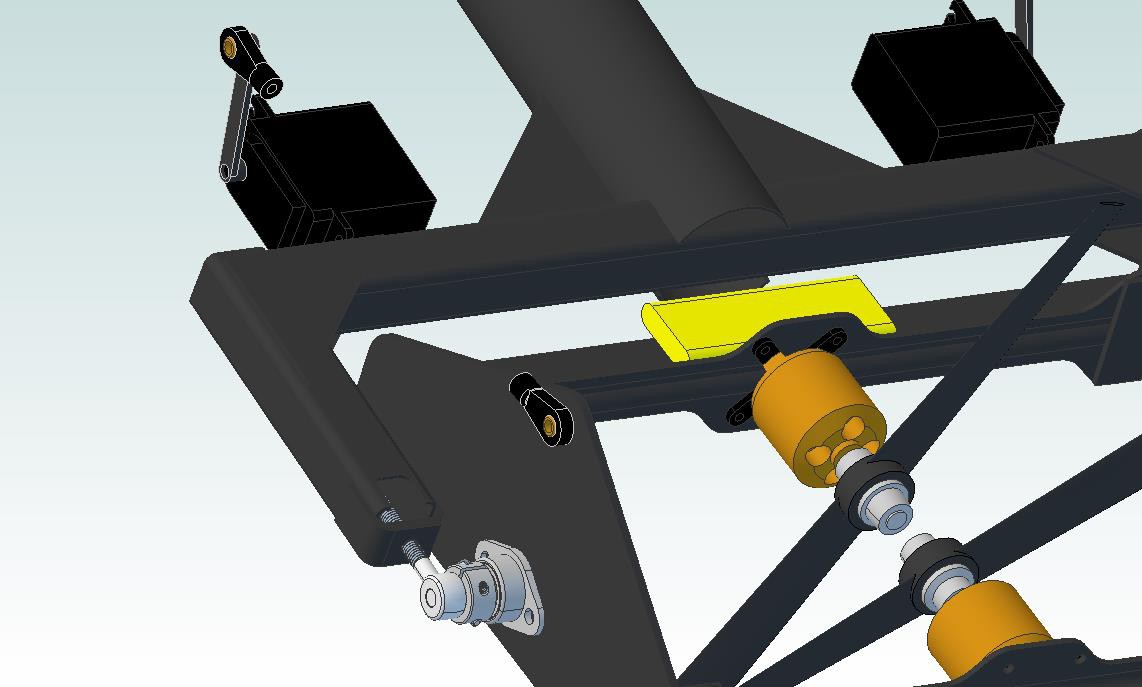

Quick update on v07. I modified the rotating thrust frame a bit so it's supported by a pair of rod ends; this is lighter, cheaper, and easier to align than the previous design that just showed a few holes through the CFRP square tube. I also started testing different servo mounting ideas; since I'm not as worried about servo weight or width (although both are important), I swapped out the slim servo from v06 for a standard 20x40 model. The unit I specified is insanely fast and powerful, and I included two in the model; again, I need to do some torque calculations to see if I can get away with a single unit (although they are only 60 grams).

Notably missing is the threaded rod that connects the two Heim joints. I've constrained them to stay aligned but haven't modeled up a longer rod yet. Also, I've added a split shaft collar on either side (visible between the stainless rod end and the flange mounted bearing here) to secure each shaft laterally. The split design should make this relatively easy to take apart.

On another note, Cubify has started to slow down. I'm using less than 25% of memory and CPU and my graphics card shouldn't be anywhere near maxed out, but I think the program isn't a fan of having so many individual parts and constraints in the assembly. I'm less worried about the slow speed than I am about the fact that it seems to have dropped a few assembly constraints; sometimes when I grab something that should rotate (such as the theta frame), it decides to drop an axle and move around a bit outside its intended range of motion. I might have just forgotten to constrain the model adequately; either way, I'm going to dig back in to doing nested subassemblies to reduce the complexity of the finished assembly. Anyone that's done this with Cubify Design--I'd love some advice. How do you structure your complex assembly trees?

ALSO, PARTS! Yup, more parts are on the way. Rod ends, split shaft collars, shafts, bushings (for the slip ring) and flange bearings should arrive later this week; I'm hoping the Rho brushless gimbal motor arrives around this time too (although it's got a much longer journey). I've also been bugging vendors about the GE power converter, so hopefully I can lock down a lead time for that unit soon. I'm anxious to finalize and construct the mechanical systems so I can move on to instrumentation and control algorithms!

zakqwy

zakqwy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Are you sure? yes | no

Are you sure? yes | no