I beefed up the guide rails. Seems to handle the weight fine on 12mm rails, HOWEVER...

A change in rails means a change in bearings. I don't have any 12mm linear bearings just kicking around, so I opted to print some. Printed in igus Tribo and PLA, I came up with the same issue: lateral compression. When the stock bearing holder was tightened down, both the tribo and PLA bushings compressed enough that instead of providing easy travel, I found a tight grip! :P

I built a custom hold-down with PLA (which meant complete dis-assembly of the new and re-assembly of the original bed) that cuddled the bearings to distribute the outward pressures, but to attach it, I needed longer screws... Searching long and hard, I finally came up with some longer M4 screws of equal length. Screwed it together, reassembled the new bed and associated hardware, plugged it in and.....

The power supply would not turn on. I tried the supplied power converter and nothing. What the heck?

Turns out I tightened the longer screws too far and hit the printrboard with one of them, somehow creating a tear in the space-time continuum that absorbed electricity before it was produced...

Sigh... Took care of that issue and ran it. The mutant printrbot bed bucked like a green stallion. At the end of motion (stop point, direction reversal) the bed ends wiggled like you wouldn't believe. This was probably due to the bearings popping out of their places. PLA can be pretty slippery.

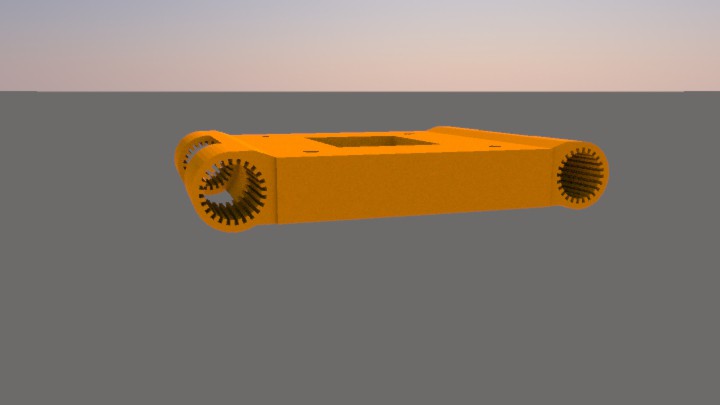

Hopefully I have found a solution; why have separate bearings at all?

A one-piece x-axis bushing block. Will print out soon and let you know how that goes!

ken.do

ken.do

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.