Ok... so the printing bushings didn't work out.

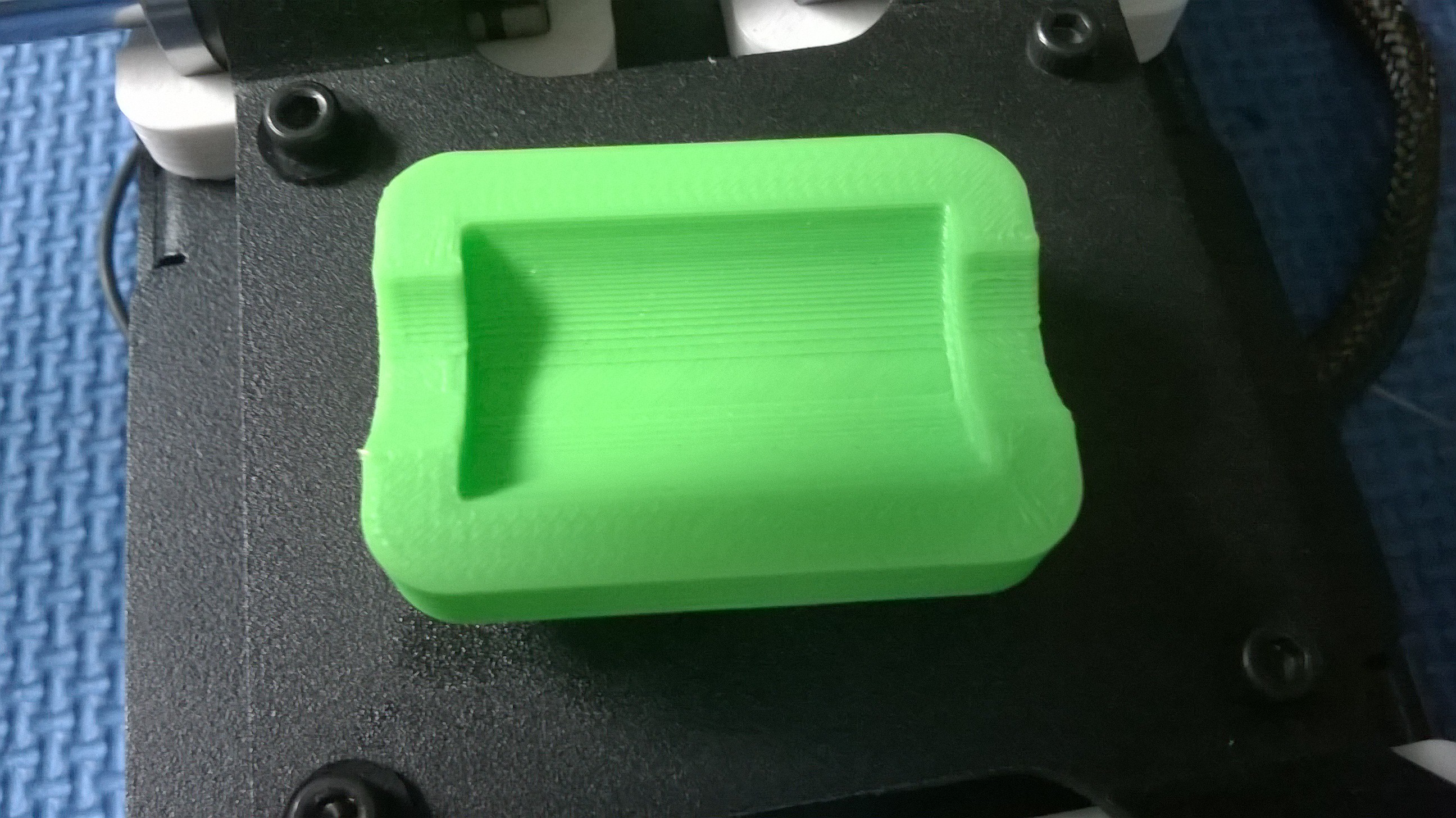

I finally got some 12mm linear bearings and tried installing them without modification. The 12mm bearings are quite a bit longer than the stock 8mm bearings, so they didn't fit in the frame holes (this was expected). I designed and printed some cradles that slot into the holes in the frame to hold the bearings in place. These are the originals:

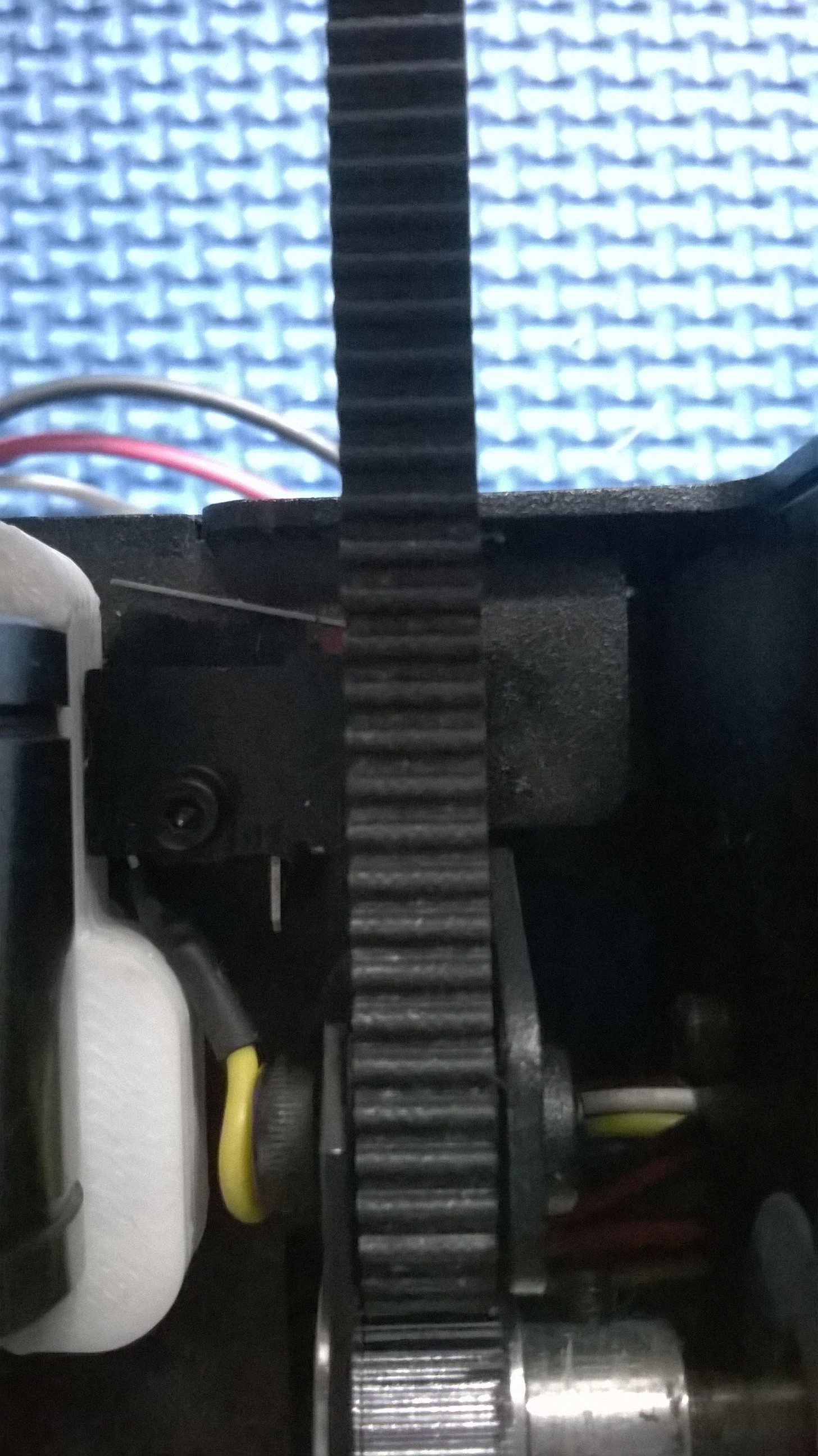

Great idea! But there were some issues. The insert bit fit too loose, one cradle interfered with the endstop switch, and the whole cradle stuck out too far. A quick redesign and reprint, and everything fits. But the end of the x-axis rails no longer connects with the endstop before it hits the bearing. I drilled a hole and put in a machine screw to hit the endstop switch and voila! Success.

First print was the other x-axis end. Seems like I have reduced but not eliminated the jiggles... yet.

ken.do

ken.do

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.