-

Hack Chat Transcript, Part 2

02/22/2023 at 22:06 • 0 comments![]() i vent ours outside , since it has a lot of contaminants in it

i vent ours outside , since it has a lot of contaminants in it![]() Probably with some filler in the rubber.

Probably with some filler in the rubber.![]() co2, fibre, all of them outside you can do it into an active carbon filter as well to help, but its a lot of gas and very small particulate

co2, fibre, all of them outside you can do it into an active carbon filter as well to help, but its a lot of gas and very small particulate![]() would bubbling through water do the job instead of a filter?

would bubbling through water do the job instead of a filter?![]() World's worst hookah

World's worst hookah![]() it'd need a lot of flow, but maybe, waterjets do use the water to help with that too, so its feasible, but there is still the gas depending on what you're cutting

it'd need a lot of flow, but maybe, waterjets do use the water to help with that too, so its feasible, but there is still the gas depending on what you're cutting![]() Hey @Jonathan Schwartz - we're past an hour now. Want to keep going or wrap it up?

Hey @Jonathan Schwartz - we're past an hour now. Want to keep going or wrap it up?![]() Aliexpress has some sweet-looking "80 watt" 450nm lasers. How much should I trust the offer? (Assuming incoming power instead of optical.)

Aliexpress has some sweet-looking "80 watt" 450nm lasers. How much should I trust the offer? (Assuming incoming power instead of optical.)![]() they are reportedly combining power from two diodes.

they are reportedly combining power from two diodes.![]() it may have multiple chips and beam combining in-module.

it may have multiple chips and beam combining in-module.![]() I had good experiences with thin white material cutting when the line was dyed yellow.

I had good experiences with thin white material cutting when the line was dyed yellow.![]() Thank you!

Thank you!![]() makes a lot more sense when you're watching the youtube too heh

makes a lot more sense when you're watching the youtube too heh![]() another trick, engraving polyolefins. paint the engraving areas (text) with a black pen, then scan with defocused blue laser.

another trick, engraving polyolefins. paint the engraving areas (text) with a black pen, then scan with defocused blue laser.![]() translucent material ignores the beam, paint heats and bakes into surface.

translucent material ignores the beam, paint heats and bakes into surface.![]() TRICKS! Do tell do tell do tell!!!

TRICKS! Do tell do tell do tell!!!![]() the trick was to make sure text on polypropylene bottles of solvents won't wash off.

the trick was to make sure text on polypropylene bottles of solvents won't wash off.![]() Any interesting fails? My one was trying to use nascent iodine generated from laser decomposition of iodoform, to etch copper on circuitboards. The copper totally ignored the process and everything stank like an old hospital for DAYS.

Any interesting fails? My one was trying to use nascent iodine generated from laser decomposition of iodoform, to etch copper on circuitboards. The copper totally ignored the process and everything stank like an old hospital for DAYS.![]() colour is interesting, we managed once to make repeatable colour with our mopa but never again.

colour is interesting, we managed once to make repeatable colour with our mopa but never again.![]() logical. focal point on surface vs in the middle of the material thickness.

logical. focal point on surface vs in the middle of the material thickness.![]() its very sensitive to temperature

its very sensitive to temperature![]() thought. selective surface melting. coat a surface with a powder, eg. plastic or solder, and then raster/trace over.

thought. selective surface melting. coat a surface with a powder, eg. plastic or solder, and then raster/trace over.![]() which is a big issue with fibres and metal, the work area heats up and changes the cut properties. so much easier with co2 wood/plastic

which is a big issue with fibres and metal, the work area heats up and changes the cut properties. so much easier with co2 wood/plastic![]() then brush off the unmelted powder.

then brush off the unmelted powder.![]() you can also engrave atypical stuff. I had success with sugar candy.

you can also engrave atypical stuff. I had success with sugar candy.![]()

![]()

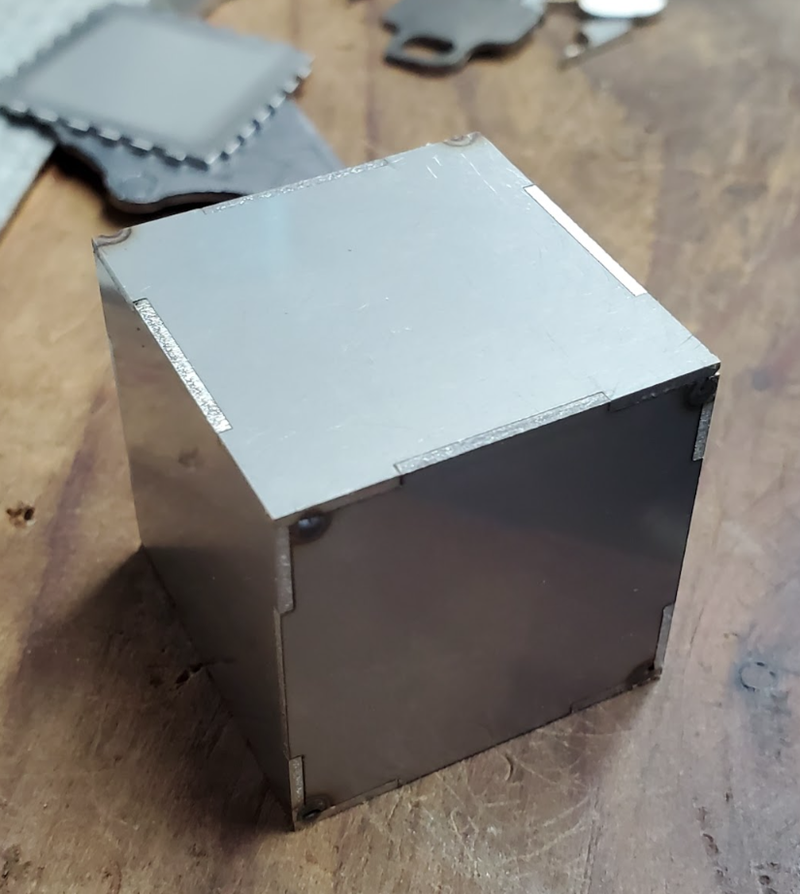

![]() i like making keychains :)

i like making keychains :)![]() what about a 5-axis head for the laser? engraving non-flat objects?

what about a 5-axis head for the laser? engraving non-flat objects?![]() carbon steel

carbon steel![]() yes

yes![]() 3/16th

3/16th![]() in the garage

in the garage![]() LA

LA![]() sure , i'm in northridge

sure , i'm in northridge![]() that's a SWEET machine!

that's a SWEET machine!![]()

https://www.improwis.com/projects/food_LaserEngravedCandy/

Laser engraved candy

Because, why not? Does everything need a justification? This was the inspiration: Bittersweets, the despair.com Valentine candies A 40W CO2 K40-III laser cutter was employed. A test image ("test" text) was used for the engraving. The candy used are the kind consisting of pressed sugar, with some added starch, citric acid, flavorings and dyes.

![]() 1kW fibre

1kW fibre![]() could it be done via 3d-scanning the object, then autogenerating the paths of the 5-axis thing to deliver beam perpendicularly to the object where desired?

could it be done via 3d-scanning the object, then autogenerating the paths of the 5-axis thing to deliver beam perpendicularly to the object where desired?![]() sure, we are usually hanging out saturdays and doing stuff

sure, we are usually hanging out saturdays and doing stuff![]() g-code is the easy part. gcode is nothing but positions of the machine. a bit of math. brain-melting math at times but still just math.

g-code is the easy part. gcode is nothing but positions of the machine. a bit of math. brain-melting math at times but still just math.![]()

![]()

![]() you can laser weld too

you can laser weld too![]() 3d gcode (and multiaxis) can get crazy. i never got beyond 2.5d yet, and failed to understand CAM software correctly so mostly just generating the toolpaths in python.

3d gcode (and multiaxis) can get crazy. i never got beyond 2.5d yet, and failed to understand CAM software correctly so mostly just generating the toolpaths in python.![]() do you mean the 3d capture obama project?

do you mean the 3d capture obama project?![]() ahh ok, i meant this one https://www.bbc.com/news/av/world-us-canada-30306967

ahh ok, i meant this one https://www.bbc.com/news/av/world-us-canada-30306967![]() femtosecond lasers are fun too. any knowledge of them?

femtosecond lasers are fun too. any knowledge of them?![]() or the copper-vapor ones?

or the copper-vapor ones?![]() would love to get a femtosecond

would love to get a femtosecond![]() short pulsed lasers can vaporize material before the underlying layers can even notice something is happening.

short pulsed lasers can vaporize material before the underlying layers can even notice something is happening.![]() @Jonathan Schwartz - thanks so much for your time today, this was really helpful. And thanks to everyone for the great questions!

@Jonathan Schwartz - thanks so much for your time today, this was really helpful. And thanks to everyone for the great questions!FYI, I'll post a transcript in a few minutes, along with a link to the YT video. Thanks all!

![]() thanks a lot!

thanks a lot!![]() Jonathan, I joined late but the info you shared was very useful, I will be rewatching this one.

Jonathan, I joined late but the info you shared was very useful, I will be rewatching this one.![]() also you can cut biomaterials. lasers are used in medicine.

also you can cut biomaterials. lasers are used in medicine.![]() co2 as a scalpel. got hand in a beam, and it healed nicely.

co2 as a scalpel. got hand in a beam, and it healed nicely.![]() so neat

so neat![]() yup, tattoo removal lasers can be used for welding if the q-switch gets removed.

yup, tattoo removal lasers can be used for welding if the q-switch gets removed.![]() cheers

cheers![]() cheers!!

cheers!!![]() yeah ebay cheap tattoo removal lasers :)

yeah ebay cheap tattoo removal lasers :)![]() stryropyro style

stryropyro style![]() lasers don't care what they are used for. if you do not tell the tube it is for medical uses, it will happily deliver its scalpel-cauter like work.

lasers don't care what they are used for. if you do not tell the tube it is for medical uses, it will happily deliver its scalpel-cauter like work.![]() blue laser works too, though I am a wimp and tried it only on a piece of ham instead of myself. (the CO2 test was accident.)

blue laser works too, though I am a wimp and tried it only on a piece of ham instead of myself. (the CO2 test was accident.)![]() ...should try melting acrylic powder (eg. the nail-art material) into surface of clear acrylic.

...should try melting acrylic powder (eg. the nail-art material) into surface of clear acrylic.![]() ...or cocoa powder into white chocolate.

...or cocoa powder into white chocolate.![]() heh

heh![]() food shenanigans have the advantage that you can easily dispose of the fails. (and the successes too.)

food shenanigans have the advantage that you can easily dispose of the fails. (and the successes too.)![]() i wonder if i can slice pizza

i wonder if i can slice pizza![]() wisconsin uni tried to cut cheese. turned out you need a uv laser for good cut, without melting more than cutting.

wisconsin uni tried to cut cheese. turned out you need a uv laser for good cut, without melting more than cutting.![]() lasercut pizza will be on youtube. i think i saw it.

lasercut pizza will be on youtube. i think i saw it.![]() yeah its amazing how many folks think, laser, food lets try it .. our hackerspace had many varied smells

yeah its amazing how many folks think, laser, food lets try it .. our hackerspace had many varied smells![]() the fat

the fat![]() how much cooling does the kilowatt machine need? how big/heavy it is?

how much cooling does the kilowatt machine need? how big/heavy it is?![]() it has a dedicated water color fan thing thats a decent size

it has a dedicated water color fan thing thats a decent size![]() i ahve some pics somewhere i think

i ahve some pics somewhere i think![]() a water chiller?

a water chiller?![]() https://gweikecnc.com/product/107.html its a gweike, who pretty much supply most everyone these days

https://gweikecnc.com/product/107.html its a gweike, who pretty much supply most everyone these days![]() yeah it runs water to the head

yeah it runs water to the head![]()

![]()

![]()

![]()

![]() and relative size

and relative size![]() sweetie!

sweetie!![]() the two tanks were the best we could get on a saturday of n2/o2 persuaded a local brewery supply shop to sell us them, but replaced them with much larger ones

the two tanks were the best we could get on a saturday of n2/o2 persuaded a local brewery supply shop to sell us them, but replaced them with much larger ones![]() saw the oxygen separator zeolite beads on aliexpress. for pressure-swing separation.

saw the oxygen separator zeolite beads on aliexpress. for pressure-swing separation.![]() could work for both oxygen generation and nitrogen-enriched stream.

could work for both oxygen generation and nitrogen-enriched stream.![]() yeah the o2 is very low pressure so that tank we've had since the start, the n2 though you go thru like crazy

yeah the o2 is very low pressure so that tank we've had since the start, the n2 though you go thru like crazy![]() pressurize some air, then cycle compression-decompression through cylinders with the zeolite.

pressurize some air, then cycle compression-decompression through cylinders with the zeolite.![]() electrochemical medical oxygen sensors can be bought (annoyingly expensive) too. going up to 100% o2.

electrochemical medical oxygen sensors can be bought (annoyingly expensive) too. going up to 100% o2.![]() n2 runs about 12 bar

n2 runs about 12 bar![]() what is its role in the process? mechanical blowing off stuff from the cut?

what is its role in the process? mechanical blowing off stuff from the cut?![]() yeah we looked at medical ones, but the pressure and the amount they generate per cost, i think it was about 5K USD for one that makes a very small amount, so going with the rotary compressor with a fridge/dryer setup

yeah we looked at medical ones, but the pressure and the amount they generate per cost, i think it was about 5K USD for one that makes a very small amount, so going with the rotary compressor with a fridge/dryer setup![]() for o2 it helps it burn, the n2 shields

for o2 it helps it burn, the n2 shields![]() so deeper cuts/nice cuts

so deeper cuts/nice cuts![]() there are also industrial ones. same principle, bigger size, no medical nonsense paperwork/certs/price.

there are also industrial ones. same principle, bigger size, no medical nonsense paperwork/certs/price.![]() yeah iirc the issue was the pressure

yeah iirc the issue was the pressure![]() flow speed? as the pressure converts to speed in the nozzle?

flow speed? as the pressure converts to speed in the nozzle?![]() we found a chinese compressor for 4K new that can run upto like 25 bar

we found a chinese compressor for 4K new that can run upto like 25 bar![]() not bad!

not bad!![]() tank pressure, since for the n2 upto a 3mm nozzle with 12 bar

tank pressure, since for the n2 upto a 3mm nozzle with 12 bar![]() so a 300 tank lasts maybe 12-15 minutes and thats around what 140 bar?

so a 300 tank lasts maybe 12-15 minutes and thats around what 140 bar?![]() there are also membrane-based nitrogen separators.

there are also membrane-based nitrogen separators.![]() yeah we looked at a whole range of medical supply ones, they just didnt generate anywhere near enough for the cost,since medical

yeah we looked at a whole range of medical supply ones, they just didnt generate anywhere near enough for the cost,since medical![]() a pair or three medical oxygen generators is sometimes used as alternative to bottled oxygen for smaller-scale glassworking.

a pair or three medical oxygen generators is sometimes used as alternative to bottled oxygen for smaller-scale glassworking.![]() like terra https://www.terrauniversal.com/portable-nitrogen-generator-2700-99.html

like terra https://www.terrauniversal.com/portable-nitrogen-generator-2700-99.html![]() we had a big-ass generator for gas assist in a plastic moulding factory.

we had a big-ass generator for gas assist in a plastic moulding factory.![]() so like 6 scfh

so like 6 scfh![]()

![]()

![]() yeah this is what we bought

yeah this is what we bought![]() like with an electric car battery, you could have a nitrogen production unit running 24/7 and feeding a tank and taking out of the tank as needed at higher flow than the generator would give.

like with an electric car battery, you could have a nitrogen production unit running 24/7 and feeding a tank and taking out of the tank as needed at higher flow than the generator would give.![]() three phase, 15HP, just have to find a place to put it

three phase, 15HP, just have to find a place to put it![]() a second floor of the garage. :P

a second floor of the garage. :P![]() or a basement under the garage.

or a basement under the garage.![]() i think its going outside in the garden heh, no basements here

i think its going outside in the garden heh, no basements here![]() bad geology?

bad geology?![]() yeah northridge, earthquakes, liquefaction zone

yeah northridge, earthquakes, liquefaction zone![]() yuck.

yuck.![]() yeah you know its bad when you live in a place that has a quake named for it

yeah you know its bad when you live in a place that has a quake named for it![]() fun! get shakin'!

fun! get shakin'! -

Hack Chat Transcript, Part 1

02/22/2023 at 22:05 • 0 commentsI'm here if you guys want to ask a couple questions before we start.

![]() Hi Jon! Welcome back!

Hi Jon! Welcome back!![]() Thanks Dan

Thanks Dan![]() Hey :), I've got a rather longish question - I'm looking at getting an 830nm laser @ 30mW for an experiment I'm trying to replicate, I was looking at some on here - https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=1487

Hey :), I've got a rather longish question - I'm looking at getting an 830nm laser @ 30mW for an experiment I'm trying to replicate, I was looking at some on here - https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=1487but they're only 3mW, I'm wondering if you have any recommendations for sites to look at. I was also wondering, can you get laser goggles that protect against IR, and up to what power laser can they protect against (I wasn't sure also if they can protect your eyes if you directly accidentally look at the beam? I assume maybe not?). I'm also looking for a 20x beam expander for the IR laser (in order to create laser speckle), but the ones on thorlabs are very expensive (I assume I can't use a microscope objective, which i have used with a red laser as that would be glass?).

![]() What do you need it for? There are lots of options if you dont need the best one on the market

What do you need it for? There are lots of options if you dont need the best one on the market

I doubt I need anything too fancy![]() It's basically to create laser speckle to replicate this -

It's basically to create laser speckle to replicate this - ![]() Amazon has a lot of Chinese lasers that are really good.

Amazon has a lot of Chinese lasers that are really good.![]() and the glasses

and the glasses![]() Cool, and the glasses would protect against IR?

Cool, and the glasses would protect against IR?![]() they are generaly considered 90% effective at blocking but that would be a direct hit which does not happen almost ever

they are generaly considered 90% effective at blocking but that would be a direct hit which does not happen almost ever![]() ah cool

ah cool![]() I was a bit wary of amazon/aliexpress as i thougt the power of laser might be incorrect?

I was a bit wary of amazon/aliexpress as i thougt the power of laser might be incorrect?![]() they can be

they can be![]() but normally it is advertised as more power. let me explain on vid.

but normally it is advertised as more power. let me explain on vid.![]() okey doke, thanks

okey doke, thanks![]() @Jonathan Schwartz - the YT vid says the stream will start in an hour, just FYI

@Jonathan Schwartz - the YT vid says the stream will start in an hour, just FYI![]() Hi folks, we're going to get started now. I'm Dan, I'll be moderating today along with Dusan as we welcome Jonathan Schwartz back to the Hack Chat. Last time we did a "Lasers 101" chat, and today we're going to talk more about the nuts and bolts of buying a laser cutter/engraver

Hi folks, we're going to get started now. I'm Dan, I'll be moderating today along with Dusan as we welcome Jonathan Schwartz back to the Hack Chat. Last time we did a "Lasers 101" chat, and today we're going to talk more about the nuts and bolts of buying a laser cutter/engraver![]() I am live

I am live![]() Hi Dan, Jonathan

Hi Dan, Jonathan![]() hey

hey![]() welcome everyone!

welcome everyone!![]() Also, there's a simulcast livestream over at

Also, there's a simulcast livestream over at ![]() I will answer questions from here on the vid

I will answer questions from here on the vid![]() While we're waiting, Jon, can you give us a little about how you got started in the laser business?

While we're waiting, Jon, can you give us a little about how you got started in the laser business?![]() I will answer on the vid

I will answer on the vid![]() Everyone make sure you jump into the YT vid too -- Jon's answering questions over there.

Everyone make sure you jump into the YT vid too -- Jon's answering questions over there.![]()

https://www.youtube.com/watch?v=qcX5F3n68RM

![]() Hi there, spiritplumber (person who makes the L-Cheapo laser)

Hi there, spiritplumber (person who makes the L-Cheapo laser)![]() Hi @Matteo Borri !

Hi @Matteo Borri !![]() we're still making the l-cheapo mk7 so if anyone has a question on diode lasers I can try to help :)

we're still making the l-cheapo mk7 so if anyone has a question on diode lasers I can try to help :)![]() we also put the pcb's on the wiki so if people want to make their own, go right ahead.

we also put the pcb's on the wiki so if people want to make their own, go right ahead.![]() aloha! I have a Epilog Helix that is now about 14yo. I do not run a biz with it, mostly used for hobby work for a while but havent used much in last few years. It has Issues running long times.

aloha! I have a Epilog Helix that is now about 14yo. I do not run a biz with it, mostly used for hobby work for a while but havent used much in last few years. It has Issues running long times.![]() 14 years is a pretty awesome service life

14 years is a pretty awesome service life![]() how are you cooling it?

how are you cooling it?![]() Howdy all, I've owned all manner of cheap laser cutters, and have run them for kit businesses. The latest one was the trickiest

Howdy all, I've owned all manner of cheap laser cutters, and have run them for kit businesses. The latest one was the trickiest![]() Can you give us an idea of optical laser power vs cutting/engraving capability

Can you give us an idea of optical laser power vs cutting/engraving capability![]() Newcomers -- don't forget to tune into the live stream too:

Newcomers -- don't forget to tune into the live stream too: ![]() That's where Jon is going into depth on answers

That's where Jon is going into depth on answers![]() 14y but 3rd tube and many many months sitting unused

14y but 3rd tube and many many months sitting unused![]() "Buy once, cry once", right?

"Buy once, cry once", right?![]() Chris in South Korea here, I *finally* woke up early enough to join a Hack Chat

Chris in South Korea here, I *finally* woke up early enough to join a Hack Chat![]() hello fellow photon wranglers

hello fellow photon wranglers![]() @Jonathan Schwartz - if I can take it back even further: How do you decide if you even need to buy a laser? As opposed to, say, a plasma cutter or a waterjet. Off the top of my head, if you're looking to build a business around metal cutting, seems like the money you'd need to get a fiber laser might make non-laser alternatives attractive.

@Jonathan Schwartz - if I can take it back even further: How do you decide if you even need to buy a laser? As opposed to, say, a plasma cutter or a waterjet. Off the top of my head, if you're looking to build a business around metal cutting, seems like the money you'd need to get a fiber laser might make non-laser alternatives attractive.![]() 100-120watts? thats pretty powerful. using 40-60w was fine for most acrylic and wood i did.

100-120watts? thats pretty powerful. using 40-60w was fine for most acrylic and wood i did.![]()

![]() if i was going todo thick stuff i would definitely look at plasma or waterjet. especially for metal

if i was going todo thick stuff i would definitely look at plasma or waterjet. especially for metal![]() the finish on the fiber is nicer than a plasma, lots of mess with a plasma too

the finish on the fiber is nicer than a plasma, lots of mess with a plasma too![]() plasma is cheaper though, and needs less consumables so there is that

plasma is cheaper though, and needs less consumables so there is that![]() Higher power lasers DEFINITELY need the protective case. The protective glass is also very important. If you cut anything even slightly reflective, the laser light can bounce out of the enclosure and possibly damage eyes.

Higher power lasers DEFINITELY need the protective case. The protective glass is also very important. If you cut anything even slightly reflective, the laser light can bounce out of the enclosure and possibly damage eyes.![]() Wood enclosure? yikes. I've had enough issues with wood target catching fire. a wood enclosure is asking for a spectacular fire.

Wood enclosure? yikes. I've had enough issues with wood target catching fire. a wood enclosure is asking for a spectacular fire.![]() I'm thinking of the use case where you're trying to build a business around cutting. I know a guy who worked for a metal supplier and he says the number of people that come in asking for a quick part to be cut out of sheet steel could build a tidy little business

I'm thinking of the use case where you're trying to build a business around cutting. I know a guy who worked for a metal supplier and he says the number of people that come in asking for a quick part to be cut out of sheet steel could build a tidy little business![]() theyre getting cheap enough now you can have a metal cutting fibre at home, i have one in the garage

theyre getting cheap enough now you can have a metal cutting fibre at home, i have one in the garage![]() Hmmm...

Hmmm...![]() its only 1kW so cuts like upto 10mm carbon steel, maybe 5mm alu or so

its only 1kW so cuts like upto 10mm carbon steel, maybe 5mm alu or so![]() fume extraction - very important, but be aware the air flow over wood cuts can fan embers to keep them glowing - and eatting the material!

fume extraction - very important, but be aware the air flow over wood cuts can fan embers to keep them glowing - and eatting the material!![]() you just need more stuff than you do with a co2 or a low wattage fibre , like a galvo 60w type which just mostly engraves

you just need more stuff than you do with a co2 or a low wattage fibre , like a galvo 60w type which just mostly engraves![]() could a nitrogen generator be used for the gas instead of air? or oxygen for steel cutting?

could a nitrogen generator be used for the gas instead of air? or oxygen for steel cutting?![]() and ALWAYS stay near the laser when running, and dont get too distracted. it only takes a few moments for a fire to get started and really mess up your machine

and ALWAYS stay near the laser when running, and dont get too distracted. it only takes a few moments for a fire to get started and really mess up your machine![]() thought. fire detector via opencv. the visual signature of a well-going cut will be much different than a thing burning uncontrolled. can either run the alarm or co2-blanket the workspace.

thought. fire detector via opencv. the visual signature of a well-going cut will be much different than a thing burning uncontrolled. can either run the alarm or co2-blanket the workspace.![]() Wait how cheap were you able to get a 1kw laser for

Wait how cheap were you able to get a 1kw laser for![]() And the 10mm steel needs gas assist I assume

And the 10mm steel needs gas assist I assume![]() would wood enclosure with fire-resistant (intumescent for example?) paint/coating mitigate the fire risk?

would wood enclosure with fire-resistant (intumescent for example?) paint/coating mitigate the fire risk?![]() pretty much all fibre cutting needs gas assist, either 02 or nitrogen

pretty much all fibre cutting needs gas assist, either 02 or nitrogen![]() you can pick up a metal cutting fibre for about 18K USD

you can pick up a metal cutting fibre for about 18K USD![]() wood is not necessarily uniform. Some species are uniform (baltic birch) but others are horribly non-uniform (eg Koa). It depends on the density and type of grain. More colorful, variable grain is also likely more variable in density.

wood is not necessarily uniform. Some species are uniform (baltic birch) but others are horribly non-uniform (eg Koa). It depends on the density and type of grain. More colorful, variable grain is also likely more variable in density.![]() Things are getting cheap in the fiber market then, I guess

Things are getting cheap in the fiber market then, I guess![]() and it uses a lot of n2, so you'll be getting 300 tanks all day long, i just bought a rotary screw compressor with a dryer , which hopefully means i can replace the n2

and it uses a lot of n2, so you'll be getting 300 tanks all day long, i just bought a rotary screw compressor with a dryer , which hopefully means i can replace the n2![]() yeah i bought ours a few years ago, they're pretty cheap

yeah i bought ours a few years ago, they're pretty cheap![]() for >1kW you'll likely need three phase

for >1kW you'll likely need three phase![]() Even fire retardant wood seems like a bad idea with such a strong laser

Even fire retardant wood seems like a bad idea with such a strong laser![]() That could be a problem in a residential setting. Rotary converter, maybe

That could be a problem in a residential setting. Rotary converter, maybe![]() that's interesting re. needing 3 phase, what's the input power for a 1kW machine?

that's interesting re. needing 3 phase, what's the input power for a 1kW machine?![]() @charliex thats pretty expensive for a hobby/makerspace but if you are gonna make a biz, then 18+k isnt too bad an investment. Of course all the additional costs drive that up - power, fumes, consumables (gas)

@charliex thats pretty expensive for a hobby/makerspace but if you are gonna make a biz, then 18+k isnt too bad an investment. Of course all the additional costs drive that up - power, fumes, consumables (gas)![]() it's cheap for a machine that can cut metal cleanly

it's cheap for a machine that can cut metal cleanly![]() thought. an electric car battery to provide the high power for the machine for the time when it runs, as long as it averages to below what the mains can give over the day.

thought. an electric car battery to provide the high power for the machine for the time when it runs, as long as it averages to below what the mains can give over the day.![]() compared to a waterjet for instance, plus all the stuff you'd need for support for a waterjet, which you're very unlikely to get at home cept for something very very basic like a wazer

compared to a waterjet for instance, plus all the stuff you'd need for support for a waterjet, which you're very unlikely to get at home cept for something very very basic like a wazer![]() ^Water jet sand is stupid expensive

^Water jet sand is stupid expensive![]() the 1kW i run off a 50A 220VAC,

the 1kW i run off a 50A 220VAC,![]() i have a rotary converter for 3phase, they're cheap and easy enough nowadays

i have a rotary converter for 3phase, they're cheap and easy enough nowadays![]() a suitable compressor is gonna be at least 15HP if you aren't using cylinders for the n2, i really hope it solves it, but waiting for it to arrive

a suitable compressor is gonna be at least 15HP if you aren't using cylinders for the n2, i really hope it solves it, but waiting for it to arrive![]() ...after world war 3 there will be enough discarded milspec antidrone antimissile highpower cw lasers...

...after world war 3 there will be enough discarded milspec antidrone antimissile highpower cw lasers...![]() Another reminder for latecomers - make sure you're in the live stream too:

Another reminder for latecomers - make sure you're in the live stream too: ![]() ahh is that why its quiet in here:)

ahh is that why its quiet in here:)![]() It pays to be paranoid, I guess

It pays to be paranoid, I guess![]() Hi, while browsing hackaday I came across this chat and I have a few laser related questions in my current project. I'm trying to build a homodyne laser interferometer using a cheap laser diode. I did read a bit about the topic on Sam's Laser FAQ, but since he uses HeNe lasers, I'm a bit lost to what I exactly need to look in a laser diode to replace it. For its usage, I would use it for machine calibration (I know it's just a bit overkill for the intended purpose) and maybe CMM in the future when I learn a bit more. I would like it to be able to measure distances up to 1 meter, maybe 2, but precision wise, if its remotely better than a micron I would be more than happy with it. Thank you in advance for your help.

Hi, while browsing hackaday I came across this chat and I have a few laser related questions in my current project. I'm trying to build a homodyne laser interferometer using a cheap laser diode. I did read a bit about the topic on Sam's Laser FAQ, but since he uses HeNe lasers, I'm a bit lost to what I exactly need to look in a laser diode to replace it. For its usage, I would use it for machine calibration (I know it's just a bit overkill for the intended purpose) and maybe CMM in the future when I learn a bit more. I would like it to be able to measure distances up to 1 meter, maybe 2, but precision wise, if its remotely better than a micron I would be more than happy with it. Thank you in advance for your help.![]() laser diodes are pretty lousy, beam quality wise. maybe sufficient. green 532nm frequency-doubled Nd:YAG could be better for similarly low price.

laser diodes are pretty lousy, beam quality wise. maybe sufficient. green 532nm frequency-doubled Nd:YAG could be better for similarly low price.![]() @Tin Lerinc - Jonathan may have some insights on this, but we're concentrating on laser cutters and engravers. But I bet I know someone who can help you -- Les Wright. He's into all sorts of laser projects like that.

@Tin Lerinc - Jonathan may have some insights on this, but we're concentrating on laser cutters and engravers. But I bet I know someone who can help you -- Les Wright. He's into all sorts of laser projects like that.![]() If you like, I can give him you info and maybe he can reach out to you

If you like, I can give him you info and maybe he can reach out to you![]() @Jonathan Schwartz - sounds like filling tanks for welding. It's gotten really expensive

@Jonathan Schwartz - sounds like filling tanks for welding. It's gotten really expensive![]() I've bought an optical table with an interferometer setup on, but only tried a red laser diode so far with it, and haven't been able to see the interference patterns yet, not sure why though :(

I've bought an optical table with an interferometer setup on, but only tried a red laser diode so far with it, and haven't been able to see the interference patterns yet, not sure why though :(![]() (mine is a Michelson interferometer)

(mine is a Michelson interferometer)![]() i can run thru a 300 sized n2 tank in about 15 minutes

i can run thru a 300 sized n2 tank in about 15 minutes![]() which i think its about 60-80$ refill

which i think its about 60-80$ refill![]() and also a trip to physical therapy after moving a few of those tanks, o2 lasts for ever since you hardly use any at these levels. and oddly enough a lot of gas companies don't want to do residential deliveries :)

and also a trip to physical therapy after moving a few of those tanks, o2 lasts for ever since you hardly use any at these levels. and oddly enough a lot of gas companies don't want to do residential deliveries :)![]() @Dan Maloney If you can, sure, I would like to learn more if possible.

@Dan Maloney If you can, sure, I would like to learn more if possible.![]() random thought, for the stink, could the volatiles be degraded by eg. a low temperature plasma?

random thought, for the stink, could the volatiles be degraded by eg. a low temperature plasma?![]() what about laser welding, or even laser brazing/soldering?

what about laser welding, or even laser brazing/soldering?![]() @Jonathan Schwartz Thank you anyways for your answer.

@Jonathan Schwartz Thank you anyways for your answer.![]() a K40-III "Blue Horror" class machine is a nice thing to have. replace the electronics to run with g-code. The discharge tubes take some current to light up, and the low-power end is unreliable and won't go all the way to zero. this can be worked around by switching the beam, going pixel by pixel and delivering a measured number of microseconds at reliably-enough power.

a K40-III "Blue Horror" class machine is a nice thing to have. replace the electronics to run with g-code. The discharge tubes take some current to light up, and the low-power end is unreliable and won't go all the way to zero. this can be worked around by switching the beam, going pixel by pixel and delivering a measured number of microseconds at reliably-enough power.![]() what problems? do tell! my one runs ancient patched Marlin, with lots of my tweaks.

what problems? do tell! my one runs ancient patched Marlin, with lots of my tweaks.![]() (Technically raspi is a computer too.) I run it as an ATmega2560 board with Marlin, slaved to raspberry pi running octoprint.

(Technically raspi is a computer too.) I run it as an ATmega2560 board with Marlin, slaved to raspberry pi running octoprint.![]()

https://www.youtube.com/shorts/EQerPa7Ee9s

laser time, fibre 3/16th steel

![]() I am thinking of buying my first laser cutter. On the exhaust system: Do I need to exhaust directly outside or can I feed that exhaust into my building's HVAC return?

I am thinking of buying my first laser cutter. On the exhaust system: Do I need to exhaust directly outside or can I feed that exhaust into my building's HVAC return?![]() Cough cough cough!!!!

Cough cough cough!!!!![]() sparks a flyin'

sparks a flyin'![]() You've got to consider make-up air too. If you're sucking the volume of the shop out every, say, five minutes, you've got to provide at least that much air from outside

You've got to consider make-up air too. If you're sucking the volume of the shop out every, say, five minutes, you've got to provide at least that much air from outside![]() Also, I had issues with some rubber sheet. When cutting gaskets it generated weird campfire-like sparks long lived enough to survive the travel all the way out through the blue hose out of the window. Replaced t

Also, I had issues with some rubber sheet. When cutting gaskets it generated weird campfire-like sparks long lived enough to survive the travel all the way out through the blue hose out of the window. Replaced t

Lutetium

Lutetium