I started thinking back to my brief but thoroughly enjoyable experience with Kerbal Space Program and remembered a tip from the wiki: the thrust vector should be in line with the center of mass. In my mind, that means a gimbaled fan needs to be designed to apply force directly to a point along the center axis of the structure. Their site has a better (albeit brief) explanation here: http://wiki.kerbalspaceprogram.com/wiki/Center_of_thrust

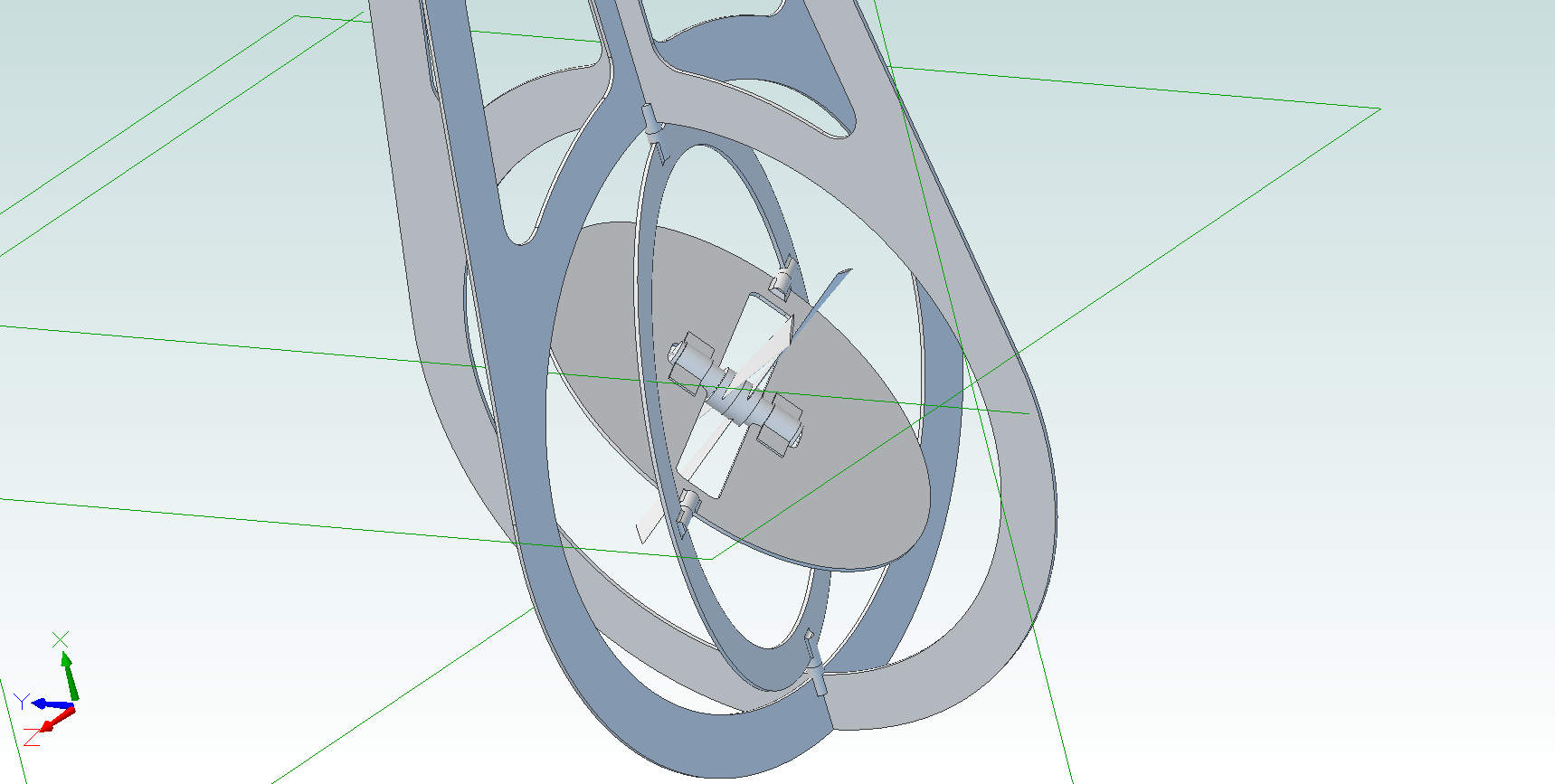

So how does that happen? I putzed about a bit this evening and put together some rough sketches. Nothing based on real-world dimensions, but I tried to keep assembly constraints correct so that I can rotate the thruster about to check interferences and so forth:

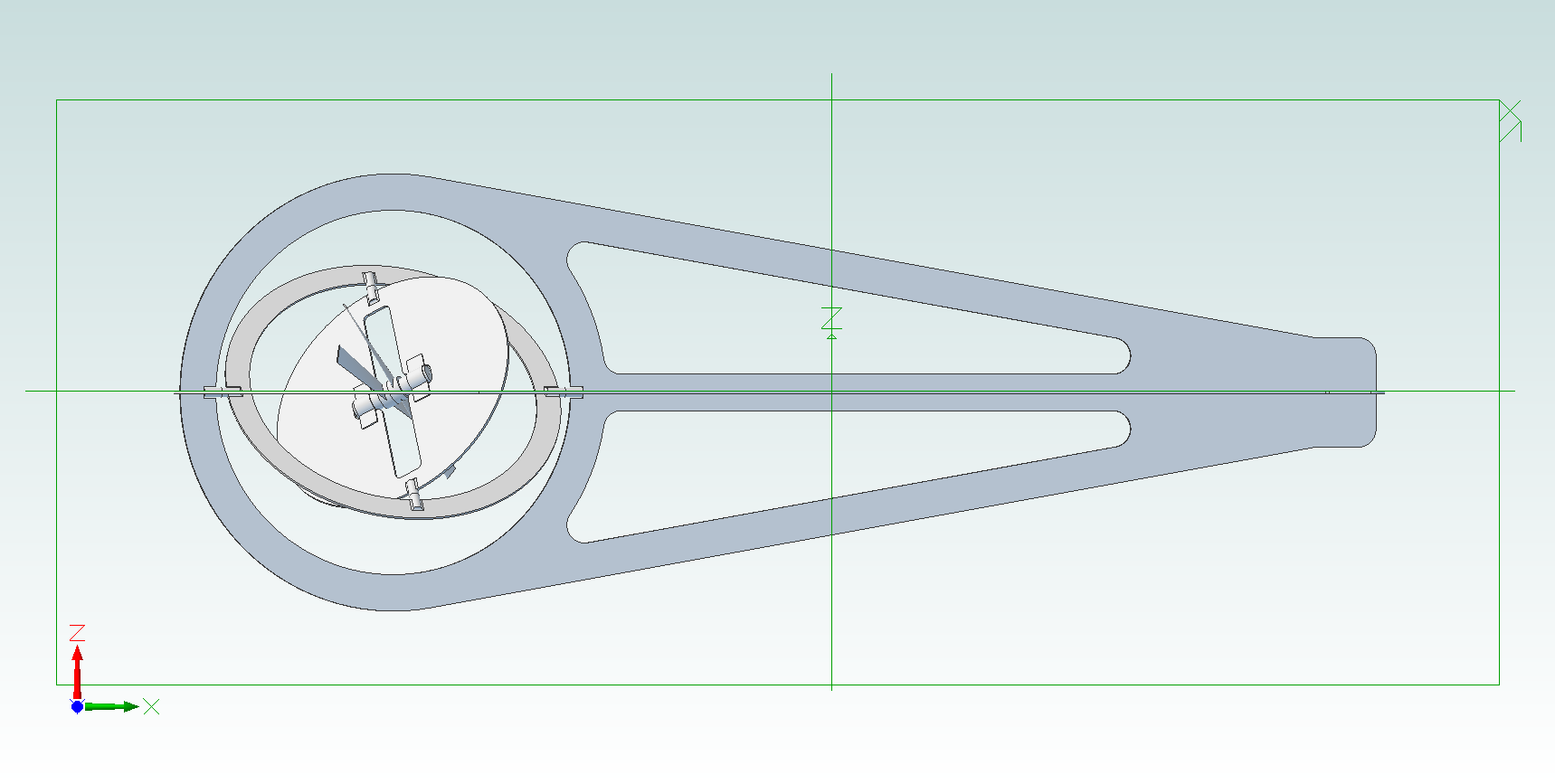

Zoomed out version lying on its side (remember, the arrow points up!):

We'll call this design GimbleBot_v01. A few notes:

- No actuation shown (or considered yet). Direct driving the two gimbal axes would be pretty sweet, since linkages would be an extra thing to go wrong. Also, if the gimbal servos are both mounted on the rigid frame, the inner gimbal drive would have to compensate as the outer ring rotated. Does that make sense? Seems like it would be trouble, both from a control perspective and from a physical capability standpoint (i.e. I would probably end up limiting range of motion).

- In the second picture, the flat area at the point of the triangle would hold sensors, electronics, that sort of thing. I did recently order a few brushless motor controllers; they're designed for the RC world so they're tiny, and I figure those could be mounted directly adjacent to the motors on the motor mount disk. I also ordered an off-the-shelf contra-rotating propeller unit, which (if it seems like the v01 design holds water) is already obsolete. Oh well.

- Here's a fundamental change: previously, I hadn't really pieced the gimbal together in my head; well, actually, I thought of it more like a rocket gimbal, with all the 'guts' at the bottom and some type of a ball-and-socket-like interface to locate the gimbal with respect to the main frame. As such, I planned to have a definite 'pitch' and 'roll' axis (at least, that's what I think I called them in the previous post). This design is more like a polar coordinate system; the outer ring rotates around the axis of the frame (and, if the props are really centered, the 'center of thrust'), and the inner ring elevates the thrust vector.

- That probably wasn't clear. In other words, when the craft is in an unstable state (like when it's hovering and gets pushed), the outer ring rotates around the frame axis to determine the 'correction thrust direction' while the inner ring rotates to change the 'correction thrust severity'.

- This could have weird control implications. When the control algorithm tells the actuators to change the thrust vector, relative actuation speed of the two actuators will dramatically affect how the craft responds. I wonder if control loop oscillation would show up as helical flight? Maybe balancing the actuation speed of the two gimbal axes is another critical factor: will they need to reach their respective set points at the same time?

- I haven't worked with the stuff in the past, but this design kinda built itself for laser-cut CFRP panels. The model shows them at 2mm thick; presumably I'll need to adjust that here and there. Additionally, the frame construction in the model was simplified to have a base frame and two half pieces that are stuck on; for the actual model, it would make sense to cut opposing slots in two base pieces that interlock for additional mechanical strength. Also, gussets. Glued gussets. In any case, I'm guessing CFRP is the only readily available material that will hit my (as of yet unknown) strength-to-weight ratio constraints.

Nothing finalized about this, even for v01; I've just found it's easier to visualize stuff on a computer screen, and 3D modeling assembly constraints make it easy to drag rotating bits around to see how they look. Feedback?

zakqwy

zakqwy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Are you sure? yes | no

Thanks for the comment! Everyone is qualified to give feedback.

Are you sure? yes | no