Workshop stuff

Metalworking, Repairs, Tools and Tinkering

Metalworking, Repairs, Tools and Tinkering

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

It has been a while since I did a bucket project.

I was trying to thoroughly clean an object (remove n-1 paint layers, where n was the total number of layers) And I remembered I had a broken electric toothbrush lying around as 'project to be', which could come in handy.

It didn't work on the paint as I hoped, but it is quite handy for cleaning in the workshop.

I was browsing through my Youtube uploads and came across these two old video's. I'll share these, just for fun.

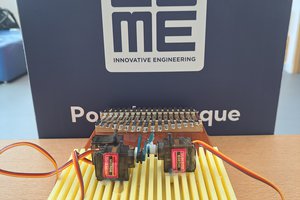

One of the projects in my bucket is a 'leave me alone machine' with all six servos daisy chained. A bit in the spirit of the device in the next video. When working on a project for a small contest I accidentally discovered the auto-switching feature. This is the result:

This was the first project I made with this sort of servo controlling

Makes me smile every time I see it.

There are three simple ne555 based control boards for the servos. the led is switched by setting and resetting a flipflop.

I'm not really sure any more how it's wired, but there are two switches on the upper arm, one on the end and one operated by adjustable stoppers on the upper rod.

the upper arm itself is fixed to a servo and also rotates around (and is partly supported by) a potentiometer shaft. The position of the shaft is fixed, and the pot body rotates with the arm.

The rotation of this pot controls a servo and sort of acts as one half of a multiway 'switch' (not sure about the name, but wikipedia tells me it's a traveller system) where the wiper is the hot lead.

I dug up a schematic for the controller, the pot is RV2.

iirc R3 is a pot too, adjusted for a waveform with a ~20 ms cycle. RV1+RV2 control the length of the high part of the pulse. RV1 is a multi-turn pot adjusted to locate the servo position.

Another video from my workshop.

It's not really about the boring, it just turned out this way (no pun intended). I am just doing a small project to solve a minor nuisance. And I have a self-centering inside micrometer I wanted to try. It has a range of 30 -35 mm so I needed to make a hole that size.

Also trying a form tool on my small lathe (210 x 400 / 8x16") and getting more chatter then I hoped for. I wonder if people with a similar lathe have similar problems.

In the mean time I use the form tool for the part I actually made it for, but it needed a lot of extra grinding, because It needed to round the edge of a hole and it didn't have clearance for it.

I followed up on my tapping experiment (see earlier log entry) and modified my drill press a bit. And it even kind of works.

Here's a protip for dailing in a workpiece in the lathe.

Showing some nice finds from the thrift store, and testing a method to tap workpieces in the drill press without having a spring-loaded centre.

The workpiece I test the tapping on isn't the best for this test. I considered tapping something else for this video, but I also found an interesting YouTube video which gave me an idea. Now this is a project and I have to make some parts for it.

I know I can just make a spring loaded centre, and be done with it, but what's the fun in that?

Some time ago I had this idea when I was cleaning my hobby room / workshop while I was looking for a place to put all the stuff I had ideas for. Back then bucket-lists were a thing, and I ended up having a real bucket with things I want to use for projects. Here is the introduction I uploaded to YT some months ago:

(The hexagon stuff will get it's own project page after I make the next one (#3))

In the introduction I mention my Stickvise, but I'm not counting it as a bucket project, because:

I decided then what the first projects were going to be, but other things kept coming up so I had to wait for a convenient moment between projects. Now I finally used some things from the bucket, and I show it in the video below. These are not highly sophisticated projects, but some general workshop stuff.

Here is the video:

Some projects from the bucket might get their own project page, others are just small things I will put in this workshop project or maybe not even mention here. But everything will be recorded and uploaded to youtube.

And If you like 'The Bucket' idea fill your own and start documenting your small projects. We could make a list of buckets, that would be an awesome pun.

I made a video about something I made recently, it's a nice example of what I call overengineering. And I included a bit with a nice tiny improvement for my set of number punches.

I think there are at least two types of overengineering in the workshop, specs and features. I think I went a bit overboard on the features of this guiding block. And I am afraid I have to admit, not having punched long numbers into stuff before, I didn't even realise the option of using a scrap piece of metal as guide until I was nearly finished with this tool project.

(No workpieces were case hardened or surface ground during the creation of this project)

I haven't really done much for my Infinity Cube project the last months. I do not consider it finished but I've been busy or distracted with all sorts of stuff. One of the problems is there is too much play in the gears, which make a rattling sound when turning. But if I want to test it with it's own hardware I have to assemble it, and then I can't work on it.

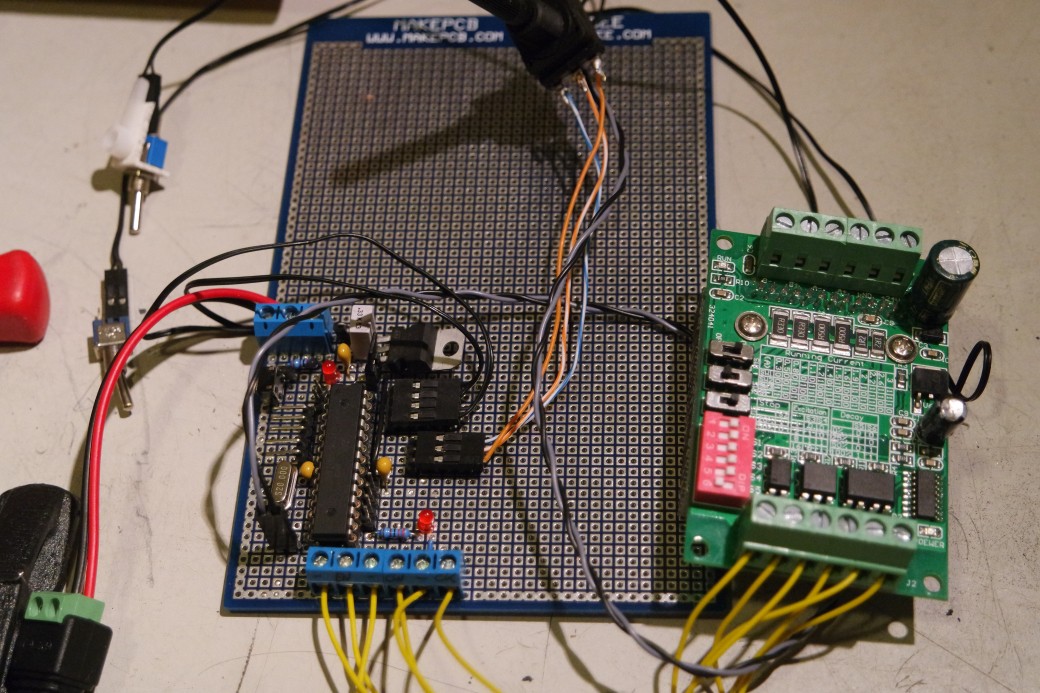

So I decided to make a small pulse generator to control the stepper motor. I also have a new driver which should be able to handle the maximum current for the motor I have (I'm not sure if my stepsticks can handle it).

I do not consider this a part of that project, because I don't know if I'm going to use this board in it. I made the controller for this driver specifically, but it's always handy to have one of these lying around. It's a relative simple board, which I 'improvised' on a prototyping print. It's a basic atmega88 design, not unlike an arduino I think. The big difference is in the software, I'm used to programming AVRs in assembly. I based the schematics on the finished board ;)

I uploaded the Atmel Studio 7 and the schematics and KiCad 4.01 project files to github, but I'm not used to that yet, so I hope it went OK: https://github.com/ScrapOverEngineering/Atmega88-Stepper-controller-puls-generator.git

It is usable, feel free to use this.

It's one of those project that only has to function, no fancy enclosure:

Here is an oldie I just found on my hard-drive while searching for some specific code to copy-paste. One drowsy Sunday afternoon I decided my microcontroller needed some swag (or whatever it was called back then).

Here is the result:

It's an Attiny2313 sporting a custom polycarbonate IC socket with blue LED lighting, gold plated turned headers for programming, gold plated +5V and Gnd connections, a X2 100 nF decoupling capacitor rated up to 250V, Tuned pull-up with a multiturn variable resistor for the reset line and a silver pin 1 indicator notch. Overclocked with a 24,576 MHz crystal this bad boy could out-flop the atmegas, and even blink a Led.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

By using our website and services, you expressly agree to the placement of our performance, functionality, and advertising cookies. Learn More

Adam Jensen

Adam Jensen

Alexander

Alexander

Babo96

Babo96