[Katie] opened this month's meet with announcements, local events of interest, and a reminder that Hackaday Prize is in progress. The Open Hardware Design Challenge is about to conclude and it'll move on to the Robotics Module Challenge in a few days.

Our first speaker was [Susan Hough] who works for United States Geological Survey at their local Pasadena office. We received an overview of what geologists have been thinking about and looking for when examining earthquakes that might have been induced or triggered by human activity. Recent headlines focused on the sharp rise of small earthquakes in Oklahoma correlated with hydraulic fracturing ('fracking') for oil and gas production. [Susan] talked about her research looking into Southern California's past as an oil producer in the early to mid 1900s. There was a clear correlation between oil production and earthquake activity and there are lessons applicable to what's happening today.

Part of helping us get an intuitive grasp of what might be happening in the grounds far below. [Susan] illustration how it's possible to increase pressure without increasing volume by taking a can of carbonated beverage and started shaking it. Fortunately for the front-row audience, she did not proceed to demonstrate pressure release.

After being enlightened on earthquakes, we got to find out about the Willo project. Regular attendees of Hackaday LA meets at Supplyframe DesignLab have seen bits and pieces of this project around the lab over past months and now we finally see how it all comes together. It's great to have the DesignLab staff take the stage and talk about what they've done.

[Dan Hienzsch] opened with a project overview and iterating through early prototypes. Then he walked us through the process of fabricating Willo's aluminum base and all the lessons he learned on the way.

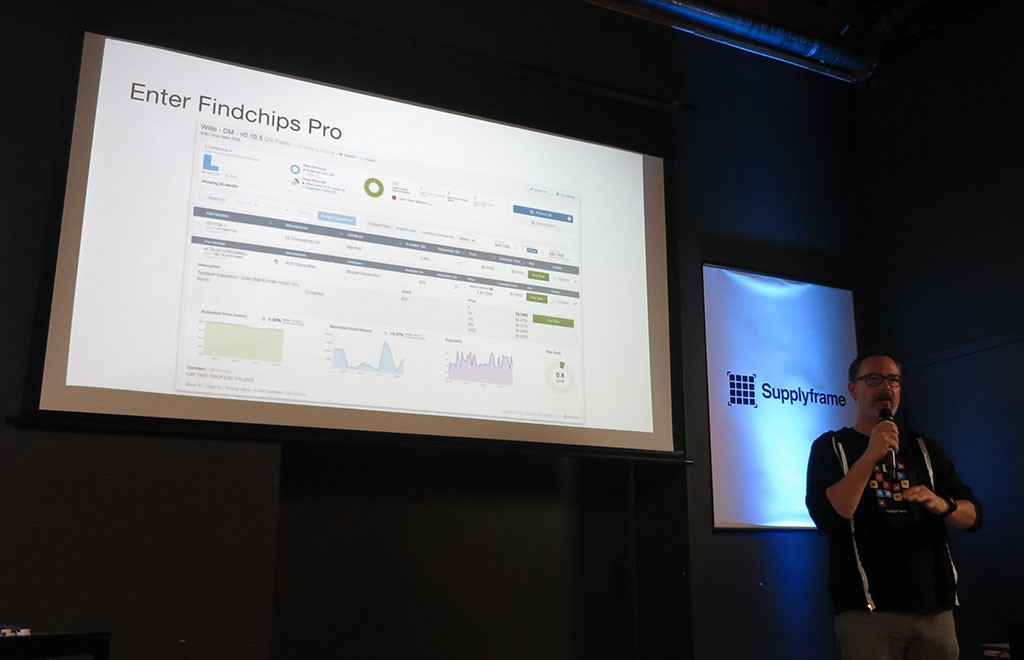

One highlight was seeing Findchips Pro in action. This is a product of event sponsor Supplyframe and seeing how it helps a project like Willo gives us an idea why supporting the Hackaday community is in Supplyframe's business interest. One day, the hobbyists and tinkerers will become customers!

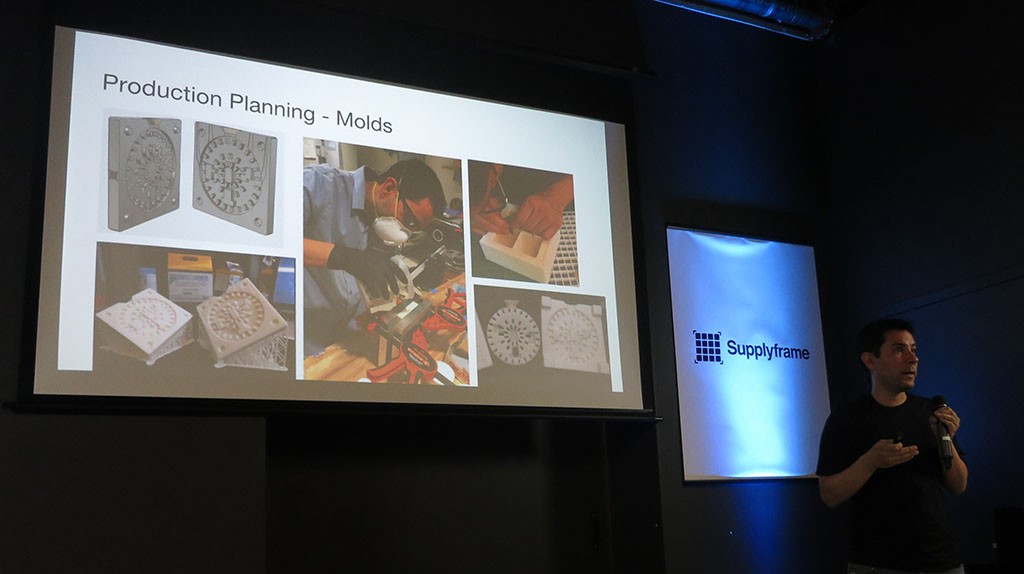

[Giovanni Salinas] then took the microphone and gave us an overview of designing for manufacturing, iterating through design of the product to meet all objectives from industrial design to making sure it can be built with the equipment at the lab. Then he dove deep into one specific part of Willo, and his trials and tribulations trying to meet all design objectives while staying within all his constraints.

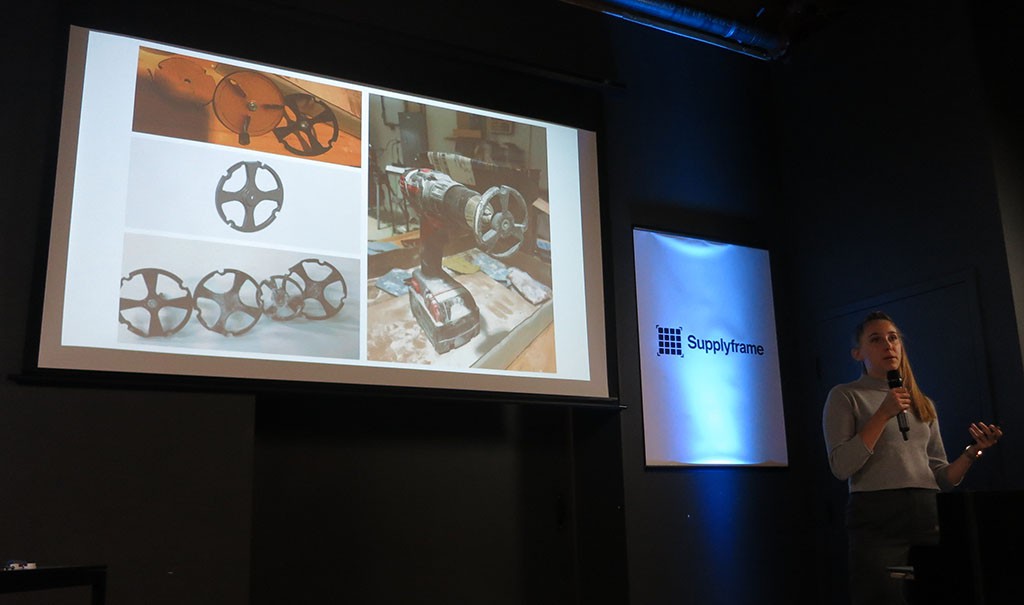

[Majenta Strongheart] rounded out the story with some of the tooling they had to build in order to help them build Willo. Tooling design is a part of any production, and these machines behind the product is rarely seen by the public and usually underappreciated. Today she made sure these unsung heroes got a turn in the spotlight.

The table at the front of the room was set up with several of these (well used) tools, as well as Willo prototypes and some failed pieces that each taught their own valuable lesson on product manufacturing.

Two sets of Willo were set up in the hallway so we could see the triumphant conclusion of all those sweat and tears.

Keep an eye on Hackaday LA's Meetup page for information on our next meet!

Roger

Roger

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.