Simple Injection Molding Machine

- 12" x 12" x 24" Footprint

- 6" x 6" Molds

- Different Clamping Forces

- 2 Part Resin Injection

- Ejector Pins

Building a tabletop injection molding machine.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Simple Injection Molding Machine

So I have been looking at where to source my precision rods and bearings. I have done some other projects with linear motion so I have a little experience. I am trying to design around relatively inexpensive parts. Mcmaster is not the best source for inexpensive parts, but if you can find it on McMaster then you can find it somewhere else cheap as well.

For the rods I am thinking about these:

Hardened Precision Steel Shaft

For the bearings I am thinking about these:

Dust Resistant Linear Sleeve Bearings

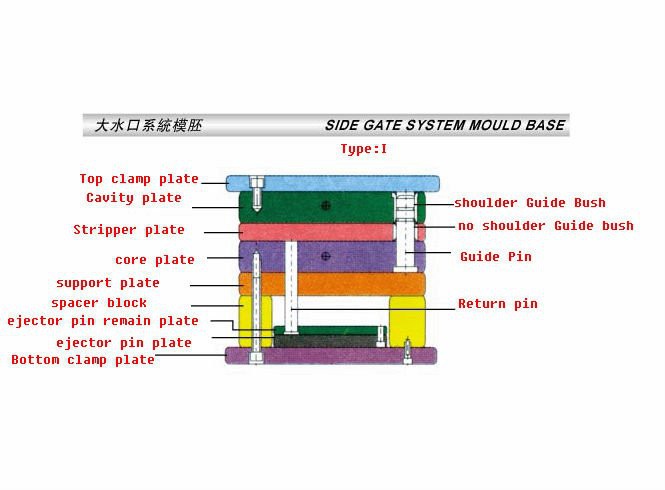

I also did a little research and have been looking at standard mold design. There is a huge amount of information on injection molding and it has taken me a while to really wrap my brain around some of the aspects of the mold design. This molding machine will be too small to use a standard mold design, but some elements can be copied. I am planning on doing something similar to this design. However, I will not have a spacer blocks, and the bottom clamp plate will be combined with the support plate.

I was looking on mcmaster for a dowel pin for another project and noticed that they sell ejector pins too.

http://www.mcmaster.com/#headed-precision-pins/=113he7c

Not terribly surprising, but one more piece of the puzzle. They are about $5 for a 1/4 inch diameter hardened pin. I figured I could fine them somewhere and worst case I could machine my own. But these would be precision ground and hardened which will be great.

Anyone interested in working together on this project? I am planning on continuing to design and build it, but I am open to working together. I have access to most of the equipment to machine the parts. If anyone is interested we could maybe work out a deal where I machine more than one copy of parts in exchange for raw material costs.

I am still working on the design in my free time. It is mostly a thought project now. Something to think about and add details to. I find doing CAD design relaxing. Here are a few things I have been thinking about and adding details

I also did some looking at other DIY builds to see how practical it is to build a mechanism to melt and inject pellets. Heating and melting the pellets is simple enough. I have made a few 3d printers that are melting filament, and my first aluminum mold for the Tank Chain project has heaters built in. But the injection part is a little more work. Not sure how hard it will be to build up enough pressure. I am currently thinking of using something like what DIY filament making machines use.

Something like this:

http://3dprintingforbeginners.com/how-to-make-diy-filament-for-your-3d-printer/

Anyone know a good source for augers like this?

This project is quite daunting and could easily take years to accomplish. Building a small injection molding machine is by no means a simple task and I don't want anyone to think I am fooling myself into thinking it is. I have spent about a year learning about injection molding and doing some simple projects. If you have not checked out my Modular Continuous Track System please do. It documents my experiments with silicone molds and 2 part resin injection.

So this is not my first project and I am quite lucky to have both some funding behind this project as well as access to quite a bit of tools. I would attempt this unless I did have these resources. I have built 2 cnc machines, and a few 3d printers. I don't think this prepares me for this project, but it helps a little.

With a project of this size it makes sense to create smaller milestones. I am currently doing quite a bit of molding using a two part resin and aluminum molds. But I am injecting it by hand and opening the molds by hand. So creating some smaller goals will allow me to use this project earlier. So below is my starting point for an outline.

Stage 1 - Simple Mold Opening / Closing

This version will not be much more than a frame that can open and close the aluminum mold which I am already using.

Stage 2 - Automated Resin Molding Machine

This version will add in the use of a static mixer and resin dispensing. The idea is that the resin I am using has a pot life of 30 minutes, and by heating the mold it might be possible to remove parts from the mold before the resin cures in the static mixer. If this is the case, the parts could be removed and the mold injected again using the same static mixer. This would allow for a semi-automated injection mold.

2 part resin is quite a bit easier to work with than traditional plastic pellets. It just requires mixing and injecting. The main issue with 2 part resins is that they are slow to cure.

Stage 3 - Full Injection Molding Machine

This would be the fully finished machine. The main part of this stage is going to figure out how to design and build the pellet hopper, screw drive, heater and ram. Since this will require higher pressure injection, the closing mechanism will also have to be stronger. So I might increase to a larger pneumatic cylinder, or possibly go to hydraulic. It will also probably require the addition of cooling lines to remove the heat from the mold.

Well I started another random project. I have been doing a lot with resin based injection molding lately and just got my first parts out of a professional injection molding machine. It is really cool and makes me want my own machine. I am not sure I will ever actually build this machine. There is a ton of design work to do and money to invest in the parts. But it doesn't cost me any time to design it, and it will help me determine if building a machine is practical or if I should just invest in buying my own machine.

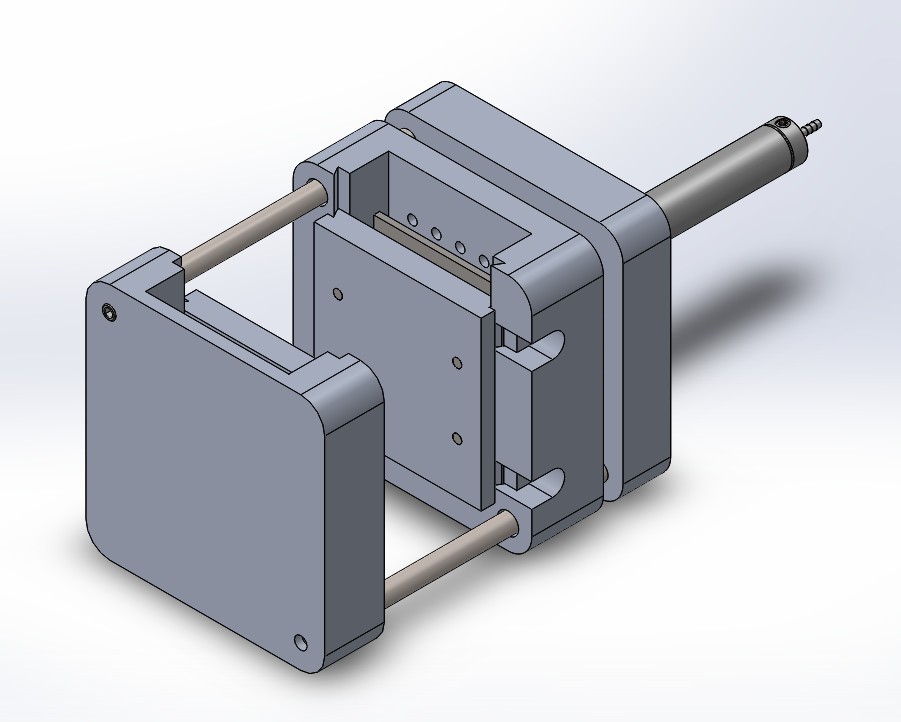

Either way I find doing CAD work like this relaxing after a stressful day at work. There are no deadlines to finish the design and I can work on whatever part I find interesting. Here is where I am at after about 1 day of design work.

Create an account to leave a comment. Already have an account? Log In.

Hi, just some comments on your plan as you have laid it out.

- For the augur, it won't function properly unless you have stepped zones on it. It needs to continuously shear the granules as they work towards the front. There are loads of designs around on the net for this. Apart from the thread design, it also needs a check ring at the front that will shut off the plastic from going back over the screw when injecting. .But a simple plunger would work if the right barrel diameter is used. Babyplast do a very nice desktop machine that only utilizes plungers.

There is an alternative way of doing this, where an augur type screw feeds onto a plunger, but that would add to complexity ( a company called Soddick use this on a lot of their moulding machines)

For ejector pins - I think it might be easier to build these into the mold rather then into the machine itself. Every product will have a different requirement for diameter and position of the ejector pin. From the machine, a central rod that will just push the ejector plat forward would suffice. For a very simple design, this could even be a static rod or bolt, that is struck by the mold as it opens, and this pushes the ejector pins forward.

Clamping - it can be possible to use mechanical force to hold the mold closed during injection rather then depending on the piston that opens and closes the mold. The most traditional way to do it would be to use a toggle system, so it locks up like a vice grip. But there would be other ways that would involve sliding in a mechanical lock once the mold is closed..

Ejection - you mention fitting ejection on both sides. This is unusual, the part needs to come onto one half to eject in most instances. But if it is necessary, I would suggest again building the ejection into the mold on the fixed side (not built into the machine), and just activating by the opening of the mold. So as the platen opens it pulls the ejector plate forward on the fixed side. using a small chain or linked rod system.

hello! I'm quite new to hackaday. I grew up in my dad's injection molding & machine shop. I'm no industrial designer, but I fancy myself an engineer and problem solver and would love to help! Have a good day...

Etienne

That would be great. I am still tinkering with the design, but it would be great to work together on this project. I think there are a decent number of people who might be able to use it. Maybe sell some kits down the road or something to help people get started.

A friend of mine and I are working on automating a manual injection machine. I am interested in collaborating in this project. You'll just have to give me some time, I'll try to catch up with your project in the following days.

Become a member to follow this project and never miss any updates

saw this and thought about your project

http://www.allforge.org/

Vaporware or no?