After removing the pedals from the bike, I thought I would use the bottom bracket to attach the pegs.

Nope.

I've simplified and strengthened the whole shebang by running the jackshaft through the bottom bracket. This seems obvious now (luckily) but before I did this all of the power (2.4kW) was forced to pull from this dinky motor kit which is what originally bent all of the steel plates. I'm having a hard time thinking of how to explain this better, but it suffices to say that the whole system is much more ridged and tough now.

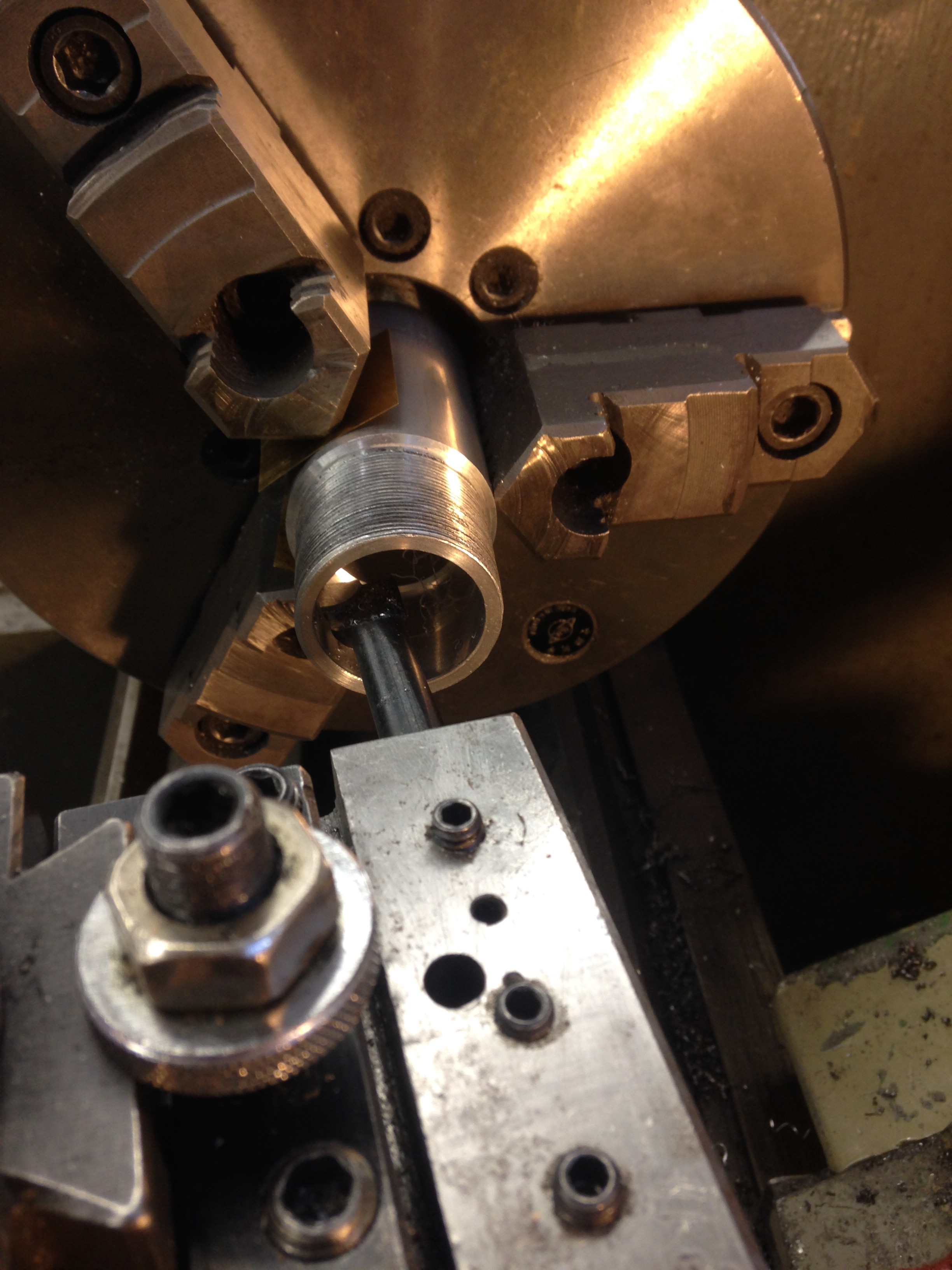

To adapt everything I made several custom parts on the lathe. The chuck was about 17 thousands off so I had fun shimming it every time I did something.

I made custom bearing sleeves for the bottom bracket so the jackshaft+bearings would fit right.

Shimming the chuck

Modifying Lightning Rod's stuff.

Custom sleeve and bearings in the lefthand thread bottom bracket cup.

Adam Curtis

Adam Curtis

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.