![]() OK, let's get things going. I'm Dan, I'll be moderating today along with Dusan as we welcome Ahron Wayne to the Hack Chat. Ahron has done some cool work with X-rays and CT to visualize ink on carbonized papyrus scrolls for the Vesuvius Challenge:

OK, let's get things going. I'm Dan, I'll be moderating today along with Dusan as we welcome Ahron Wayne to the Hack Chat. Ahron has done some cool work with X-rays and CT to visualize ink on carbonized papyrus scrolls for the Vesuvius Challenge:

|

![]() https://hackaday.com/2023/11/02/2000-year-old-charred-manuscripts-reveal-their-secrets/

https://hackaday.com/2023/11/02/2000-year-old-charred-manuscripts-reveal-their-secrets/

|

![]() Hello and welcome everyone!

Hello and welcome everyone!

|

![]() Welcome to the Hack Chat Ahron. Can you kick things off with a little about your background and how you got into the challenge?

Welcome to the Hack Chat Ahron. Can you kick things off with a little about your background and how you got into the challenge?

|

![]() @anfractuosity I'm a bit of a broken record in The Challenge talking about the wavelength you've mentioned --- Thz are PERFECT for ink-paper discrimination and that kind of thing because they can make it through the material while being influenced by the chemistry of organics (i.e contrast between paper and ink). The only annoying thing is it's really hard to make and detect the frequency (thz gap)

@anfractuosity I'm a bit of a broken record in The Challenge talking about the wavelength you've mentioned --- Thz are PERFECT for ink-paper discrimination and that kind of thing because they can make it through the material while being influenced by the chemistry of organics (i.e contrast between paper and ink). The only annoying thing is it's really hard to make and detect the frequency (thz gap)

|

![]() Hi Dan! Thanks for inviting me

Hi Dan! Thanks for inviting me

|

![]() ahh, thanks a lot

ahh, thanks a lot

|

![]() So my background is a bit varied. I'm mostly biologist by training but I do industrial X-Ray CT as my main job. While there I was curious about whether you could look inside a pack of pokemon cards (coming full circle to my teaser a couple days ago), and this led me to the herculaneum scrolls --- it's a very similar problem. I reached out to some of the original authors, especially Stephen Parsons and developed a good relationship. Later I saw the vesuvius challenge on the news, I mentioned it to him, and he told me to join

So my background is a bit varied. I'm mostly biologist by training but I do industrial X-Ray CT as my main job. While there I was curious about whether you could look inside a pack of pokemon cards (coming full circle to my teaser a couple days ago), and this led me to the herculaneum scrolls --- it's a very similar problem. I reached out to some of the original authors, especially Stephen Parsons and developed a good relationship. Later I saw the vesuvius challenge on the news, I mentioned it to him, and he told me to join

|

![]() Thz was a thing at least since 2016. I had been sending this paper to people involved at the time: https://www.nature.com/articles/ncomms12665

Thz was a thing at least since 2016. I had been sending this paper to people involved at the time: https://www.nature.com/articles/ncomms12665

|

![]() nothing quite came of it

nothing quite came of it

|

![]() i understand the depth discrimination hasnt gotten better

i understand the depth discrimination hasnt gotten better

|

![]() @hannes.hoffmann I think it's more of an applications thing than anything --- CT is so well researched and developed that it's relatively easy to find a machine to throw your scroll in (though the scrolls were scanned at the Diamond light source). Everything THZ is basically custom.

@hannes.hoffmann I think it's more of an applications thing than anything --- CT is so well researched and developed that it's relatively easy to find a machine to throw your scroll in (though the scrolls were scanned at the Diamond light source). Everything THZ is basically custom.

|

![]() What accelerating voltage did you use? And what sort of detector?

What accelerating voltage did you use? And what sort of detector?

|

![]() There is a similar problem with imaging motion picture film rolls which are too badly deteriorated to unroll. I imagine a higher resolution than for imaging scrolls would be required. The silver in B&W film would be more opaque than the film base but discrimination of the dyes in color film would be difficult I am assuming.

There is a similar problem with imaging motion picture film rolls which are too badly deteriorated to unroll. I imagine a higher resolution than for imaging scrolls would be required. The silver in B&W film would be more opaque than the film base but discrimination of the dyes in color film would be difficult I am assuming.

|

![]() isn't colour film, done with layers per colour, or am i imagining that

isn't colour film, done with layers per colour, or am i imagining that

|

![]() That's how colour film is done.

That's how colour film is done.

|

![]() So the Vesuvius challenge has its own dataset --- the real scrolls, from the volcanoes, were scanned at the Diamond light source, a synchotron. Basically a super advanced lightbulb for x-rays. You can get a monochromatic (single wavelength) that way --- I believe the first scroll was scanned at 58 khz, with a cool detector as well.

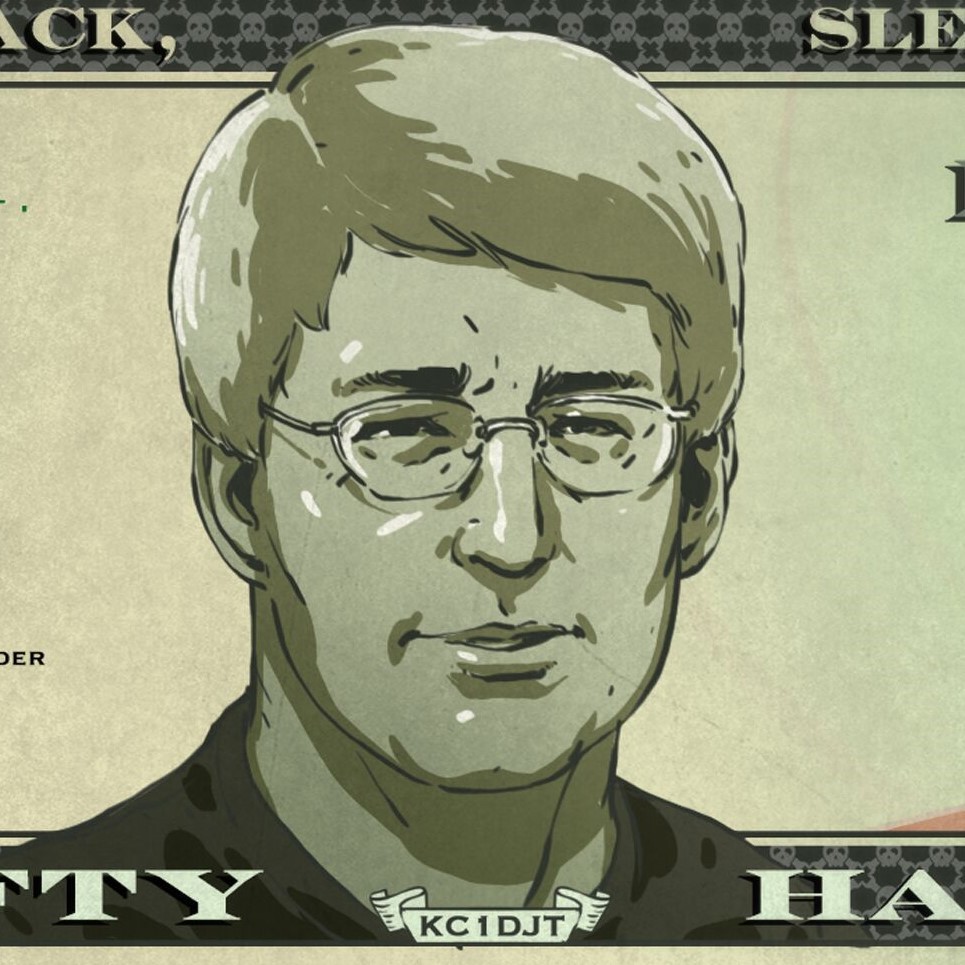

In my lab experiments, next to me I have a GE Explore Locus SP with a Kevex PXS-925 x-ray source (very old and mostly broken) that I mostly run at 60kv. The detector is also pretty weird because back then they had to couple the scintillator to the detector with a bundle of optical fibers.

So the Vesuvius challenge has its own dataset --- the real scrolls, from the volcanoes, were scanned at the Diamond light source, a synchotron. Basically a super advanced lightbulb for x-rays. You can get a monochromatic (single wavelength) that way --- I believe the first scroll was scanned at 58 khz, with a cool detector as well.

In my lab experiments, next to me I have a GE Explore Locus SP with a Kevex PXS-925 x-ray source (very old and mostly broken) that I mostly run at 60kv. The detector is also pretty weird because back then they had to couple the scintillator to the detector with a bundle of optical fibers.

|

![]() A minimum of four layers but I know of films with up to seven.

A minimum of four layers but I know of films with up to seven.

|

![]()

![]()

|

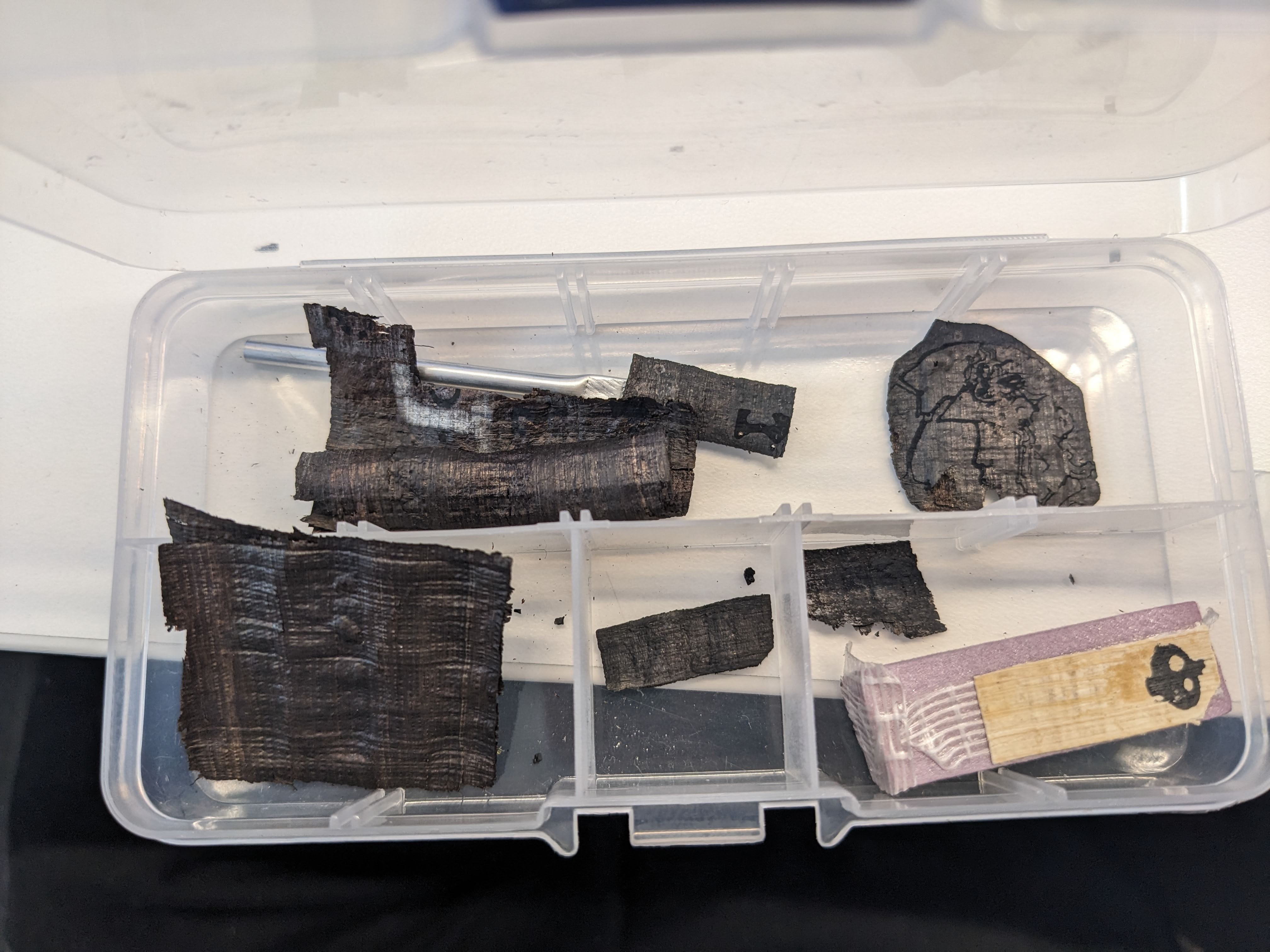

![]() The machine I have next to me --- from ebay

The machine I have next to me --- from ebay

|

![]() Is 60kV fixed, or can you lower that? The fibers protect the sensor i think?

Is 60kV fixed, or can you lower that? The fibers protect the sensor i think?

|

![]() (with the lead cover on of course :) )

(with the lead cover on of course :) )

|

![]() This tube can run from 40 to 90 kv. I mostly do it at the lower end to protect against wear/arcing, a common failure mode.

The optical fibers connect the scintillator (produces visible light from x-rays) to the sensor, which actually detects the light. In more modern systems there is a direct connection without said fibers

This tube can run from 40 to 90 kv. I mostly do it at the lower end to protect against wear/arcing, a common failure mode.

The optical fibers connect the scintillator (produces visible light from x-rays) to the sensor, which actually detects the light. In more modern systems there is a direct connection without said fibers

|

![]() Re the film, I think only three of the layers are silver-containing.

Re the film, I think only three of the layers are silver-containing.

|

![]() And the silver gets dissolved after developing.

And the silver gets dissolved after developing.

|

![]() So only the dye remains.

So only the dye remains.

|

![]() Does the tube arc inside, or across the outer surface?

Does the tube arc inside, or across the outer surface?

|

![]() Does that have a single channel detector? I'm guessing that having multiple fingers might mean multiple channels?

Does that have a single channel detector? I'm guessing that having multiple fingers might mean multiple channels?

|

![]() Fibers

Fibers

|

![]() @Thomas Shaddack I imagine this would be an easier problem (famous last words) because the silver would be relatively opaque the x-rays. With the scrolls, ink and papyrus are basically the same --- the AI models need to use 3d morphology to discriminate the two

@Thomas Shaddack I imagine this would be an easier problem (famous last words) because the silver would be relatively opaque the x-rays. With the scrolls, ink and papyrus are basically the same --- the AI models need to use 3d morphology to discriminate the two

|

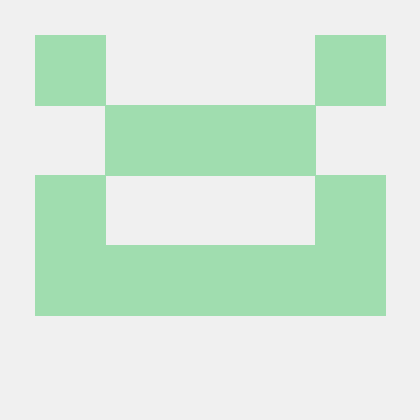

![]() Here, let me give an image of the optical fibers on my detector (again, only for old systems)

Here, let me give an image of the optical fibers on my detector (again, only for old systems)

|

![]() Does it use a CMOS/CCD sensor then i guess behind the scintillator, what res is that?

Does it use a CMOS/CCD sensor then i guess behind the scintillator, what res is that?

|

![]() Is the 40 to 90 kv range continous? can you choose any level in between?

Is the 40 to 90 kv range continous? can you choose any level in between?

|

![]()

![]()

|

![]() From the log: https://hackaday.io/project/191395-x-ray-ct-scanners-get-new-life/log/223337-image-offsets-ancient-scrolls-broken-shutters

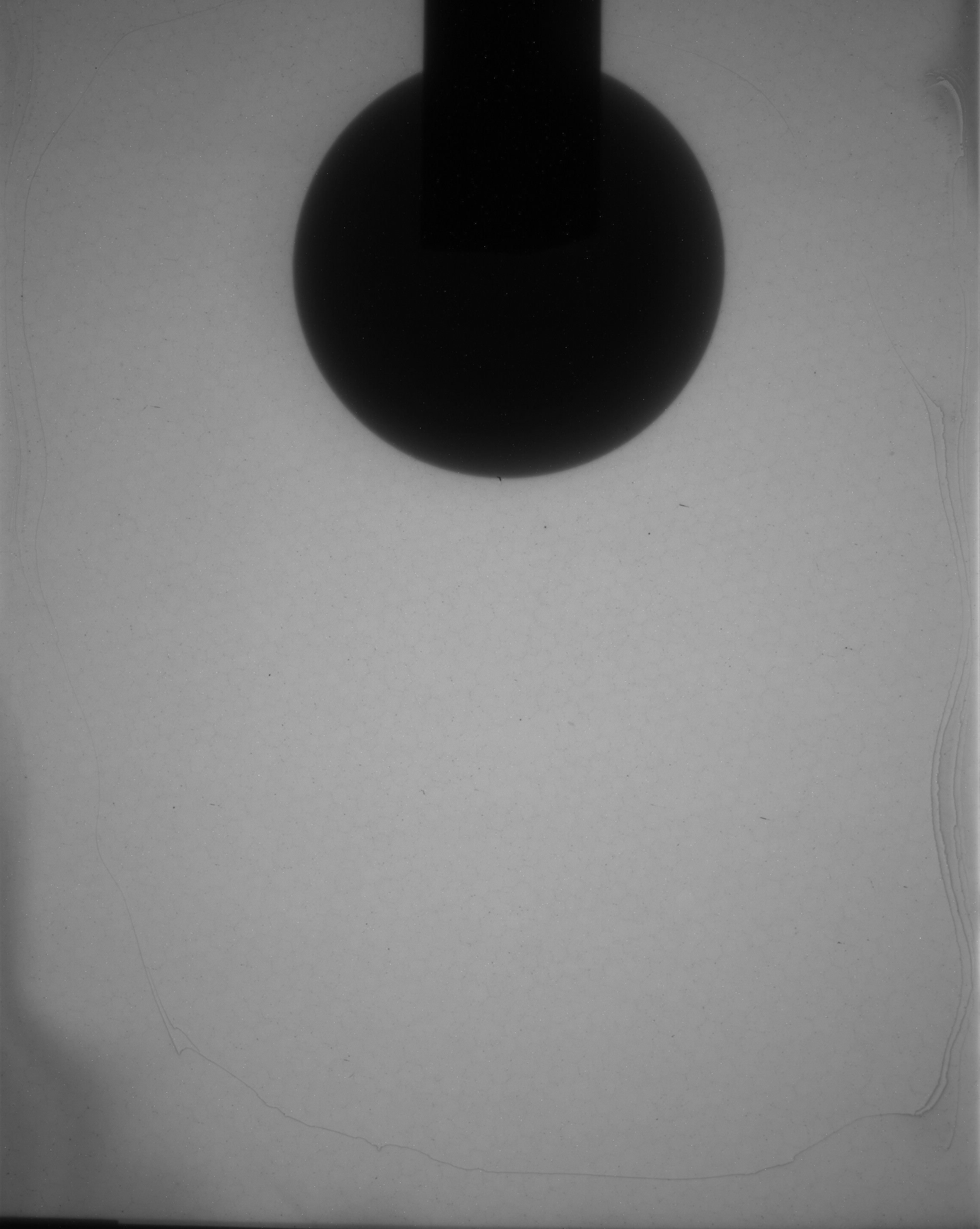

A raw image of my old scintillator

The optical fibers are the hexagonal shaped segments

From the log: https://hackaday.io/project/191395-x-ray-ct-scanners-get-new-life/log/223337-image-offsets-ancient-scrolls-broken-shutters

A raw image of my old scintillator

The optical fibers are the hexagonal shaped segments

|

![]() Yes, exactly, there is a CCD beyond the scintillator. In this system the pitch is 23 microns and about 2 by 2.5 k over a field of view of about 50 mm

Yes, exactly, there is a CCD beyond the scintillator. In this system the pitch is 23 microns and about 2 by 2.5 k over a field of view of about 50 mm

|

![]() So a SMALL detector! The modern industrial ones I use at work can be multiple feet wide. This system is from 2003

So a SMALL detector! The modern industrial ones I use at work can be multiple feet wide. This system is from 2003

|

![]() I imagine it would be too much trouble to route each fiber to a unique pixel in the sensor.

I imagine it would be too much trouble to route each fiber to a unique pixel in the sensor.

|

![]() I think I saw a DIY method with a scintillator plate, 45-deg angled mirror so the sensor is outside of the beam path, and an ordinary lens-camera.

I think I saw a DIY method with a scintillator plate, 45-deg angled mirror so the sensor is outside of the beam path, and an ordinary lens-camera.

|

![]() Plate from an xray film cassette.

Plate from an xray film cassette.

|

![]() I'm not sure if they actually go to that much trouble to connect each pixel to a fiber, but it was crazy what they had to do back then. Incidentally, that image pretty much goes entirely away when you do a flat-field correction.

I'm not sure if they actually go to that much trouble to connect each pixel to a fiber, but it was crazy what they had to do back then. Incidentally, that image pretty much goes entirely away when you do a flat-field correction.

|

![]()

![]()

|

![]() i love the optical properties of a fiber optic taper, often used in night vision goggles too. in 2001 I was using one to couple bioluminescent light from a biochip to a ccd. greetings from Scotland!

i love the optical properties of a fiber optic taper, often used in night vision goggles too. in 2001 I was using one to couple bioluminescent light from a biochip to a ccd. greetings from Scotland!

|

![]()

![]()

|

![]() @Patrick Hickey, cool! That's exactly what one of the original designers called it, an optical taper. They must have been all the rage!

@Patrick Hickey, cool! That's exactly what one of the original designers called it, an optical taper. They must have been all the rage!

|

![]() Hi @Patrick. Those tapers are the same thing dentists and surgeons have on their magnifying glasses, right?

Hi @Patrick. Those tapers are the same thing dentists and surgeons have on their magnifying glasses, right?

|

![]()

![]()

|

![]() I'm wondering about other possible ways for a home CAT scanner. Does it seem reasonable to take a non-scanning X-ray machine and add a mechanism to take images from many angles and then process them?

I'm wondering about other possible ways for a home CAT scanner. Does it seem reasonable to take a non-scanning X-ray machine and add a mechanism to take images from many angles and then process them?

|

![]() https://www.rp-photonics.com/fiber_optic_tapers.html

I think the purpose was because they couldn't make large enough CMOS/CCD chips easily, and it was a way to increase the field of view and have a larger detector.

https://www.rp-photonics.com/fiber_optic_tapers.html

I think the purpose was because they couldn't make large enough CMOS/CCD chips easily, and it was a way to increase the field of view and have a larger detector.

|

![]() Array of parallel optical fibers, fused and drawn to thinner crosssection.

Array of parallel optical fibers, fused and drawn to thinner crosssection.

|

![]() I believe the usual way is to put the sample on a rotary table, and take lots of photos at different angles and then feed it into the CT algorithm.

I believe the usual way is to put the sample on a rotary table, and take lots of photos at different angles and then feed it into the CT algorithm.

|

![]() Could it be considered a sibling method to photogrammetry? 3d scanning but through volume?

Could it be considered a sibling method to photogrammetry? 3d scanning but through volume?

|

![]() Yes, this is basically how CT works. The hard part for a basic system is the source and detector. Once you have those, you can plop a part on a microwave turntable if you want and get to work

Yes, this is basically how CT works. The hard part for a basic system is the source and detector. Once you have those, you can plop a part on a microwave turntable if you want and get to work

|

![]() @CLamb i think Krasnow made one with a phosphor screen - https://benkrasnow.blogspot.com/2013/01/diy-x-ray-ct-scanner-controlled-by.html

@CLamb i think Krasnow made one with a phosphor screen - https://benkrasnow.blogspot.com/2013/01/diy-x-ray-ct-scanner-controlled-by.html

|

![]() Photogrammetry uses identifiable features as reference points. Most CT recon uses a high pass filter make edges and then schmears those edges across a rotation

Photogrammetry uses identifiable features as reference points. Most CT recon uses a high pass filter make edges and then schmears those edges across a rotation

|

![]() Yeah, he CT scanned a chicken, LOL

Yeah, he CT scanned a chicken, LOL

|

![]() Wouldn't also moving the sample in a third dimension improve the result?

Wouldn't also moving the sample in a third dimension improve the result?

|

![]() (by the way, I also did a project with 3D micro reconstruction with a visible light camera, including photogrammetry but also depth from focus https://hackaday.io/project/169362-ladybug-beefy-3d-printer-motorized-microscope)

(by the way, I also did a project with 3D micro reconstruction with a visible light camera, including photogrammetry but also depth from focus https://hackaday.io/project/169362-ladybug-beefy-3d-printer-motorized-microscope)

|

![]() What's the angular resolution like with your scanner out of interest, < 1 degree? (not sure how you normally quote such resolution?)

What's the angular resolution like with your scanner out of interest, < 1 degree? (not sure how you normally quote such resolution?)

|

![]() https://hackaday.com/2013/01/09/ben-krasnow-builds-a-ct-scanner/

https://hackaday.com/2013/01/09/ben-krasnow-builds-a-ct-scanner/

|

![]() There's a big argument about resolution, but a useful proxy is minimum voxel size. This system can go down to 6 microns, and one at work, 50 nanometers. SIgnal-to-noise is a whole different issue to tackle; my x-ray source is weak, so I mostly image at much larger voxel sizes to save time

There's a big argument about resolution, but a useful proxy is minimum voxel size. This system can go down to 6 microns, and one at work, 50 nanometers. SIgnal-to-noise is a whole different issue to tackle; my x-ray source is weak, so I mostly image at much larger voxel sizes to save time

|

![]() What are the legal issues involved in owning and using an X-ray imager? I imagine some licensing is required in every USA state.

What are the legal issues involved in owning and using an X-ray imager? I imagine some licensing is required in every USA state.

|

![]() The scrolls for the challenge were scanned at 8 and 3 microns resolution. To do this on a lab CT machine over the whole scroll would take days, weeks, or months

The scrolls for the challenge were scanned at 8 and 3 microns resolution. To do this on a lab CT machine over the whole scroll would take days, weeks, or months

|

![]() It is indeed a state by state issue.

It is indeed a state by state issue.

|

![]() Everything is legal if you don't get caught.

Everything is legal if you don't get caught.

|

![]() @Thomas Shaddack X ray systems can arc internally or externally. The external are usually from a supply connector to the housing. Internal arc also occur and are often fatal for the tube. Systems that are off for a long time often recommend a conditioning warm up done at low kv and power to help prevent internal arcs.

@Thomas Shaddack X ray systems can arc internally or externally. The external are usually from a supply connector to the housing. Internal arc also occur and are often fatal for the tube. Systems that are off for a long time often recommend a conditioning warm up done at low kv and power to help prevent internal arcs.

|

![]() @Thomas Shaddack If I make my work public I'll get caught.

@Thomas Shaddack If I make my work public I'll get caught.

|

![]() Sounds like an ion pump, sort of. Remove the residual leaked-in/outgassed molecules/atoms by ionizing them and then trapping them into anode/getter?

Sounds like an ion pump, sort of. Remove the residual leaked-in/outgassed molecules/atoms by ionizing them and then trapping them into anode/getter?

|

![]() Thanks Wilki! yeah, the manufacturer has a routine they recommend for this tube. Since I run it at such a low kv and power, I usually just start it at 40 kv - no current for 10-20 minutes, then 50-60 kv at 10-20 microamps and call it a day. If I were imaging at a higher voltage and power you definitely have to be careful

Thanks Wilki! yeah, the manufacturer has a routine they recommend for this tube. Since I run it at such a low kv and power, I usually just start it at 40 kv - no current for 10-20 minutes, then 50-60 kv at 10-20 microamps and call it a day. If I were imaging at a higher voltage and power you definitely have to be careful

|

![]() Days, weeks, or months?! Can you narrow that down b a bit?

Days, weeks, or months?! Can you narrow that down b a bit?

|

![]() Can we use sensitive-enough current-voltage sensing to diagnose the tube vacuum?

Can we use sensitive-enough current-voltage sensing to diagnose the tube vacuum?

|

![]() The tubes are a wear item unfortunately. This one is from 2007, from ebay, was $1200... yoikes

The tubes are a wear item unfortunately. This one is from 2007, from ebay, was $1200... yoikes

|

![]() wow, for the whole machine though too?

wow, for the whole machine though too?

|

![]() @hannes. 3 microns --- 10 times longer scan than 8 microns just by itself. And then the choice of source, detector and size of scroll are all factors. I'd say... a month on a machine at work to get the whole scroll at 8 microns resolution.

@hannes. 3 microns --- 10 times longer scan than 8 microns just by itself. And then the choice of source, detector and size of scroll are all factors. I'd say... a month on a machine at work to get the whole scroll at 8 microns resolution.

|

![]() I've seen projects where ordinary consumer type tubes were used at excessive voltages to generate X-rays. I don't think that would work for this.

I've seen projects where ordinary consumer type tubes were used at excessive voltages to generate X-rays. I don't think that would work for this.

|

![]() Off overnight should get some warmup. Off for a week should get a careful warmup. My experience is mostly with a 150 kv, 80 kw system so it's probably much more severe.

Off overnight should get some warmup. Off for a week should get a careful warmup. My experience is mostly with a 150 kv, 80 kw system so it's probably much more severe.

|

![]() The machine was $1500 (technically, 2 for the price of one) local pickup only, but both had dead tubes. So I needed to find a new tube seperately. Hence why I drive it so conservatively.

The machine was $1500 (technically, 2 for the price of one) local pickup only, but both had dead tubes. So I needed to find a new tube seperately. Hence why I drive it so conservatively.

|

![]() We need diy glassworking people to step in. We could work around the trouble with filament by using a tungsten tip and heat it by induction from the outside. We could integrate a ion pump, just hook up high voltage and attach external magnet.

We need diy glassworking people to step in. We could work around the trouble with filament by using a tungsten tip and heat it by induction from the outside. We could integrate a ion pump, just hook up high voltage and attach external magnet.

|

![]() they also use synchrotron x-rays for imaging chips apparently, https://spectrum.ieee.org/chip-x-ray has some cool photos

they also use synchrotron x-rays for imaging chips apparently, https://spectrum.ieee.org/chip-x-ray has some cool photos

|

![]() At work the systems have top voltages of 130kv, 225, and 450kv. But modern systems that are meant for a lot more abuse. Back when this was made, the manufacturer basically said you should turn it on and leave it running all the time

At work the systems have top voltages of 130kv, 225, and 450kv. But modern systems that are meant for a lot more abuse. Back when this was made, the manufacturer basically said you should turn it on and leave it running all the time

|

![]() What's the advantage of higher voltages?

What's the advantage of higher voltages?

|

![]() For good imaging you want a small focal spot where the x-rays are produced. Well overdriving commercial tubes do that?

For good imaging you want a small focal spot where the x-rays are produced. Well overdriving commercial tubes do that?

|

![]() More voltage = get through thicker, denser, higher atomic number stuff

More voltage = get through thicker, denser, higher atomic number stuff

|

![]() Used tubes often have a crater burned into the anode, ruining the spot size. Could external magnet deflect the beam a little, to a fresh portion of the anode?

Used tubes often have a crater burned into the anode, ruining the spot size. Could external magnet deflect the beam a little, to a fresh portion of the anode?

|

![]() My machine was for preclinical research --- biology stuff only mostly, though you can still get some cool 2D images

My machine was for preclinical research --- biology stuff only mostly, though you can still get some cool 2D images

|

![]() So, shorter wavelength photons?

So, shorter wavelength photons?

|

![]() @Ahron Wayne, I may have missed this, but what's the working volume of your scanner?

@Ahron Wayne, I may have missed this, but what's the working volume of your scanner?

|

![]() About the size of a large walnut, or a lego guy

About the size of a large walnut, or a lego guy

|

![]()

![]()

|

![]() Or top half of a snickers bar

Or top half of a snickers bar

|

![]() Wow, a lot smaller than I thought. Fun Size Snickers for scale, lol

Wow, a lot smaller than I thought. Fun Size Snickers for scale, lol

|

![]() interesting, what was it designed for as that seems fairly small. Have you tried a pcb in it

interesting, what was it designed for as that seems fairly small. Have you tried a pcb in it

|

![]() It has a physical tungsten shutter that blocks x-rays for setting the exposure time

It has a physical tungsten shutter that blocks x-rays for setting the exposure time

|

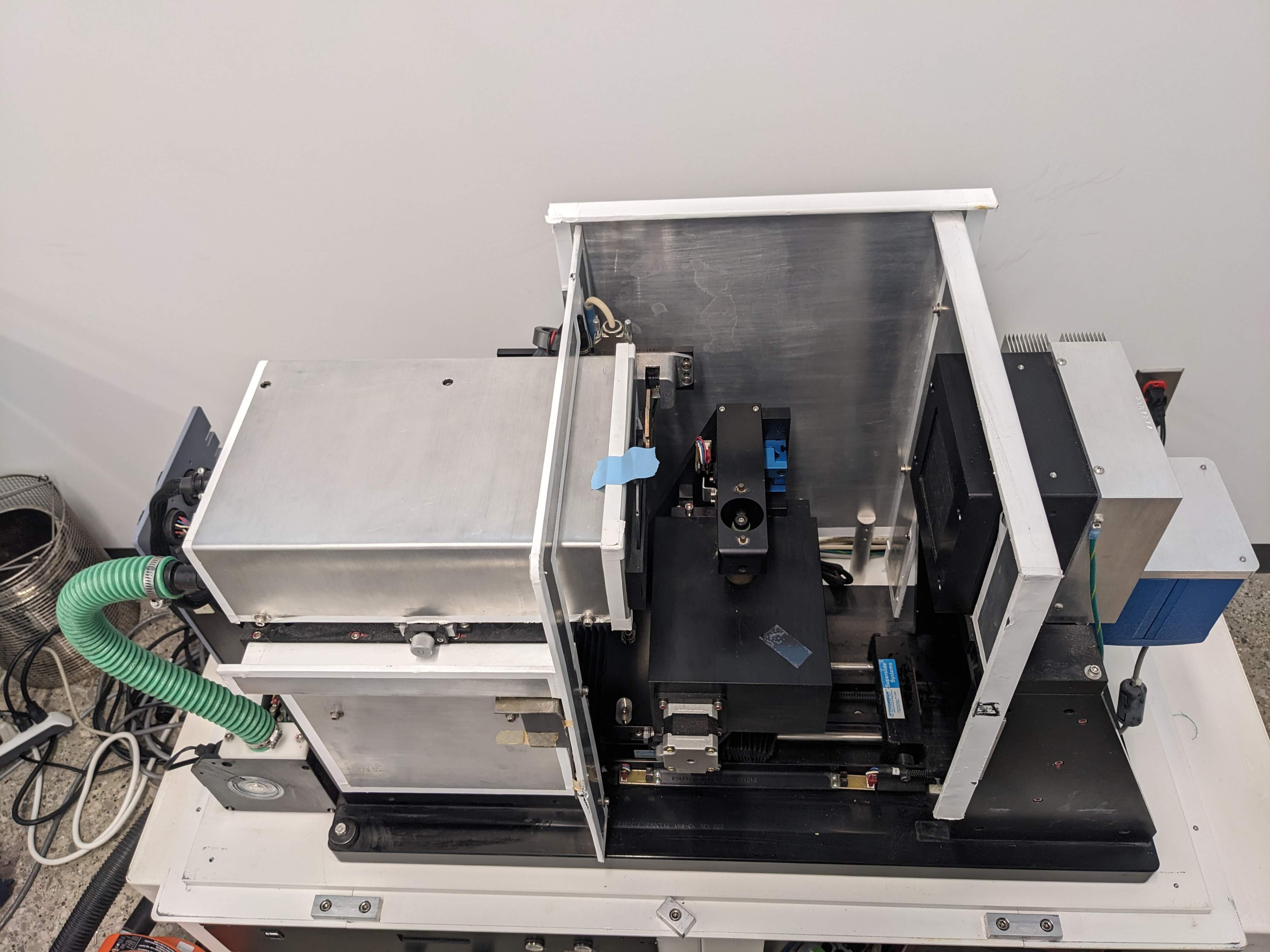

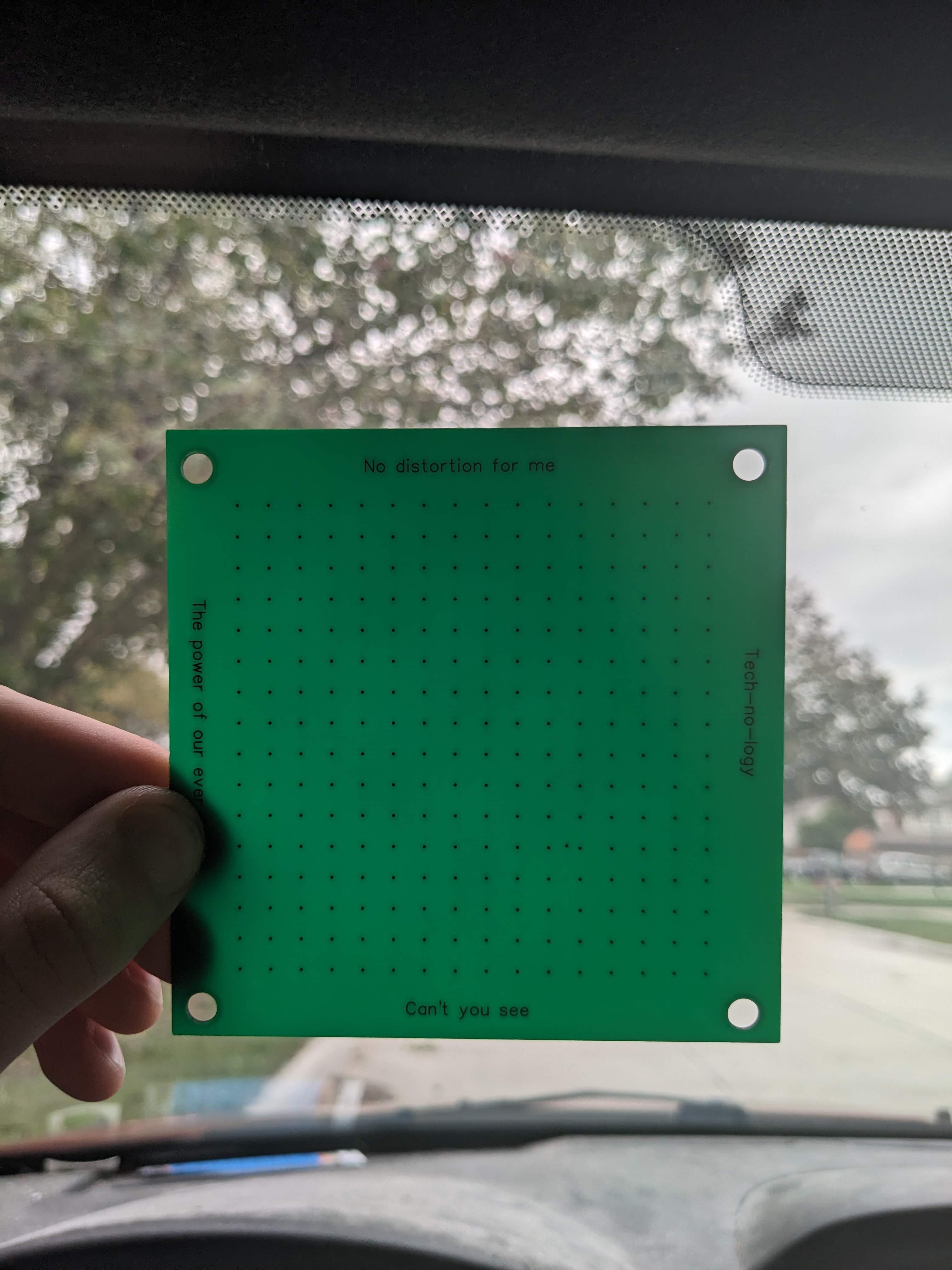

![]() I've put in some electrical stuff, yeah, but not done any CT scans. Actually my calibration grid is a PCB

I've put in some electrical stuff, yeah, but not done any CT scans. Actually my calibration grid is a PCB

|

![]() How was the experience with the scanner's software? Did you depend on it fit most processing or were you working with the low level signals?

How was the experience with the scanner's software? Did you depend on it fit most processing or were you working with the low level signals?

|

![]()

![]()

|

![]() The copper pads are used to dewarp the detector (mostly from the optical taper mentioned earlier)

The copper pads are used to dewarp the detector (mostly from the optical taper mentioned earlier)

|

![]() What is the merit of using a piece of LCD display for a calibration grid, for submillimeter uses (eg. microscopy)? The glass has a very regular pattern of etched metallization on it, when the panel gets delaminated (easy on broken one, just peel off a shard after removing the polarizer).

What is the merit of using a piece of LCD display for a calibration grid, for submillimeter uses (eg. microscopy)? The glass has a very regular pattern of etched metallization on it, when the panel gets delaminated (easy on broken one, just peel off a shard after removing the polarizer).

|

![]() have you considered finding a sponsor for this?

have you considered finding a sponsor for this?

|

![]() Oy, the software was a nightmare to setup. I went through 3 computers and multiple images, and know more about windows XP now then I would ever like to. Some utilities just never ran, like the "shutter server". Had to connect directly to the motor and bypass it.

Oy, the software was a nightmare to setup. I went through 3 computers and multiple images, and know more about windows XP now then I would ever like to. Some utilities just never ran, like the "shutter server". Had to connect directly to the motor and bypass it.

|

![]() *disk images. The company that used to service the machine was very helpful though in sending me all the old utilities. Would never have been able to get it going without them.

I do the image reconstruction on the old XP machine and then bring it to a modern system and correct it some more with Fiji/imagej. I'm right now trying to get my own reconstruction pipeline working so I can have more control over that process as well

*disk images. The company that used to service the machine was very helpful though in sending me all the old utilities. Would never have been able to get it going without them.

I do the image reconstruction on the old XP machine and then bring it to a modern system and correct it some more with Fiji/imagej. I'm right now trying to get my own reconstruction pipeline working so I can have more control over that process as well

|

![]() But yeah, I avoid working at the low-level whenever I possibly can --- like the detector uses a custom LVDS signalling method and while theoretically, I could have eventually reverse engineered it, it was a LOT easier to get the custom capture card of which there were 3 left sitting in a warehouse somewhere

But yeah, I avoid working at the low-level whenever I possibly can --- like the detector uses a custom LVDS signalling method and while theoretically, I could have eventually reverse engineered it, it was a LOT easier to get the custom capture card of which there were 3 left sitting in a warehouse somewhere

|

![]() In a way the project was sponsored by the Vesuvius Challenge Thanks!! I won one of the open-source contribution prizes that just about exactly paid for the machine, new source, and all the cables.

In a way the project was sponsored by the Vesuvius Challenge Thanks!! I won one of the open-source contribution prizes that just about exactly paid for the machine, new source, and all the cables.

|

![]() cool :) Is there such a thing as a solid state x-ray emitter, similar to how magnetrons can be replaced by solid state? (Not found anything from a quick google)

cool :) Is there such a thing as a solid state x-ray emitter, similar to how magnetrons can be replaced by solid state? (Not found anything from a quick google)

|

![]() Anyone have any interesting ideas for what to scan? (Small, low density)

Anyone have any interesting ideas for what to scan? (Small, low density)

|

![]() >> Anyone have any interesting ideas for what to scan? (Small, low density)

Unopened Scratchers

>> Anyone have any interesting ideas for what to scan? (Small, low density)

Unopened Scratchers

|

![]() Solid state x-ray emission is a desired holy grail. Not my expertise but if you look at how we're just now getting to UV LEDs, there is a long way to go.

Solid state x-ray emission is a desired holy grail. Not my expertise but if you look at how we're just now getting to UV LEDs, there is a long way to go.

|

![]() You and everyone else Valentine...

You and everyone else Valentine...

|

![]() haha

haha

|

![]() a coin might be kind of cool, to see the 3d resolution

a coin might be kind of cool, to see the 3d resolution

|

![]() also a lock

also a lock

|

![]() Insects!

Insects!

|

![]() Ooh, I should at least do a 2D of a lock

Ooh, I should at least do a 2D of a lock

|

![]() Packaged chips or transistors. See some kinds of damage (burned bond wires, namely, or voiding of the chip-to-frame solder.)

Packaged chips or transistors. See some kinds of damage (burned bond wires, namely, or voiding of the chip-to-frame solder.)

|

![]() And I ABSOLUTELY need to scan more insects, I honestly don't know why I haven't yet

And I ABSOLUTELY need to scan more insects, I honestly don't know why I haven't yet

|

![]() What a buzz!

What a buzz!

|

![]() Try the snickers bar and see if you can resolve the wrapper. I always find it interesting when a medical scan resolves clothing while I'm segmenting it.

Try the snickers bar and see if you can resolve the wrapper. I always find it interesting when a medical scan resolves clothing while I'm segmenting it.

|

![]() Too much industrial stuff makes me feel like I'm working at home, though

Too much industrial stuff makes me feel like I'm working at home, though

|

![]() Two broods of cicadas will be emerging in New Jersey this Spring. Should I catch a few for you?

Two broods of cicadas will be emerging in New Jersey this Spring. Should I catch a few for you?

|

![]() tooth.

tooth.

|

![]() Can absolutely resolve the wrapper

Can absolutely resolve the wrapper

|

![]() Sure, send me a cicada...

Sure, send me a cicada...

|

![]() Coincidentally, I'm working on an article about using film to replace the dead CMOS sensor in an X-ray cabinet designed for scanning chips and such.

Coincidentally, I'm working on an article about using film to replace the dead CMOS sensor in an X-ray cabinet designed for scanning chips and such.

|

![]()

![]()

|

![]() Way ahead of you! (prof. son's baby tooth)

Way ahead of you! (prof. son's baby tooth)

|

![]() Dan Maloney 3:00 PMOK, let's get things going. I'm Dan, I'll be moderating today along with Dusan as we welcome Ahron Wayne to the Hack Chat. Ahron has done some cool work with X-rays and CT to visualize ink on carbonized papyrus scrolls for the Vesuvius Challenge:

Dan Maloney 3:00 PMOK, let's get things going. I'm Dan, I'll be moderating today along with Dusan as we welcome Ahron Wayne to the Hack Chat. Ahron has done some cool work with X-rays and CT to visualize ink on carbonized papyrus scrolls for the Vesuvius Challenge:![]() Dan Maloney 3:00 PMhttps://hackaday.com/2023/11/02/2000-year-old-charred-manuscripts-reveal-their-secrets/

Dan Maloney 3:00 PMhttps://hackaday.com/2023/11/02/2000-year-old-charred-manuscripts-reveal-their-secrets/![]() Dusan Petrovic 3:00 PMHello and welcome everyone!

Dusan Petrovic 3:00 PMHello and welcome everyone!![]() Dan Maloney 3:01 PMWelcome to the Hack Chat Ahron. Can you kick things off with a little about your background and how you got into the challenge?

Dan Maloney 3:01 PMWelcome to the Hack Chat Ahron. Can you kick things off with a little about your background and how you got into the challenge?![]() Ahron Wayne 3:01 PM@anfractuosity I'm a bit of a broken record in The Challenge talking about the wavelength you've mentioned --- Thz are PERFECT for ink-paper discrimination and that kind of thing because they can make it through the material while being influenced by the chemistry of organics (i.e contrast between paper and ink). The only annoying thing is it's really hard to make and detect the frequency (thz gap)

Ahron Wayne 3:01 PM@anfractuosity I'm a bit of a broken record in The Challenge talking about the wavelength you've mentioned --- Thz are PERFECT for ink-paper discrimination and that kind of thing because they can make it through the material while being influenced by the chemistry of organics (i.e contrast between paper and ink). The only annoying thing is it's really hard to make and detect the frequency (thz gap)![]() Ahron Wayne 3:01 PMHi Dan! Thanks for inviting me

Ahron Wayne 3:01 PMHi Dan! Thanks for inviting me![]() anfractuosity 3:02 PMahh, thanks a lot

anfractuosity 3:02 PMahh, thanks a lot![]() Ahron Wayne 3:03 PMSo my background is a bit varied. I'm mostly biologist by training but I do industrial X-Ray CT as my main job. While there I was curious about whether you could look inside a pack of pokemon cards (coming full circle to my teaser a couple days ago), and this led me to the herculaneum scrolls --- it's a very similar problem. I reached out to some of the original authors, especially Stephen Parsons and developed a good relationship. Later I saw the vesuvius challenge on the news, I mentioned it to him, and he told me to join

Ahron Wayne 3:03 PMSo my background is a bit varied. I'm mostly biologist by training but I do industrial X-Ray CT as my main job. While there I was curious about whether you could look inside a pack of pokemon cards (coming full circle to my teaser a couple days ago), and this led me to the herculaneum scrolls --- it's a very similar problem. I reached out to some of the original authors, especially Stephen Parsons and developed a good relationship. Later I saw the vesuvius challenge on the news, I mentioned it to him, and he told me to join![]() hannes.hoffmann 3:04 PMThz was a thing at least since 2016. I had been sending this paper to people involved at the time: https://www.nature.com/articles/ncomms12665

hannes.hoffmann 3:04 PMThz was a thing at least since 2016. I had been sending this paper to people involved at the time: https://www.nature.com/articles/ncomms12665![]() hannes.hoffmann 3:04 PMnothing quite came of it

hannes.hoffmann 3:04 PMnothing quite came of it![]() hannes.hoffmann 3:05 PMi understand the depth discrimination hasnt gotten better

hannes.hoffmann 3:05 PMi understand the depth discrimination hasnt gotten better![]() Ahron Wayne 3:05 PM@hannes.hoffmann I think it's more of an applications thing than anything --- CT is so well researched and developed that it's relatively easy to find a machine to throw your scroll in (though the scrolls were scanned at the Diamond light source). Everything THZ is basically custom.

Ahron Wayne 3:05 PM@hannes.hoffmann I think it's more of an applications thing than anything --- CT is so well researched and developed that it's relatively easy to find a machine to throw your scroll in (though the scrolls were scanned at the Diamond light source). Everything THZ is basically custom.![]() wilkij1 3:06 PMWhat accelerating voltage did you use? And what sort of detector?

wilkij1 3:06 PMWhat accelerating voltage did you use? And what sort of detector?![]() CLamb 3:07 PMThere is a similar problem with imaging motion picture film rolls which are too badly deteriorated to unroll. I imagine a higher resolution than for imaging scrolls would be required. The silver in B&W film would be more opaque than the film base but discrimination of the dyes in color film would be difficult I am assuming.

CLamb 3:07 PMThere is a similar problem with imaging motion picture film rolls which are too badly deteriorated to unroll. I imagine a higher resolution than for imaging scrolls would be required. The silver in B&W film would be more opaque than the film base but discrimination of the dyes in color film would be difficult I am assuming.![]() anfractuosity 3:08 PMisn't colour film, done with layers per colour, or am i imagining that

anfractuosity 3:08 PMisn't colour film, done with layers per colour, or am i imagining that![]() CLamb 3:08 PMThat's how colour film is done.

CLamb 3:08 PMThat's how colour film is done.![]() Ahron Wayne 3:09 PMSo the Vesuvius challenge has its own dataset --- the real scrolls, from the volcanoes, were scanned at the Diamond light source, a synchotron. Basically a super advanced lightbulb for x-rays. You can get a monochromatic (single wavelength) that way --- I believe the first scroll was scanned at 58 khz, with a cool detector as well. In my lab experiments, next to me I have a GE Explore Locus SP with a Kevex PXS-925 x-ray source (very old and mostly broken) that I mostly run at 60kv. The detector is also pretty weird because back then they had to couple the scintillator to the detector with a bundle of optical fibers.

Ahron Wayne 3:09 PMSo the Vesuvius challenge has its own dataset --- the real scrolls, from the volcanoes, were scanned at the Diamond light source, a synchotron. Basically a super advanced lightbulb for x-rays. You can get a monochromatic (single wavelength) that way --- I believe the first scroll was scanned at 58 khz, with a cool detector as well. In my lab experiments, next to me I have a GE Explore Locus SP with a Kevex PXS-925 x-ray source (very old and mostly broken) that I mostly run at 60kv. The detector is also pretty weird because back then they had to couple the scintillator to the detector with a bundle of optical fibers.![]() CLamb 3:09 PMA minimum of four layers but I know of films with up to seven.

CLamb 3:09 PMA minimum of four layers but I know of films with up to seven.![]() Ahron Wayne 3:10 PM

Ahron Wayne 3:10 PM![]()

![]() Ahron Wayne 3:10 PMThe machine I have next to me --- from ebay

Ahron Wayne 3:10 PMThe machine I have next to me --- from ebay![]() anfractuosity 3:10 PMIs 60kV fixed, or can you lower that? The fibers protect the sensor i think?

anfractuosity 3:10 PMIs 60kV fixed, or can you lower that? The fibers protect the sensor i think?![]() Ahron Wayne 3:10 PM(with the lead cover on of course :) )

Ahron Wayne 3:10 PM(with the lead cover on of course :) )![]() Ahron Wayne 3:11 PMThis tube can run from 40 to 90 kv. I mostly do it at the lower end to protect against wear/arcing, a common failure mode. The optical fibers connect the scintillator (produces visible light from x-rays) to the sensor, which actually detects the light. In more modern systems there is a direct connection without said fibers

Ahron Wayne 3:11 PMThis tube can run from 40 to 90 kv. I mostly do it at the lower end to protect against wear/arcing, a common failure mode. The optical fibers connect the scintillator (produces visible light from x-rays) to the sensor, which actually detects the light. In more modern systems there is a direct connection without said fibers![]() Thomas Shaddack 3:12 PMRe the film, I think only three of the layers are silver-containing.

Thomas Shaddack 3:12 PMRe the film, I think only three of the layers are silver-containing.![]() Thomas Shaddack 3:12 PMAnd the silver gets dissolved after developing.

Thomas Shaddack 3:12 PMAnd the silver gets dissolved after developing.![]() Thomas Shaddack 3:12 PMSo only the dye remains.

Thomas Shaddack 3:12 PMSo only the dye remains.![]() Thomas Shaddack 3:12 PMDoes the tube arc inside, or across the outer surface?

Thomas Shaddack 3:12 PMDoes the tube arc inside, or across the outer surface?![]() wilkij1 3:12 PMDoes that have a single channel detector? I'm guessing that having multiple fingers might mean multiple channels?

wilkij1 3:12 PMDoes that have a single channel detector? I'm guessing that having multiple fingers might mean multiple channels?![]() wilkij1 3:13 PMFibers

wilkij1 3:13 PMFibers![]() Ahron Wayne 3:13 PM@Thomas Shaddack I imagine this would be an easier problem (famous last words) because the silver would be relatively opaque the x-rays. With the scrolls, ink and papyrus are basically the same --- the AI models need to use 3d morphology to discriminate the two

Ahron Wayne 3:13 PM@Thomas Shaddack I imagine this would be an easier problem (famous last words) because the silver would be relatively opaque the x-rays. With the scrolls, ink and papyrus are basically the same --- the AI models need to use 3d morphology to discriminate the two![]() Ahron Wayne 3:14 PMHere, let me give an image of the optical fibers on my detector (again, only for old systems)

Ahron Wayne 3:14 PMHere, let me give an image of the optical fibers on my detector (again, only for old systems)![]() anfractuosity 3:14 PMDoes it use a CMOS/CCD sensor then i guess behind the scintillator, what res is that?

anfractuosity 3:14 PMDoes it use a CMOS/CCD sensor then i guess behind the scintillator, what res is that?![]() hannes.hoffmann 3:14 PMIs the 40 to 90 kv range continous? can you choose any level in between?

hannes.hoffmann 3:14 PMIs the 40 to 90 kv range continous? can you choose any level in between?![]() Ahron Wayne 3:15 PM

Ahron Wayne 3:15 PM![]()

![]() Ahron Wayne 3:15 PMFrom the log: https://hackaday.io/project/191395-x-ray-ct-scanners-get-new-life/log/223337-image-offsets-ancient-scrolls-broken-shutters A raw image of my old scintillator The optical fibers are the hexagonal shaped segments

Ahron Wayne 3:15 PMFrom the log: https://hackaday.io/project/191395-x-ray-ct-scanners-get-new-life/log/223337-image-offsets-ancient-scrolls-broken-shutters A raw image of my old scintillator The optical fibers are the hexagonal shaped segments![]() Ahron Wayne 3:16 PMYes, exactly, there is a CCD beyond the scintillator. In this system the pitch is 23 microns and about 2 by 2.5 k over a field of view of about 50 mm

Ahron Wayne 3:16 PMYes, exactly, there is a CCD beyond the scintillator. In this system the pitch is 23 microns and about 2 by 2.5 k over a field of view of about 50 mm![]() Ahron Wayne 3:16 PMSo a SMALL detector! The modern industrial ones I use at work can be multiple feet wide. This system is from 2003

Ahron Wayne 3:16 PMSo a SMALL detector! The modern industrial ones I use at work can be multiple feet wide. This system is from 2003![]() CLamb 3:17 PMI imagine it would be too much trouble to route each fiber to a unique pixel in the sensor.

CLamb 3:17 PMI imagine it would be too much trouble to route each fiber to a unique pixel in the sensor.![]() Thomas Shaddack 3:17 PMI think I saw a DIY method with a scintillator plate, 45-deg angled mirror so the sensor is outside of the beam path, and an ordinary lens-camera.

Thomas Shaddack 3:17 PMI think I saw a DIY method with a scintillator plate, 45-deg angled mirror so the sensor is outside of the beam path, and an ordinary lens-camera.![]() Thomas Shaddack 3:18 PMPlate from an xray film cassette.

Thomas Shaddack 3:18 PMPlate from an xray film cassette.![]() Ahron Wayne 3:18 PMI'm not sure if they actually go to that much trouble to connect each pixel to a fiber, but it was crazy what they had to do back then. Incidentally, that image pretty much goes entirely away when you do a flat-field correction.

Ahron Wayne 3:18 PMI'm not sure if they actually go to that much trouble to connect each pixel to a fiber, but it was crazy what they had to do back then. Incidentally, that image pretty much goes entirely away when you do a flat-field correction.![]() Ahron Wayne 3:18 PM

Ahron Wayne 3:18 PM![]()

![]() Patrick Hickey 3:18 PMi love the optical properties of a fiber optic taper, often used in night vision goggles too. in 2001 I was using one to couple bioluminescent light from a biochip to a ccd. greetings from Scotland!

Patrick Hickey 3:18 PMi love the optical properties of a fiber optic taper, often used in night vision goggles too. in 2001 I was using one to couple bioluminescent light from a biochip to a ccd. greetings from Scotland!![]() Ahron Wayne 3:18 PM

Ahron Wayne 3:18 PM![]()

![]() Ahron Wayne 3:19 PM@Patrick Hickey, cool! That's exactly what one of the original designers called it, an optical taper. They must have been all the rage!

Ahron Wayne 3:19 PM@Patrick Hickey, cool! That's exactly what one of the original designers called it, an optical taper. They must have been all the rage!![]() Dan Maloney 3:20 PMHi @Patrick. Those tapers are the same thing dentists and surgeons have on their magnifying glasses, right?

Dan Maloney 3:20 PMHi @Patrick. Those tapers are the same thing dentists and surgeons have on their magnifying glasses, right?![]() Ahron Wayne 3:21 PM

Ahron Wayne 3:21 PM![]()

![]() CLamb 3:21 PMI'm wondering about other possible ways for a home CAT scanner. Does it seem reasonable to take a non-scanning X-ray machine and add a mechanism to take images from many angles and then process them?

CLamb 3:21 PMI'm wondering about other possible ways for a home CAT scanner. Does it seem reasonable to take a non-scanning X-ray machine and add a mechanism to take images from many angles and then process them?![]() Ahron Wayne 3:22 PMhttps://www.rp-photonics.com/fiber_optic_tapers.html I think the purpose was because they couldn't make large enough CMOS/CCD chips easily, and it was a way to increase the field of view and have a larger detector.

Ahron Wayne 3:22 PMhttps://www.rp-photonics.com/fiber_optic_tapers.html I think the purpose was because they couldn't make large enough CMOS/CCD chips easily, and it was a way to increase the field of view and have a larger detector.![]() Thomas Shaddack 3:22 PMArray of parallel optical fibers, fused and drawn to thinner crosssection.

Thomas Shaddack 3:22 PMArray of parallel optical fibers, fused and drawn to thinner crosssection.![]() Thomas Shaddack 3:22 PMI believe the usual way is to put the sample on a rotary table, and take lots of photos at different angles and then feed it into the CT algorithm.

Thomas Shaddack 3:22 PMI believe the usual way is to put the sample on a rotary table, and take lots of photos at different angles and then feed it into the CT algorithm.![]() Thomas Shaddack 3:23 PMCould it be considered a sibling method to photogrammetry? 3d scanning but through volume?

Thomas Shaddack 3:23 PMCould it be considered a sibling method to photogrammetry? 3d scanning but through volume?![]() Ahron Wayne 3:24 PMYes, this is basically how CT works. The hard part for a basic system is the source and detector. Once you have those, you can plop a part on a microwave turntable if you want and get to work

Ahron Wayne 3:24 PMYes, this is basically how CT works. The hard part for a basic system is the source and detector. Once you have those, you can plop a part on a microwave turntable if you want and get to work![]() anfractuosity 3:24 PM@CLamb i think Krasnow made one with a phosphor screen - https://benkrasnow.blogspot.com/2013/01/diy-x-ray-ct-scanner-controlled-by.html

anfractuosity 3:24 PM@CLamb i think Krasnow made one with a phosphor screen - https://benkrasnow.blogspot.com/2013/01/diy-x-ray-ct-scanner-controlled-by.html![]() Ahron Wayne 3:24 PMPhotogrammetry uses identifiable features as reference points. Most CT recon uses a high pass filter make edges and then schmears those edges across a rotation

Ahron Wayne 3:24 PMPhotogrammetry uses identifiable features as reference points. Most CT recon uses a high pass filter make edges and then schmears those edges across a rotation![]() Ahron Wayne 3:25 PMYeah, he CT scanned a chicken, LOL

Ahron Wayne 3:25 PMYeah, he CT scanned a chicken, LOL![]() CLamb 3:25 PMWouldn't also moving the sample in a third dimension improve the result?

CLamb 3:25 PMWouldn't also moving the sample in a third dimension improve the result?![]() Ahron Wayne 3:26 PM(by the way, I also did a project with 3D micro reconstruction with a visible light camera, including photogrammetry but also depth from focus https://hackaday.io/project/169362-ladybug-beefy-3d-printer-motorized-microscope)

Ahron Wayne 3:26 PM(by the way, I also did a project with 3D micro reconstruction with a visible light camera, including photogrammetry but also depth from focus https://hackaday.io/project/169362-ladybug-beefy-3d-printer-motorized-microscope)![]() anfractuosity 3:26 PMWhat's the angular resolution like with your scanner out of interest, < 1 degree? (not sure how you normally quote such resolution?)

anfractuosity 3:26 PMWhat's the angular resolution like with your scanner out of interest, < 1 degree? (not sure how you normally quote such resolution?)![]() Dan Maloney 3:27 PMhttps://hackaday.com/2013/01/09/ben-krasnow-builds-a-ct-scanner/

Dan Maloney 3:27 PMhttps://hackaday.com/2013/01/09/ben-krasnow-builds-a-ct-scanner/![]() Ahron Wayne 3:27 PMThere's a big argument about resolution, but a useful proxy is minimum voxel size. This system can go down to 6 microns, and one at work, 50 nanometers. SIgnal-to-noise is a whole different issue to tackle; my x-ray source is weak, so I mostly image at much larger voxel sizes to save time

Ahron Wayne 3:27 PMThere's a big argument about resolution, but a useful proxy is minimum voxel size. This system can go down to 6 microns, and one at work, 50 nanometers. SIgnal-to-noise is a whole different issue to tackle; my x-ray source is weak, so I mostly image at much larger voxel sizes to save time![]() CLamb 3:28 PMWhat are the legal issues involved in owning and using an X-ray imager? I imagine some licensing is required in every USA state.

CLamb 3:28 PMWhat are the legal issues involved in owning and using an X-ray imager? I imagine some licensing is required in every USA state.![]() Ahron Wayne 3:28 PMThe scrolls for the challenge were scanned at 8 and 3 microns resolution. To do this on a lab CT machine over the whole scroll would take days, weeks, or months

Ahron Wayne 3:28 PMThe scrolls for the challenge were scanned at 8 and 3 microns resolution. To do this on a lab CT machine over the whole scroll would take days, weeks, or months![]() Ahron Wayne 3:29 PMIt is indeed a state by state issue.

Ahron Wayne 3:29 PMIt is indeed a state by state issue.![]() Thomas Shaddack 3:29 PMEverything is legal if you don't get caught.

Thomas Shaddack 3:29 PMEverything is legal if you don't get caught.![]() wilkij1 3:29 PM@Thomas Shaddack X ray systems can arc internally or externally. The external are usually from a supply connector to the housing. Internal arc also occur and are often fatal for the tube. Systems that are off for a long time often recommend a conditioning warm up done at low kv and power to help prevent internal arcs.

wilkij1 3:29 PM@Thomas Shaddack X ray systems can arc internally or externally. The external are usually from a supply connector to the housing. Internal arc also occur and are often fatal for the tube. Systems that are off for a long time often recommend a conditioning warm up done at low kv and power to help prevent internal arcs.![]() CLamb 3:30 PM@Thomas Shaddack If I make my work public I'll get caught.

CLamb 3:30 PM@Thomas Shaddack If I make my work public I'll get caught.![]() Thomas Shaddack 3:30 PMSounds like an ion pump, sort of. Remove the residual leaked-in/outgassed molecules/atoms by ionizing them and then trapping them into anode/getter?

Thomas Shaddack 3:30 PMSounds like an ion pump, sort of. Remove the residual leaked-in/outgassed molecules/atoms by ionizing them and then trapping them into anode/getter?![]() Ahron Wayne 3:31 PMThanks Wilki! yeah, the manufacturer has a routine they recommend for this tube. Since I run it at such a low kv and power, I usually just start it at 40 kv - no current for 10-20 minutes, then 50-60 kv at 10-20 microamps and call it a day. If I were imaging at a higher voltage and power you definitely have to be careful

Ahron Wayne 3:31 PMThanks Wilki! yeah, the manufacturer has a routine they recommend for this tube. Since I run it at such a low kv and power, I usually just start it at 40 kv - no current for 10-20 minutes, then 50-60 kv at 10-20 microamps and call it a day. If I were imaging at a higher voltage and power you definitely have to be careful![]() hannes.hoffmann 3:31 PMDays, weeks, or months?! Can you narrow that down b a bit?

hannes.hoffmann 3:31 PMDays, weeks, or months?! Can you narrow that down b a bit?![]() Thomas Shaddack 3:32 PMCan we use sensitive-enough current-voltage sensing to diagnose the tube vacuum?

Thomas Shaddack 3:32 PMCan we use sensitive-enough current-voltage sensing to diagnose the tube vacuum?![]() Ahron Wayne 3:32 PMThe tubes are a wear item unfortunately. This one is from 2007, from ebay, was $1200... yoikes

Ahron Wayne 3:32 PMThe tubes are a wear item unfortunately. This one is from 2007, from ebay, was $1200... yoikes![]() anfractuosity 3:33 PMwow, for the whole machine though too?

anfractuosity 3:33 PMwow, for the whole machine though too?![]() Ahron Wayne 3:33 PM@hannes. 3 microns --- 10 times longer scan than 8 microns just by itself. And then the choice of source, detector and size of scroll are all factors. I'd say... a month on a machine at work to get the whole scroll at 8 microns resolution.

Ahron Wayne 3:33 PM@hannes. 3 microns --- 10 times longer scan than 8 microns just by itself. And then the choice of source, detector and size of scroll are all factors. I'd say... a month on a machine at work to get the whole scroll at 8 microns resolution.![]() CLamb 3:33 PMI've seen projects where ordinary consumer type tubes were used at excessive voltages to generate X-rays. I don't think that would work for this.

CLamb 3:33 PMI've seen projects where ordinary consumer type tubes were used at excessive voltages to generate X-rays. I don't think that would work for this.![]() wilkij1 3:33 PMOff overnight should get some warmup. Off for a week should get a careful warmup. My experience is mostly with a 150 kv, 80 kw system so it's probably much more severe.

wilkij1 3:33 PMOff overnight should get some warmup. Off for a week should get a careful warmup. My experience is mostly with a 150 kv, 80 kw system so it's probably much more severe.![]() Ahron Wayne 3:34 PMThe machine was $1500 (technically, 2 for the price of one) local pickup only, but both had dead tubes. So I needed to find a new tube seperately. Hence why I drive it so conservatively.

Ahron Wayne 3:34 PMThe machine was $1500 (technically, 2 for the price of one) local pickup only, but both had dead tubes. So I needed to find a new tube seperately. Hence why I drive it so conservatively.![]() Thomas Shaddack 3:34 PMWe need diy glassworking people to step in. We could work around the trouble with filament by using a tungsten tip and heat it by induction from the outside. We could integrate a ion pump, just hook up high voltage and attach external magnet.

Thomas Shaddack 3:34 PMWe need diy glassworking people to step in. We could work around the trouble with filament by using a tungsten tip and heat it by induction from the outside. We could integrate a ion pump, just hook up high voltage and attach external magnet.![]() anfractuosity 3:35 PMthey also use synchrotron x-rays for imaging chips apparently, https://spectrum.ieee.org/chip-x-ray has some cool photos

anfractuosity 3:35 PMthey also use synchrotron x-rays for imaging chips apparently, https://spectrum.ieee.org/chip-x-ray has some cool photos![]() Ahron Wayne 3:35 PMAt work the systems have top voltages of 130kv, 225, and 450kv. But modern systems that are meant for a lot more abuse. Back when this was made, the manufacturer basically said you should turn it on and leave it running all the time

Ahron Wayne 3:35 PMAt work the systems have top voltages of 130kv, 225, and 450kv. But modern systems that are meant for a lot more abuse. Back when this was made, the manufacturer basically said you should turn it on and leave it running all the time![]() CLamb 3:36 PMWhat's the advantage of higher voltages?

CLamb 3:36 PMWhat's the advantage of higher voltages?![]() wilkij1 3:36 PMFor good imaging you want a small focal spot where the x-rays are produced. Well overdriving commercial tubes do that?

wilkij1 3:36 PMFor good imaging you want a small focal spot where the x-rays are produced. Well overdriving commercial tubes do that?![]() Ahron Wayne 3:36 PMMore voltage = get through thicker, denser, higher atomic number stuff

Ahron Wayne 3:36 PMMore voltage = get through thicker, denser, higher atomic number stuff![]() Thomas Shaddack 3:37 PMUsed tubes often have a crater burned into the anode, ruining the spot size. Could external magnet deflect the beam a little, to a fresh portion of the anode?

Thomas Shaddack 3:37 PMUsed tubes often have a crater burned into the anode, ruining the spot size. Could external magnet deflect the beam a little, to a fresh portion of the anode?![]() Ahron Wayne 3:37 PMMy machine was for preclinical research --- biology stuff only mostly, though you can still get some cool 2D images

Ahron Wayne 3:37 PMMy machine was for preclinical research --- biology stuff only mostly, though you can still get some cool 2D images![]() CLamb 3:37 PMSo, shorter wavelength photons?

CLamb 3:37 PMSo, shorter wavelength photons?![]() Dan Maloney 3:37 PM@Ahron Wayne, I may have missed this, but what's the working volume of your scanner?

Dan Maloney 3:37 PM@Ahron Wayne, I may have missed this, but what's the working volume of your scanner?![]() Ahron Wayne 3:38 PMAbout the size of a large walnut, or a lego guy

Ahron Wayne 3:38 PMAbout the size of a large walnut, or a lego guy![]() Ahron Wayne 3:38 PM

Ahron Wayne 3:38 PM![]()

![]() Ahron Wayne 3:38 PMOr top half of a snickers bar

Ahron Wayne 3:38 PMOr top half of a snickers bar![]() Dan Maloney 3:38 PMWow, a lot smaller than I thought. Fun Size Snickers for scale, lol

Dan Maloney 3:38 PMWow, a lot smaller than I thought. Fun Size Snickers for scale, lol![]() anfractuosity 3:38 PMinteresting, what was it designed for as that seems fairly small. Have you tried a pcb in it

anfractuosity 3:38 PMinteresting, what was it designed for as that seems fairly small. Have you tried a pcb in it![]() Ahron Wayne 3:39 PMIt has a physical tungsten shutter that blocks x-rays for setting the exposure time

Ahron Wayne 3:39 PMIt has a physical tungsten shutter that blocks x-rays for setting the exposure time![]() Ahron Wayne 3:39 PMI've put in some electrical stuff, yeah, but not done any CT scans. Actually my calibration grid is a PCB

Ahron Wayne 3:39 PMI've put in some electrical stuff, yeah, but not done any CT scans. Actually my calibration grid is a PCB![]() wilkij1 3:40 PMHow was the experience with the scanner's software? Did you depend on it fit most processing or were you working with the low level signals?

wilkij1 3:40 PMHow was the experience with the scanner's software? Did you depend on it fit most processing or were you working with the low level signals?![]() Ahron Wayne 3:40 PM

Ahron Wayne 3:40 PM![]()

![]() Ahron Wayne 3:40 PMThe copper pads are used to dewarp the detector (mostly from the optical taper mentioned earlier)

Ahron Wayne 3:40 PMThe copper pads are used to dewarp the detector (mostly from the optical taper mentioned earlier)![]() Thomas Shaddack 3:41 PMWhat is the merit of using a piece of LCD display for a calibration grid, for submillimeter uses (eg. microscopy)? The glass has a very regular pattern of etched metallization on it, when the panel gets delaminated (easy on broken one, just peel off a shard after removing the polarizer).

Thomas Shaddack 3:41 PMWhat is the merit of using a piece of LCD display for a calibration grid, for submillimeter uses (eg. microscopy)? The glass has a very regular pattern of etched metallization on it, when the panel gets delaminated (easy on broken one, just peel off a shard after removing the polarizer).![]() hannes.hoffmann 3:41 PMhave you considered finding a sponsor for this?

hannes.hoffmann 3:41 PMhave you considered finding a sponsor for this?![]() Ahron Wayne 3:41 PMOy, the software was a nightmare to setup. I went through 3 computers and multiple images, and know more about windows XP now then I would ever like to. Some utilities just never ran, like the "shutter server". Had to connect directly to the motor and bypass it.

Ahron Wayne 3:41 PMOy, the software was a nightmare to setup. I went through 3 computers and multiple images, and know more about windows XP now then I would ever like to. Some utilities just never ran, like the "shutter server". Had to connect directly to the motor and bypass it.![]() Ahron Wayne 3:43 PM*disk images. The company that used to service the machine was very helpful though in sending me all the old utilities. Would never have been able to get it going without them. I do the image reconstruction on the old XP machine and then bring it to a modern system and correct it some more with Fiji/imagej. I'm right now trying to get my own reconstruction pipeline working so I can have more control over that process as well

Ahron Wayne 3:43 PM*disk images. The company that used to service the machine was very helpful though in sending me all the old utilities. Would never have been able to get it going without them. I do the image reconstruction on the old XP machine and then bring it to a modern system and correct it some more with Fiji/imagej. I'm right now trying to get my own reconstruction pipeline working so I can have more control over that process as well![]() Ahron Wayne 3:44 PMBut yeah, I avoid working at the low-level whenever I possibly can --- like the detector uses a custom LVDS signalling method and while theoretically, I could have eventually reverse engineered it, it was a LOT easier to get the custom capture card of which there were 3 left sitting in a warehouse somewhere

Ahron Wayne 3:44 PMBut yeah, I avoid working at the low-level whenever I possibly can --- like the detector uses a custom LVDS signalling method and while theoretically, I could have eventually reverse engineered it, it was a LOT easier to get the custom capture card of which there were 3 left sitting in a warehouse somewhere![]() Ahron Wayne 3:46 PMIn a way the project was sponsored by the Vesuvius Challenge Thanks!! I won one of the open-source contribution prizes that just about exactly paid for the machine, new source, and all the cables.

Ahron Wayne 3:46 PMIn a way the project was sponsored by the Vesuvius Challenge Thanks!! I won one of the open-source contribution prizes that just about exactly paid for the machine, new source, and all the cables.![]() anfractuosity 3:47 PMcool :) Is there such a thing as a solid state x-ray emitter, similar to how magnetrons can be replaced by solid state? (Not found anything from a quick google)

anfractuosity 3:47 PMcool :) Is there such a thing as a solid state x-ray emitter, similar to how magnetrons can be replaced by solid state? (Not found anything from a quick google)![]() Ahron Wayne 3:47 PMAnyone have any interesting ideas for what to scan? (Small, low density)

Ahron Wayne 3:47 PMAnyone have any interesting ideas for what to scan? (Small, low density)![]() VALENTINE 3:48 PM>> Anyone have any interesting ideas for what to scan? (Small, low density) Unopened Scratchers

VALENTINE 3:48 PM>> Anyone have any interesting ideas for what to scan? (Small, low density) Unopened Scratchers![]() Ahron Wayne 3:48 PMSolid state x-ray emission is a desired holy grail. Not my expertise but if you look at how we're just now getting to UV LEDs, there is a long way to go.

Ahron Wayne 3:48 PMSolid state x-ray emission is a desired holy grail. Not my expertise but if you look at how we're just now getting to UV LEDs, there is a long way to go.![]() Ahron Wayne 3:49 PMYou and everyone else Valentine...

Ahron Wayne 3:49 PMYou and everyone else Valentine...![]() anfractuosity 3:49 PMhaha

anfractuosity 3:49 PMhaha![]() anfractuosity 3:49 PMa coin might be kind of cool, to see the 3d resolution

anfractuosity 3:49 PMa coin might be kind of cool, to see the 3d resolution![]() anfractuosity 3:50 PMalso a lock

anfractuosity 3:50 PMalso a lock![]() CLamb 3:50 PMInsects!

CLamb 3:50 PMInsects!![]() Ahron Wayne 3:50 PMOoh, I should at least do a 2D of a lock

Ahron Wayne 3:50 PMOoh, I should at least do a 2D of a lock![]() Thomas Shaddack 3:50 PMPackaged chips or transistors. See some kinds of damage (burned bond wires, namely, or voiding of the chip-to-frame solder.)

Thomas Shaddack 3:50 PMPackaged chips or transistors. See some kinds of damage (burned bond wires, namely, or voiding of the chip-to-frame solder.)![]() Ahron Wayne 3:51 PMAnd I ABSOLUTELY need to scan more insects, I honestly don't know why I haven't yet

Ahron Wayne 3:51 PMAnd I ABSOLUTELY need to scan more insects, I honestly don't know why I haven't yet![]() Thomas Shaddack 3:51 PMWhat a buzz!

Thomas Shaddack 3:51 PMWhat a buzz!![]() wilkij1 3:51 PMTry the snickers bar and see if you can resolve the wrapper. I always find it interesting when a medical scan resolves clothing while I'm segmenting it.

wilkij1 3:51 PMTry the snickers bar and see if you can resolve the wrapper. I always find it interesting when a medical scan resolves clothing while I'm segmenting it.![]() Ahron Wayne 3:51 PMToo much industrial stuff makes me feel like I'm working at home, though

Ahron Wayne 3:51 PMToo much industrial stuff makes me feel like I'm working at home, though![]() CLamb 3:51 PMTwo broods of cicadas will be emerging in New Jersey this Spring. Should I catch a few for you?

CLamb 3:51 PMTwo broods of cicadas will be emerging in New Jersey this Spring. Should I catch a few for you?![]() Thomas Shaddack 3:51 PMtooth.

Thomas Shaddack 3:51 PMtooth.![]() Ahron Wayne 3:52 PMCan absolutely resolve the wrapper

Ahron Wayne 3:52 PMCan absolutely resolve the wrapper![]() Ahron Wayne 3:52 PMSure, send me a cicada...

Ahron Wayne 3:52 PMSure, send me a cicada...![]() Dan Maloney 3:53 PMCoincidentally, I'm working on an article about using film to replace the dead CMOS sensor in an X-ray cabinet designed for scanning chips and such.

Dan Maloney 3:53 PMCoincidentally, I'm working on an article about using film to replace the dead CMOS sensor in an X-ray cabinet designed for scanning chips and such.![]() Ahron Wayne 3:53 PM

Ahron Wayne 3:53 PM![]()

![]() Ahron Wayne 3:53 PMWay ahead of you! (prof. son's baby tooth)

Ahron Wayne 3:53 PMWay ahead of you! (prof. son's baby tooth)![]() Thomas Shaddack 3:53 PMCould polaroid-class instant camera film work for xrays (or autoradiography)?

Thomas Shaddack 3:53 PMCould polaroid-class instant camera film work for xrays (or autoradiography)?![]() bruniss 3:54 PMdiagnosis: crack

bruniss 3:54 PMdiagnosis: crack![]() Ahron Wayne 3:54 PMLol. Hey Bruniss

Ahron Wayne 3:54 PMLol. Hey Bruniss![]() Dan Maloney 3:54 PMThey actually use both Ilford 4x5 film and Instax instant film in the project. Both work pretty well

Dan Maloney 3:54 PMThey actually use both Ilford 4x5 film and Instax instant film in the project. Both work pretty well![]() CLamb 3:54 PM@Dan Mahoney Photographic film? Are you imaging the film directly or is there a luminescent intermediary.

CLamb 3:54 PM@Dan Mahoney Photographic film? Are you imaging the film directly or is there a luminescent intermediary.![]() CLamb 3:56 PM@Dan Maloney I mean "exposing" not "imaging".

CLamb 3:56 PM@Dan Maloney I mean "exposing" not "imaging".![]() Dan Maloney 3:57 PMNot me, writing it up as a daily for the blog. Couple of guys presented the work at Schmoocon last week or so. Pretty sure they used some kind of intensifying screen, I'll have to check

Dan Maloney 3:57 PMNot me, writing it up as a daily for the blog. Couple of guys presented the work at Schmoocon last week or so. Pretty sure they used some kind of intensifying screen, I'll have to check![]() Dan Maloney 3:57 PMNope, I take that back -- no screens, direct exposure. Long exposure times, like 120-180 seconds

Dan Maloney 3:57 PMNope, I take that back -- no screens, direct exposure. Long exposure times, like 120-180 seconds![]() Ahron Wayne 3:58 PMSheesh.

Ahron Wayne 3:58 PMSheesh.![]() Dan Maloney 3:58 PMDon't want to derail the chat, though -- just a side note. Article will be out in the next day or two

Dan Maloney 3:58 PMDon't want to derail the chat, though -- just a side note. Article will be out in the next day or two![]() anfractuosity 3:58 PMwow, didn't know that'd work

anfractuosity 3:58 PMwow, didn't know that'd work![]() Ahron Wayne 3:58 PM

Ahron Wayne 3:58 PM![]()

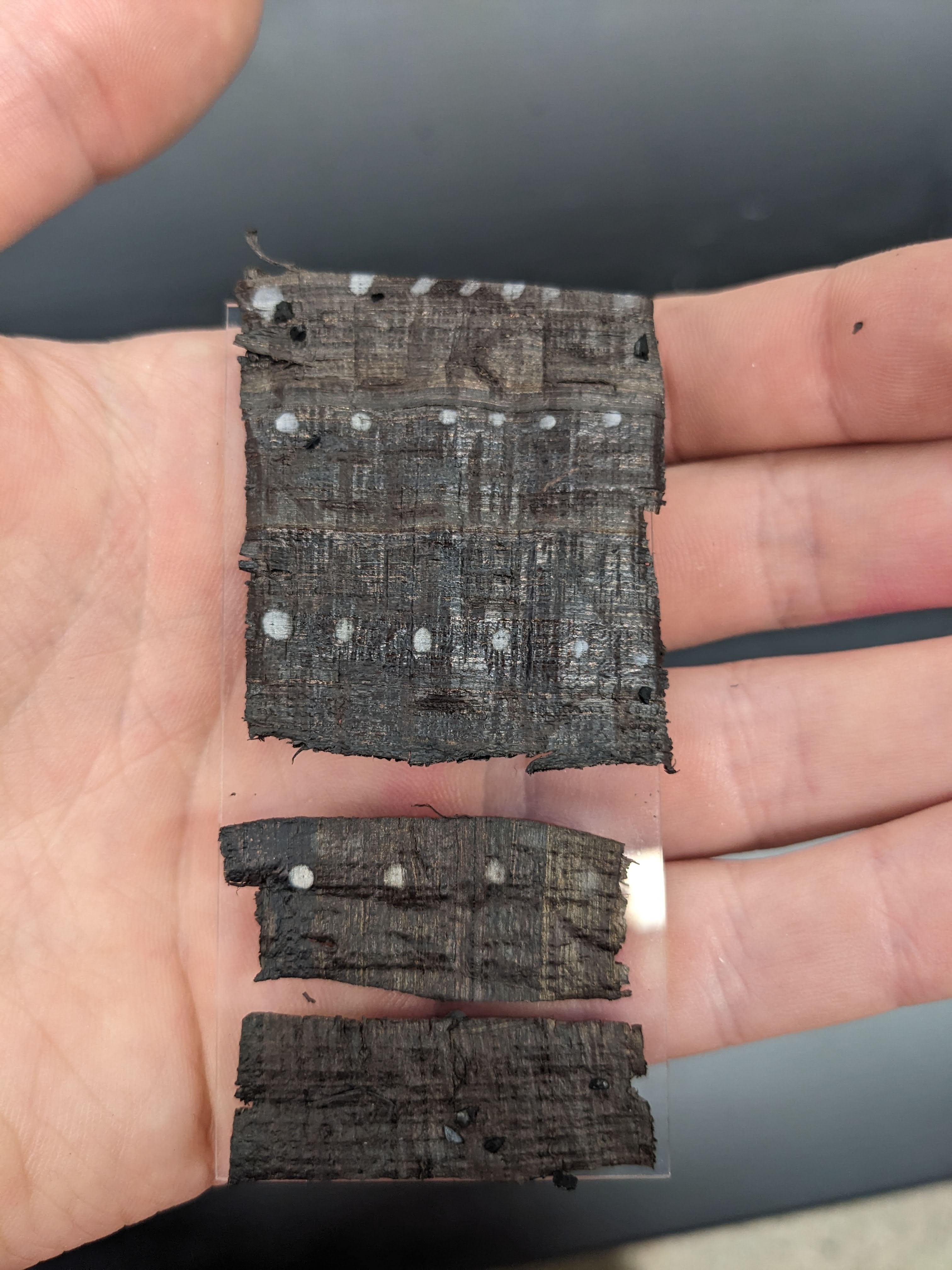

![]() Ahron Wayne 3:58 PMAny questions on the act of making pretend scrolls?

Ahron Wayne 3:58 PMAny questions on the act of making pretend scrolls?![]() anfractuosity 3:58 PMhaha cool, what material is that

anfractuosity 3:58 PMhaha cool, what material is that![]() Dan Maloney 3:59 PMOh yeah, meant to ask about your roasted scrolls. Where does one get papyrus these days?

Dan Maloney 3:59 PMOh yeah, meant to ask about your roasted scrolls. Where does one get papyrus these days?![]() Will Fitzgerald 3:59 PMWhat kind of ink did you use?

Will Fitzgerald 3:59 PMWhat kind of ink did you use?![]() hannes.hoffmann 3:59 PMThings to scan: spring onions. Preferably dried/carbonized.

hannes.hoffmann 3:59 PMThings to scan: spring onions. Preferably dried/carbonized.![]() Ahron Wayne 3:59 PM

Ahron Wayne 3:59 PM![]()

![]() Thomas Shaddack 3:59 PMPieces of charcoal. Also internal structure remaining from the wood.

Thomas Shaddack 3:59 PMPieces of charcoal. Also internal structure remaining from the wood.![]() Ahron Wayne 4:00 PMI tried to get papyrus from a few different sources --- I mainly found small postcard sized sheets, thicker than the ancient stuff, and more realistic swathes that came directly from egypt (it literally had nile river in the return address). Amazon and Ebay were the actual sellers

Ahron Wayne 4:00 PMI tried to get papyrus from a few different sources --- I mainly found small postcard sized sheets, thicker than the ancient stuff, and more realistic swathes that came directly from egypt (it literally had nile river in the return address). Amazon and Ebay were the actual sellers![]() Dan Maloney 4:01 PMTIL that Egypt still has a papyrus industry...

Dan Maloney 4:01 PMTIL that Egypt still has a papyrus industry...![]() Ahron Wayne 4:01 PM@Will Fitzgerald , I got ink from standard fountain pens and also different India inks, which do have modern binders but are still mostly just carbon... hopefully... And I also tried to mix up my own dense inks to act as reference points, which is surprisingly harder than I thought.

Ahron Wayne 4:01 PM@Will Fitzgerald , I got ink from standard fountain pens and also different India inks, which do have modern binders but are still mostly just carbon... hopefully... And I also tried to mix up my own dense inks to act as reference points, which is surprisingly harder than I thought.![]() Ahron Wayne 4:02 PM

Ahron Wayne 4:02 PM![]()

![]() CLamb 4:02 PMWas it the carbon in the ink the component which was most radio opaque?

CLamb 4:02 PMWas it the carbon in the ink the component which was most radio opaque?![]() Thomas Shaddack 4:02 PMbarium sulfate wouldn't work?

Thomas Shaddack 4:02 PMbarium sulfate wouldn't work?![]() Ahron Wayne 4:02 PMI used a 3D printer holding a pen to try and standardize the writing process somewhat.

Ahron Wayne 4:02 PMI used a 3D printer holding a pen to try and standardize the writing process somewhat.![]() Thomas Shaddack 4:02 PMit's available as pigment grade, I think.

Thomas Shaddack 4:02 PMit's available as pigment grade, I think.![]() Ahron Wayne 4:03 PM@thomas, if I could find it as a wax stick or something, sure. I did try barium sulfate, but it's hard to write with --- insoluble.

Ahron Wayne 4:03 PM@thomas, if I could find it as a wax stick or something, sure. I did try barium sulfate, but it's hard to write with --- insoluble.![]() CLamb 4:03 PMDid you ever try to duplicate the ink on the real scrolls?

CLamb 4:03 PMDid you ever try to duplicate the ink on the real scrolls?![]() Dan Maloney 4:03 PMIs the chemical composition of Roman ink known? There has to be some kind of record -- seems like they wrote down everything

Dan Maloney 4:03 PMIs the chemical composition of Roman ink known? There has to be some kind of record -- seems like they wrote down everything![]() Thomas Shaddack 4:04 PMPigments are insoluble (if soluble it's a dye, I think). Carbon itself. It's then about the size/shape of particles, and keeping them dispersed.

Thomas Shaddack 4:04 PMPigments are insoluble (if soluble it's a dye, I think). Carbon itself. It's then about the size/shape of particles, and keeping them dispersed.![]() anfractuosity 4:04 PMHave you heard of sumi ink, that uses soot too

anfractuosity 4:04 PMHave you heard of sumi ink, that uses soot too![]() Ahron Wayne 4:04 PMThe basic recipe for carbon ink is --- burn some fat underneath a tarp. Scrape the black stuff that forms. Profit. (in other words, india ink)

Ahron Wayne 4:04 PMThe basic recipe for carbon ink is --- burn some fat underneath a tarp. Scrape the black stuff that forms. Profit. (in other words, india ink)![]() SimonAllen 4:06 PMI wonder if carbon or charcoal ground with a pestle and mortar would work

SimonAllen 4:06 PMI wonder if carbon or charcoal ground with a pestle and mortar would work![]() CLamb 4:07 PMIn modern times lampblack is the carbon that is usually used as a pigment.

CLamb 4:07 PMIn modern times lampblack is the carbon that is usually used as a pigment.![]() Thomas Shaddack 4:07 PMSoot is better. Nanotech.

Thomas Shaddack 4:07 PMSoot is better. Nanotech.![]() hannes.hoffmann 4:07 PMgrinding charoal down to ink particle size is a pain. You bascally need romen slave labour to grind on long enough. That, or floatation.

hannes.hoffmann 4:07 PMgrinding charoal down to ink particle size is a pain. You bascally need romen slave labour to grind on long enough. That, or floatation.![]() Thomas Shaddack 4:08 PMor a postdoc.

Thomas Shaddack 4:08 PMor a postdoc.![]() wilkij1 4:08 PMCalcium? Carbonates are pretty soluble, I think. That would triple your atomic number, which would be a big help.

wilkij1 4:08 PMCalcium? Carbonates are pretty soluble, I think. That would triple your atomic number, which would be a big help.![]() Ahron Wayne 4:09 PMThere are so many factors when created simulations --- ink, papyrus, carbonization, the fact that it's not being aged 2000 years. My thoughts are that if you get enough sheer variation the ML models would figure it out. Though maybe that's why I wasn't in the running for the grand prize

Ahron Wayne 4:09 PMThere are so many factors when created simulations --- ink, papyrus, carbonization, the fact that it's not being aged 2000 years. My thoughts are that if you get enough sheer variation the ML models would figure it out. Though maybe that's why I wasn't in the running for the grand prize![]() Thomas Shaddack 4:09 PMcalcium carbonate is rather insoluble. if you dissolve it, the white pigment property gets gone.

Thomas Shaddack 4:09 PMcalcium carbonate is rather insoluble. if you dissolve it, the white pigment property gets gone.![]() Ahron Wayne 4:09 PM@wilkij1 Chalk is probably in fact the easiest way to mark boundaries of your papyrus yeah.

Ahron Wayne 4:09 PM@wilkij1 Chalk is probably in fact the easiest way to mark boundaries of your papyrus yeah.![]() Thomas Shaddack 4:10 PMbut you can precipitate it carefully to fine enough particles, and if you coat them with some surfactant to get them all electrostatically charged so they repulse each other and don't coagulate so easily, you can get a good enough ink.

Thomas Shaddack 4:10 PMbut you can precipitate it carefully to fine enough particles, and if you coat them with some surfactant to get them all electrostatically charged so they repulse each other and don't coagulate so easily, you can get a good enough ink.![]() hannes.hoffmann 4:10 PMbut why calcium? if what you want is just any attenuation by an ink, dissolve metal salts in it. There are tungsten salts that are less toxic than the lead stuff.