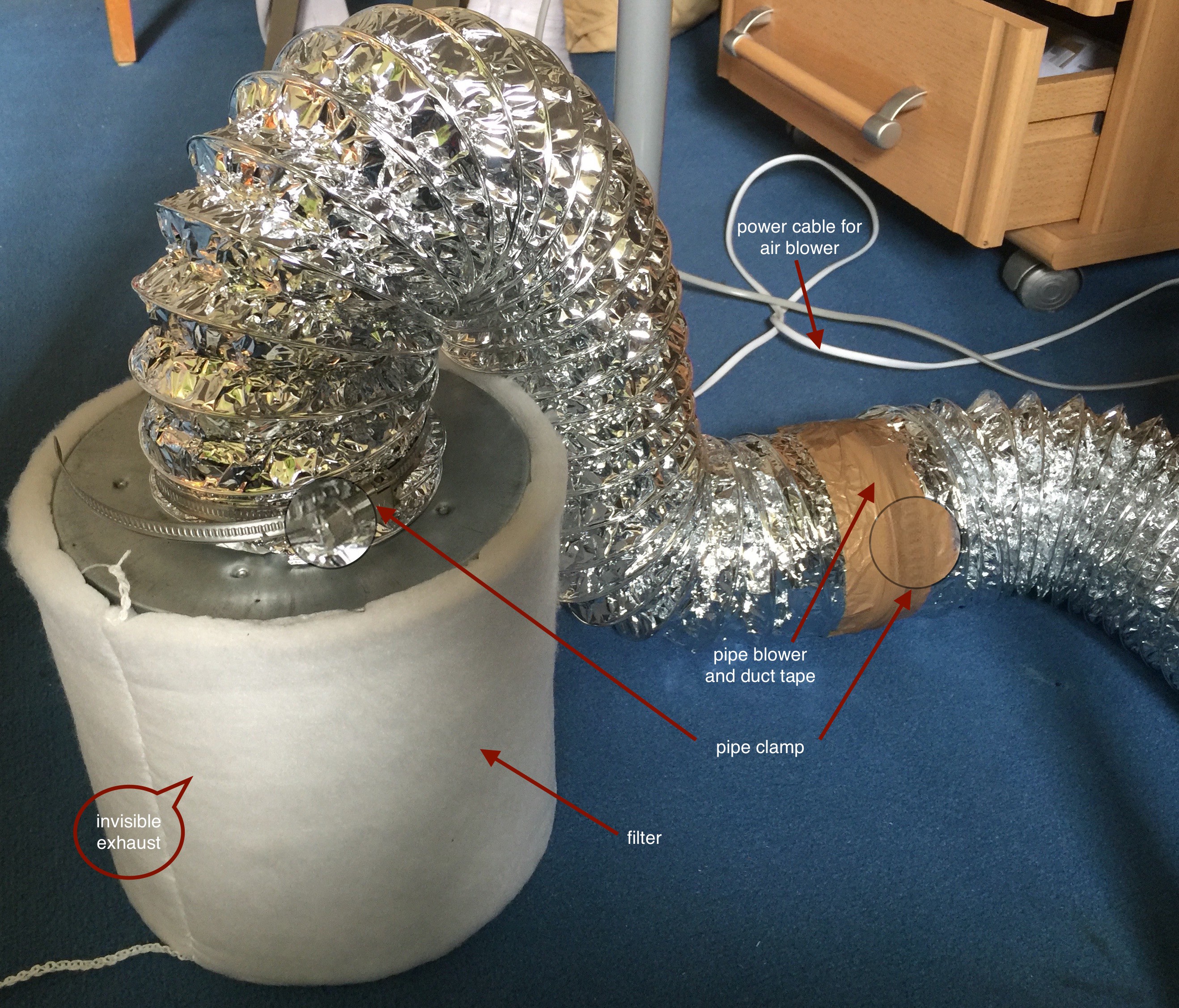

I sew a 100mm hole to the back of the laser cutter box. Then I attached a tin hub at the back side and used silicone do fix it and make it air tight.

Then I attached the flex pipe using a pipe clamp. I cut 1/3 of the pipe off. The one end was attached to the blower and was fixed to the blower using a pipe clamp. The other end of the bower was attached to the second pipe, the second pipe was attached to the filter.

After turning on the blower, you can hear a really nice industrial sound. I used a lighter to see if its sucking in the flame. It's working!

!WARNING!: The filter works pretty well. Any fumes adsorb to the char coal and therefore there is no smell at all. Unfortunately carbon monoxide cannot be filtered and is simply bypassing the filter. CO is completely colorless and does not smell like anything. You should always have the window opened while working. The filter and the pipe should be placed outside, i.e. by hanging it out of the window. Use always a CO detector near by the laser cutter. Never ever do it without a detector. You cannot see, feel or smell that gas. You rely completely to technology here. If you become dizzy, turn off the machine immediately and leave the room. If your CO detector starts an alarm, keep out of the room until the alarm stops, then it's "maybe" safe to enter the room again. If you do everything without any mistakes (no holes in the pipe, an airtight lid and pipe hub) then all fumes should be blown out of the window. Please keep this always in mind. In addition you should be advised that you should always wear laser protection glasses. A laser cutter is a dangerous device.

Jack Pearse

Jack Pearse

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Cool construction. Regarding the carbon monoxide I wouldn´t worry unless you have a kilowatt laser. The plastic fumes are far more toxic - but your filter can eat them up completely

Are you sure? yes | no