this stuff:

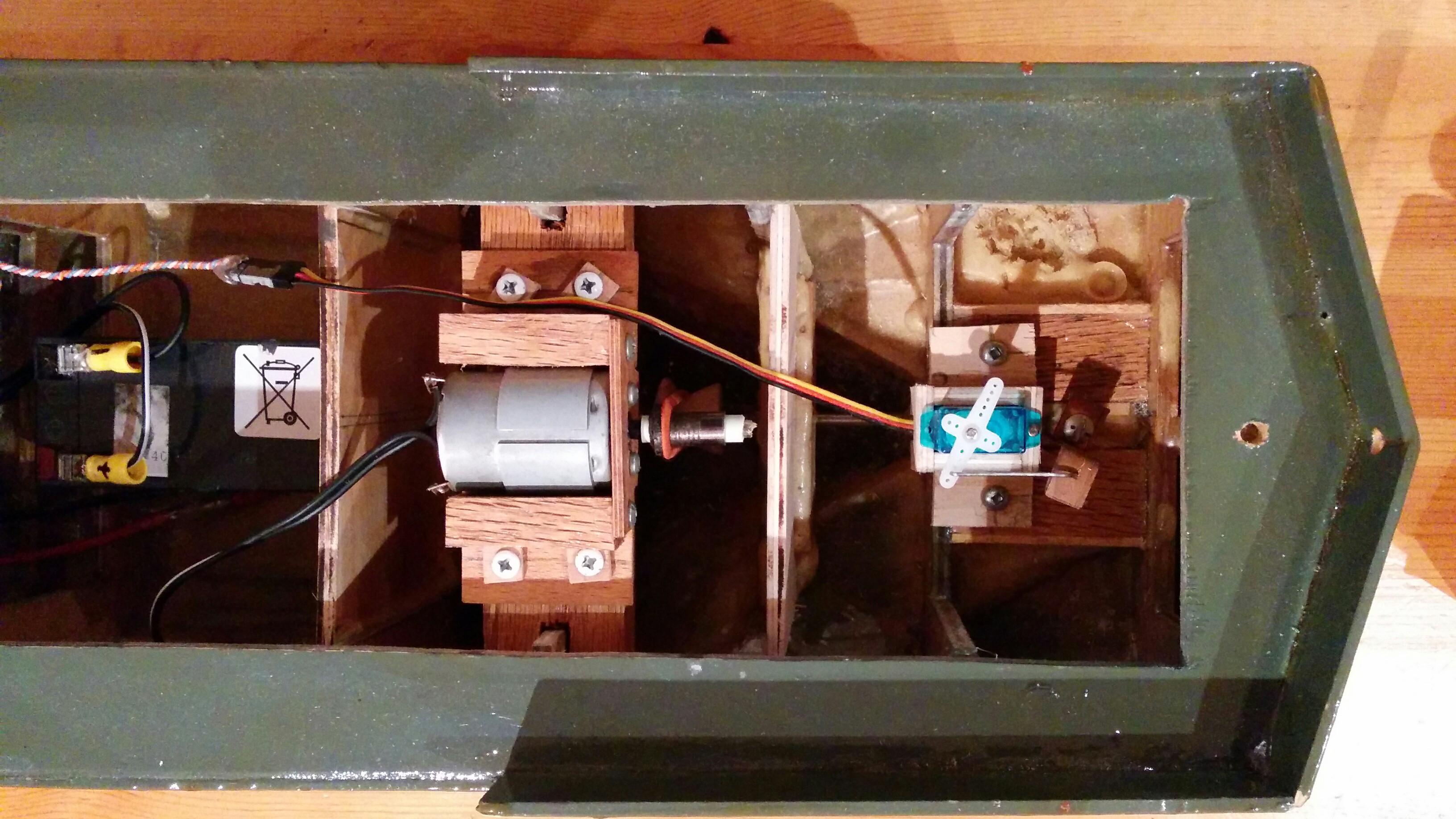

here's the inside of the boat:

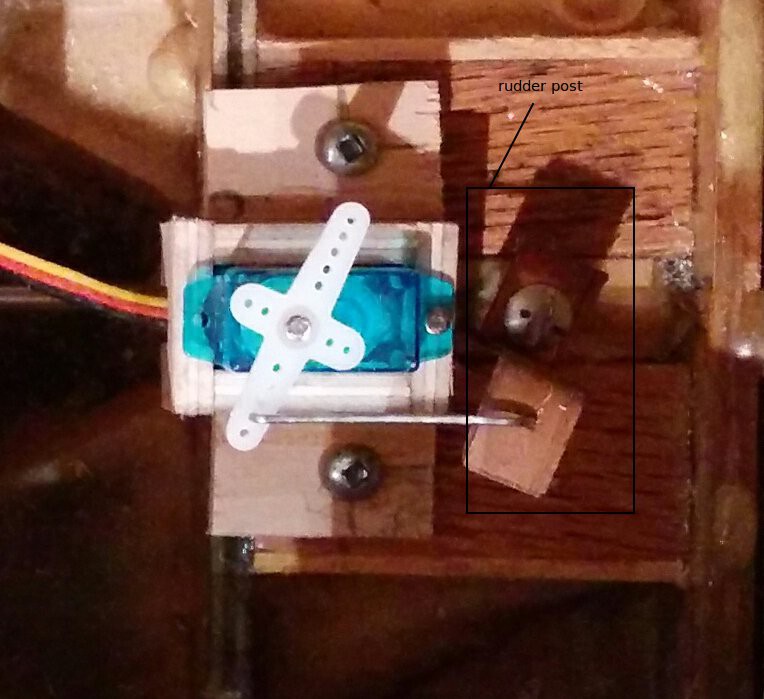

basically the drive system has to do two things: propel the boat and steer it. I'll talk about steering first. the steering system is pretty simple, the servo is linked to the rudder post and the rudder is bolted to the rudder post. here's the linkage inside the boat:

and here's the rudder post on it's own:

propulsion:

the propulsion system was a little more difficult to build. in order to have spinning propeller there must be a hole drilled in the hull, naturally this lets water in, there are a few ways to deal with this:

1. angle the stuffing tube: if the stuffing tube is angled enough its end can be brought above the waterline, this prevents water from getting into the hull. an angled stuffing tube is the simplest solution, but it comes with a few disadvantages. first: since the propeller is angled the thrust vector it produces is angled, meaning that some of the motor's output is wasted trying to lift the hull out of the water. second: as the boat pitches and rolls the waterline can briefly change, if it rises past the end of the stuffing tube the hull can flood.

2. use a bilge pump: have a pump and a water detection circuit to bail out the hull. this method is often used on real boats, but isn't very applicable on model boats, as I found out. small reliable pumps that can provide enough suction to draw water out of the hull are fairly expensive and delicate. I had originally planed on using a bilge pump, the pump that I was using couldn't handle the strain and burned out.

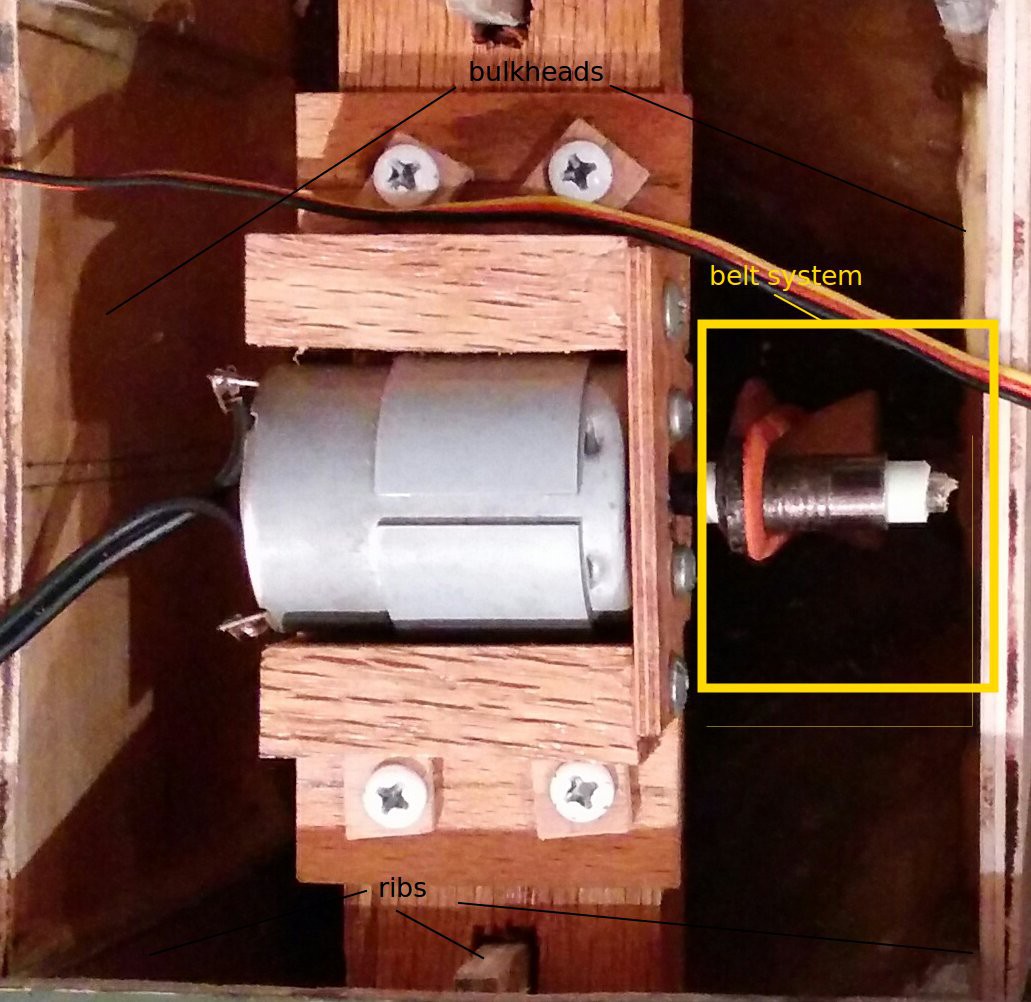

3. wet compartments: include a structure within the boat that limits were the water can flow. this is the method that I ended up using. I added bulkheads at ribs H and F, and connected the motor to the propshaft via a belt. this way the motor is raised up out of the water and the bilge can flood to an extent.

here's the motor mount and bulkheads:

zaphod

zaphod

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.