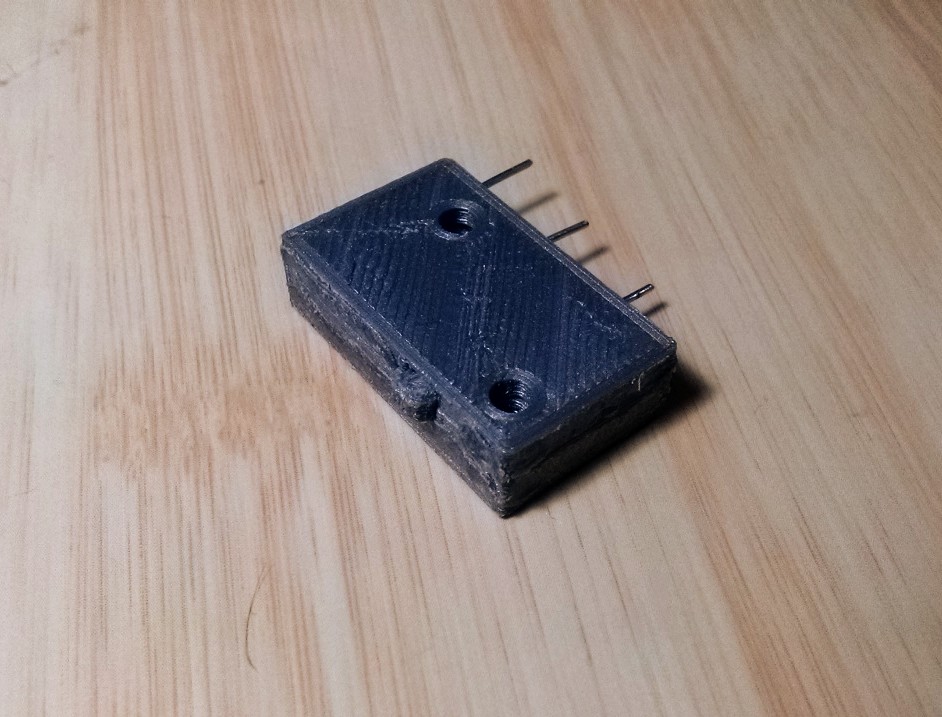

March 6, 2016 | ProgressTH We've friction-welded the contacts in place, then welded the case closed. We did this using a rotary tool and a small collet to hold an approximately 20mm long piece of PLA 3D printing filament and using the slowest setting. Applying pressure and moving the spinning filament along the seams creates a weld.

Everything seems to be working, and this is basically what we'll be using this switch for in the centrifuge, turning on and off a motor.

Follow ProgressTH.org on Facebook here or on Twitter here.

ProgressTH

ProgressTH

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.