-

Anodizing and sub-assembly

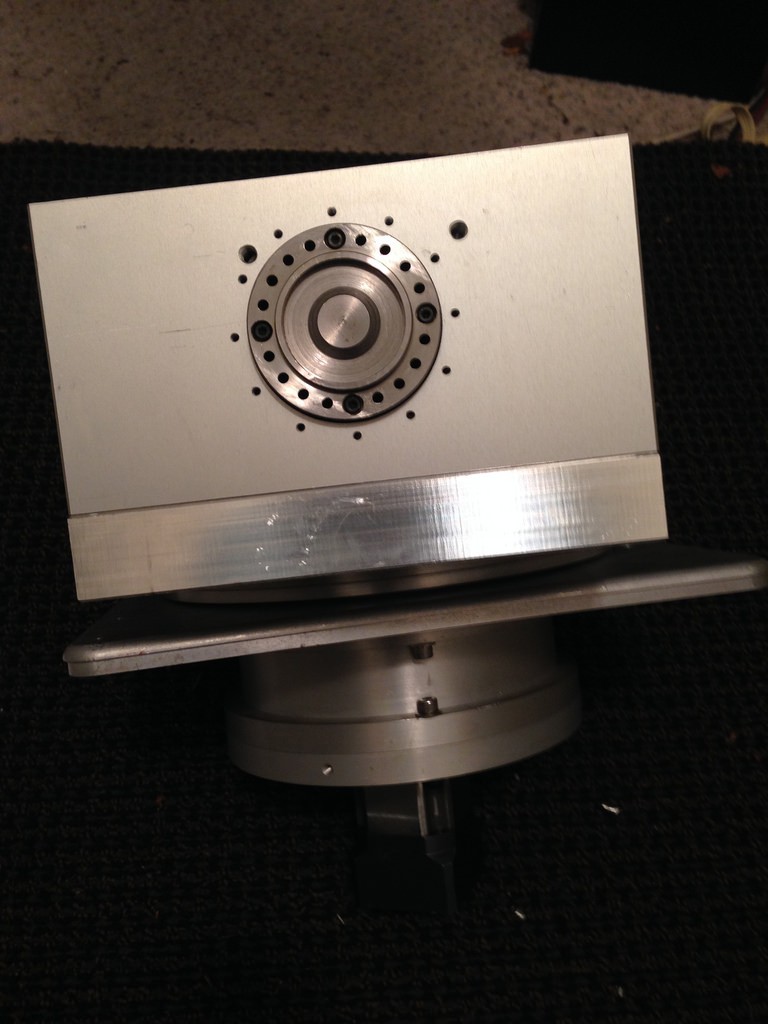

05/16/2014 at 17:36 • 0 commentsI got the parts back from anodizing yesterday and assembled them last night. Everything went together well and the bearings for the tilt went in with a nice sliding fit.

This weekend I am going to machine up the base that this sits in, it will sit on a thrust bearing and another taper bearing for alignment. I also have some worm gears to help with adjustment.

This thing is getting heavy! I am thinking about building it on a small trailer so I can just drive it where I want to put it. The trailer would have outriggers for leveling and getting the wheels off the ground.

![IMG_8563]()

![IMG_8565]()

![IMG_8559]()

![IMG_8567]()

-

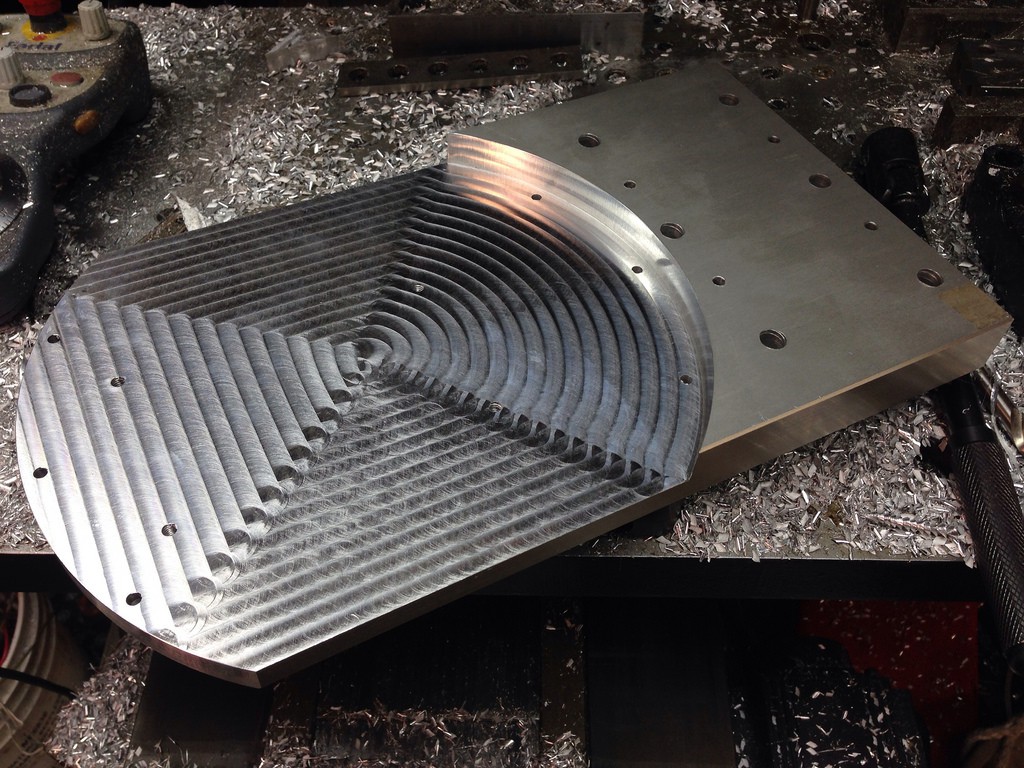

RA Drive Frame Completed

05/08/2014 at 04:33 • 0 commentsI started on the frame that holds the main drive last night. I had the original piece the big harmonic drive mounted to as well as some of the aluminum for the base. It is all 1/2" aluminum. Finished up that part tonight. The plates have bores for bearings and curved slots for the angle adjustment. It will got up to 60degrees of tilt. I am still working out the design of the base section, I have got a good idea what I want to do, just not sure.

I might send some of the parts out for bead blasting and anodizing.

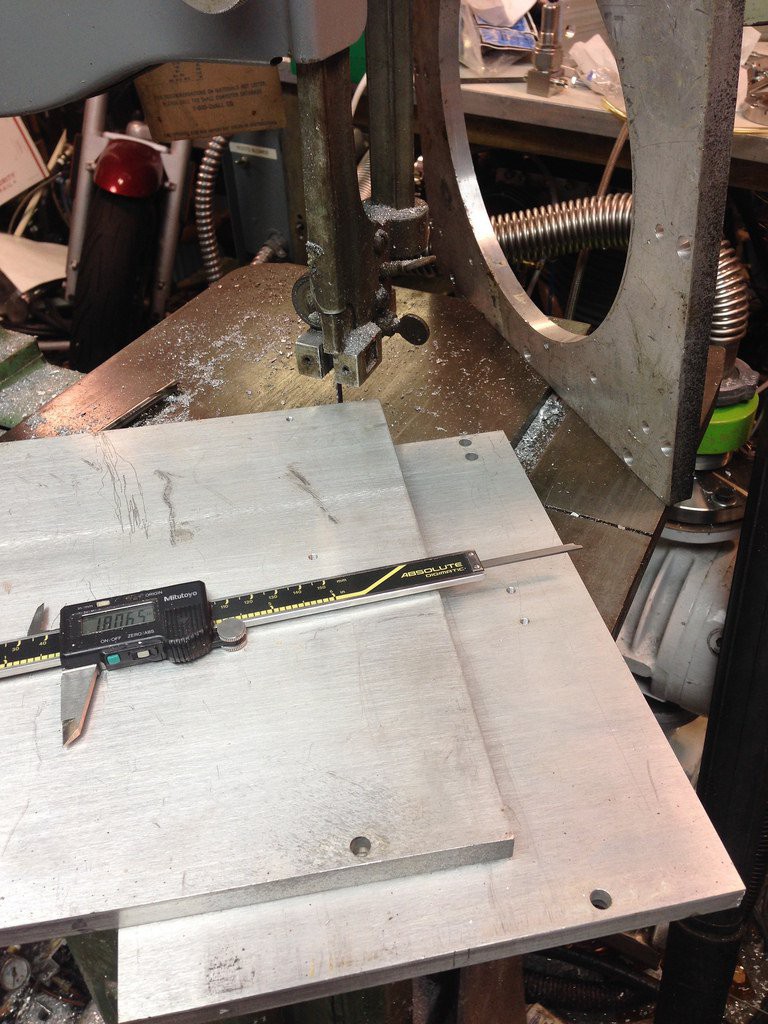

Side pieces and top before machining:

![]()

Completed frame:

![]()

Drive mounted in frame:

![]()

-

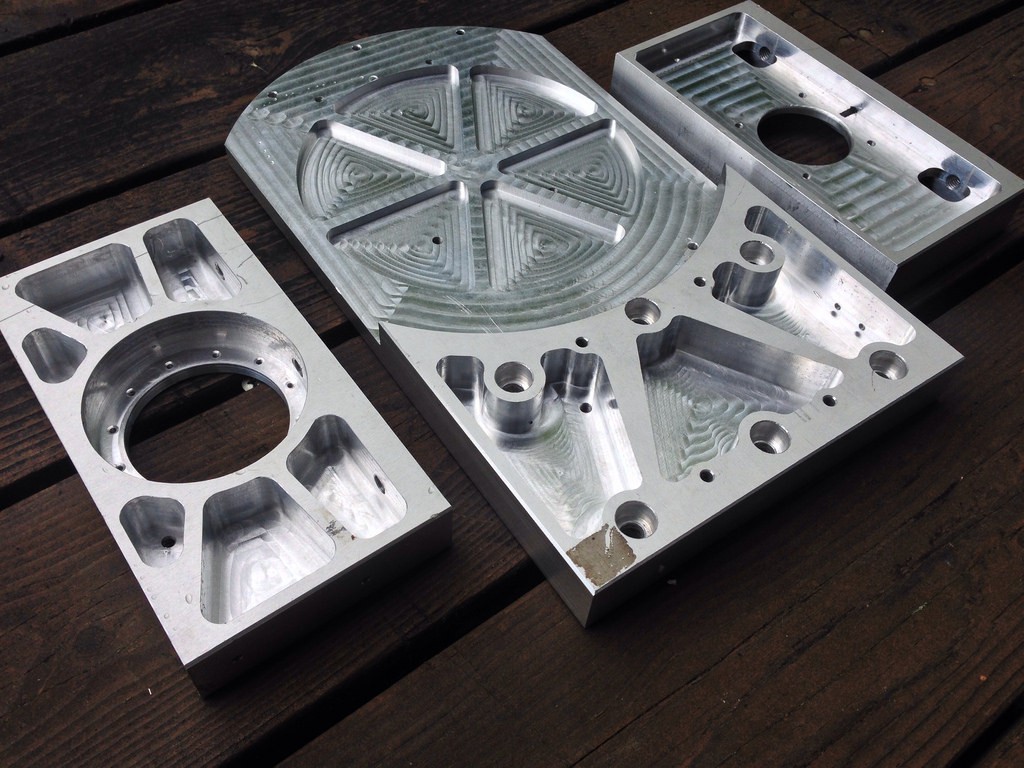

Lightening of parts

05/04/2014 at 21:49 • 0 commentsI weighed the three parts I machined out the day and they came in at 12lbs! Ouch! I modified the design to incorporate lightening cutouts. After about 5 hours of milling and one destroyed cutter plus one remade part I have them finished. I still need to bolt them together and ream out for the taper pins to lock everything together.

![]()

-

Machining Parts

05/02/2014 at 06:06 • 0 commentsSpent a couple hours making chips last night. This the plate that the Dec motor and gearboxes mount to, it attaches to the big harmonic drive. I still need to counterbore for the screws.

![]()

And some video of chips flying.

The part is 8" wide and 14" long.

Made the motor and gearbox mount tonight. One little goof. I entered a .1 when it should have been a -.1 and started a bore shifted but caught it early.

Next up is building a losmandy style saddle and the frame for the RA drive. Starting to get a bit heavy too, up to about 50lbs now.

![]()

![]()

-

Little Harmonic Drive

04/29/2014 at 07:35 • 0 commentsI ordered the smaller harmonic drive from Ebay monday night, $180 shipped. It showed up on my door wednesday morning... From South Korea. Wow...

The drive is pretty nice and should work great. It feels a bit lumpy turning by hand but connected to a motor is seems fine. I did decide to use the lower res servo on this axis. This axis just stays in one spot one you are locked on, the RA axis does all the tracking. If all else fails I can pick up another motor for the other J2S drive I have.

For a control I am going to try using an arduino, this guy came up with a ASCOM compatible arduino based controller for mounts with step/dir drives. It can connect to a PC and be controlled from ASCOM or LX200 compatible software or through bluetooth with an Android app he wrote. He also wrote an ASCOM compatible driver for the Quantix camera I am using. That saves a lot of time...

http://www.stellarjourney.com/index.php?r=site/equipment_onstep

Finished up a bunch of the CAD this last weekend and started machining the parts, I was not happy with the surface finish I was getting with the end mill I had on hand so I ordered another variable flute end mill for aluminum from Lake Shore Carbide. They make some real nice cutters that leave a mirror finish on sidewalls. Digging around in the shop I found a bunch of the 1/2" aluminum that the robot was made out of, I will use that for the support sections. I also found a piece of 1-3/16" x 7-7/8" aluminum stock about 5' long in the shop I had pulled out of a machine that handled IC dies. It will become the Dec motor mount and probably the dovetail saddle for the telescope to mount to.

DIY Harmonic Drive Equatorial Mount

A home built equatorial mount for my telescope built mostly recycled components I have had lying around.

Jerry Biehler

Jerry Biehler