It wore through a lot faster than the expensive Vibram. The string did well, since these were only worn for 151 miles.

Other changes would be reverting the length to the original Walmart size, since the lacing was never accurate enough to precisely center the paw. The string can't be trimmed until after some running. Softer adhesive needs to be used to terminate the string.

Finally had a sole fall completely off because of the hot glue becoming disengaged. It could have been hot pavement. The decision was made to use E6000 to adhere the soles from now on.

The mane problem is E6000 reacts with rubber to cause it to warp. The 1st attempt to deal with the problem was tacking the outside with hot glue after making a bead of E6000 on the inside. This still didn't produce a durable seam & made it heavier.

A new Vibram sheet costing 25% more than the last one arrived. Not sure if it was a tariff or Pandering Powell.

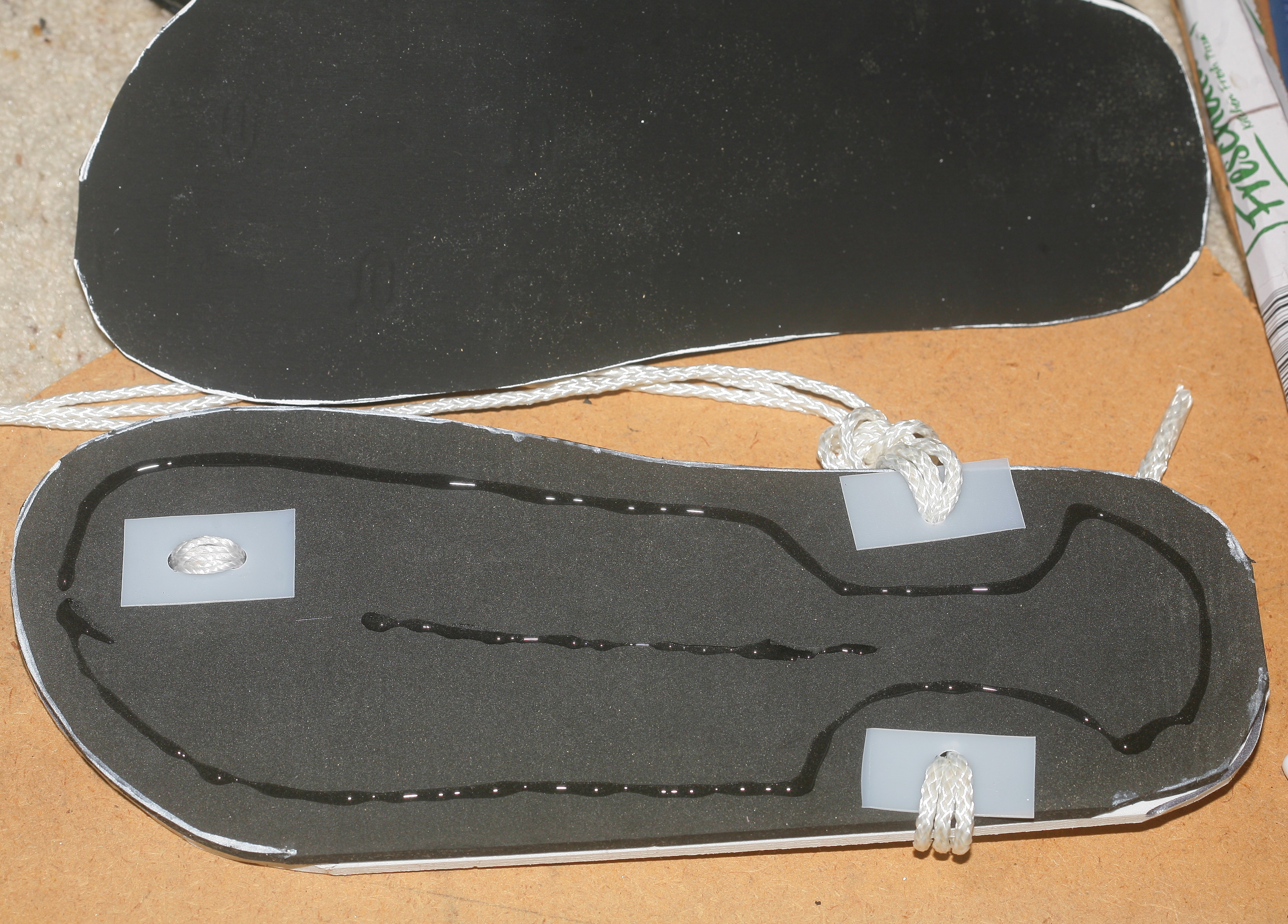

Getting the ideal seam requires a jig. Cut up the last of the flip flops to press the seams together while not pressing the string. It had been a long time since lions wore those flip flops for 13 miles & even longer since they were a radical design. They lasted 50 miles if they were lucky.

Glue pattern

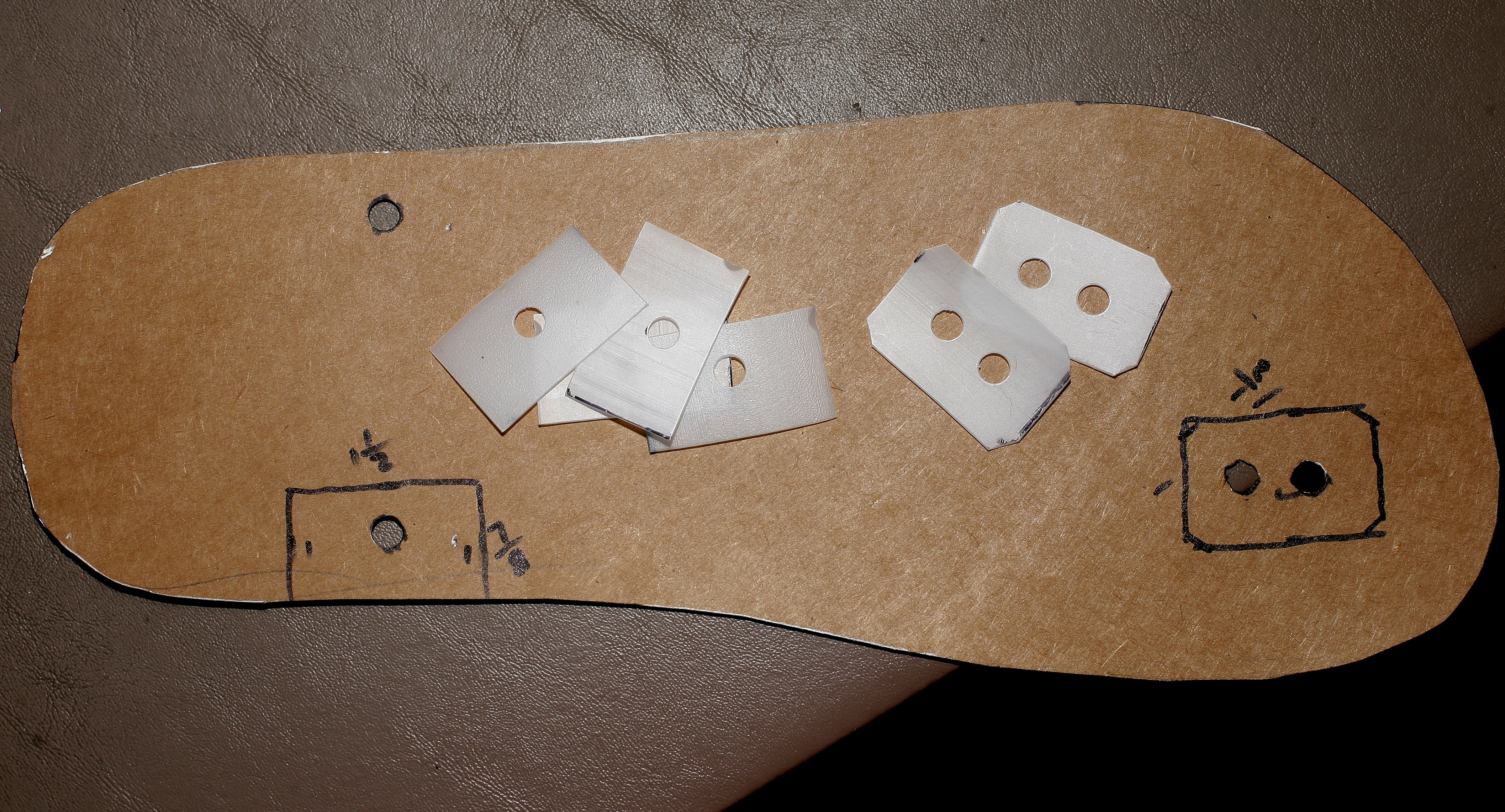

The plastic hardware was rounded to try to reduce the wear on the sole.

Latest measurements of the plastic bits. They have to be long & narrow to prevent the string from getting under.

Gravity was not enough to do the job & they still warped. Wood clamps would be required. Chinese are manufacturing magicians.

Hot gluing over the CA glue areas ended the chafing from those parts. The white string caused less chafing than the yellow string, but frayed more.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.