-

Hack Chat Transcript, Part 2

06/23/2021 at 20:08 • 0 comments

![]() I wasn't going to this time, I swear!

I wasn't going to this time, I swear!![]() @polyfractal greeting from scotland. I recently salvaged a biorad radiance 2100 confocal, currently trying to source a solid state laser to replace the argon ion laser, any recommendations for a 488nm module supplier?

@polyfractal greeting from scotland. I recently salvaged a biorad radiance 2100 confocal, currently trying to source a solid state laser to replace the argon ion laser, any recommendations for a 488nm module supplier?![]() with "only" 60,000 views and 200 comments, one of whom is applied science guy? :)

with "only" 60,000 views and 200 comments, one of whom is applied science guy? :)yep that one @Ahron Wayne! the results weren't great, but it was a fun project and with some tweaking i think it could work.

And yeah it gained a bunch of traction in the last few months thanks to the big influx of traffic, but it was a "dud" for a very long time which can be demoralizing if you let it get to you :)

@Patrick Hickey oh nice! congrats! afraid I don't have any that come to mind, 488nm is a bit of an oddball wavelength. tbh I do most of my scavenging from ebay too so dont know many real vendors :)

![]() I'll add that one to my watch later then, and it answers my question as to whether you'll turn your attention to metal printing.

I'll add that one to my watch later then, and it answers my question as to whether you'll turn your attention to metal printing.is the argon laser dead, or just don't want the hassle of big inefficient gas laser?

![]() If you're actually trying to repair/use the laser Sam's laserfaq is a great source: https://www.repairfaq.org/sam/lasersam.htm

If you're actually trying to repair/use the laser Sam's laserfaq is a great source: https://www.repairfaq.org/sam/lasersam.htm@Ahron Wayne heh. I do have some vague plans to work on SLA + nanoparticles + sintering. not quite direct metal printing but roundabout way to get there. ditto to ceramics. Mostly boils down to small enough particles and keeping them colloidal, which usually needs some extra chemistry to work (e.g. alumina will remain suspended in resin if you add some citric acid)

![]() cool, thanks @polyfractal i found a good supplier based in poland “lambdawave” they have many flavours of lasers, arduino controllable and low prices. Hope to connect with you in future! Patrick

cool, thanks @polyfractal i found a good supplier based in poland “lambdawave” they have many flavours of lasers, arduino controllable and low prices. Hope to connect with you in future! Patrickrelated to that old lattice video actually, i'm currently working on some new electroforming projects, building up a really thick deposit on 3D prints for functional reasons. we'll see if it works out for the particular project, but feels underutilized by hobbyists :)

![]() What resin? I did some research on a now likely dead project with printing resins...

What resin? I did some research on a now likely dead project with printing resins...![]() @polyfractal please keep us updated on that. I've been working on bound metal printing with filament for the past few months and there's a huge amount of potential, but I'm especially excited about the idea of working with powders mixed with resin because you might be able to mix your own alloys and also get huge details. One company described SLA-metal powder as "like butter" being spread on the plate which presents its own challenges of course.

@polyfractal please keep us updated on that. I've been working on bound metal printing with filament for the past few months and there's a huge amount of potential, but I'm especially excited about the idea of working with powders mixed with resin because you might be able to mix your own alloys and also get huge details. One company described SLA-metal powder as "like butter" being spread on the plate which presents its own challenges of course.![]() @polyfractal You should definitely check out the Virtual Foundry/Bradley woods, he got started with electroforming 3D printing exactly as you're describing before he started manufacturing metal filaments.

@polyfractal You should definitely check out the Virtual Foundry/Bradley woods, he got started with electroforming 3D printing exactly as you're describing before he started manufacturing metal filaments.@Thomas Shaddack just generic cheap SLA resin so far (elegoo maybe?). Haven't done much work on it yet, just enough to realize that particles either need chemical modification to stay in suspension, or some kind of agitator, or they need to be nano-sized. hit pause on it for a while to work on other projects

![]() There is also some talk in the community about debinding ceramics and other materials and then infiltrating them with metal for composites with no shrink.

There is also some talk in the community about debinding ceramics and other materials and then infiltrating them with metal for composites with no shrink.ooh interesting, will check out Virtual Foundry!

![]() I tried some localized thermal laser decomposition of copper oxide in epoxy. it indeed created copper.

I tried some localized thermal laser decomposition of copper oxide in epoxy. it indeed created copper.![]() metal matrix composites???

metal matrix composites???![]() thought: MMC done by electroforming on carbon fiber.

thought: MMC done by electroforming on carbon fiber.![]() @polyfractal ++

@polyfractal ++![]() @polyfractal microgravity should also avoid separation

@polyfractal microgravity should also avoid separation![]()

![]()

![]() The results would also look super cool to scan with your laser doohickey. This is using a conventional USB microscope to scan

The results would also look super cool to scan with your laser doohickey. This is using a conventional USB microscope to scanhaha, now just need to convince Bezos to take me up on his launch :)

![]() But he might not be "allowed" back...

But he might not be "allowed" back...![]() One-way trip?

One-way trip?![]() going to experiment with ar0230 sensor on a raspi. very high sensitivity 2-megapixel camera, datasheet promises a 16-bit raw. may be handy for the spectrum acquisition from the microscope.

going to experiment with ar0230 sensor on a raspi. very high sensitivity 2-megapixel camera, datasheet promises a 16-bit raw. may be handy for the spectrum acquisition from the microscope.@Thomas Shaddack interesting! did you load up the copper oxide into the epoxy yourself or was it a commercial product? Pulsed laser?

![]() Myself. It was a fairly coarse copper oxide so the result sucked. Handheld 5-watt 450nm blue.

Myself. It was a fairly coarse copper oxide so the result sucked. Handheld 5-watt 450nm blue.![]() CW.

CW.rad! might give that a shot myself

![]() Should try acrylate. Burnt epoxy STINKS. The amines, likely...

Should try acrylate. Burnt epoxy STINKS. The amines, likely...kinda sorta related, this paper has always intrigued me and I've wanted to try it: https://www.sciencedirect.com/science/article/abs/pii/S0169433220330907 tl;dr: coat something in copper, then lase the surface with just enough energy to oxidize the copper selectively

![]() Bezos Blue Origin microgravity will only last ~ 3 minutes, I think Elon can do much better.

Bezos Blue Origin microgravity will only last ~ 3 minutes, I think Elon can do much better.![]() Tried if copper on circuitboard could be etched away with nascent iodine from laser decomposition with CO2 laser of iodoform. The board didn't even notice and I stank like an old hospital for next two days.

Tried if copper on circuitboard could be etched away with nascent iodine from laser decomposition with CO2 laser of iodoform. The board didn't even notice and I stank like an old hospital for next two days.lol

i really need to get myself a CO2 laser at some point, the wavelength seems super handy to have around the shop

![]() For my goals the problem is avoiding copper oxidation, not causing it... I mean, once you selectively oxidize it, how do you avoid it happening to the rest?

For my goals the problem is avoiding copper oxidation, not causing it... I mean, once you selectively oxidize it, how do you avoid it happening to the rest?![]() Todo, same rig, laser soldering. If the beam can melt solder paste with high enough precision.

Todo, same rig, laser soldering. If the beam can melt solder paste with high enough precision.![]() Cheapo K40-III. Replace electronics with arduino/Marlin for easy support of gcode, the original software SUCKS.

Cheapo K40-III. Replace electronics with arduino/Marlin for easy support of gcode, the original software SUCKS.![]() Enough to earn the machine the nickname "Blue Horror".

Enough to earn the machine the nickname "Blue Horror".![]() So it's 1:00 here, which means we've been at it for an hour now. If Zach needs to get back to work, we'll have to let him go with our thanks. I really enjoyed this chat today, learned a lot. Feel free to stick around and continue the chat, of course -- the channel is always open. Thanks Zach!

So it's 1:00 here, which means we've been at it for an hour now. If Zach needs to get back to work, we'll have to let him go with our thanks. I really enjoyed this chat today, learned a lot. Feel free to stick around and continue the chat, of course -- the channel is always open. Thanks Zach!![]() And thanks to everyone for the great questions, too. Transcript to follow shortly.

And thanks to everyone for the great questions, too. Transcript to follow shortly.@Ahron Wayne yeah, the thought crossed my mind as well :) i figure you'd have to throw some kind of dielectric on top (Al2O3 or photoresist or something) after oxidizing

![]() Got it. And thank you Zach!

Got it. And thank you Zach!Thanks for inviting me @Dan Maloney! was really fun, and i have a list of notes to look into :) I'm good for a few more minutes, but have to jet and take care of my dog in a bit (she just had surgery :( )

![]() Thanks Zack. Great chat, learned plenty.

Thanks Zack. Great chat, learned plenty. -

Hack Chat Transcript, Part 1

06/23/2021 at 20:07 • 0 comments![]() OK, looks like people are checking in now, so let's kick things off. Welcome to the Hack Chat, I'm Dan and I'll be moderating today along with Dusan. Today we're excited to welcome Zachary Tong to the Hack Chat -- you've probably seen some of his cool stuff on the Breaking Taps YT channel. Today, we're going to focus on microscopy, though. See what I did there?

OK, looks like people are checking in now, so let's kick things off. Welcome to the Hack Chat, I'm Dan and I'll be moderating today along with Dusan. Today we're excited to welcome Zachary Tong to the Hack Chat -- you've probably seen some of his cool stuff on the Breaking Taps YT channel. Today, we're going to focus on microscopy, though. See what I did there?![]() Hello and welcome!

Hello and welcome!![]() I'm not sure I've seen Zach log in yet, though. Are you out there yet, Zach?

I'm not sure I've seen Zach log in yet, though. Are you out there yet, Zach?Heya! This is Zach / Breaking Taps. :)

![]() Oh, that's right -- forgot about the @polyfractal thing. Sorry!

Oh, that's right -- forgot about the @polyfractal thing. Sorry!![]() I looked at the laser microscopy video, it is amazing. You showen how easy it is to make.. still have you considered moving a prism or galvo to move the laser bundel?

I looked at the laser microscopy video, it is amazing. You showen how easy it is to make.. still have you considered moving a prism or galvo to move the laser bundel?Hehe yeah sorry, I'm "polyfractal" pretty much everywhere except on my YT channel :)

![]() Can you get us started with a little about your background?

Can you get us started with a little about your background?Sure! I typed up a little background before-hand.

So my background is actually in biology, which might be a surprise for folks that have seen some of my videos. Or maybe not, considering my poor engineering/EE skills hah. I have a degree in cell bio and worked in a wet lab for a number of years (culturing kidney and primary hippocampal neurons, running assays, etc). However for the last 10 or so years I've been in software. Most of that time working on the analytics functionality of a search engine called Elasticsearch.

Anyhow, I started my YT channel when I picked up metalworking, and it's slowly morphed into material science and microfab stuff. As my projects have gotten "smaller" over time, I keep finding myself needing (or wanting) new ways to measure/quantify the projects. Which has led to a proliferation of microscopes in my shop :)

To date, I have a few optical microscopes, a DIY laser confocal, a DIY "macro" atomic force microscope, a real AFM and a raman spectrometer. Contemplating building a chromatic confocal next, or maybe a white light interferometer. Definitely enjoy building instruments, even if they don't end up quite as useful as the real commercial ones :)

@Hexastorm Thanks! Yeah, considering some options to speed it up if I ever do v2. A galvo seems like a good approach, and you can get them pretty cheap (metal etching fiber lasers use them, so they are relatively mass-produced and cheap). A bunch of folks suggested CD/DVD optical units as an option too, which basically has all the guts pre-built and you just have to interface with it

![]() Are you planning on realeasing the code for your LSM?

Are you planning on realeasing the code for your LSM?@perlsackhd I wasnt originally but a bunch of folks have asked, so I'm currently compiling to throw on github somewhere. Need to find a RPi that i've temporarily misplaced :) The code is quite poor though, just quick bodges to get it working and interface with OpenFlexure (i hacked a new endpoint onto their server code)

![]() A couple of links for reference, in case you haven't seen them:

A couple of links for reference, in case you haven't seen them:![]()

https://hackaday.com/2021/04/26/3d-printed-laser-scanning-confocal-microscope-measures-microns/

3D-Printed Laser Scanning Confocal Microscope Measures Microns

When one thinks about microscopy, it seems to be mostly qualitative. Looking at a slide teeming with bacteria or protozoans is less about making measurements and more about recognizing features and describing their appearance. Not all microscopes are created equal, though, with some being far more optimized for making fine measurements of the microscopic realm.

![]()

https://hackaday.com/2021/06/12/macro-model-makes-atomic-force-microscopy-easier-to-understand/

Macro Model Makes Atomic Force Microscopy Easier To Understand

For anyone that's fiddled around with a magnifying glass, it's pretty easy to understand how optical microscopes work. And as microscopes are just an elaboration on a simple hand lens, so too are electron microscopes an elaboration on the optical kind, with electrons and magnets standing in for light and lenses.

![]() @polyfractal you should check out my video, I have a laser scanner with a fpga . Actually after seeing your video I thought of adding reading

@polyfractal you should check out my video, I have a laser scanner with a fpga . Actually after seeing your video I thought of adding reading![]()

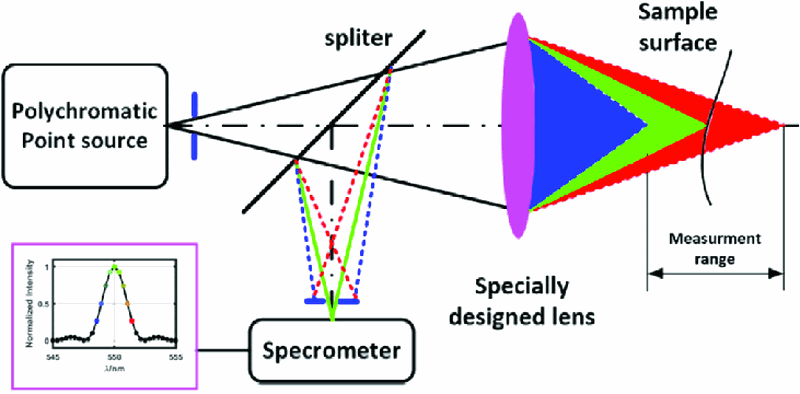

sorta followup on the v2 subject, one variation I'm considering next is a "chromatic confocal", which scans the full Z-stack simultaneously. It's a really clever setup which "abuses" chromatic aberration to determine the height. They are considerably faster than regular confocals if you don't need fluorescense, etc and just want heightmaps

@Hexastorm will take a look after, cheers for the link!

![]() Ist it possible with the your icspi afm to take force curves to get local material parameters?

Ist it possible with the your icspi afm to take force curves to get local material parameters?![]() That's really cool. What special about the "specially designed lens" - designed to maximize chromatic aberration, I suppose?

That's really cool. What special about the "specially designed lens" - designed to maximize chromatic aberration, I suppose?![]() Doesn't the chromatic confocal get influenced by the color of the sample?

Doesn't the chromatic confocal get influenced by the color of the sample?![]() @polyfractal project is here https://hackaday.io/project/21933-open-hardware-fast-high-resolution-laser ... you should also check out the startup spiden.com they have an interest in your work and use light + ai to detect biomarkers, anyhow enough promotion 😉

@polyfractal project is here https://hackaday.io/project/21933-open-hardware-fast-high-resolution-laser ... you should also check out the startup spiden.com they have an interest in your work and use light + ai to detect biomarkers, anyhow enough promotion 😉@lageos I _think_ it can take force curves (i saw mention in the manual) but to be honest I haven't played with it yet so can't really say much else. I think it's part of the advanced config/settings i haven't really touched yet

![]() @Dan Maloney The lense is needed so that the diffrent Wavelengths have diffrent focal distances

@Dan Maloney The lense is needed so that the diffrent Wavelengths have diffrent focal distances@Dan Maloney Yep, pretty much. I think they are known as "hyperchromatic" lenses, but i believe you can also stack up a bunch of spherical lenses and stretch out the colors

@Nicolas Tremblay yeah, my understanding is that some of the "special sauce" in the commercial units is the software that helps determine when it sees a peak, since color does affect the absolute amount returned. but in theory with a good spectrometer and some intelligent thresholding you can work around it. Nanovea and the other companies claim it works on all colors and reflective so there's _some_ way to do it

@Hexastorm that's neat! Definitely going to have a closer read. I'm noodling over a direct write laser lithography system in the future so this would be good reading for that too :)

![]() Ok, so the error correction is mostly on the software side with a bit of pre-filtering.

Ok, so the error correction is mostly on the software side with a bit of pre-filtering.![]() I'm surprised you haven't delved into a self hacked SEM.

I'm surprised you haven't delved into a self hacked SEM.yeah, that's at least how I've interpreted it based on some papers and noodling over the commercial units marketing material :) but i'm sure the devil is in the details, as I learned with the regular confocal hehe

![]() Random thought. Confocal microscope, using two-photon process for curing photoresists with resolution quite below the diffraction limit.

Random thought. Confocal microscope, using two-photon process for curing photoresists with resolution quite below the diffraction limit.![]() Read that as *curling*, was confused

Read that as *curling*, was confused![]() if the resist is curling, your adhesion to substrate sucks. :P

if the resist is curling, your adhesion to substrate sucks. :P:D

@kjansky1 yunno, I keep wanting to (there are some cool papers for mini SEMs using permanent magnets!) but tbh my EE skills are terrible, and HV scares the daylights out of me. Slowly working on learning more because I'd love to, but yeah, the electronics part is my nemesis. Really want to work on a focussed ion beam even more than SEM actually, but same issues

![]() The danger of HV depends more on the deliverable current (and energy). You can get dozens to maybe hundreds kV from static spark. It's the current that kills, the voltage only pushes it through.

The danger of HV depends more on the deliverable current (and energy). You can get dozens to maybe hundreds kV from static spark. It's the current that kills, the voltage only pushes it through.![]() And then to be even more specific, if you have a high voltage across your body, you will also have a high current going through it too. V=IR is always always always true.

And then to be even more specific, if you have a high voltage across your body, you will also have a high current going through it too. V=IR is always always always true.![]() @polyfractal , have you ever considered laser induced forward transfer? would be curious to see a simple setup

@polyfractal , have you ever considered laser induced forward transfer? would be curious to see a simple setupgood to know! actually on that note, if anyone has recommendations on HV texts/tutorials/etc I'd be grateful! Sometimes hard to find good learning resources that aren't like "Build a tesla coil!" style resources

![]() Also I just wanted to comment that it's cool you have a bio background before this. I started in biochemistry and the transition to engineering was interesting to say the least.

Also I just wanted to comment that it's cool you have a bio background before this. I started in biochemistry and the transition to engineering was interesting to say the least.![]() Depends on how "hard" the power supply is. If it is weak, the voltage quickly drops.

Depends on how "hard" the power supply is. If it is weak, the voltage quickly drops.![]() Read somewhere of a hacked SEM with a reworked gun from a old CRT for the beam.

Read somewhere of a hacked SEM with a reworked gun from a old CRT for the beam.![]() For HV, go look up Plasma Channel. He might help you

For HV, go look up Plasma Channel. He might help you![]() @polyfractal how long did it take you to make the laser confocal video (excluding construction) ?

@polyfractal how long did it take you to make the laser confocal video (excluding construction) ?![]()

https://hackaday.io/event/174398-into-the-plasmaverse-hack-chat

Into the Plasmaverse Hack Chat

Jay Bowles will host the Hack Chat on Wednesday, September 23, 2020 at noon Pacific Time. Time zones got you down? Here's a handy time converter! Most kids catch on to the fact that matter can exist in three states -- solid, liquid, and gas -- pretty early in life, usually after playing in the snow a few times.

![]() Anybody here knowledgeable about DIC (differential interference contrast), especiallyin the reflected light variant? how does the choics of a DIC prism depend on the lens?

Anybody here knowledgeable about DIC (differential interference contrast), especiallyin the reflected light variant? how does the choics of a DIC prism depend on the lens?![]() We had Jay on last year!

We had Jay on last year!![]() @Dan Maloney , yup, that was a fun one :P

@Dan Maloney , yup, that was a fun one :P@Hexastorm yes! I love that you know of the technique, it's super cool. I've tried a few times but haven't had a lot of luck getting "clean" transfer. just molten splatter, or complete vaporization. Part of the issue I think is the laser software -- the literal worst software ever made, EzCAD -- which makes it hard to precisely control the beam. E.g. hard to drop a single pulse where you want it. But I think it should be doable with a bit more tuning, it's pretty trivial to get "large" transfer like copper from one slide to another

Will check out Plasma Channel, thanks!

@Ahron Wayne yay another bio! Yeah I imagine transferring into a real engineering role would be quite a change :) Software was a decent side-move for me since I always did software stuff on the side (originally was a CS major)

@Hexastorm like just the filming/editing part of the video?

![]() @polyfractal yes

@polyfractal yes![]() I did some experiments with control of a CO2 laser. Notoriously hard to get low power from the tube, the discharge won't light/stay at low currents. but the power supply responds *fast* so the amount of energy delivered can be easily controlled by the pulse time, which is easy to generate with a spare timer on the arduino with just a bit of patch of Marlin.

I did some experiments with control of a CO2 laser. Notoriously hard to get low power from the tube, the discharge won't light/stay at low currents. but the power supply responds *fast* so the amount of energy delivered can be easily controlled by the pulse time, which is easy to generate with a spare timer on the arduino with just a bit of patch of Marlin.![]() @polyfractal What project would you recommend for a beginner who wants to dip his toes in diy microscopes?

@polyfractal What project would you recommend for a beginner who wants to dip his toes in diy microscopes?gotcha. Filming is typically a few hours tops. I like to just let the camera roll and do takes until I'm happy with the delivery, then move on to the next section and repeat. Afterwards grab any b-roll as required. Makes editing longer though since there is like 2 continuous hours of footage to work through. Editing is probably 5-6 hours total, plus thumbnails and all that jazz. but yeah after a project is "done" i can usually get the video part done in a weekend'ish

![]() Uhm... So that's it? Just a bunch of people chatting?

Uhm... So that's it? Just a bunch of people chatting?![]() That would be the case if I was ever in a "real" role, still goofing off in an academic setting :) I have considered being in software just because it's so in demand and it's accessible for work. Not sure if my Python skills are good enough for a "real" job though.

That would be the case if I was ever in a "real" role, still goofing off in an academic setting :) I have considered being in software just because it's so in demand and it's accessible for work. Not sure if my Python skills are good enough for a "real" job though. @perisackhd I would recommend you start relatively macro, like with a USB microscope or RPI lens flipped backward. Or you can work with an existing project like openflexure.

@Timo afraid I don't know much about how DIC works, only used it as an end-user in lab :(

![]() @polyfractal did you have a "big break" when it came to making videos, or did you have a steady clip of subscribers from the beginning?

@polyfractal did you have a "big break" when it came to making videos, or did you have a steady clip of subscribers from the beginning?@perlsackhd ++ what @Ahron Wayne mentioned. OpenFlexure is a pretty great little ecosystem. Or just hooking a microscope objective up to an RPi camera yourself, the simplest form is just an objective + camera. Make sure to get a non-infinity objective, they are typically around 160mm. meaning the camera just needs to be 160mm away. The infinity lenses are focused to infinity which is great when you need other stuff in the optical stack (like beamsplitters, etc) but complicates things since you'll need another lens to focus it onto the camera

![]() @Birk -- that's why we call it a "Hack Chat"

@Birk -- that's why we call it a "Hack Chat"![]() Open flexure seems like a great start to get into "optical" microscopy

Open flexure seems like a great start to get into "optical" microscopy![]() Feel free to join in with questions, though

Feel free to join in with questions, though![]() How about something like this: Fiber-optic confocal microscope using a MEMS scanner and miniature objective lens

How about something like this: Fiber-optic confocal microscope using a MEMS scanner and miniature objective lensHJ Shin, MC Pierce, D Lee, H Ra, O Solgaard… - Optics …, 2007 - osapublishing.org

@Ahron Wayne definitely had a "big break" moment. I was slowly accumulating subscribers up until about 5-6k, then the YT algo decided to push a ton of traffic to my high speed chatter video and that really blew up the subscriber count. Ben Krasnow also noticed the copper deposition video and tweeted, which brough in a lot of cool folks :)

![]() @perlsackhd and not to gotcha @polyfractal but if it's non-infinity, it doesn't have to be *exactly* that distance away (something I worried about when I got into macro). If the lens is closer to your sensor the image will just be less magnified.

@perlsackhd and not to gotcha @polyfractal but if it's non-infinity, it doesn't have to be *exactly* that distance away (something I worried about when I got into macro). If the lens is closer to your sensor the image will just be less magnified.++

![]() @polyfractal I indeed first saw you through your high speed chatter video. 5-6k is still really great to me too.

@polyfractal I indeed first saw you through your high speed chatter video. 5-6k is still really great to me too.![]() Cough cough, Hackaday ;-)

Cough cough, Hackaday ;-)that's actually one thing i like (and sometimes curse) about optics, there's a lot of manual fiddling/tuning you can do to get things working. and it's relatively accessible since you can stick a piece of paper in between lenses to see what's going on

![]()

https://hackaday.com/2020/01/16/analyzing-cnc-tool-chatter-with-audacity/

Analyzing CNC Tool Chatter With Audacity

When you're operating a machine that's powerful enough to tear a solid metal block to shards, it pays to be attentive to details. The angular momentum of the spindle of a modern CNC machine can be trouble if it gets unleashed the wrong way, which is why generations of machinists have developed an ear for the telltale sign of impending doom: chatter.

hehehe

:) <3 HaD

![]() Think that was the first time I had seen one of your vids, actually, so it probably was that mysterious YT algo push.

Think that was the first time I had seen one of your vids, actually, so it probably was that mysterious YT algo push.and yeah, I was pleased as punch at 5-6k! didnt know what to do with myself when it like tripled in a week :)

the YT algo gods move in mysterious ways

![]() @polyfractal I too saw the chattering video first then long time nothing and after seeing the LSM video remembered the Chattering video

@polyfractal I too saw the chattering video first then long time nothing and after seeing the LSM video remembered the Chattering video![]() What is a video that you worked really hard on, or just otherwise wish got a lot more attention?

What is a video that you worked really hard on, or just otherwise wish got a lot more attention?@kjansky1 just had a quick skim, that looks really neat! only downside is that fiber stuff can sometimes be expensive, but it does remove a lot of the alignment issues too which is great, and the fiber itself acts as the pinhole, etc etc

![]() heyy

heyy![]() i need help plss

i need help plss@Ahron Wayne hmmmm, good question. I have a soft spot for a video about hollow microlattices, sorta based on a Science paper, which for various reasons didn't do super well (at the beginning of my transition to material science topics, too much faffing around in the beginning, etc). but I thought it was a neat topic :)

More recently I did a video about sputter shadow masks, but included a Blade Runner trailer spoof and was too cutsey with the title/thumbnail which really penalized traffic. oh well :)

obligatory hackaday link to save Dan having to go digging for it :)

Lutetium

Lutetium