Graphene Oxide Nano Ribbons can be synthesized from iMWCNT feedstock via a modified hummer's method. The epoxide/oxygen groups are present mainly on the periphery of the graphene using this method allowing very low defect graphene to be covalently bonded to an epoxy bulk. This produces a composite with much higher stiffness and modulus than pristine epoxy.

Slightly oxidized iMWCNT have been explored as well and do not offer the performance I am looking for as it is believed by me that the crystalline graphite present harms itself during failure, so it is important to not have any single layers of graphene touching other graphene but to be completely seperate. Consequently loadings higher than 3% w/w have a detrimental effect on performance.

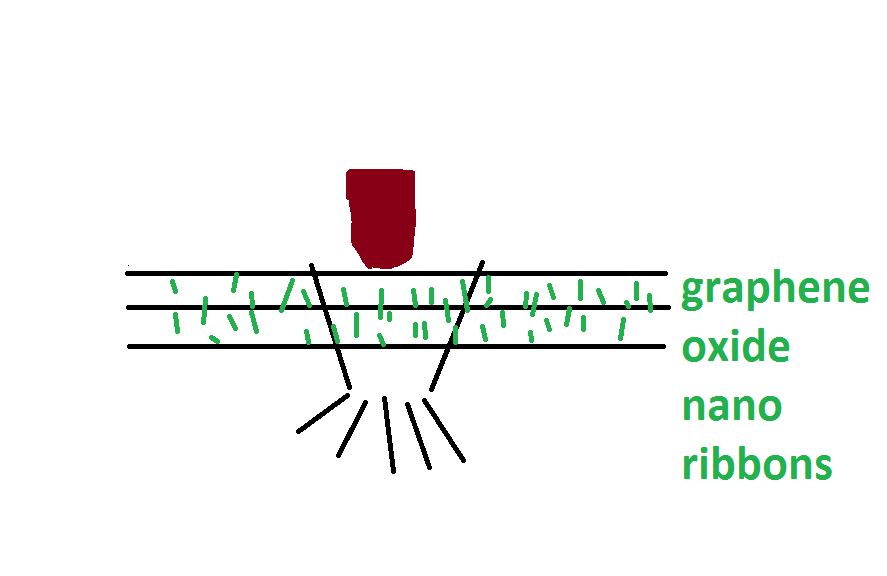

Alignment is also important as some composites call for disorder and others in my opinion alignment orthogonal to the plane of impact. Using high voltage (10kV) AC and aluminum screens I align nano-particles through the thickness of the composite.

I subscribe to the shear plugging theory of terminal ballistics in hard armor meaning a material must be stronger through thickness than perpendicular to the plane of impact. This keeps layers of composite from providing ballistic resistance through failure, instead I would like to provide ballistic resistance through engagement of the composite as a whole.

Had to go hard in the paint for that one.

MECHANICUS

MECHANICUS

Bonez

Bonez

Michael Chapiro

Michael Chapiro

ElectroBoy

ElectroBoy