![]() OK welcome one and all to the Hack Chat! I'm Dan, I'll be moderating today along with Dusan as we welcome Niklas from Advanced Tinkering. We're going to be talking about nothing, or as close to it as we can get -- high vacuum

OK welcome one and all to the Hack Chat! I'm Dan, I'll be moderating today along with Dusan as we welcome Niklas from Advanced Tinkering. We're going to be talking about nothing, or as close to it as we can get -- high vacuum

|

![]() Welcome everyone!

Welcome everyone!

|

![]() Niklas, You've got an eclectic mix of topics on your channel. Why don't we start with a little about your background?

Niklas, You've got an eclectic mix of topics on your channel. Why don't we start with a little about your background?

|

![]() Luckily I wrote a few sentences beforehand ^^

Luckily I wrote a few sentences beforehand ^^

|

![]() Like many of you here, I've been tinkering with various projects since childhood. Initially, I was more focused on dismantling things. The part where I put them back together or build something of my own came later.

About two years ago, I decided to document one of my projects and upload it to YouTube. Since my projects don't aim to have scientific value and my interests span across different fields, I named the channel Advanced Tinkering.

I've worked on a few projects related to chemistry, electronics, and lately, a lot on vacuum and high vacuum. The various types of vacuum pumps (oil or mercury diffusion pumps, turbomolecular pumps, titanium sublimation pumps, rotary vane pumps, membrane pumps, etc.) and the physics behind them are fascinating.

In my vacuum chamber, I've already evaporated various metals like aluminum, titanium, silver, copper, and chromium to coat surfaces like glass or plastic.

First and foremost, I want to emphasize that I am by no means an expert. My expertise lies more in chemistry, and I don't have formal training in many of the areas I cover in my videos. But I believe the appeal lies precisely in acquiring new skills and knowledge.

Thanks to the internet, there's a unique opportunity to connect with experts and enthusiasts from various fields and learn from each other. And I hope today will be a day where we can learn from each other!

Like many of you here, I've been tinkering with various projects since childhood. Initially, I was more focused on dismantling things. The part where I put them back together or build something of my own came later.

About two years ago, I decided to document one of my projects and upload it to YouTube. Since my projects don't aim to have scientific value and my interests span across different fields, I named the channel Advanced Tinkering.

I've worked on a few projects related to chemistry, electronics, and lately, a lot on vacuum and high vacuum. The various types of vacuum pumps (oil or mercury diffusion pumps, turbomolecular pumps, titanium sublimation pumps, rotary vane pumps, membrane pumps, etc.) and the physics behind them are fascinating.

In my vacuum chamber, I've already evaporated various metals like aluminum, titanium, silver, copper, and chromium to coat surfaces like glass or plastic.

First and foremost, I want to emphasize that I am by no means an expert. My expertise lies more in chemistry, and I don't have formal training in many of the areas I cover in my videos. But I believe the appeal lies precisely in acquiring new skills and knowledge.

Thanks to the internet, there's a unique opportunity to connect with experts and enthusiasts from various fields and learn from each other. And I hope today will be a day where we can learn from each other!

|

![]() "Titanium sublimation" - that's one I've never heard of

"Titanium sublimation" - that's one I've never heard of

|

![]() like an ion pump?

like an ion pump?

|

![]() How this type of pump works could actually be observed when I evaporated titanium in the chamber to coat a glass pane. The titanium becomes gaseous and then deposits as a thin film on the next surface. Since titanium (without an oxide layer) is highly reactive, it reacts with the remaining gas molecules in the vacuum, binds them, and thus reduces the pressure.

How this type of pump works could actually be observed when I evaporated titanium in the chamber to coat a glass pane. The titanium becomes gaseous and then deposits as a thin film on the next surface. Since titanium (without an oxide layer) is highly reactive, it reacts with the remaining gas molecules in the vacuum, binds them, and thus reduces the pressure.

|

![]() This is a pump principle that can only be used at very low pressures.

This is a pump principle that can only be used at very low pressures.

|

![]() Just like a Diffusion Pump can only be used at lower pressures ^^

Just like a Diffusion Pump can only be used at lower pressures ^^

|

![]() Random thought I am entertaining for some time. Could a homemade vacuum tube have integrated ion/titanium pump? Suck it out with something conventional/common/available, seal, then put it into magnetic field and run high voltage through the dedicated electrodes and finish the suck? Could also be used to "top up" the vacuum later after the inevitable outgassing and microleaks do their job.

Random thought I am entertaining for some time. Could a homemade vacuum tube have integrated ion/titanium pump? Suck it out with something conventional/common/available, seal, then put it into magnetic field and run high voltage through the dedicated electrodes and finish the suck? Could also be used to "top up" the vacuum later after the inevitable outgassing and microleaks do their job.

|

![]() Variation on a getter.

Variation on a getter.

|

![]() Interesting. Do methods like that perform better at scavenging oxygen or nitrogen? Seems like both, since there TiN and TiO2. But maybe it performs better for oxygen since each Ti ion takes out two oxygens?

Interesting. Do methods like that perform better at scavenging oxygen or nitrogen? Seems like both, since there TiN and TiO2. But maybe it performs better for oxygen since each Ti ion takes out two oxygens?

|

![]() The GE Talaria projection tube had a built-in ion gauge and some absorbent rocks in the tube to get the leftover gas from the oil film that it needed to diffract the electron beam and form an image. The most fascinating display tech ever invented.

The GE Talaria projection tube had a built-in ion gauge and some absorbent rocks in the tube to get the leftover gas from the oil film that it needed to diffract the electron beam and form an image. The most fascinating display tech ever invented.

|

![]() @Thomas Shaddack I'm not sure. There may be getter materials, that contain titanium.

@Thomas Shaddack I'm not sure. There may be getter materials, that contain titanium.

|

![]() What types of seals are you using? I was always told 10^-6 torr is about as good as you can get with o-rings

What types of seals are you using? I was always told 10^-6 torr is about as good as you can get with o-rings

|

![]() @Dan Maloney I honestly can't say for sure. As far as I know, oxygen is easier to bind, simply because of its higher reactivity

@Dan Maloney I honestly can't say for sure. As far as I know, oxygen is easier to bind, simply because of its higher reactivity

|

![]() @Allen I use KF flanges, so O-ring seals. CF (copper) seals would indeed be better, as you mentioned. However, if you frequently open and rebuild the chamber, it quickly becomes expensive since theoretically, you should only use the copper seals once. Of course, this also depends on the number/size of the O-rings and how good your pump is. With my large turbomolecular pump, I have already reached the 10^-7 Torr range, even without baking out the chamber.

@Allen I use KF flanges, so O-ring seals. CF (copper) seals would indeed be better, as you mentioned. However, if you frequently open and rebuild the chamber, it quickly becomes expensive since theoretically, you should only use the copper seals once. Of course, this also depends on the number/size of the O-rings and how good your pump is. With my large turbomolecular pump, I have already reached the 10^-7 Torr range, even without baking out the chamber.

|

![]() How many stages of pump?

How many stages of pump?

|

![]() Oh! quite good! :) Yes, copper can get expensive. Back in the day they used indium wire seals... no idea if that might work. Helicoflex can be used in place of o-ring, but requires mirror finish in groove

Oh! quite good! :) Yes, copper can get expensive. Back in the day they used indium wire seals... no idea if that might work. Helicoflex can be used in place of o-ring, but requires mirror finish in groove

|

![]() Can a low-melt solder be used for the seals (between metal parts)? Put in place, heat with induction or with an embedded heater, melt, wet, cool?

Can a low-melt solder be used for the seals (between metal parts)? Put in place, heat with induction or with an embedded heater, melt, wet, cool?

|

![]() @dmoisan I have a rotary vane roughing pump and a turbomolecular pump.

@dmoisan I have a rotary vane roughing pump and a turbomolecular pump.

|

![]() I dislike maintenance, and don't really want to be swapping out my rotary vane roughing pump's vacuum oil every few days like it feels like I'm supposed to. How often do you change your roughing pump oil? Or, do you know of another type of roughing pump that is sufficient (and still obtainable for a hobbyist) that doesn't need much maintenance?

I dislike maintenance, and don't really want to be swapping out my rotary vane roughing pump's vacuum oil every few days like it feels like I'm supposed to. How often do you change your roughing pump oil? Or, do you know of another type of roughing pump that is sufficient (and still obtainable for a hobbyist) that doesn't need much maintenance?

|

![]() Yes, indium or even solder can be used. I think applied science sealed a penning gauge with solder (but had some problems with the flux migrating into the vacuum over time)

Yes, indium or even solder can be used. I think applied science sealed a penning gauge with solder (but had some problems with the flux migrating into the vacuum over time)

|

![]() (I did once have a problem where my roughing pump got rusty, I think; oil went brown and I got a new pump because I no longer trusted it)

(I did once have a problem where my roughing pump got rusty, I think; oil went brown and I got a new pump because I no longer trusted it)

|

![]() Oooo... are you making your own magnetron?

Oooo... are you making your own magnetron?

|

![]() It can be done! :)

It can be done! :)

|

![]() @Erhannis Both questions depend on a lot of different factors. If you don't draw any dirt into your rotary vane pump, you hardly ever need to change the oil. At most, you might need to top it up occasionally. I'm not exactly sure what the operating manuals specify for oil change intervals.

Whether you can use a different pump type depends on your high vacuum pump. Newer turbomolecular pumps can even run with a membrane pump as a backing pump.

@Erhannis Both questions depend on a lot of different factors. If you don't draw any dirt into your rotary vane pump, you hardly ever need to change the oil. At most, you might need to top it up occasionally. I'm not exactly sure what the operating manuals specify for oil change intervals.

Whether you can use a different pump type depends on your high vacuum pump. Newer turbomolecular pumps can even run with a membrane pump as a backing pump.

|

![]() Who are the best suppliers for high vacuum equipment? What is typically available in the price range for a hobbyist?

Who are the best suppliers for high vacuum equipment? What is typically available in the price range for a hobbyist?

|

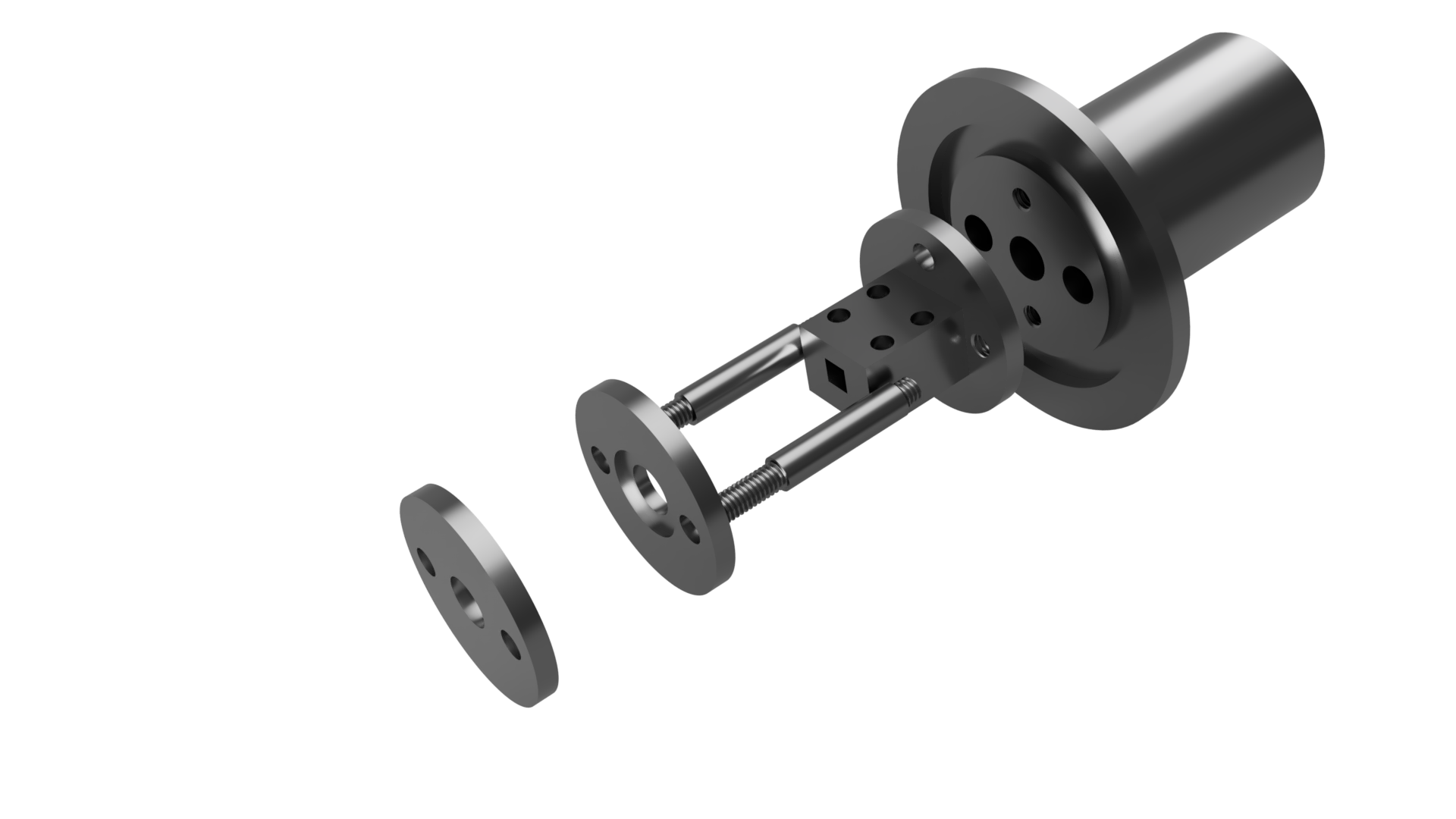

![]() @Allen Yes :) I designed a Magnetron a few weeks/months ago and just got the parts machined (I unfortunately don't own a lathe or mill). Im currently building the power supply. I hope to be able to test it next week

@Allen Yes :) I designed a Magnetron a few weeks/months ago and just got the parts machined (I unfortunately don't own a lathe or mill). Im currently building the power supply. I hope to be able to test it next week

|

![]() Awesome!

Awesome!

|

![]() What will be on the other end of the mag?

What will be on the other end of the mag?

|

![]() @JStocke12 Used equipment is the way to go. Almost everything new is way to expensive for a hobbyist

@JStocke12 Used equipment is the way to go. Almost everything new is way to expensive for a hobbyist

|

![]() Take a look at ebay and similar sites regularly and you will find some good deals

Take a look at ebay and similar sites regularly and you will find some good deals

|

![]() I got my Pfeiffer rotary vane pump for 200 Euros. And it was almost new.

I got my Pfeiffer rotary vane pump for 200 Euros. And it was almost new.

|

![]() For other hobbies, we have the standard introduction projects: soldering, benchy, turner cube, etc... What is a good introduction project to high vacuum in your mind?

For other hobbies, we have the standard introduction projects: soldering, benchy, turner cube, etc... What is a good introduction project to high vacuum in your mind?

|

![]() When budget time rolls around, companies and universities make sure they use up every last dime so they don't get cut next year. That's why practically new stuff ends up on the secondary market.

When budget time rolls around, companies and universities make sure they use up every last dime so they don't get cut next year. That's why practically new stuff ends up on the secondary market.

|

![]() If you want to make a poor-man's knudsen cell, look at Tempco Heatercoil and a steel vessel with an aperture... it doesn't have to be pretty. (some materials effuse better than sputter)- then you can co-deposit!

If you want to make a poor-man's knudsen cell, look at Tempco Heatercoil and a steel vessel with an aperture... it doesn't have to be pretty. (some materials effuse better than sputter)- then you can co-deposit!

|

![]() @AdvancedTinkering Huh, interesting. I'd been told that moisture from the air gets in the oil and rusts your pump. Mine did rust, but I can't guarantee I wasn't like, boiling water with it or something haha. I did with GREAT effort freeze dry some stuff, and man the cryo trap was a pain to keep cold, so much dry ice

Re: mill/lathe, you wouldn't happen to live near Ohio, would you? I have a mini cnc lathe and mini cnc mill you could use, haha.

@AdvancedTinkering Huh, interesting. I'd been told that moisture from the air gets in the oil and rusts your pump. Mine did rust, but I can't guarantee I wasn't like, boiling water with it or something haha. I did with GREAT effort freeze dry some stuff, and man the cryo trap was a pain to keep cold, so much dry ice

Re: mill/lathe, you wouldn't happen to live near Ohio, would you? I have a mini cnc lathe and mini cnc mill you could use, haha.

|

![]() Are there any 3d printable materials suitable for high vacuum? Hightechs like PVDF?

Are there any 3d printable materials suitable for high vacuum? Hightechs like PVDF?

|

![]() There are sinterable-metal printer filaments that after thermal processing yield copper, bronze, stainless, inconel...

There are sinterable-metal printer filaments that after thermal processing yield copper, bronze, stainless, inconel...

|

![]() @Shane Hmm... It's hard to say. The question is whether you have something specific in mind that you want to achieve with the high vacuum. If so, I would suggest breaking down this project into small stages that you can achieve sequentially on the way to your goal.

If it's simply about reaching high vacuum, I would start with a regular vacuum first. And that usually begins with a pump. For example, you could generate gas discharges in the "vacuum." With a neon power supply and a glass tube or bulb, you can already create beautiful gas discharges.

@Shane Hmm... It's hard to say. The question is whether you have something specific in mind that you want to achieve with the high vacuum. If so, I would suggest breaking down this project into small stages that you can achieve sequentially on the way to your goal.

If it's simply about reaching high vacuum, I would start with a regular vacuum first. And that usually begins with a pump. For example, you could generate gas discharges in the "vacuum." With a neon power supply and a glass tube or bulb, you can already create beautiful gas discharges.

|

![]()

![]()

|

![]() My Logo is a gas discharge for example

My Logo is a gas discharge for example

|

![]() I tried to build my own cathode ray tube using a rotary vane pump, and I got a little electric discharge but no nice beam. How do you stay safe around high voltage?

I tried to build my own cathode ray tube using a rotary vane pump, and I got a little electric discharge but no nice beam. How do you stay safe around high voltage?

|

![]() @Erhannis Rotary vane pumps usually have a gas ballast that you can open to remove moisture from the oil. But if you don't have a cold trap and, for example, freeze-dry, the pump will eventually rust, haha.

I live in Germany. So unfortunately, it's a bit too far away to just drop by, :D But thanks for the offer!

@Erhannis Rotary vane pumps usually have a gas ballast that you can open to remove moisture from the oil. But if you don't have a cold trap and, for example, freeze-dry, the pump will eventually rust, haha.

I live in Germany. So unfortunately, it's a bit too far away to just drop by, :D But thanks for the offer!

|

![]() https://hackaday.com/2024/01/06/an-adjustable-high-voltage-power-supply-built-with-safety-in-mind/

https://hackaday.com/2024/01/06/an-adjustable-high-voltage-power-supply-built-with-safety-in-mind/

|

![]() @JStocke12 That's a very comprehensive question, and I'm probably not qualified enough to provide an exact answer. However, there are many good resources available online for that. Perhaps this Instructables article could be a good starting point: https://www.instructables.com/Work-safely-with-high-voltage/

@JStocke12 That's a very comprehensive question, and I'm probably not qualified enough to provide an exact answer. However, there are many good resources available online for that. Perhaps this Instructables article could be a good starting point: https://www.instructables.com/Work-safely-with-high-voltage/

|

![]() @Thomas Shaddack As far as I know, all FDM-printed plastics have the issue of small voids or air inclusions. I could imagine that SLA-printed high-tech plastics might be suitable for high vacuum purposes, but I can't say for sure. It also depends on what level of vacuum you want to achieve. Generally, though, plastics (at least most of them) are a bad idea for high vacuum applications, especially 3D-printed ones.

@Thomas Shaddack As far as I know, all FDM-printed plastics have the issue of small voids or air inclusions. I could imagine that SLA-printed high-tech plastics might be suitable for high vacuum purposes, but I can't say for sure. It also depends on what level of vacuum you want to achieve. Generally, though, plastics (at least most of them) are a bad idea for high vacuum applications, especially 3D-printed ones.

|

![]() Re high voltage, we did some experiments with using candle gel as a reworkable potting compound. Stays in place unless melted, so won't spill into the carpet and cause wrath of the resident female to descend upon thine noggin. Can be removed with relative ease, even a hotplate of the 3d printer will do.

Re high voltage, we did some experiments with using candle gel as a reworkable potting compound. Stays in place unless melted, so won't spill into the carpet and cause wrath of the resident female to descend upon thine noggin. Can be removed with relative ease, even a hotplate of the 3d printer will do.

|

![]() Advantages of both oil and epoxy.

Advantages of both oil and epoxy.

|

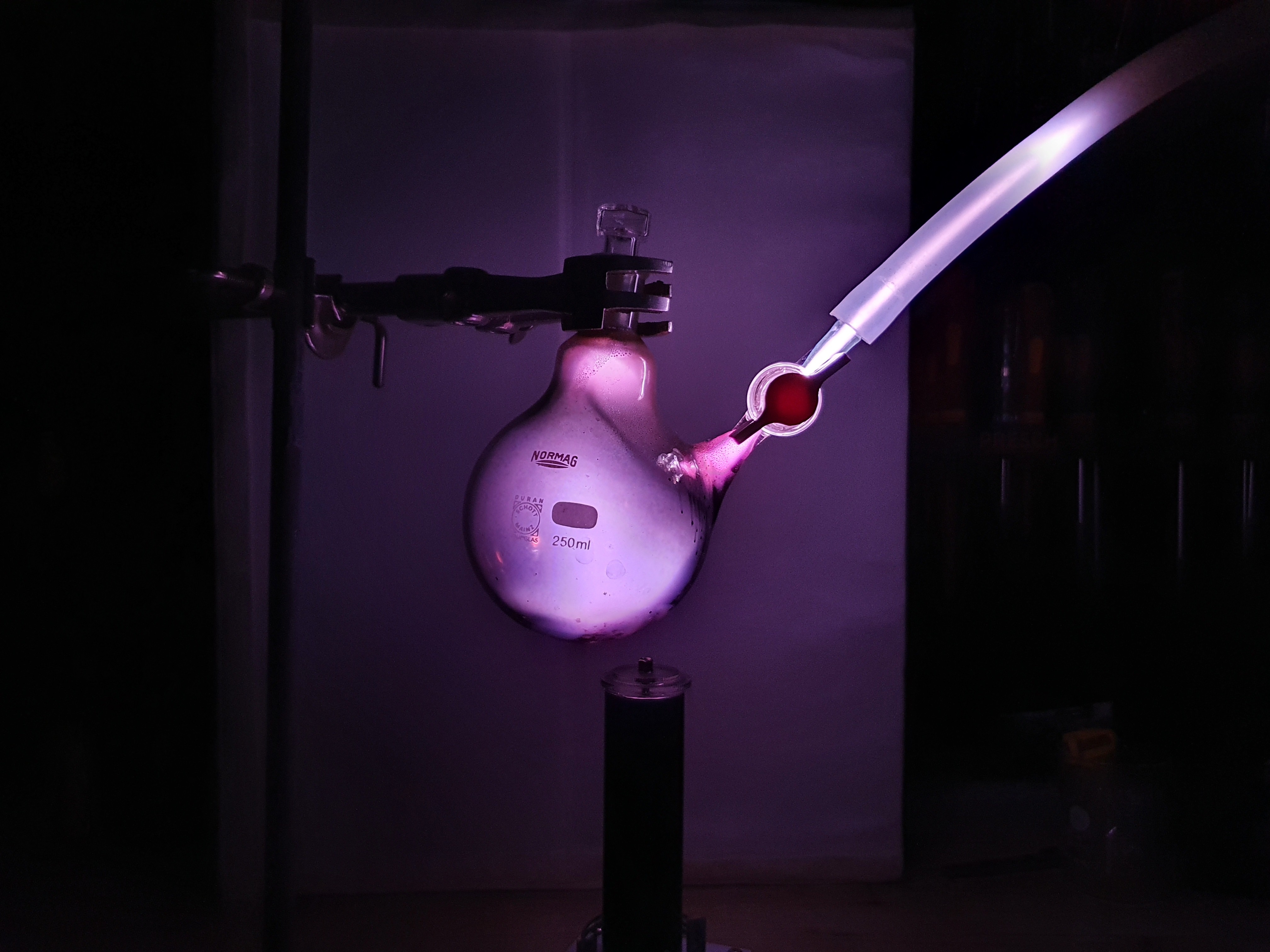

![]() @Allen I have used a similar principle to build my atomic beam furnace (there is also a video about it) which is basically a knudsen cell. Unfortunately, I have not been successful in producing a visible potassium or silver film with it so far.

@Allen I have used a similar principle to build my atomic beam furnace (there is also a video about it) which is basically a knudsen cell. Unfortunately, I have not been successful in producing a visible potassium or silver film with it so far.

|

![]() What about glass-metal seals? Any tricks? Ceramics-metal? Some exotic active brazes that can wet ceramics?

What about glass-metal seals? Any tricks? Ceramics-metal? Some exotic active brazes that can wet ceramics?

|

![]() ( @Thomas Shaddack re: FDM, the thing about voids sounds true, but if you were to try it anyway, https://en.wikipedia.org/wiki/Materials_for_use_in_vacuum says that at least material-wise PEEK has relatively low outgassing, and there are PEEK filaments, though expensive )

( @Thomas Shaddack re: FDM, the thing about voids sounds true, but if you were to try it anyway, https://en.wikipedia.org/wiki/Materials_for_use_in_vacuum says that at least material-wise PEEK has relatively low outgassing, and there are PEEK filaments, though expensive )

|

![]() Titanium powder mixed into regular brazing paste, so it dissolves in ordinary braze and turns it into active?

Titanium powder mixed into regular brazing paste, so it dissolves in ordinary braze and turns it into active?

|

![]() @Erhannis I wrote that article!

@Erhannis I wrote that article!

|

![]()

![]()

|

![]() @Thomas Shaddack Oh hahahaha! Excellent resource, thanks!

@Thomas Shaddack Oh hahahaha! Excellent resource, thanks!

|

![]() @Allen That was the Atomic beam furnace design. The outside gets heated and in front of the opening is a collimator and an optical flit to create a narrow beam.

@Allen That was the Atomic beam furnace design. The outside gets heated and in front of the opening is a collimator and an optical flit to create a narrow beam.

|

![]() Glass/metal seals are tricky. I haven't brazed any ceramics yet. I've only melted relatively thin tungsten electrodes into glass.

Glass/metal seals are tricky. I haven't brazed any ceramics yet. I've only melted relatively thin tungsten electrodes into glass.

|

![]() I heard about a sol-gel trick for mitigating microcracks along the seals. Let some silanol soak in, and form glass in there.

I heard about a sol-gel trick for mitigating microcracks along the seals. Let some silanol soak in, and form glass in there.

|

![]() Dalibor Farny has been doing some experiments with glass-metal seals. That's for his Nixie tubes, though -- not sure that's exactly the same class of vacuum

Dalibor Farny has been doing some experiments with glass-metal seals. That's for his Nixie tubes, though -- not sure that's exactly the same class of vacuum

|

![]() Nixies are gas-filled.

Nixies are gas-filled.

|

![]() I love Dalibor Farnys channel. His videos are great

I love Dalibor Farnys channel. His videos are great

|

![]() @Thomas Shaddack But the seals he is used are definitely vacuum tight

@Thomas Shaddack But the seals he is used are definitely vacuum tight

|

![]() *using

*using

|

![]() I think he also tested it in one video. If i remember correctly, he sealed off an ion gauge and tested it a few weeks later

I think he also tested it in one video. If i remember correctly, he sealed off an ion gauge and tested it a few weeks later

|

![]() That could be a good way to test toys. How difficult is to make an ion gauge? Or, later, have an integrated module of ion pump and ion gauge, for tube diagnostics and "topping up"?

That could be a good way to test toys. How difficult is to make an ion gauge? Or, later, have an integrated module of ion pump and ion gauge, for tube diagnostics and "topping up"?

|

![]() Ah, I was wrong. He tested if borax is a suitable coating: https://www.youtube.com/watch?v=ylmuYxDzRvI

Ah, I was wrong. He tested if borax is a suitable coating: https://www.youtube.com/watch?v=ylmuYxDzRvI

|

![]() https://www.youtube.com/watch?v=3nsg0q2Pz6g

https://www.youtube.com/watch?v=3nsg0q2Pz6g

|

![]() Oops -- still a good video

Oops -- still a good video

|

![]() Glass Ion Gauges are just beautiful :)

Glass Ion Gauges are just beautiful :)

|

![]() Random thought. Microwave postheating of a propane flame, to avoid the need for oxygen for the torch. Pump extra energy into the plasma instead of generating it within.

Random thought. Microwave postheating of a propane flame, to avoid the need for oxygen for the torch. Pump extra energy into the plasma instead of generating it within.

|

![]() On the topic of gauges, I've frequently wondered about the accuracy of my ebay gauges. What kinds of absolute measurements could be made, to calibrate gauges, without using (significant) 3rd-party tools? Like, by measuring breakdown distance at mains voltage, or using the triple point of water, or something. Maybe a range of phenomena for different pressure ranges.

On the topic of gauges, I've frequently wondered about the accuracy of my ebay gauges. What kinds of absolute measurements could be made, to calibrate gauges, without using (significant) 3rd-party tools? Like, by measuring breakdown distance at mains voltage, or using the triple point of water, or something. Maybe a range of phenomena for different pressure ranges.

|

![]() All calibration methods I know either require a reference or use complex setups. I don't believe one can reliably calibrate a vacuum gauge, for example, with the triple point of water. I read an interesting article about other methods that are typically used. Let me quickly find it.

All calibration methods I know either require a reference or use complex setups. I don't believe one can reliably calibrate a vacuum gauge, for example, with the triple point of water. I read an interesting article about other methods that are typically used. Let me quickly find it.

|

![]() https://www.leybold.com/en-ie/knowledge/vacuum-fundamentals/vacuum-measurement/how-to-calibrate-vacuum-gauges

https://www.leybold.com/en-ie/knowledge/vacuum-fundamentals/vacuum-measurement/how-to-calibrate-vacuum-gauges

|

![]() Thanks; I'll give it a look

Thanks; I'll give it a look

|

![]() OK, we're up past the top of the hour, so we're going to have to wrap things up. I want to thank Niklas for his time today, really cool topic and a lot of great discussion. Great questions, too -- thanks to everyone!

OK, we're up past the top of the hour, so we're going to have to wrap things up. I want to thank Niklas for his time today, really cool topic and a lot of great discussion. Great questions, too -- thanks to everyone!

|

![]() @Erhannis Might also be interesting for you

@Erhannis Might also be interesting for you

|

![]() If anybody's near Ohio and wants to collaborate on vacuum stuff, I've got some equipment and space; hit me up haha

If anybody's near Ohio and wants to collaborate on vacuum stuff, I've got some equipment and space; hit me up haha

|

![]() @AdvancedTinkering Thanks!

@AdvancedTinkering Thanks!

|

![]() @AdvancedTinkering Thank you!

@AdvancedTinkering Thank you!

|

![]() Thanks for having me Dan! And thanks to everyone for participating.

Thanks for having me Dan! And thanks to everyone for participating.

|

![]() Good talk, thanks!

Good talk, thanks!

|

![]() You bet, my pleasure! Looking forward to more cool videos (no pressure)

You bet, my pleasure! Looking forward to more cool videos (no pressure)

|

![]() Thanks Niklas

Thanks Niklas

|

![]() Transcript coming up. Thanks everyone!

Transcript coming up. Thanks everyone!

|

![]() Dan Maloney 3:00 PMOK welcome one and all to the Hack Chat! I'm Dan, I'll be moderating today along with Dusan as we welcome Niklas from Advanced Tinkering. We're going to be talking about nothing, or as close to it as we can get -- high vacuum

Dan Maloney 3:00 PMOK welcome one and all to the Hack Chat! I'm Dan, I'll be moderating today along with Dusan as we welcome Niklas from Advanced Tinkering. We're going to be talking about nothing, or as close to it as we can get -- high vacuum![]() AdvancedTinkering 3:01 PMWelcome everyone!

AdvancedTinkering 3:01 PMWelcome everyone!![]() Dan Maloney 3:01 PMNiklas, You've got an eclectic mix of topics on your channel. Why don't we start with a little about your background?

Dan Maloney 3:01 PMNiklas, You've got an eclectic mix of topics on your channel. Why don't we start with a little about your background?![]() AdvancedTinkering 3:03 PMLuckily I wrote a few sentences beforehand ^^

AdvancedTinkering 3:03 PMLuckily I wrote a few sentences beforehand ^^![]() AdvancedTinkering 3:03 PMLike many of you here, I've been tinkering with various projects since childhood. Initially, I was more focused on dismantling things. The part where I put them back together or build something of my own came later. About two years ago, I decided to document one of my projects and upload it to YouTube. Since my projects don't aim to have scientific value and my interests span across different fields, I named the channel Advanced Tinkering. I've worked on a few projects related to chemistry, electronics, and lately, a lot on vacuum and high vacuum. The various types of vacuum pumps (oil or mercury diffusion pumps, turbomolecular pumps, titanium sublimation pumps, rotary vane pumps, membrane pumps, etc.) and the physics behind them are fascinating. In my vacuum chamber, I've already evaporated various metals like aluminum, titanium, silver, copper, and chromium to coat surfaces like glass or plastic. First and foremost, I want to emphasize that I am by no means an expert. My expertise lies more in chemistry, and I don't have formal training in many of the areas I cover in my videos. But I believe the appeal lies precisely in acquiring new skills and knowledge. Thanks to the internet, there's a unique opportunity to connect with experts and enthusiasts from various fields and learn from each other. And I hope today will be a day where we can learn from each other!

AdvancedTinkering 3:03 PMLike many of you here, I've been tinkering with various projects since childhood. Initially, I was more focused on dismantling things. The part where I put them back together or build something of my own came later. About two years ago, I decided to document one of my projects and upload it to YouTube. Since my projects don't aim to have scientific value and my interests span across different fields, I named the channel Advanced Tinkering. I've worked on a few projects related to chemistry, electronics, and lately, a lot on vacuum and high vacuum. The various types of vacuum pumps (oil or mercury diffusion pumps, turbomolecular pumps, titanium sublimation pumps, rotary vane pumps, membrane pumps, etc.) and the physics behind them are fascinating. In my vacuum chamber, I've already evaporated various metals like aluminum, titanium, silver, copper, and chromium to coat surfaces like glass or plastic. First and foremost, I want to emphasize that I am by no means an expert. My expertise lies more in chemistry, and I don't have formal training in many of the areas I cover in my videos. But I believe the appeal lies precisely in acquiring new skills and knowledge. Thanks to the internet, there's a unique opportunity to connect with experts and enthusiasts from various fields and learn from each other. And I hope today will be a day where we can learn from each other!![]() Dan Maloney 3:05 PM"Titanium sublimation" - that's one I've never heard of

Dan Maloney 3:05 PM"Titanium sublimation" - that's one I've never heard of![]() Allen 3:06 PMlike an ion pump?

Allen 3:06 PMlike an ion pump?![]() AdvancedTinkering 3:08 PMHow this type of pump works could actually be observed when I evaporated titanium in the chamber to coat a glass pane. The titanium becomes gaseous and then deposits as a thin film on the next surface. Since titanium (without an oxide layer) is highly reactive, it reacts with the remaining gas molecules in the vacuum, binds them, and thus reduces the pressure.

AdvancedTinkering 3:08 PMHow this type of pump works could actually be observed when I evaporated titanium in the chamber to coat a glass pane. The titanium becomes gaseous and then deposits as a thin film on the next surface. Since titanium (without an oxide layer) is highly reactive, it reacts with the remaining gas molecules in the vacuum, binds them, and thus reduces the pressure.![]() AdvancedTinkering 3:09 PMThis is a pump principle that can only be used at very low pressures.

AdvancedTinkering 3:09 PMThis is a pump principle that can only be used at very low pressures.![]() AdvancedTinkering 3:09 PMJust like a Diffusion Pump can only be used at lower pressures ^^

AdvancedTinkering 3:09 PMJust like a Diffusion Pump can only be used at lower pressures ^^![]() Thomas Shaddack 3:10 PMRandom thought I am entertaining for some time. Could a homemade vacuum tube have integrated ion/titanium pump? Suck it out with something conventional/common/available, seal, then put it into magnetic field and run high voltage through the dedicated electrodes and finish the suck? Could also be used to "top up" the vacuum later after the inevitable outgassing and microleaks do their job.

Thomas Shaddack 3:10 PMRandom thought I am entertaining for some time. Could a homemade vacuum tube have integrated ion/titanium pump? Suck it out with something conventional/common/available, seal, then put it into magnetic field and run high voltage through the dedicated electrodes and finish the suck? Could also be used to "top up" the vacuum later after the inevitable outgassing and microleaks do their job.![]() Thomas Shaddack 3:10 PMVariation on a getter.

Thomas Shaddack 3:10 PMVariation on a getter.![]() Dan Maloney 3:11 PMInteresting. Do methods like that perform better at scavenging oxygen or nitrogen? Seems like both, since there TiN and TiO2. But maybe it performs better for oxygen since each Ti ion takes out two oxygens?

Dan Maloney 3:11 PMInteresting. Do methods like that perform better at scavenging oxygen or nitrogen? Seems like both, since there TiN and TiO2. But maybe it performs better for oxygen since each Ti ion takes out two oxygens?![]() dmoisan 3:12 PMThe GE Talaria projection tube had a built-in ion gauge and some absorbent rocks in the tube to get the leftover gas from the oil film that it needed to diffract the electron beam and form an image. The most fascinating display tech ever invented.

dmoisan 3:12 PMThe GE Talaria projection tube had a built-in ion gauge and some absorbent rocks in the tube to get the leftover gas from the oil film that it needed to diffract the electron beam and form an image. The most fascinating display tech ever invented.![]() AdvancedTinkering 3:13 PM@Thomas Shaddack I'm not sure. There may be getter materials, that contain titanium.

AdvancedTinkering 3:13 PM@Thomas Shaddack I'm not sure. There may be getter materials, that contain titanium.![]() Allen 3:13 PMWhat types of seals are you using? I was always told 10^-6 torr is about as good as you can get with o-rings

Allen 3:13 PMWhat types of seals are you using? I was always told 10^-6 torr is about as good as you can get with o-rings![]() AdvancedTinkering 3:14 PM@Dan Maloney I honestly can't say for sure. As far as I know, oxygen is easier to bind, simply because of its higher reactivity

AdvancedTinkering 3:14 PM@Dan Maloney I honestly can't say for sure. As far as I know, oxygen is easier to bind, simply because of its higher reactivity![]() AdvancedTinkering 3:18 PM@Allen I use KF flanges, so O-ring seals. CF (copper) seals would indeed be better, as you mentioned. However, if you frequently open and rebuild the chamber, it quickly becomes expensive since theoretically, you should only use the copper seals once. Of course, this also depends on the number/size of the O-rings and how good your pump is. With my large turbomolecular pump, I have already reached the 10^-7 Torr range, even without baking out the chamber.

AdvancedTinkering 3:18 PM@Allen I use KF flanges, so O-ring seals. CF (copper) seals would indeed be better, as you mentioned. However, if you frequently open and rebuild the chamber, it quickly becomes expensive since theoretically, you should only use the copper seals once. Of course, this also depends on the number/size of the O-rings and how good your pump is. With my large turbomolecular pump, I have already reached the 10^-7 Torr range, even without baking out the chamber.![]() dmoisan 3:18 PMHow many stages of pump?

dmoisan 3:18 PMHow many stages of pump?![]() Allen 3:19 PMOh! quite good! :) Yes, copper can get expensive. Back in the day they used indium wire seals... no idea if that might work. Helicoflex can be used in place of o-ring, but requires mirror finish in groove

Allen 3:19 PMOh! quite good! :) Yes, copper can get expensive. Back in the day they used indium wire seals... no idea if that might work. Helicoflex can be used in place of o-ring, but requires mirror finish in groove![]() Thomas Shaddack 3:19 PMCan a low-melt solder be used for the seals (between metal parts)? Put in place, heat with induction or with an embedded heater, melt, wet, cool?

Thomas Shaddack 3:19 PMCan a low-melt solder be used for the seals (between metal parts)? Put in place, heat with induction or with an embedded heater, melt, wet, cool?![]() AdvancedTinkering 3:19 PM@dmoisan I have a rotary vane roughing pump and a turbomolecular pump.

AdvancedTinkering 3:19 PM@dmoisan I have a rotary vane roughing pump and a turbomolecular pump.![]() Erhannis 3:20 PMI dislike maintenance, and don't really want to be swapping out my rotary vane roughing pump's vacuum oil every few days like it feels like I'm supposed to. How often do you change your roughing pump oil? Or, do you know of another type of roughing pump that is sufficient (and still obtainable for a hobbyist) that doesn't need much maintenance?

Erhannis 3:20 PMI dislike maintenance, and don't really want to be swapping out my rotary vane roughing pump's vacuum oil every few days like it feels like I'm supposed to. How often do you change your roughing pump oil? Or, do you know of another type of roughing pump that is sufficient (and still obtainable for a hobbyist) that doesn't need much maintenance?![]() AdvancedTinkering 3:20 PMYes, indium or even solder can be used. I think applied science sealed a penning gauge with solder (but had some problems with the flux migrating into the vacuum over time)

AdvancedTinkering 3:20 PMYes, indium or even solder can be used. I think applied science sealed a penning gauge with solder (but had some problems with the flux migrating into the vacuum over time)![]() Erhannis 3:21 PM(I did once have a problem where my roughing pump got rusty, I think; oil went brown and I got a new pump because I no longer trusted it)

Erhannis 3:21 PM(I did once have a problem where my roughing pump got rusty, I think; oil went brown and I got a new pump because I no longer trusted it)![]() Allen 3:21 PMOooo... are you making your own magnetron?

Allen 3:21 PMOooo... are you making your own magnetron?![]() Allen 3:22 PMIt can be done! :)

Allen 3:22 PMIt can be done! :)![]() AdvancedTinkering 3:24 PM@Erhannis Both questions depend on a lot of different factors. If you don't draw any dirt into your rotary vane pump, you hardly ever need to change the oil. At most, you might need to top it up occasionally. I'm not exactly sure what the operating manuals specify for oil change intervals. Whether you can use a different pump type depends on your high vacuum pump. Newer turbomolecular pumps can even run with a membrane pump as a backing pump.

AdvancedTinkering 3:24 PM@Erhannis Both questions depend on a lot of different factors. If you don't draw any dirt into your rotary vane pump, you hardly ever need to change the oil. At most, you might need to top it up occasionally. I'm not exactly sure what the operating manuals specify for oil change intervals. Whether you can use a different pump type depends on your high vacuum pump. Newer turbomolecular pumps can even run with a membrane pump as a backing pump.![]() JStocke12 3:24 PMWho are the best suppliers for high vacuum equipment? What is typically available in the price range for a hobbyist?

JStocke12 3:24 PMWho are the best suppliers for high vacuum equipment? What is typically available in the price range for a hobbyist?![]() AdvancedTinkering 3:25 PM@Allen Yes :) I designed a Magnetron a few weeks/months ago and just got the parts machined (I unfortunately don't own a lathe or mill). Im currently building the power supply. I hope to be able to test it next week

AdvancedTinkering 3:25 PM@Allen Yes :) I designed a Magnetron a few weeks/months ago and just got the parts machined (I unfortunately don't own a lathe or mill). Im currently building the power supply. I hope to be able to test it next week![]() Allen 3:26 PMAwesome!

Allen 3:26 PMAwesome!![]() dmoisan 3:26 PMWhat will be on the other end of the mag?

dmoisan 3:26 PMWhat will be on the other end of the mag?![]() AdvancedTinkering 3:26 PM@JStocke12 Used equipment is the way to go. Almost everything new is way to expensive for a hobbyist

AdvancedTinkering 3:26 PM@JStocke12 Used equipment is the way to go. Almost everything new is way to expensive for a hobbyist![]() AdvancedTinkering 3:27 PMTake a look at ebay and similar sites regularly and you will find some good deals

AdvancedTinkering 3:27 PMTake a look at ebay and similar sites regularly and you will find some good deals![]() AdvancedTinkering 3:28 PMI got my Pfeiffer rotary vane pump for 200 Euros. And it was almost new.

AdvancedTinkering 3:28 PMI got my Pfeiffer rotary vane pump for 200 Euros. And it was almost new.![]() Machinist.Mage 3:28 PMFor other hobbies, we have the standard introduction projects: soldering, benchy, turner cube, etc... What is a good introduction project to high vacuum in your mind?

Machinist.Mage 3:28 PMFor other hobbies, we have the standard introduction projects: soldering, benchy, turner cube, etc... What is a good introduction project to high vacuum in your mind?![]() Dan Maloney 3:28 PMWhen budget time rolls around, companies and universities make sure they use up every last dime so they don't get cut next year. That's why practically new stuff ends up on the secondary market.

Dan Maloney 3:28 PMWhen budget time rolls around, companies and universities make sure they use up every last dime so they don't get cut next year. That's why practically new stuff ends up on the secondary market.![]() Allen 3:28 PMIf you want to make a poor-man's knudsen cell, look at Tempco Heatercoil and a steel vessel with an aperture... it doesn't have to be pretty. (some materials effuse better than sputter)- then you can co-deposit!

Allen 3:28 PMIf you want to make a poor-man's knudsen cell, look at Tempco Heatercoil and a steel vessel with an aperture... it doesn't have to be pretty. (some materials effuse better than sputter)- then you can co-deposit!![]() Erhannis 3:29 PM@AdvancedTinkering Huh, interesting. I'd been told that moisture from the air gets in the oil and rusts your pump. Mine did rust, but I can't guarantee I wasn't like, boiling water with it or something haha. I did with GREAT effort freeze dry some stuff, and man the cryo trap was a pain to keep cold, so much dry ice Re: mill/lathe, you wouldn't happen to live near Ohio, would you? I have a mini cnc lathe and mini cnc mill you could use, haha.

Erhannis 3:29 PM@AdvancedTinkering Huh, interesting. I'd been told that moisture from the air gets in the oil and rusts your pump. Mine did rust, but I can't guarantee I wasn't like, boiling water with it or something haha. I did with GREAT effort freeze dry some stuff, and man the cryo trap was a pain to keep cold, so much dry ice Re: mill/lathe, you wouldn't happen to live near Ohio, would you? I have a mini cnc lathe and mini cnc mill you could use, haha.![]() Thomas Shaddack 3:31 PMAre there any 3d printable materials suitable for high vacuum? Hightechs like PVDF?

Thomas Shaddack 3:31 PMAre there any 3d printable materials suitable for high vacuum? Hightechs like PVDF?![]() Thomas Shaddack 3:32 PMThere are sinterable-metal printer filaments that after thermal processing yield copper, bronze, stainless, inconel...

Thomas Shaddack 3:32 PMThere are sinterable-metal printer filaments that after thermal processing yield copper, bronze, stainless, inconel...![]() AdvancedTinkering 3:32 PM@Shane Hmm... It's hard to say. The question is whether you have something specific in mind that you want to achieve with the high vacuum. If so, I would suggest breaking down this project into small stages that you can achieve sequentially on the way to your goal. If it's simply about reaching high vacuum, I would start with a regular vacuum first. And that usually begins with a pump. For example, you could generate gas discharges in the "vacuum." With a neon power supply and a glass tube or bulb, you can already create beautiful gas discharges.

AdvancedTinkering 3:32 PM@Shane Hmm... It's hard to say. The question is whether you have something specific in mind that you want to achieve with the high vacuum. If so, I would suggest breaking down this project into small stages that you can achieve sequentially on the way to your goal. If it's simply about reaching high vacuum, I would start with a regular vacuum first. And that usually begins with a pump. For example, you could generate gas discharges in the "vacuum." With a neon power supply and a glass tube or bulb, you can already create beautiful gas discharges.![]() AdvancedTinkering 3:34 PM

AdvancedTinkering 3:34 PM![]()

![]() AdvancedTinkering 3:34 PMMy Logo is a gas discharge for example

AdvancedTinkering 3:34 PMMy Logo is a gas discharge for example![]() JStocke12 3:35 PMI tried to build my own cathode ray tube using a rotary vane pump, and I got a little electric discharge but no nice beam. How do you stay safe around high voltage?

JStocke12 3:35 PMI tried to build my own cathode ray tube using a rotary vane pump, and I got a little electric discharge but no nice beam. How do you stay safe around high voltage?![]() AdvancedTinkering 3:37 PM@Erhannis Rotary vane pumps usually have a gas ballast that you can open to remove moisture from the oil. But if you don't have a cold trap and, for example, freeze-dry, the pump will eventually rust, haha. I live in Germany. So unfortunately, it's a bit too far away to just drop by, :D But thanks for the offer!

AdvancedTinkering 3:37 PM@Erhannis Rotary vane pumps usually have a gas ballast that you can open to remove moisture from the oil. But if you don't have a cold trap and, for example, freeze-dry, the pump will eventually rust, haha. I live in Germany. So unfortunately, it's a bit too far away to just drop by, :D But thanks for the offer!![]() Dan Maloney 3:37 PMhttps://hackaday.com/2024/01/06/an-adjustable-high-voltage-power-supply-built-with-safety-in-mind/

Dan Maloney 3:37 PMhttps://hackaday.com/2024/01/06/an-adjustable-high-voltage-power-supply-built-with-safety-in-mind/![]() AdvancedTinkering 3:39 PM@JStocke12 That's a very comprehensive question, and I'm probably not qualified enough to provide an exact answer. However, there are many good resources available online for that. Perhaps this Instructables article could be a good starting point: https://www.instructables.com/Work-safely-with-high-voltage/

AdvancedTinkering 3:39 PM@JStocke12 That's a very comprehensive question, and I'm probably not qualified enough to provide an exact answer. However, there are many good resources available online for that. Perhaps this Instructables article could be a good starting point: https://www.instructables.com/Work-safely-with-high-voltage/![]() AdvancedTinkering 3:42 PM@Thomas Shaddack As far as I know, all FDM-printed plastics have the issue of small voids or air inclusions. I could imagine that SLA-printed high-tech plastics might be suitable for high vacuum purposes, but I can't say for sure. It also depends on what level of vacuum you want to achieve. Generally, though, plastics (at least most of them) are a bad idea for high vacuum applications, especially 3D-printed ones.

AdvancedTinkering 3:42 PM@Thomas Shaddack As far as I know, all FDM-printed plastics have the issue of small voids or air inclusions. I could imagine that SLA-printed high-tech plastics might be suitable for high vacuum purposes, but I can't say for sure. It also depends on what level of vacuum you want to achieve. Generally, though, plastics (at least most of them) are a bad idea for high vacuum applications, especially 3D-printed ones.![]() Thomas Shaddack 3:42 PMRe high voltage, we did some experiments with using candle gel as a reworkable potting compound. Stays in place unless melted, so won't spill into the carpet and cause wrath of the resident female to descend upon thine noggin. Can be removed with relative ease, even a hotplate of the 3d printer will do.

Thomas Shaddack 3:42 PMRe high voltage, we did some experiments with using candle gel as a reworkable potting compound. Stays in place unless melted, so won't spill into the carpet and cause wrath of the resident female to descend upon thine noggin. Can be removed with relative ease, even a hotplate of the 3d printer will do.![]() Thomas Shaddack 3:43 PMAdvantages of both oil and epoxy.

Thomas Shaddack 3:43 PMAdvantages of both oil and epoxy.![]() AdvancedTinkering 3:44 PM@Allen I have used a similar principle to build my atomic beam furnace (there is also a video about it) which is basically a knudsen cell. Unfortunately, I have not been successful in producing a visible potassium or silver film with it so far.

AdvancedTinkering 3:44 PM@Allen I have used a similar principle to build my atomic beam furnace (there is also a video about it) which is basically a knudsen cell. Unfortunately, I have not been successful in producing a visible potassium or silver film with it so far.![]() Thomas Shaddack 3:44 PMWhat about glass-metal seals? Any tricks? Ceramics-metal? Some exotic active brazes that can wet ceramics?

Thomas Shaddack 3:44 PMWhat about glass-metal seals? Any tricks? Ceramics-metal? Some exotic active brazes that can wet ceramics?![]() Erhannis 3:45 PM( @Thomas Shaddack re: FDM, the thing about voids sounds true, but if you were to try it anyway, https://en.wikipedia.org/wiki/Materials_for_use_in_vacuum says that at least material-wise PEEK has relatively low outgassing, and there are PEEK filaments, though expensive )

Erhannis 3:45 PM( @Thomas Shaddack re: FDM, the thing about voids sounds true, but if you were to try it anyway, https://en.wikipedia.org/wiki/Materials_for_use_in_vacuum says that at least material-wise PEEK has relatively low outgassing, and there are PEEK filaments, though expensive )![]() Thomas Shaddack 3:45 PMTitanium powder mixed into regular brazing paste, so it dissolves in ordinary braze and turns it into active?

Thomas Shaddack 3:45 PMTitanium powder mixed into regular brazing paste, so it dissolves in ordinary braze and turns it into active?![]() Thomas Shaddack 3:45 PM@Erhannis I wrote that article!

Thomas Shaddack 3:45 PM@Erhannis I wrote that article!![]() AdvancedTinkering 3:46 PM

AdvancedTinkering 3:46 PM![]()

![]() Erhannis 3:46 PM@Thomas Shaddack Oh hahahaha! Excellent resource, thanks!

Erhannis 3:46 PM@Thomas Shaddack Oh hahahaha! Excellent resource, thanks!![]() AdvancedTinkering 3:47 PM@Allen That was the Atomic beam furnace design. The outside gets heated and in front of the opening is a collimator and an optical flit to create a narrow beam.

AdvancedTinkering 3:47 PM@Allen That was the Atomic beam furnace design. The outside gets heated and in front of the opening is a collimator and an optical flit to create a narrow beam.![]() AdvancedTinkering 3:49 PMGlass/metal seals are tricky. I haven't brazed any ceramics yet. I've only melted relatively thin tungsten electrodes into glass.

AdvancedTinkering 3:49 PMGlass/metal seals are tricky. I haven't brazed any ceramics yet. I've only melted relatively thin tungsten electrodes into glass.![]() Thomas Shaddack 3:50 PMI heard about a sol-gel trick for mitigating microcracks along the seals. Let some silanol soak in, and form glass in there.

Thomas Shaddack 3:50 PMI heard about a sol-gel trick for mitigating microcracks along the seals. Let some silanol soak in, and form glass in there.![]() Dan Maloney 3:50 PMDalibor Farny has been doing some experiments with glass-metal seals. That's for his Nixie tubes, though -- not sure that's exactly the same class of vacuum

Dan Maloney 3:50 PMDalibor Farny has been doing some experiments with glass-metal seals. That's for his Nixie tubes, though -- not sure that's exactly the same class of vacuum![]() Thomas Shaddack 3:50 PMNixies are gas-filled.

Thomas Shaddack 3:50 PMNixies are gas-filled.![]() AdvancedTinkering 3:51 PMI love Dalibor Farnys channel. His videos are great

AdvancedTinkering 3:51 PMI love Dalibor Farnys channel. His videos are great![]() AdvancedTinkering 3:51 PM@Thomas Shaddack But the seals he is used are definitely vacuum tight

AdvancedTinkering 3:51 PM@Thomas Shaddack But the seals he is used are definitely vacuum tight![]() AdvancedTinkering 3:51 PM*using

AdvancedTinkering 3:51 PM*using![]() AdvancedTinkering 3:52 PMI think he also tested it in one video. If i remember correctly, he sealed off an ion gauge and tested it a few weeks later

AdvancedTinkering 3:52 PMI think he also tested it in one video. If i remember correctly, he sealed off an ion gauge and tested it a few weeks later![]() Thomas Shaddack 3:54 PMThat could be a good way to test toys. How difficult is to make an ion gauge? Or, later, have an integrated module of ion pump and ion gauge, for tube diagnostics and "topping up"?

Thomas Shaddack 3:54 PMThat could be a good way to test toys. How difficult is to make an ion gauge? Or, later, have an integrated module of ion pump and ion gauge, for tube diagnostics and "topping up"?![]() AdvancedTinkering 3:54 PMAh, I was wrong. He tested if borax is a suitable coating: https://www.youtube.com/watch?v=ylmuYxDzRvI

AdvancedTinkering 3:54 PMAh, I was wrong. He tested if borax is a suitable coating: https://www.youtube.com/watch?v=ylmuYxDzRvI![]() Dan Maloney 3:54 PMhttps://www.youtube.com/watch?v=3nsg0q2Pz6g

Dan Maloney 3:54 PMhttps://www.youtube.com/watch?v=3nsg0q2Pz6g![]() Dan Maloney 3:54 PMOops -- still a good video

Dan Maloney 3:54 PMOops -- still a good video![]() AdvancedTinkering 3:55 PMGlass Ion Gauges are just beautiful :)

AdvancedTinkering 3:55 PMGlass Ion Gauges are just beautiful :)![]() Thomas Shaddack 3:56 PMRandom thought. Microwave postheating of a propane flame, to avoid the need for oxygen for the torch. Pump extra energy into the plasma instead of generating it within.

Thomas Shaddack 3:56 PMRandom thought. Microwave postheating of a propane flame, to avoid the need for oxygen for the torch. Pump extra energy into the plasma instead of generating it within.![]() Erhannis 3:57 PMOn the topic of gauges, I've frequently wondered about the accuracy of my ebay gauges. What kinds of absolute measurements could be made, to calibrate gauges, without using (significant) 3rd-party tools? Like, by measuring breakdown distance at mains voltage, or using the triple point of water, or something. Maybe a range of phenomena for different pressure ranges.

Erhannis 3:57 PMOn the topic of gauges, I've frequently wondered about the accuracy of my ebay gauges. What kinds of absolute measurements could be made, to calibrate gauges, without using (significant) 3rd-party tools? Like, by measuring breakdown distance at mains voltage, or using the triple point of water, or something. Maybe a range of phenomena for different pressure ranges.![]() AdvancedTinkering 4:02 PMAll calibration methods I know either require a reference or use complex setups. I don't believe one can reliably calibrate a vacuum gauge, for example, with the triple point of water. I read an interesting article about other methods that are typically used. Let me quickly find it.

AdvancedTinkering 4:02 PMAll calibration methods I know either require a reference or use complex setups. I don't believe one can reliably calibrate a vacuum gauge, for example, with the triple point of water. I read an interesting article about other methods that are typically used. Let me quickly find it.![]() AdvancedTinkering 4:03 PMhttps://www.leybold.com/en-ie/knowledge/vacuum-fundamentals/vacuum-measurement/how-to-calibrate-vacuum-gauges

AdvancedTinkering 4:03 PMhttps://www.leybold.com/en-ie/knowledge/vacuum-fundamentals/vacuum-measurement/how-to-calibrate-vacuum-gauges![]() Erhannis 4:03 PMThanks; I'll give it a look

Erhannis 4:03 PMThanks; I'll give it a look![]() Dan Maloney 4:04 PMOK, we're up past the top of the hour, so we're going to have to wrap things up. I want to thank Niklas for his time today, really cool topic and a lot of great discussion. Great questions, too -- thanks to everyone!

Dan Maloney 4:04 PMOK, we're up past the top of the hour, so we're going to have to wrap things up. I want to thank Niklas for his time today, really cool topic and a lot of great discussion. Great questions, too -- thanks to everyone!![]() AdvancedTinkering 4:05 PM@Erhannis Might also be interesting for you

AdvancedTinkering 4:05 PM@Erhannis Might also be interesting for you![]() Erhannis 4:05 PMIf anybody's near Ohio and wants to collaborate on vacuum stuff, I've got some equipment and space; hit me up haha

Erhannis 4:05 PMIf anybody's near Ohio and wants to collaborate on vacuum stuff, I've got some equipment and space; hit me up haha![]() Erhannis 4:05 PM@AdvancedTinkering Thanks!

Erhannis 4:05 PM@AdvancedTinkering Thanks!![]() JStocke12 4:06 PM@AdvancedTinkering Thank you!

JStocke12 4:06 PM@AdvancedTinkering Thank you!![]() AdvancedTinkering 4:06 PMThanks for having me Dan! And thanks to everyone for participating.

AdvancedTinkering 4:06 PMThanks for having me Dan! And thanks to everyone for participating.![]() Thomas Shaddack 4:07 PMGood talk, thanks!

Thomas Shaddack 4:07 PMGood talk, thanks!![]() Dan Maloney 4:07 PMYou bet, my pleasure! Looking forward to more cool videos (no pressure)

Dan Maloney 4:07 PMYou bet, my pleasure! Looking forward to more cool videos (no pressure)![]() Nicolas Tremblay 4:07 PMThanks Niklas

Nicolas Tremblay 4:07 PMThanks Niklas![]() Dan Maloney 4:07 PMTranscript coming up. Thanks everyone!

Dan Maloney 4:07 PMTranscript coming up. Thanks everyone! Lutetium

Lutetium