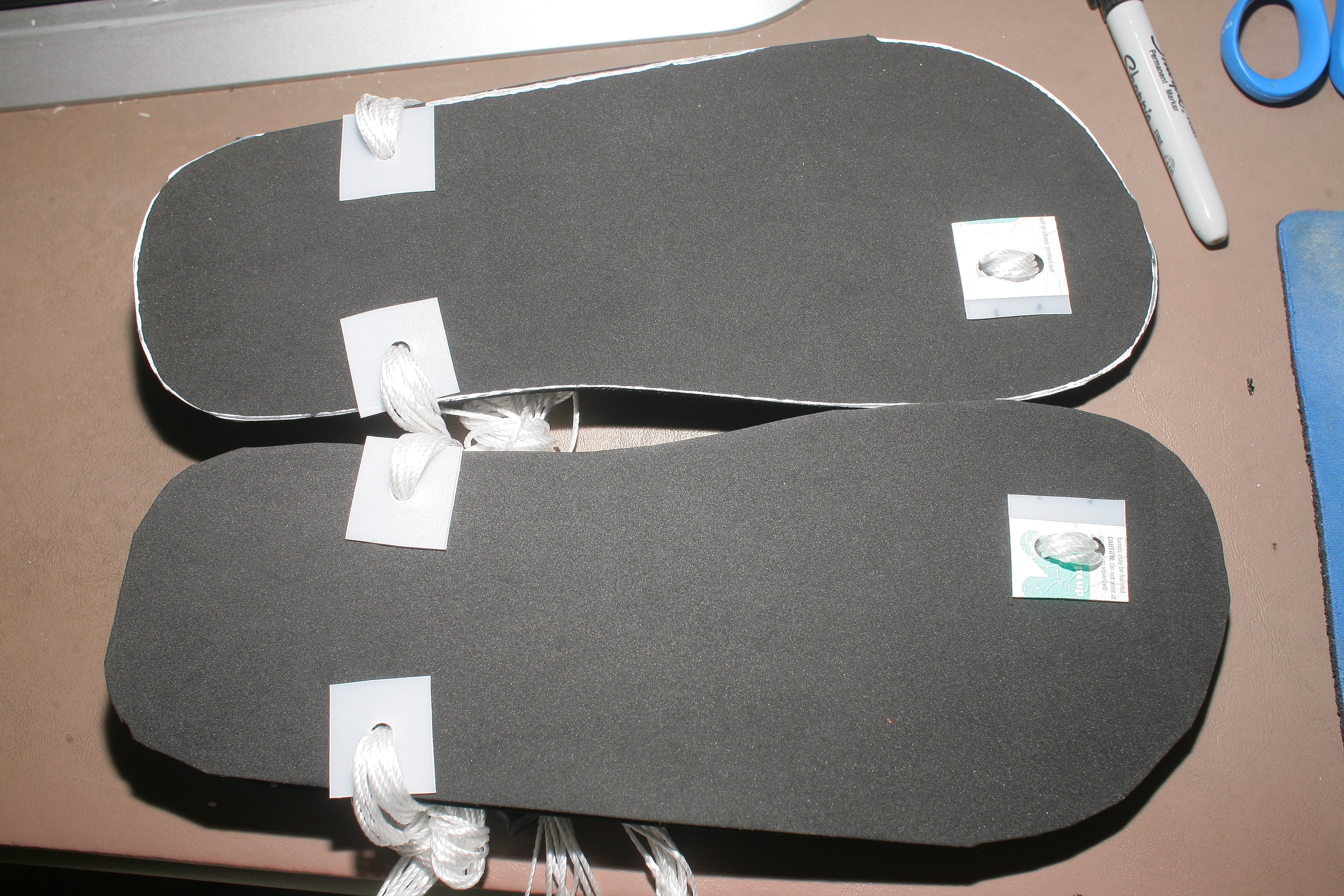

A proper hole punch provided much more accurate holes than the drill. The rear holes were 1/2" farther back than the Walmart template.

Polypropylene squares for foam reinforcement returned. Should definitely make the rear squares wider. Considered using a single sheet of tough plastic over the entire sandal, to protect from rocks. Such a variant is a must for trails. Titanium would actually now be practical in place of all the plastic, if only lions had the money. This would give the toughness of 4mm Vibram soles without the weight. It's still hard to believe lions once ran on bare 4mm soles without any foam.

The 2 layers of foam were tacked with E-6000. 1/16" string was painstakingly bundled for another attempt.

Now the string would be completely above the soles instead of extending below the soles, hopefully providing enough protection for the 1/16" string.

The soles were hot glue tacked to the foam, to allow the string to be replaced.

The soles will need extra patches, when the most heavily worn areas are determined.

After lacing, the laces were trimmed again. Getting the right lengths of rear lace is still a bit of trickery. Fortunately, a bit of effort can still shift the rear lace around without removing it.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.