We've been running with no way to home the machine which has been something we have been putting off until today.

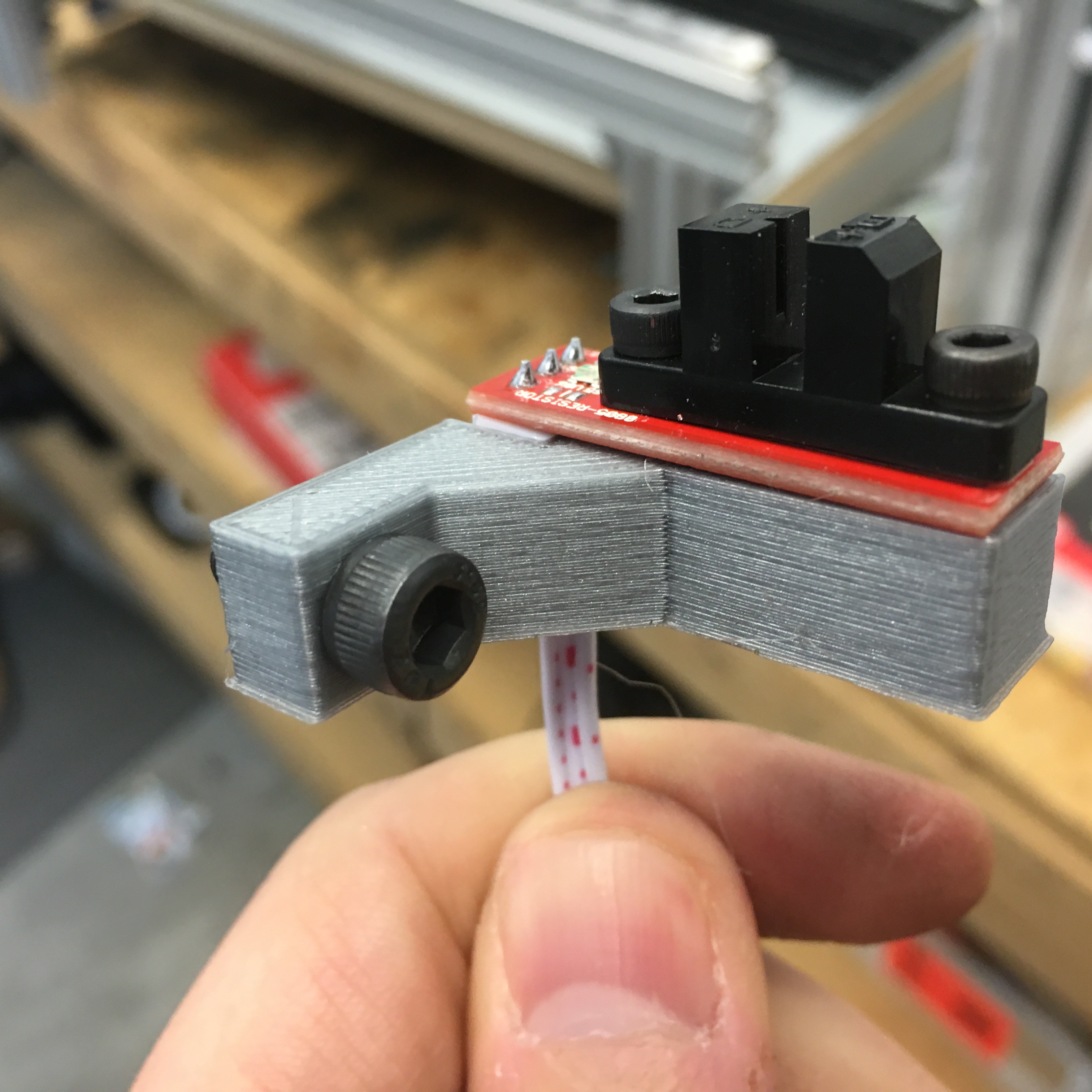

Its no secret that a lot of these projects, 3D printing, laser cutting, CNC, etc all share very similar components. The good news is that as result these components have dropped in price dramatically. When we went looking for endstops I wanted to stay away from mechanical stops and go with optical endstops. A very popular form factor in the RepRap world are the ones here: http://www.ebay.com/itm/321760461548

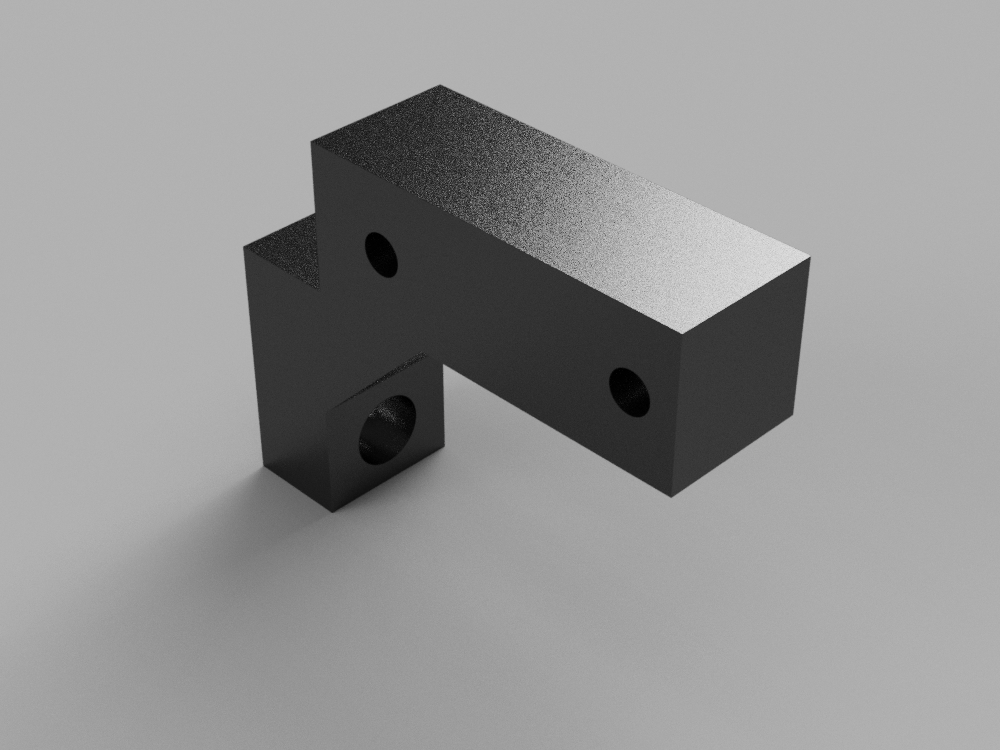

Of course they were not set up to bolt right on to the aluminum extrusion, but that isnt anything a little printer time wont solve. Here is what we ended up with:

anthony.webb

anthony.webb

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

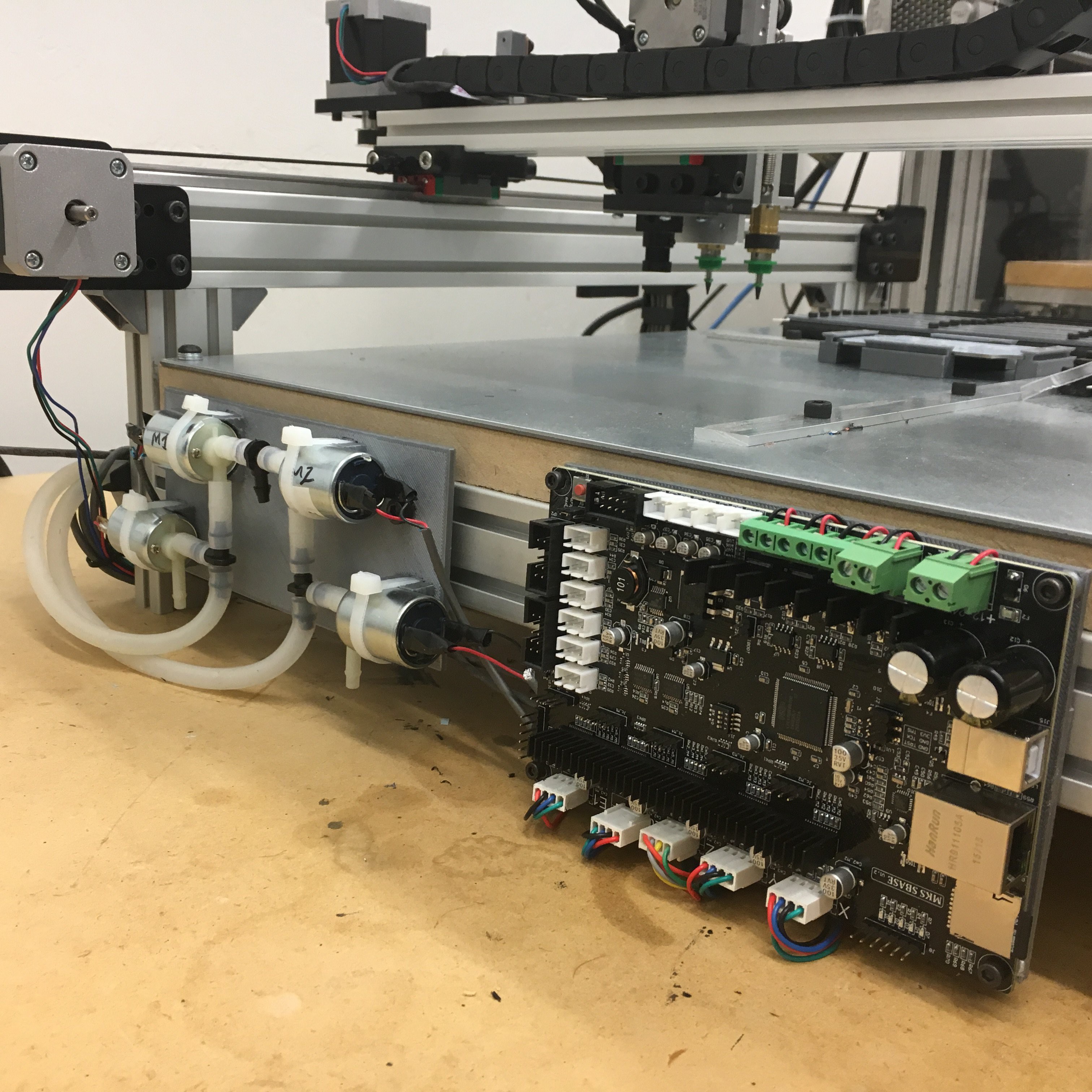

Hello. Does there any difference in the firmware of the microcontroller for Smoothieboard and for SBase?

Are you sure? yes | no

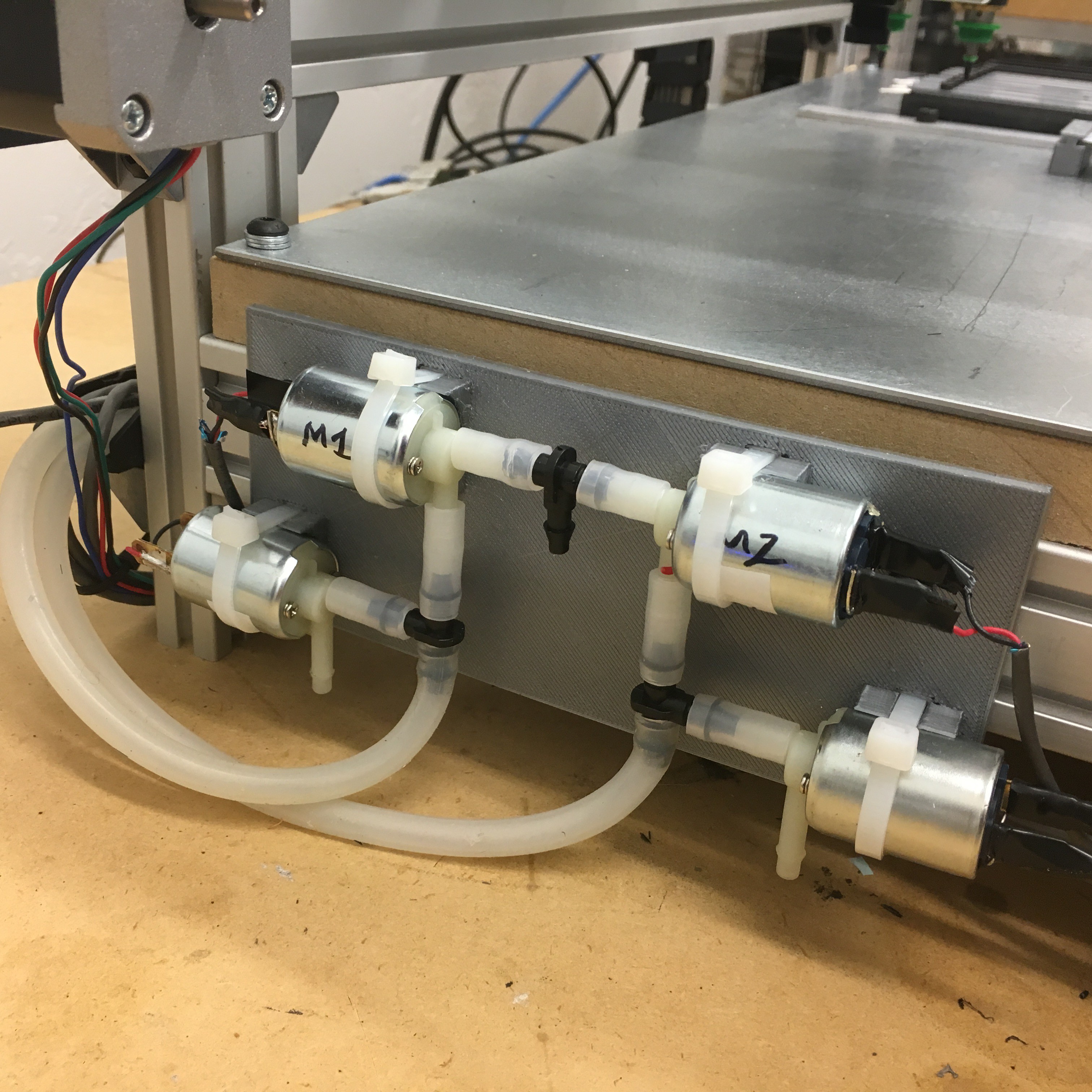

Could you give a bit more detailed information on the plumbing setup?

Are you sure? yes | no

Sure, the empty black port in the middle is where the main vacuum source sits. The white ports with nothing on them ( the 2 solenoids without labels) are bleeder valves to release the vacuum. So the bleeders are closed, M1 or M2 will open (my PNP has 2 heads) and vacuum will start, part will be picked up and placed, once placement happens M1 or M2 will then close, but a bit of a vacuum will still be there until the bleeder value (those below M1 and M2) opens, which fully releases the vacuum and the part is then free, at which time the nozzle raises and goes and finds another part to pick. Let me know if you have any more questions!

Are you sure? yes | no