-

Hack Chat Transcript, Part 2

08/14/2019 at 20:05 • 0 comments![]() In the industry, they use 13.56mhz for all plasma things, a free ISM band. But all the 13mhz equipment is so expensive.

In the industry, they use 13.56mhz for all plasma things, a free ISM band. But all the 13mhz equipment is so expensive.![]() And about the only thing 10 meters is good for right now, lol

And about the only thing 10 meters is good for right now, lol![]() Yeah, RIP

Yeah, RIP![]() Give it a few years! (hopefully)

Give it a few years! (hopefully)![]() @Sam Zeloof what would one expect to spend on a setup like your's

@Sam Zeloof what would one expect to spend on a setup like your's![]() I don't think the next solar upswing is going to be much to write home about, but maybe.

I don't think the next solar upswing is going to be much to write home about, but maybe.![]() Hard to estimate, I picked up things like a SEM which aren't strictly necessary, but in hindsight you can make basic ICs (probing only or flip chip, no wire bonding) in the low thousands of dollars without stressing too much

Hard to estimate, I picked up things like a SEM which aren't strictly necessary, but in hindsight you can make basic ICs (probing only or flip chip, no wire bonding) in the low thousands of dollars without stressing too much![]() That's pretty approachable. Hmm....

That's pretty approachable. Hmm....![]() @nixie_guy on twitter is doing amazing things, made his own diffusion furnace and a small acrylic vacuum chamber for sputtering copper, all of that costs in the hundreds of dollars

@nixie_guy on twitter is doing amazing things, made his own diffusion furnace and a small acrylic vacuum chamber for sputtering copper, all of that costs in the hundreds of dollars![]() @Sam Zeloof how much did you pay for the SEM

@Sam Zeloof how much did you pay for the SEM![]() One question: Now that you have access to "real" fab equipment, do you ever find yourself saying, "Man, I wish I had my xxxx instead of this fancy thing"?

One question: Now that you have access to "real" fab equipment, do you ever find yourself saying, "Man, I wish I had my xxxx instead of this fancy thing"?![]() can confirm. sputtering is cheap. most expensive part by far is the vacuum pump(s). the rest can be done in a mason jar

can confirm. sputtering is cheap. most expensive part by far is the vacuum pump(s). the rest can be done in a mason jar![]() @itsallgoodjames not much, it was thrown out by the university of south carolina and was broken. Look on ebay, the hardest part is transporting them

@itsallgoodjames not much, it was thrown out by the university of south carolina and was broken. Look on ebay, the hardest part is transporting them![]() @thethoughtemporium - No implosions yet? The comments on that article I wrote seemed to think you were doomed for using plain old jars.

@thethoughtemporium - No implosions yet? The comments on that article I wrote seemed to think you were doomed for using plain old jars.![]() Is it possibly to use standard refrigerator pump for sputtering?

Is it possibly to use standard refrigerator pump for sputtering?![]() @Dan Maloney the "real" fab equipment is so nice and I'm lucky to have the amount of freedom at school that I do, but it is different than working in your own lab for sure. Harder to get away with stupid ideas and missuses of tools!

@Dan Maloney the "real" fab equipment is so nice and I'm lucky to have the amount of freedom at school that I do, but it is different than working in your own lab for sure. Harder to get away with stupid ideas and missuses of tools!![]() @moh.mohx1000 no. even a decent mechanical pump isn't really that great on it's own. ideally you need a proper 2stage rotary vane pump, and then some secondary pump. diffusion pumps are classic, but im looking into titanium getter pumps as they are buildable in theory

@moh.mohx1000 no. even a decent mechanical pump isn't really that great on it's own. ideally you need a proper 2stage rotary vane pump, and then some secondary pump. diffusion pumps are classic, but im looking into titanium getter pumps as they are buildable in theory![]() @thethoughtemporium you mentioned in your vid that this pump didn't work for sputtering https://www.amazon.com/ZENY-Single-Stage-Economy-Conditioner-Refrigerant/dp/B012CFTYX4/ref=sr_1_4?keywords=vacuum+pump&qid=1565812353&s=gateway&sr=8-4 I actually had the same pump on a small chamber, with nice vacuum fittings and no leaks. Got down below 500mTorr and made nice plasma, probably enough for rough sputtering. I was impressed. But its probably harder without a stainless steel chamber, you need a real vac pump I guess.

@thethoughtemporium you mentioned in your vid that this pump didn't work for sputtering https://www.amazon.com/ZENY-Single-Stage-Economy-Conditioner-Refrigerant/dp/B012CFTYX4/ref=sr_1_4?keywords=vacuum+pump&qid=1565812353&s=gateway&sr=8-4 I actually had the same pump on a small chamber, with nice vacuum fittings and no leaks. Got down below 500mTorr and made nice plasma, probably enough for rough sputtering. I was impressed. But its probably harder without a stainless steel chamber, you need a real vac pump I guess.![]() +1 yeah, real sputtering systems have multiple turbo pumps or crypo pumps to bring the chamber to UHV (nice and clean) before sputtering at ~50 to 100 mTorr

+1 yeah, real sputtering systems have multiple turbo pumps or crypo pumps to bring the chamber to UHV (nice and clean) before sputtering at ~50 to 100 mTorr![]() things will sputter at 500mtorr but you'll hate your existence the whole time. it's so bloody slow and the coatings are porous as all hell. only time i sputtered that high was when i coated a still damp hornet that took a while to dry under vacuum/plasma

things will sputter at 500mtorr but you'll hate your existence the whole time. it's so bloody slow and the coatings are porous as all hell. only time i sputtered that high was when i coated a still damp hornet that took a while to dry under vacuum/plasma![]() and a pinning gauge for pressure measuring

and a pinning gauge for pressure measuring![]() haha sounds about right. I mainly do thermal evaporation in my chamber, which can be as fast as 100Å/s , orders of magnitude faster than sputtering

haha sounds about right. I mainly do thermal evaporation in my chamber, which can be as fast as 100Å/s , orders of magnitude faster than sputtering![]() also, and i found this out the hard way, do not attempt to sputter aluminum/titanium unless you've got a good vacuum system. the oxide layer that builds up prevents material from sputtering. anything else should work fine though. just tried carbon coatings the other day. may have managed diamond like carbon but will need to check it with a raman spec to confirm

also, and i found this out the hard way, do not attempt to sputter aluminum/titanium unless you've got a good vacuum system. the oxide layer that builds up prevents material from sputtering. anything else should work fine though. just tried carbon coatings the other day. may have managed diamond like carbon but will need to check it with a raman spec to confirm![]() is the sputtering of the thermal evaporation easier?

is the sputtering of the thermal evaporation easier?![]() im about to be swtiching to thermal, least for titanium. a nice hot titanium wire should sputter readily compared to trying to magnetron sputter it. least that's the impression i got from the literature

im about to be swtiching to thermal, least for titanium. a nice hot titanium wire should sputter readily compared to trying to magnetron sputter it. least that's the impression i got from the literature![]() Interesting, good to know. Thermal evaporation of titanium is so nice, as its wetting it acts as a Ti getter pump and sucks the chamber pressure down. Every other metal (mostly) raises the chamber pressure due to out gassing

Interesting, good to know. Thermal evaporation of titanium is so nice, as its wetting it acts as a Ti getter pump and sucks the chamber pressure down. Every other metal (mostly) raises the chamber pressure due to out gassing![]() Id say you should start with sputtering if making your first chamber, evaporation requires a turbo or diffusion pump

Id say you should start with sputtering if making your first chamber, evaporation requires a turbo or diffusion pump![]() is a microwave magnetron at all related to a sputtering magnetron?

is a microwave magnetron at all related to a sputtering magnetron?![]() yeah vaguely, uses crossed electric and magnetic fields to contain something

yeah vaguely, uses crossed electric and magnetic fields to contain something![]() im planning to add a second chamber to my system just to spray titanium as a getter pump for exactly that reason. cheapest high vacuum pump you can make essentially

im planning to add a second chamber to my system just to spray titanium as a getter pump for exactly that reason. cheapest high vacuum pump you can make essentially![]()

http://sam.zeloof.xyz/titanium-sublimation-pump/

Titanium Sublimation Pump

A quick attempt making a titanium sublimation pump. Ti welding rod was bent into a coil around aluminum round stock and placed across 30-50 amps in high vacuum yielding successful results. Chamber was roughed down to 20mTorr then pumped with turbo to 1e-5 and briefly baked out.

![]() for sure!

for sure!![]() i just picked up some thin titanium wire rather than welding rods so i can use 3-5 amps instead of 50

i just picked up some thin titanium wire rather than welding rods so i can use 3-5 amps instead of 50![]() i think the main consideration with those is you want lots of surface area around the hot titanium

i think the main consideration with those is you want lots of surface area around the hot titanium![]() Good idea, wind them into a coil maybe

Good idea, wind them into a coil maybe![]() guessing it wouldent be possible to use a microwave magnetron for sputtering?

guessing it wouldent be possible to use a microwave magnetron for sputtering?![]() actually you could, but it's a different beast

actually you could, but it's a different beast![]() magnetrons put out wayyyyy too much power for the most part

magnetrons put out wayyyyy too much power for the most part![]() Possibly, theyre so powerful you could make a nasty plasma for plasma cleaning, etching, or a fusor

Possibly, theyre so powerful you could make a nasty plasma for plasma cleaning, etching, or a fusor![]() good to know

good to know![]() Well, we got seriously down into the weeds here with the physics of fabbing chips. This was outstanding stuff, and I hate to wrap it up, but it's that time. Sam, feel free to stay on and field questions if you like, but for now I'll just say thanks for taking time out of your summer vacation to talk shop with us. I really enjoyed it.

Well, we got seriously down into the weeds here with the physics of fabbing chips. This was outstanding stuff, and I hate to wrap it up, but it's that time. Sam, feel free to stay on and field questions if you like, but for now I'll just say thanks for taking time out of your summer vacation to talk shop with us. I really enjoyed it.Remember that we'll be talking to Arko, a robot engineer at JPL next week: https://hackaday.io/event/166178-life-at-jpl-hack-chat

![]() im actually tinkering with running a microwave magnetron at 12w or so. all you need to do is sub out the usual cap for ones of lower capacitance and it works like a charm

im actually tinkering with running a microwave magnetron at 12w or so. all you need to do is sub out the usual cap for ones of lower capacitance and it works like a charm![]() Thanks Dan, and everyone, that was great

Thanks Dan, and everyone, that was great![]() thanks for the help

thanks for the help![]() @thethoughtemporium interesting, i didn't know that was possible but I guess it makes sense

@thethoughtemporium interesting, i didn't know that was possible but I guess it makes sense![]()

-

Hack Chat Transcript, Part 1

08/14/2019 at 20:04 • 0 commentsOK, let's get started. I'm really excited to have Sam Zeloof here with us today. We've been covering Sam's homebrew ICs for a while now, and it's great to have him for a realtime chat.

Welcome, Sam! Can you maybe kick things off with a little about yourself?

Hello everyone :-)

![]() We're using a laser writer for making the masks

We're using a laser writer for making the masks![]() The funny thing: The guy making the masks has also the English name Sam, but he's Chinese :D

The funny thing: The guy making the masks has also the English name Sam, but he's Chinese :D![]() Sure! My name is Sam, i'm a second year student in college now and a little over 2 years ago I started acquiring and building the equipment needed to make ICs at home

Sure! My name is Sam, i'm a second year student in college now and a little over 2 years ago I started acquiring and building the equipment needed to make ICs at home![]() "Lanzendörfer" sounds like a very traditional Chinese surname ;-)

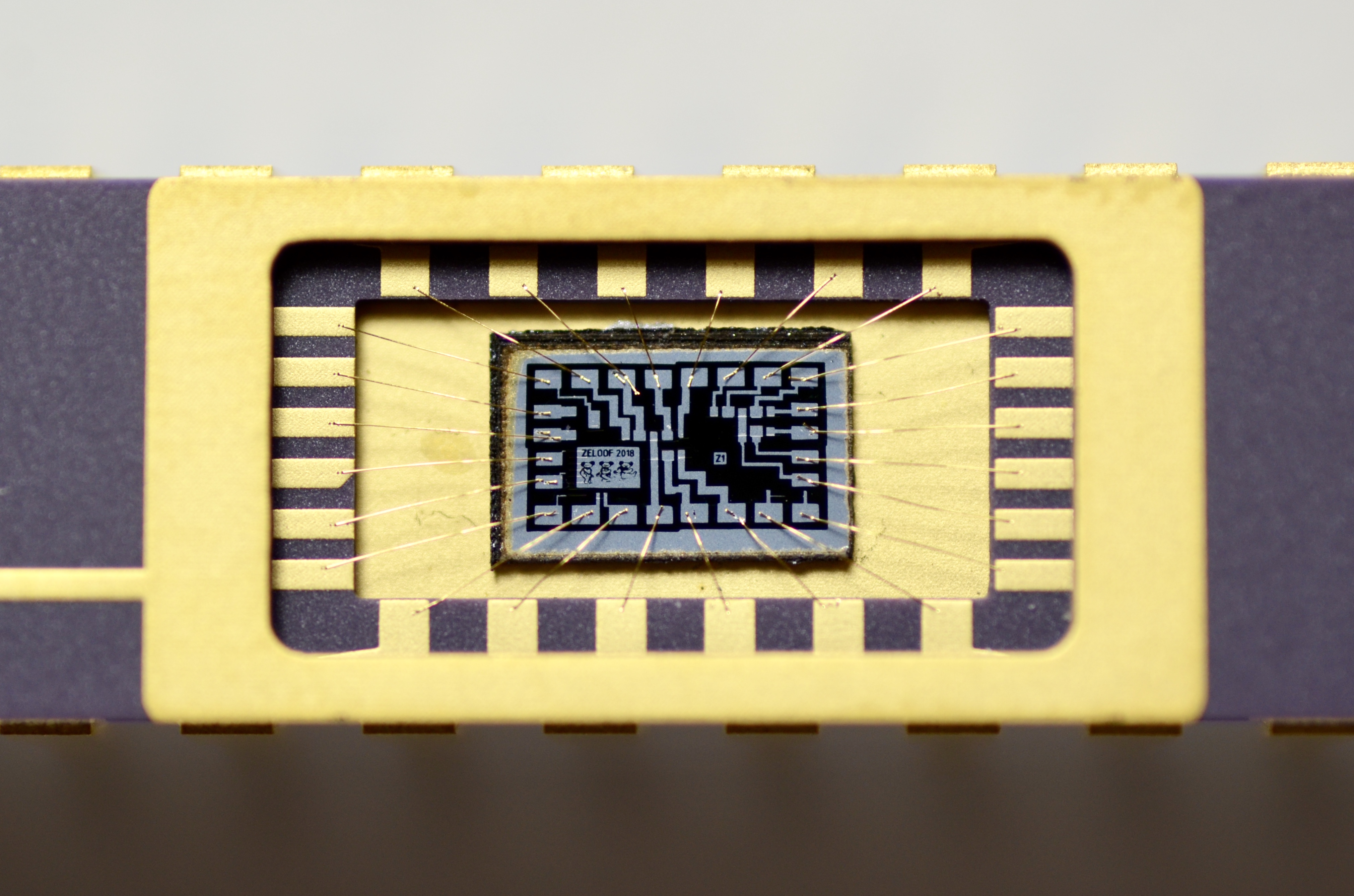

"Lanzendörfer" sounds like a very traditional Chinese surname ;-)![]() Last april I succeeded in making a diff amp chip, PMOS, with ~150um gate size and I've been improving things since then to now fab <5um ICs

Last april I succeeded in making a diff amp chip, PMOS, with ~150um gate size and I've been improving things since then to now fab <5um ICs![]()

https://hackaday.com/2017/02/25/the-fab-lab-next-door-diy-semiconductors/

The Fab Lab Next Door: DIY Semiconductors

You think you've got it going on because you can wire up some eBay modules and make some LEDs blink, or because you designed your own PCB, or maybe even because you're an RF wizard. Then you see that someone is fabricating semiconductors at home, and you realize there's always another mountain to climb.

![]() ICYMI

ICYMI![]() I'm not Chinese, I just was looking for a job opportunity to build cool hardware ;-)

I'm not Chinese, I just was looking for a job opportunity to build cool hardware ;-)![]() I'm originally from Switzerland

I'm originally from Switzerland![]() Hi Sam

Hi Sam![]() hi adam

hi adam![]() So how did your first year of college go?

So how did your first year of college go?![]() I'm not familiar with your project, but I'm guessing you are working with Si substrate. Where are you sourcing it?

I'm not familiar with your project, but I'm guessing you are working with Si substrate. Where are you sourcing it?![]() hi sam, biggest question where do you get your photoresist?

hi sam, biggest question where do you get your photoresist?![]() Pretty well, lots of work overall but I had some great experiences and was lucky enough to start working on other stuff right away. Outside of classes, I am working in the nanofab there and have started my own lab in that department to develop new fab tools and processes. Not much info on that yet but hopefully soon I can talk more about it, make a website, etc

Pretty well, lots of work overall but I had some great experiences and was lucky enough to start working on other stuff right away. Outside of classes, I am working in the nanofab there and have started my own lab in that department to develop new fab tools and processes. Not much info on that yet but hopefully soon I can talk more about it, make a website, etc![]() Yup, Si substrate. you can get small quantities on ebay or here https://www.universitywafer.com/

Yup, Si substrate. you can get small quantities on ebay or here https://www.universitywafer.com/![]() Sam: Our lambda is 500nm at the moment

Sam: Our lambda is 500nm at the moment![]() January we'll get access to an actual fab with a lambda of 250nm!!

January we'll get access to an actual fab with a lambda of 250nm!!![]() thethoughtemporium ! I saw one of your recent youtube vids and was going to reach out and offer you some photoresist, but couldn't find a contact button on your YT page. In the beginning I used PCB resist from Aliexpress (i think) but if you live in the US most companies will give out samples of their resists. Other than that, make friends in the industry...

thethoughtemporium ! I saw one of your recent youtube vids and was going to reach out and offer you some photoresist, but couldn't find a contact button on your YT page. In the beginning I used PCB resist from Aliexpress (i think) but if you live in the US most companies will give out samples of their resists. Other than that, make friends in the industry...![]() The entire PDK and process flow will be published online

The entire PDK and process flow will be published online![]() am i able to purchase one of your homemade ic's

am i able to purchase one of your homemade ic's![]() I'm guessing you are working with already doped wafers?

I'm guessing you are working with already doped wafers?![]() Yeah, at the moment 4 inch, pdoped, single side polished, prime wafers, but the process is designed

Yeah, at the moment 4 inch, pdoped, single side polished, prime wafers, but the process is designed![]() haday, yup. Commonly for NMOS circuits you start with a p-type bulk doped wafer, and the opposite is true for PMOS. For CMOS, you can start with either but commonly p doped are used, then to make P channel devices you implant a N-type well

haday, yup. Commonly for NMOS circuits you start with a p-type bulk doped wafer, and the opposite is true for PMOS. For CMOS, you can start with either but commonly p doped are used, then to make P channel devices you implant a N-type well![]() in a way, that you just have to recalculate the dose for the nwell and pwell

in a way, that you just have to recalculate the dose for the nwell and pwell![]() Exactly, Sam!

Exactly, Sam!![]() Ya pcb resist is just about all I can find. getting su-8 or similair seems to be a monumental task which seems silly considering. Was worried the answer was gonna be "make friends in the industry". Which evidently it is.

Ya pcb resist is just about all I can find. getting su-8 or similair seems to be a monumental task which seems silly considering. Was worried the answer was gonna be "make friends in the industry". Which evidently it is.![]() I''l update the document in the next few days:

I''l update the document in the next few days:https://download.libresilicon.com/process/v1/process_hightech_steps.pdf

![]() you can order small quantities of SU-8 through any school or business

you can order small quantities of SU-8 through any school or business![]() Please join next Sunday, 9pm HKT on murmur.libresilicon.com our Mumble sessions!

Please join next Sunday, 9pm HKT on murmur.libresilicon.com our Mumble sessions!![]() please!

please!![]() https://hackaday.io/project/58287-bipolar-dudes will be interested :-)

https://hackaday.io/project/58287-bipolar-dudes will be interested :-)![]() You mentioned you are completing your toolchain for 2 years now. How many tools were required to complete a fist prototype? Can you give us a gloss-over of the procedure?

You mentioned you are completing your toolchain for 2 years now. How many tools were required to complete a fist prototype? Can you give us a gloss-over of the procedure?![]() FETs are easier, in my opinion, to make. You can make them with only 1 doping step, BJT you need 2 and the base junction depth needs to be controlled very precisely

FETs are easier, in my opinion, to make. You can make them with only 1 doping step, BJT you need 2 and the base junction depth needs to be controlled very precisely![]() Hey hackadoodles - new project log and video. We did an inertial test and weren't decapitated. I call that a win. https://hackaday.io/project/165038-grinder-minder/log/167085-inertial-load-testing

Hey hackadoodles - new project log and video. We did an inertial test and weren't decapitated. I call that a win. https://hackaday.io/project/165038-grinder-minder/log/167085-inertial-load-testing![]() We've got tripple well

We've got tripple well![]() ah

ah![]() i watched your lab tour video. quite an impressive setup. Was actually thinking of picking up a DLP projector because of your demos of using it

i watched your lab tour video. quite an impressive setup. Was actually thinking of picking up a DLP projector because of your demos of using it![]() and SONOS flash :D

and SONOS flash :D![]() --> https://download.libresilicon.com/process/v1/process_hightech_steps.pdf

--> https://download.libresilicon.com/process/v1/process_hightech_steps.pdf![]() thanks, yeah DLP projects work quite nicely for maskless litho. I had great results with a newer 1080p projector and stock Hg lamp

thanks, yeah DLP projects work quite nicely for maskless litho. I had great results with a newer 1080p projector and stock Hg lamp![]() wanna have a talk on mumble?

wanna have a talk on mumble?![]() what's the smallest feature size you've managed with the dlp?

what's the smallest feature size you've managed with the dlp?![]() will any cheap 1080p projector from amazon work?

will any cheap 1080p projector from amazon work?![]() I'd really love to have another project engineer helping me ^^

I'd really love to have another project engineer helping me ^^![]() Ive made nice 1um lines and spaces, which was really pushing it. But I can't align that far down, XY stage isnt nice enough. Typically you want <20% alignment error, which is 200nm for 1um features.

Ive made nice 1um lines and spaces, which was really pushing it. But I can't align that far down, XY stage isnt nice enough. Typically you want <20% alignment error, which is 200nm for 1um features.![]() 2 - 4um is "comfortable" on my dlp setup, but of course you can reduce the field of view and just 'get' more resolution, to a point...

2 - 4um is "comfortable" on my dlp setup, but of course you can reduce the field of view and just 'get' more resolution, to a point...![]() our node is made to scale

our node is made to scale![]() itsallgoodjames any dlp will probably work, beyond that YMMV. I had some results with LCOS

itsallgoodjames any dlp will probably work, beyond that YMMV. I had some results with LCOS![]() that's not bad at all considering. what resist were you using for that? also what's the smallest feature you've managed with just the cheap pcb resist, just for sake of comparison

that's not bad at all considering. what resist were you using for that? also what's the smallest feature you've managed with just the cheap pcb resist, just for sake of comparison![]() I assume you are using some more optics after the projector to do that?

I assume you are using some more optics after the projector to do that?![]() We exchanged LOCOS for STI ;-)

We exchanged LOCOS for STI ;-)![]() Please join our mumble session this Sunday

Please join our mumble session this Sunday![]() @Sam Zeloof - Last I saw, the Z1 hadn't been wire-bonded. Were you able to get the gear needed to finish it?

@Sam Zeloof - Last I saw, the Z1 hadn't been wire-bonded. Were you able to get the gear needed to finish it?![]() @thethoughtemporium beyond 50um with PCB resist was tricky and not repeatable, but I eventually made a 10um grating. Any of the normal industry resists like SU-8 have great performance on the dlp setup. Just spin a thinner layer on to make smaller features, control the UV dose, etc.

@thethoughtemporium beyond 50um with PCB resist was tricky and not repeatable, but I eventually made a 10um grating. Any of the normal industry resists like SU-8 have great performance on the dlp setup. Just spin a thinner layer on to make smaller features, control the UV dose, etc.![]() @logxen the optics can be as simple as turning the projection lens inside the projector backwards, so it makes the image smaller instead of larger... or you can make things more complicated and start replacing the optics with quartz to pass deeper UV. But the plastic / boro glass lenses in most projectors pass <400nm OK for litho. I got 10mW / cm^2 at 365nm UV which leads to ~20 sec exposure, usual resist dose is on the order of 100mJ

@logxen the optics can be as simple as turning the projection lens inside the projector backwards, so it makes the image smaller instead of larger... or you can make things more complicated and start replacing the optics with quartz to pass deeper UV. But the plastic / boro glass lenses in most projectors pass <400nm OK for litho. I got 10mW / cm^2 at 365nm UV which leads to ~20 sec exposure, usual resist dose is on the order of 100mJ![]() I should maybe mention, that I've got access to Shenzhen equipment and manufacturers, and if anyone actually is willing to improve the resolution of your exposure equipment, instead of wining about it, we could work together and make a better, open source one

I should maybe mention, that I've got access to Shenzhen equipment and manufacturers, and if anyone actually is willing to improve the resolution of your exposure equipment, instead of wining about it, we could work together and make a better, open source one![]() Just saying

Just saying![]() yes! I finally got wire bonded chips this summer. Wire bonding is an art in itself, but the resulting chips look so nice

yes! I finally got wire bonded chips this summer. Wire bonding is an art in itself, but the resulting chips look so nice ![]() @Sam Zeloof Do you already have plans (in terms of target feature size and implemented circuitry) for the 'Z2'?

@Sam Zeloof Do you already have plans (in terms of target feature size and implemented circuitry) for the 'Z2'?![]() The wire bonder was graciously donated, but you can find them on ebay as well. getting the top metal layer (aluminum) to "stick" on the chip was a huge challenge, too

The wire bonder was graciously donated, but you can find them on ebay as well. getting the top metal layer (aluminum) to "stick" on the chip was a huge challenge, too![]() @Sam Zeloof approximately how much have you spent on your whole setup?

@Sam Zeloof approximately how much have you spent on your whole setup?![]() @Sam Zeloof how are bond wires 'stuck' on?

@Sam Zeloof how are bond wires 'stuck' on?![]() ultrasonic welding?

ultrasonic welding?![]() @morgan there's at least 10 different ways

@morgan there's at least 10 different ways![]() @Stefan Biereigel as far as circuitry, I was never interested much in making specific chips, but rather the processes. Although I do have some ideas for FPAA - like structures. As far as the feature size, the practical limit for chips at home (until someone makes a safe ion implanter) is 1 to 2um, which I am close to anyway. I would focus on changing the process, probably using polysilicon gates on the Z2 instead of aluminum

@Stefan Biereigel as far as circuitry, I was never interested much in making specific chips, but rather the processes. Although I do have some ideas for FPAA - like structures. As far as the feature size, the practical limit for chips at home (until someone makes a safe ion implanter) is 1 to 2um, which I am close to anyway. I would focus on changing the process, probably using polysilicon gates on the Z2 instead of aluminum![]() hmm, i mean 50um is still not bad. not super great for chips, but would be fine for doing traces for some simpler projects. certianly enough for a basic microelectrode array

hmm, i mean 50um is still not bad. not super great for chips, but would be fine for doing traces for some simpler projects. certianly enough for a basic microelectrode array![]() @morgan many ways, my bonder used heat, pressure, and ultrasonic

@morgan many ways, my bonder used heat, pressure, and ultrasonic![]() @Sam Zeloof Dude. Lets build a better exposure unit. Are you up for it, or do you wanna hang around on pathetic 50um??

@Sam Zeloof Dude. Lets build a better exposure unit. Are you up for it, or do you wanna hang around on pathetic 50um??![]() cool, a video I missed (and I reminder I hate the youtube suggestion system)

cool, a video I missed (and I reminder I hate the youtube suggestion system)![]() @thethoughtemporium for sure, but the good news with chips is that you can make them as big as you want. sure, it may be slower because of increased capacitance, but FET characteristics depend on the gate width to length ratio. so a linear scale-up still gives you good devices, within reason

@thethoughtemporium for sure, but the good news with chips is that you can make them as big as you want. sure, it may be slower because of increased capacitance, but FET characteristics depend on the gate width to length ratio. so a linear scale-up still gives you good devices, within reason![]() @Sam Zeloof Building shit like that is the reason I moved into a maybe-tobe war zone

@Sam Zeloof Building shit like that is the reason I moved into a maybe-tobe war zone![]() i looked at ion implantation a while back. not hard to build, it's just a linac and you can power it with a van de graff, but a nasty bugger to be around.

i looked at ion implantation a while back. not hard to build, it's just a linac and you can power it with a van de graff, but a nasty bugger to be around.![]() needs just as much shielding as a fusor

needs just as much shielding as a fusor![]() though no neutron shielding so it's technically easier. just some big sheets of lead

though no neutron shielding so it's technically easier. just some big sheets of lead![]() dude, van de graff is so old-school, I'm sure David can give you a shiny Shenzhen high voltage transformer :-)

dude, van de graff is so old-school, I'm sure David can give you a shiny Shenzhen high voltage transformer :-)![]() Yes for sure its doable, you only need ~30kv velocity to reasonably dope Si.

Yes for sure its doable, you only need ~30kv velocity to reasonably dope Si.![]() But the problem is in the dopant source, most of them are very very hazardous, phosphine, diborane, arsine

But the problem is in the dopant source, most of them are very very hazardous, phosphine, diborane, arsine![]() ya those... aren't pleasant to work with.

ya those... aren't pleasant to work with.![]() I thought about it for a while but never tried making one, but I would probably take the approach of "plasma immersion ion implantation" which has no ion mass selection (no linac, just a big chamber)

I thought about it for a while but never tried making one, but I would probably take the approach of "plasma immersion ion implantation" which has no ion mass selection (no linac, just a big chamber)![]() but isn't it just a few atoms? like 1:100 million

but isn't it just a few atoms? like 1:100 million![]() and would experiment putting small solid sources of dopant material (phosphorus, boron oxide) in the chamber and heating them to produce small and controllable amounts of dopant gas. Of course, the exhaust from the vacuum pump would be out the nearest window...

and would experiment putting small solid sources of dopant material (phosphorus, boron oxide) in the chamber and heating them to produce small and controllable amounts of dopant gas. Of course, the exhaust from the vacuum pump would be out the nearest window...![]() i've been playing around with some designs for direct ion writing. wanted to mod the magnetron to focus the plume to a beam and then move it around with some deflection lenses. no idea what sort of resolution you can get out of something like that though

i've been playing around with some designs for direct ion writing. wanted to mod the magnetron to focus the plume to a beam and then move it around with some deflection lenses. no idea what sort of resolution you can get out of something like that though![]() who needs a mask when you can just print your traces directly! least that's the dream. probably won't get to try it for a while though

who needs a mask when you can just print your traces directly! least that's the dream. probably won't get to try it for a while though![]() See Applied science video on electron microscope for that.

See Applied science video on electron microscope for that.![]() focusing the beam might me the hardest

focusing the beam might me the hardest![]() I have a green book somewhere on the theory of ion implantation, it mentions direct write doping with a technique like that. Ill dig up the title and send it later, its certainly possible but was abandoned in the industry for speed and resolution problems. Focusing a beam of positively charged things is so much harder than negatively, like electrons i think.

I have a green book somewhere on the theory of ion implantation, it mentions direct write doping with a technique like that. Ill dig up the title and send it later, its certainly possible but was abandoned in the industry for speed and resolution problems. Focusing a beam of positively charged things is so much harder than negatively, like electrons i think.![]() its a good idea, and would be so cool if you could mess with it.

its a good idea, and would be so cool if you could mess with it.![]() you also needs a lot of em shielding.

you also needs a lot of em shielding.![]() i figured as much. mostly just want to do it for the same reasons i do anything. seemed fun to mess around with XD

i figured as much. mostly just want to do it for the same reasons i do anything. seemed fun to mess around with XD![]() @Chris Gammell talks often about printing ICs on the amp hour, maybe he has some ideas how to do it?

@Chris Gammell talks often about printing ICs on the amp hour, maybe he has some ideas how to do it?![]() for sure. I have some random plasma related experiments here, that may be of interest. http://sam.zeloof.xyz/category/plasma/ Looking forward to your direct chip writer...

for sure. I have some random plasma related experiments here, that may be of interest. http://sam.zeloof.xyz/category/plasma/ Looking forward to your direct chip writer...![]() what are you using as your rf source for that rf plasma?

what are you using as your rf source for that rf plasma?![]() 10M ham radio or CB radio, 25W and sometimes with 200W LDMOS amplifier

10M ham radio or CB radio, 25W and sometimes with 200W LDMOS amplifier![]() anything will work, 1khz to 100mhz easily, as long as you have a matching network and more than a few watts

anything will work, 1khz to 100mhz easily, as long as you have a matching network and more than a few watts![]() Hah, cool. Is that why you got your ham license? Or did that happen first?

Hah, cool. Is that why you got your ham license? Or did that happen first?![]() Can I use Tesla coil for that?

Can I use Tesla coil for that?![]() hmm interesting. i just used a desktop tesla coil as my rf source XD kinda worked and ingnited plasma easily but didn't really strike me as enough power to really do anything. i'll look into a ham transmitter

hmm interesting. i just used a desktop tesla coil as my rf source XD kinda worked and ingnited plasma easily but didn't really strike me as enough power to really do anything. i'll look into a ham transmitter![]() Actually had the ham license first, but this was a nice use for it!

Actually had the ham license first, but this was a nice use for it!![]() because the coupling between the two coils is weak.

because the coupling between the two coils is weak.![]()

Lutetium

Lutetium

And about the only thing 10 meters is good for right now, lol

And about the only thing 10 meters is good for right now, lol