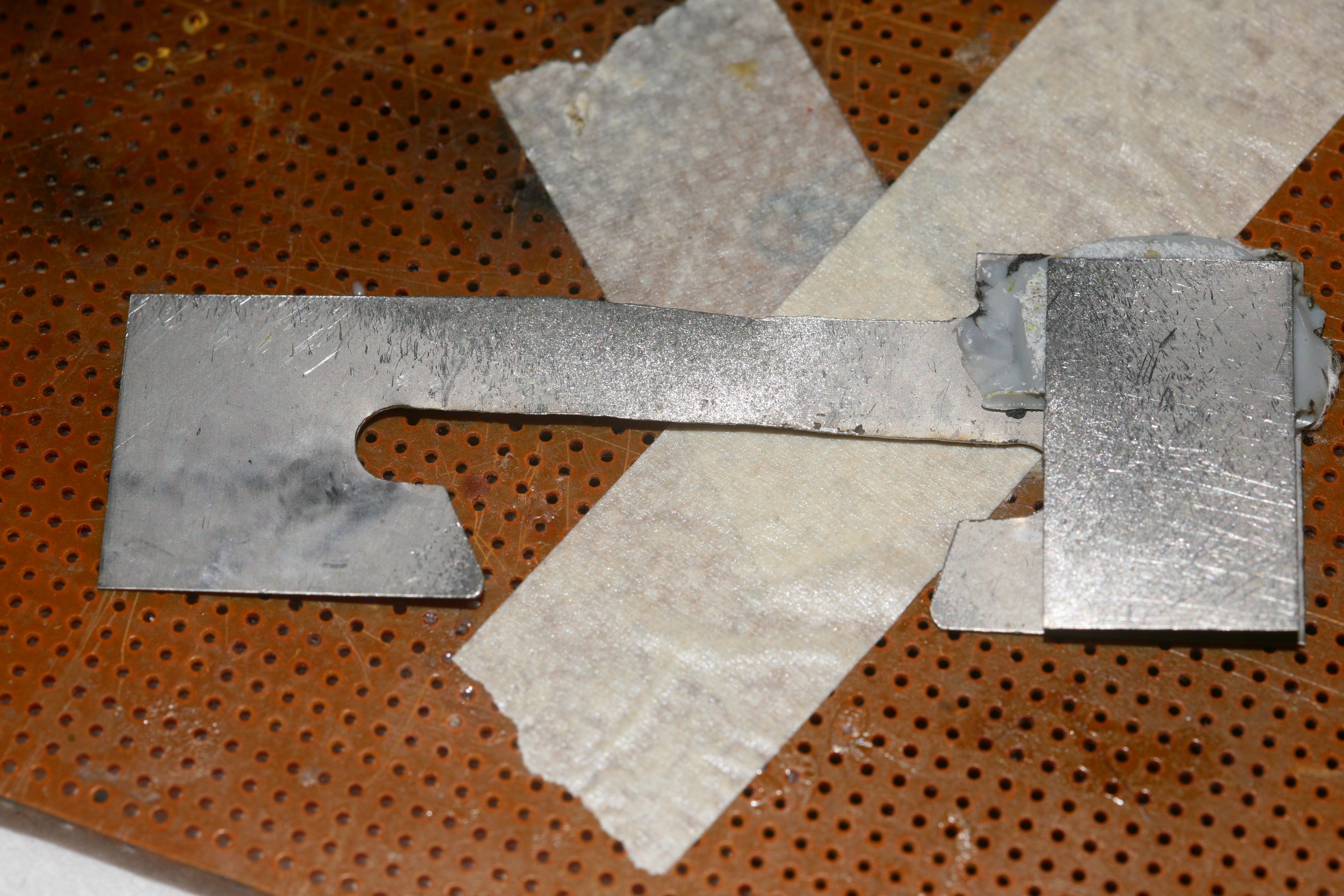

It held up nicely, after 7 miles. It was like running on tin cans. The Loctite Metal did release near the flexing point, but it probably wasn't worse than hot glued plastic.

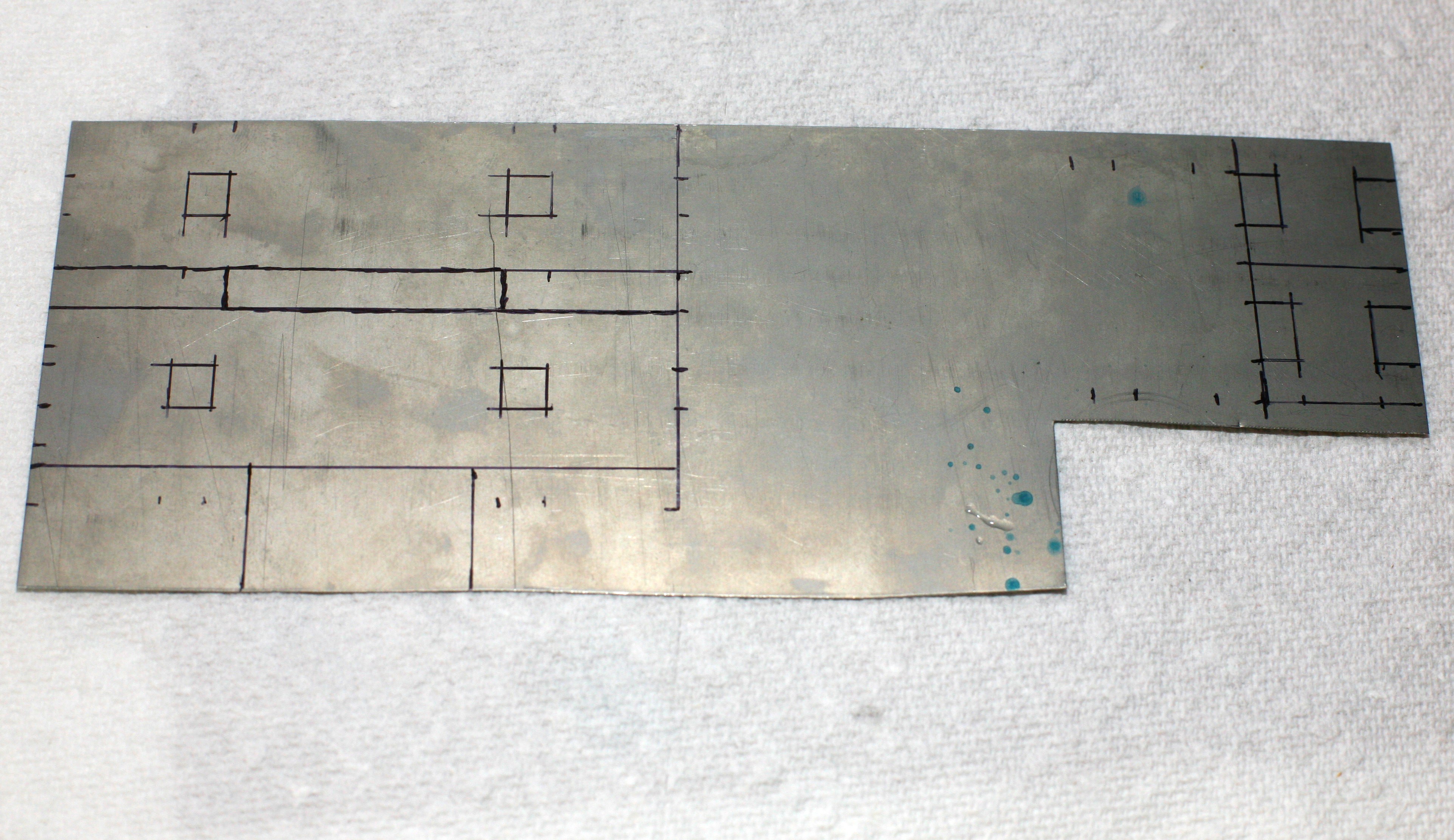

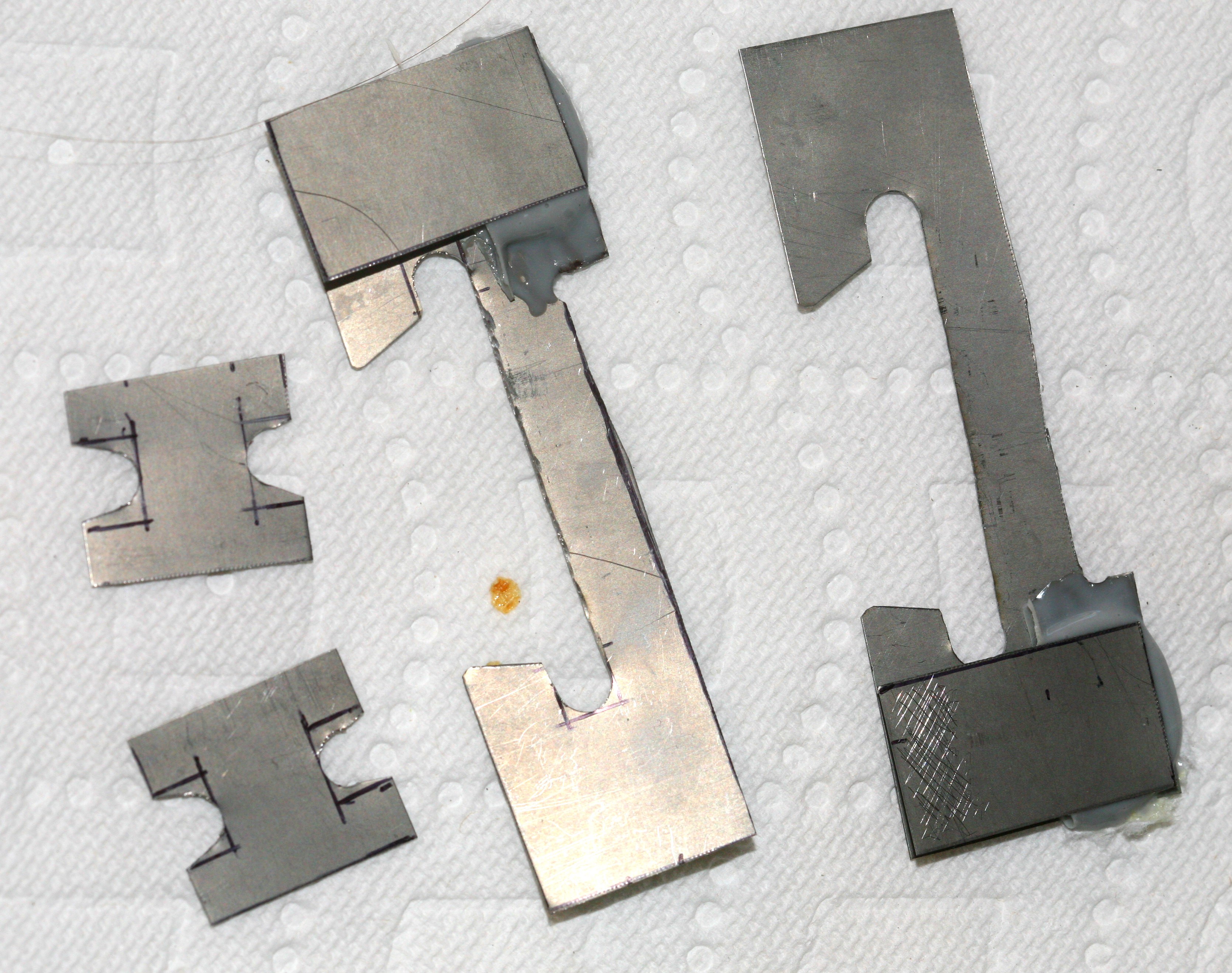

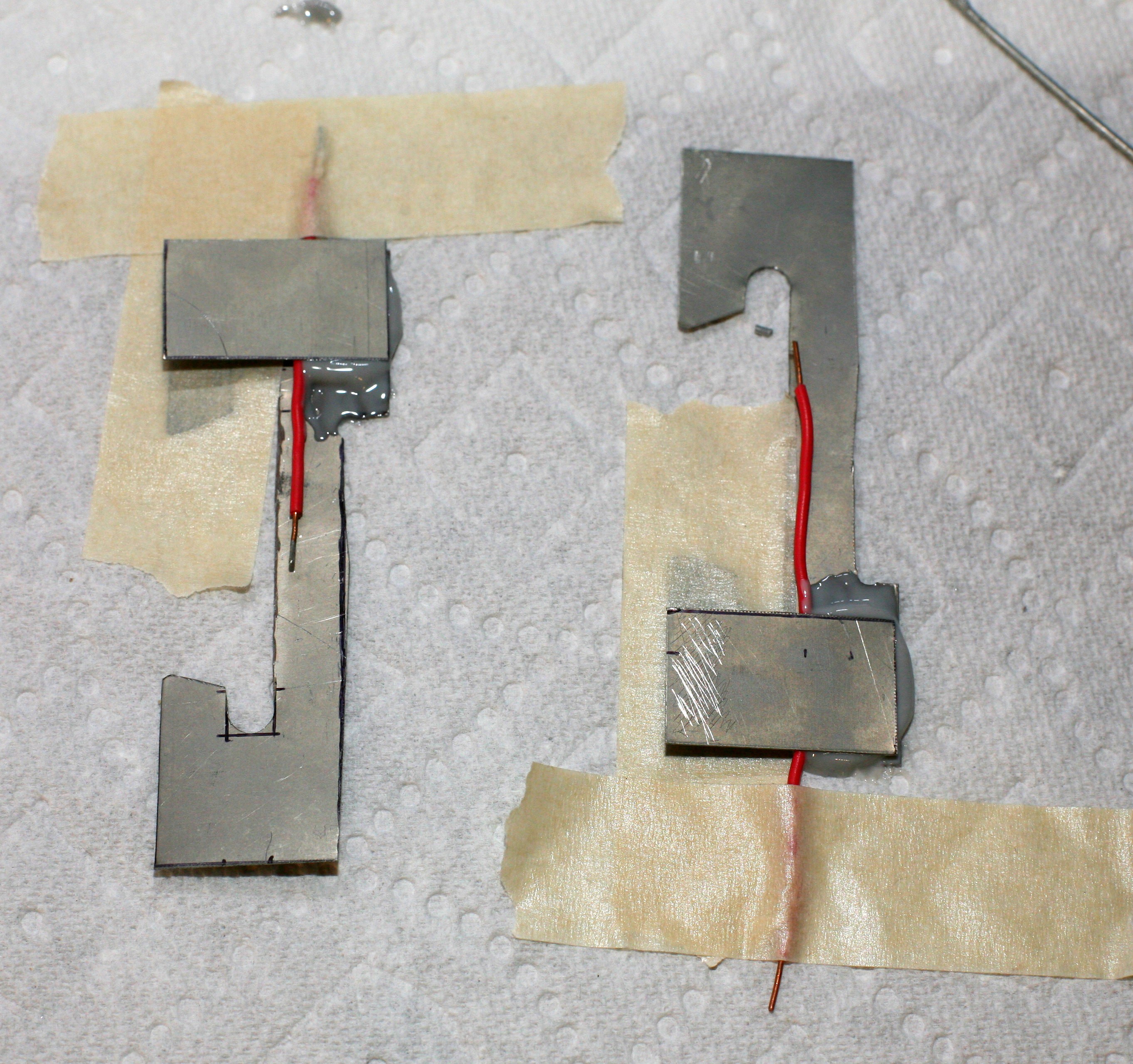

Fabrication involved a lot of drilling. Drilling holes bigger than 1/8" in titanium must be avoided. This process could probably be done with V cuts & grinding. Grinding titanium causes dramatic work hardening, but it hasn't been a problem for this application. That was all the titanium the lion kingdom can afford, for a long time.

Heat was the last remaneing problem with the laces. The resulting sweat would dry & attack the achilles tendon. After 11 miles in 90F, the 1/8" string solution didn't chafe anything. They could be any tightness. The farsteners were easy to adjust. Replaced the orange ones with black ones to make the toe plugs tighter.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.