-

CPU replaced - but not finished

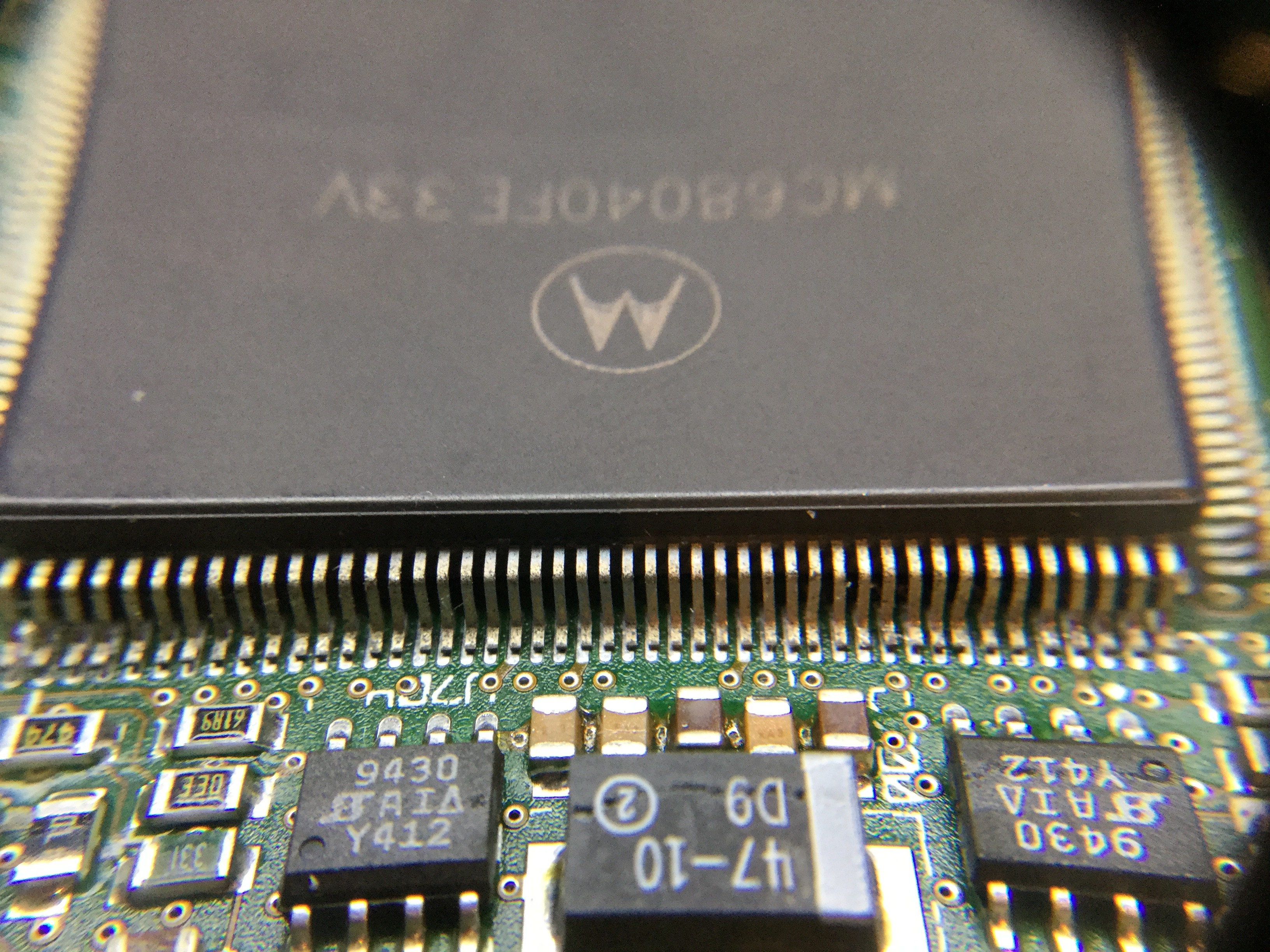

01/29/2016 at 20:50 • 0 commentsI got the new CPU soldered on. I had planned on soldering each lead with my finest tip, but this proved impractical. Also, the fine tip really doesn't supply enough heat if you need to clean up with solder wick, which I did occasionally. I switched to my standard tip and ran it along the ends of the pins while touching it occasionally with very fine solder.

At this point most of the pins look good. A few are dry, as I can move then with the tip of my SMT tweezers. I'll be bringing over to someone with a microscope this weekend so we can touch up the pins properly.

So far, I'd say this has been pretty challenging to solder. I'd considered really flooding the pins with solder and cleaning up with fluxed solder braid, but it's really tight in there and even with pre-fluxed wick, I found it didn't do a particularly reliable job of soaking up all the excess solder.

-

68040 has arrived

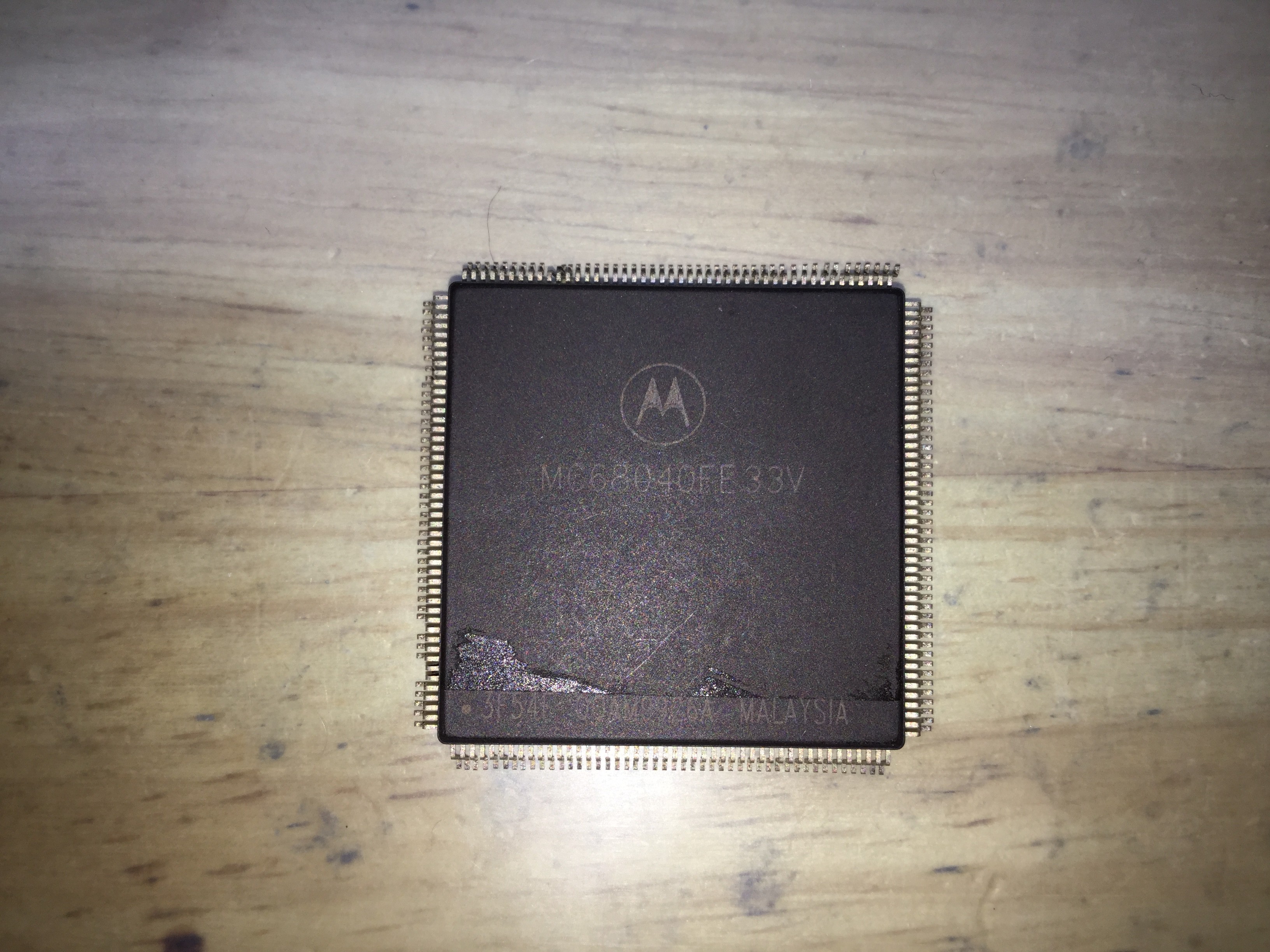

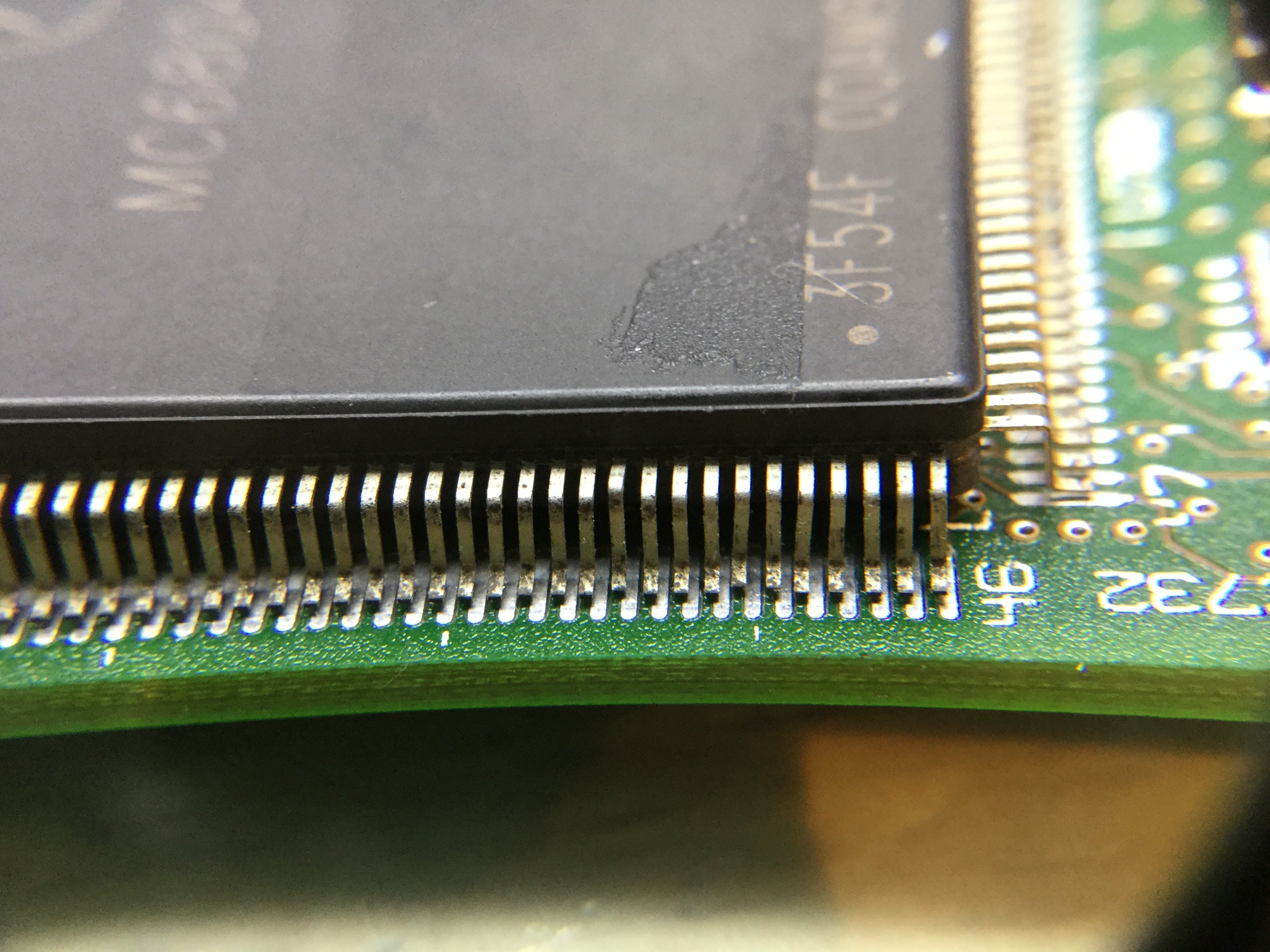

01/26/2016 at 03:36 • 0 commentsThe MC68040FE33V arrived today from China. It doesn't look like a pull, but the pins look kinda corroded. I'll have to research how this can, if at all, be cleaned up. Certainly not by rubbing the pins. Speaking of pins, they are somewhat bent. In the crappy close-ups through the jewelers loupe, I've done a cursory straightening of the pins with my fine SMT tweezers.

I will probably have to accept less than 100% perfection on the pins and do some final tweaking once the first four or so pins have been soldered on and the chip is somewhat anchored to the board.

As removed from the cardboard it was taped to:

Fixed up a little:

-

680LC040 removal!

01/17/2016 at 21:37 • 0 commentsThe daughtercard and the ChipQuik removal kit came in. In the videos below, I remove the 680LC040 and get the board ready for the 68040:

Tools and Planning:

Desoldering: (a bit long, due to fiddling with the flux and the actual chip removal)

Clean-up:

Review:

Note that I specifically chose not to use the hot-air rework station. I wanted to see if the 68LC040 could be removed with soldering iron and ChipQuik alone, as that would broaden the audience of those able to do the work. As it turns out, the hot-air station was not necessary, just patience in going over the leads enough to heat the whole chip.

68040 upgrade for Powerbook 520c

Unsoldering and resoldering a 180-pin QFP! Thrills! Excitement! A full 68040 in a Powerbook 520c!

hackaday

hackaday