![]() Hey everybody! I'm Anthony Kouttron, I'm an electrical engineer and big camera nerd. I have been repairing cameras as a hobby since ~2010 ever since mirrorless cameras began supplanting the 3CCD potato cams of the early 2000s. I've repaired full frame consumer cameras, cinema cameras, cinema accessories, and both zoom / prime photo lenses. Shoot me any questions you have involving camera repair, design troubleshooting etc...

Hey everybody! I'm Anthony Kouttron, I'm an electrical engineer and big camera nerd. I have been repairing cameras as a hobby since ~2010 ever since mirrorless cameras began supplanting the 3CCD potato cams of the early 2000s. I've repaired full frame consumer cameras, cinema cameras, cinema accessories, and both zoom / prime photo lenses. Shoot me any questions you have involving camera repair, design troubleshooting etc...

|

![]() Hey Anthony, welcome aboard!

Hey Anthony, welcome aboard!

|

![]() Thanks!

Thanks!

|

![]() We'll give it a few more minutes to let people filter in then we'll kick it off

We'll give it a few more minutes to let people filter in then we'll kick it off

|

![]() OK, hello everyone and welcome to the Hack Chat! I'm Dan, I'll be moderating today along with Dusan as we welcome Anthony Kouttron to the Hack Chat to talk about busted cameras and lenses and how to make them un-busted

OK, hello everyone and welcome to the Hack Chat! I'm Dan, I'll be moderating today along with Dusan as we welcome Anthony Kouttron to the Hack Chat to talk about busted cameras and lenses and how to make them un-busted

|

![]() Hi Dan

Hi Dan

|

![]() welcome everyone!

welcome everyone!

|

![]() Thanks for joining us today, Anthony. THe reason I asked you on with us today was that cool repair of the Sigma lens that you pulled off. I thought it had a lot of neat tips and tricks:

Thanks for joining us today, Anthony. THe reason I asked you on with us today was that cool repair of the Sigma lens that you pulled off. I thought it had a lot of neat tips and tricks:

|

![]() Glad to be here!

Glad to be here!

|

![]() https://hackaday.com/2024/05/13/broken-lens-provides-deep-dive-into-camera-repair/!

https://hackaday.com/2024/05/13/broken-lens-provides-deep-dive-into-camera-repair/!

|

![]() Welcome Anthony!

Welcome Anthony!

|

![]() And I harped a bit about how much camera repairs scare me, but it's true -- I always shied away from trying to fix any of my SLR gear, even though I'll try fixing most anything else. Is that a rational fear?

And I harped a bit about how much camera repairs scare me, but it's true -- I always shied away from trying to fix any of my SLR gear, even though I'll try fixing most anything else. Is that a rational fear?

|

![]() The biggest risk when tearing apart a camera is the flash trigger circuit and the sensor block.

The biggest risk when tearing apart a camera is the flash trigger circuit and the sensor block.

|

![]() When disassembling a camera with a flash, the integrated capacitor will hold charge for a long time. There is not usually a bleed resistor

When disassembling a camera with a flash, the integrated capacitor will hold charge for a long time. There is not usually a bleed resistor

|

![]() so you have to properly discharge the capacitor before continuing with the teardown. The camera manufacturers actually talk about this on the first page of the service manual. Taking a 5w resistor and a few jumper leads takes care of it no problem

so you have to properly discharge the capacitor before continuing with the teardown. The camera manufacturers actually talk about this on the first page of the service manual. Taking a 5w resistor and a few jumper leads takes care of it no problem

|

![]() but it is an essential step. I forgot to discharge the flash capacitor one time and my right angle tweezers touched the wrong place. my poor knipex tweezer tips were no more

but it is an essential step. I forgot to discharge the flash capacitor one time and my right angle tweezers touched the wrong place. my poor knipex tweezer tips were no more

|

![]() In regards to the sensor, if the camera does not have 5-axis stabilization, there are usually 4-6 spring loaded screws that are adjusted to make the sensor planar to the lens bayonet

In regards to the sensor, if the camera does not have 5-axis stabilization, there are usually 4-6 spring loaded screws that are adjusted to make the sensor planar to the lens bayonet

|

![]() What is the proper way to discharge the capacitor once identified?

What is the proper way to discharge the capacitor once identified?

|

![]() these screws are calibrated at the factory before the camera is shipped. you do not want to unscrew these are you will not be able to verify sensor flatness without speciality tools. I'm sure it can be done, but you will likely need a light projector and some kind of light measuring device

these screws are calibrated at the factory before the camera is shipped. you do not want to unscrew these are you will not be able to verify sensor flatness without speciality tools. I'm sure it can be done, but you will likely need a light projector and some kind of light measuring device

|

![]() Hi Dan Hi Anthony, I've been collecting film cameras with a bit of repair for a while. I learned a lot from the books of Thomas Tomosy.

Saddened to learn he passed in 2023

https://vancouversunandprovince.remembering.ca/obituary/thomas-tomosy-1088995731

Hi Dan Hi Anthony, I've been collecting film cameras with a bit of repair for a while. I learned a lot from the books of Thomas Tomosy.

Saddened to learn he passed in 2023

https://vancouversunandprovince.remembering.ca/obituary/thomas-tomosy-1088995731

|

![]() I use a 10ohm 5w resistor with insulated leads. I simply put the resistor across the capacitor and it safely discharges the cap

I use a 10ohm 5w resistor with insulated leads. I simply put the resistor across the capacitor and it safely discharges the cap

|

![]() Thanks for hosting a hack chat, whats the best series of cameras in terms of repairability?

Thanks for hosting a hack chat, whats the best series of cameras in terms of repairability?

|

![]() obviously do not touch any bare metal wire leads, make sure the leads are indulated

obviously do not touch any bare metal wire leads, make sure the leads are indulated

|

![]() I've got a Canon A1 that I left the battery in for too long and it leaked. I've heard the battery box replacement is pretty straightforward, so I should probably start with that. The camera has a lot of memories for me

I've got a Canon A1 that I left the battery in for too long and it leaked. I've heard the battery box replacement is pretty straightforward, so I should probably start with that. The camera has a lot of memories for me

|

![]()

![]()

|

![]() Hey @Andrew Smith Thanks for the info! I did not know him personally, but I'll check out his work! Camera repair is an interesting industry and it is even thereputic. Yes it can get involved, but it's fun.

Hey @Andrew Smith Thanks for the info! I did not know him personally, but I'll check out his work! Camera repair is an interesting industry and it is even thereputic. Yes it can get involved, but it's fun.

|

![]() I started repairing lenses by tearing down the many 1970s clone lenses that were available at retailers like jc.penny, sears etc...

I started repairing lenses by tearing down the many 1970s clone lenses that were available at retailers like jc.penny, sears etc...

|

![]() they were usually dubious quality but similar build construction was found on fancier lenses. It's a way where you don't have to care about making mistakes on a lens with little value

they were usually dubious quality but similar build construction was found on fancier lenses. It's a way where you don't have to care about making mistakes on a lens with little value

|

![]() When starting with lens and body deconstruction, did you purchase dead cameras and lenses to do so, or were your encounters more based on "Wow my device is dead and I guess I should try to fix it"

When starting with lens and body deconstruction, did you purchase dead cameras and lenses to do so, or were your encounters more based on "Wow my device is dead and I guess I should try to fix it"

|

![]() YOu can pick up lenses like that for super cheap online and in the few remaining IRL camera stores

YOu can pick up lenses like that for super cheap online and in the few remaining IRL camera stores

|

![]() @transistor--man That's a tough question, most of the manufacturers have service manuals, but olympus and fujifilm in particular do not have many service manuals floating around on the interwebs, which makes the repairs more difficult.

@transistor--man That's a tough question, most of the manufacturers have service manuals, but olympus and fujifilm in particular do not have many service manuals floating around on the interwebs, which makes the repairs more difficult.

|

![]() I've got a sticky Mamiya-Sekor 80mm lens for the Mamiya C330 TLR

Have you worked on those before? Any tips or suggestions?

I've got a sticky Mamiya-Sekor 80mm lens for the Mamiya C330 TLR

Have you worked on those before? Any tips or suggestions?

|

![]() the timing of this hack chat is apropos - my 200-500 just stopped being able to zoom in. Apparently it's a common problem and an easy fix.

the timing of this hack chat is apropos - my 200-500 just stopped being able to zoom in. Apparently it's a common problem and an easy fix.

|

![]() @ump A bit of both! I came across a lot of 1970s/ 80s film lenses in poor condition and I started tearing these down and servicing them back to working order. It's amazing how old grease will make an aperture completely stuck.

@ump A bit of both! I came across a lot of 1970s/ 80s film lenses in poor condition and I started tearing these down and servicing them back to working order. It's amazing how old grease will make an aperture completely stuck.

|

![]() ive had issues with cameras in the cold, are there ways to keep them working on cold nights of astro photos?

ive had issues with cameras in the cold, are there ways to keep them working on cold nights of astro photos?

|

![]() @Evan 200-500mm from which vendor?

@Evan 200-500mm from which vendor?

|

![]() nikon

nikon

|

![]() https://youtu.be/kvKOVVnlNak

https://youtu.be/kvKOVVnlNak

|

![]() @Andrew Smith I have not worked on any mamiya-sekor lenses yet but being leaf-shutter lenses, they are more complicated to service. Folks do service them though! THe sekor-c lenses are highly coveted lenses because they can cover medium-format sensors well. They are often rehoused by TLS, zero-optik etc...

@Andrew Smith I have not worked on any mamiya-sekor lenses yet but being leaf-shutter lenses, they are more complicated to service. Folks do service them though! THe sekor-c lenses are highly coveted lenses because they can cover medium-format sensors well. They are often rehoused by TLS, zero-optik etc...

|

![]() https://www.greenwoodcine.com/rentals/p/mamiya-sekor-tls-rehoused-ff-lenses

https://www.greenwoodcine.com/rentals/p/mamiya-sekor-tls-rehoused-ff-lenses

|

![]() has lens construction gotten better over time or worse? are newer lens's less accessible for repair?

has lens construction gotten better over time or worse? are newer lens's less accessible for repair?

|

![]() @transistor--man That's a good question. I'd say, overall, lens construction has improved. There were pain periods where the main manufacturers experimented with composites and non-glass reinforced plastics and yielded to broken lens mounts and collars, but in comparison to the very sloppy, very poorly machined lenses in the 1970s, lens construction has improved

@transistor--man That's a good question. I'd say, overall, lens construction has improved. There were pain periods where the main manufacturers experimented with composites and non-glass reinforced plastics and yielded to broken lens mounts and collars, but in comparison to the very sloppy, very poorly machined lenses in the 1970s, lens construction has improved

|

![]() what I will say is there is a stark contrast between proper cinema lens innerds vs consumer lenses.

what I will say is there is a stark contrast between proper cinema lens innerds vs consumer lenses.

|

![]() Do cinema lens's ever end up surplus? Ive only ever seen consumer stuff on ebay, but the large TV camera lens's are pretty rare

Do cinema lens's ever end up surplus? Ive only ever seen consumer stuff on ebay, but the large TV camera lens's are pretty rare

|

![]() cinema lenses often required parts to torqued town to specification and require the use of calibrated screwdrivers like the wiha TorqueVario Screwdrivers

cinema lenses often required parts to torqued town to specification and require the use of calibrated screwdrivers like the wiha TorqueVario Screwdrivers

|

![]() the mounts are torqued down like a car wheel. there are also offset cam lobes for fine adjustment of elements and lens assemblies in more expensive lenses that are not present on inexpensive consumer lenses

the mounts are torqued down like a car wheel. there are also offset cam lobes for fine adjustment of elements and lens assemblies in more expensive lenses that are not present on inexpensive consumer lenses

|

![]() "the very sloppy, very poorly machined lenses in the 1970s"

That was all I could afford ;-(

Although I did pick up a nice 135mm Canon lens used at a camera shop back in the 80s. Best lens I ever had. f 1.4, I think. Nice portrait lens

"the very sloppy, very poorly machined lenses in the 1970s"

That was all I could afford ;-(

Although I did pick up a nice 135mm Canon lens used at a camera shop back in the 80s. Best lens I ever had. f 1.4, I think. Nice portrait lens

|

![]() more attention to focus consistency is placed on cinema lenses like the zeiss master prime / supreme lenses. the lens helicoid will often be one CNC machined piece of brass with dampening bits to provide a very dampened but solid feel. Focus slop is not a desirable trait on any cinema lens.

more attention to focus consistency is placed on cinema lenses like the zeiss master prime / supreme lenses. the lens helicoid will often be one CNC machined piece of brass with dampening bits to provide a very dampened but solid feel. Focus slop is not a desirable trait on any cinema lens.

|

![]() I am newbie to the camera and lens repair, any suggestion on how to get started besides the books from Thomas Tomosy suggested by Andrew?

I am newbie to the camera and lens repair, any suggestion on how to get started besides the books from Thomas Tomosy suggested by Andrew?

|

![]() Is there precise range of image circle size defined for C mount lenses?

Is there precise range of image circle size defined for C mount lenses?

|

![]() @Dan Maloney Hahaha. Let me rephrase that: there was a great divergence in lens mechanics between large lens manufacturers and the clone manufacturers in the 1970-80s. I had a "best" brand canon FL breach lock style lens. The lens was assembled in two aluminum halves that did not even line up when assembled properly and the threaded screw holes stripped if you looked at them the wrong way. The nikon, canon etc... lenses of the 1970s features far better assembly standards and did not rely on guessing alignment. there were proper machined sholders and threaded rings that held down lens elements. Ironically, canon K35 lenses from the 1970s are insanely desirable even though modern lenses are better in almost every way

@Dan Maloney Hahaha. Let me rephrase that: there was a great divergence in lens mechanics between large lens manufacturers and the clone manufacturers in the 1970-80s. I had a "best" brand canon FL breach lock style lens. The lens was assembled in two aluminum halves that did not even line up when assembled properly and the threaded screw holes stripped if you looked at them the wrong way. The nikon, canon etc... lenses of the 1970s features far better assembly standards and did not rely on guessing alignment. there were proper machined sholders and threaded rings that held down lens elements. Ironically, canon K35 lenses from the 1970s are insanely desirable even though modern lenses are better in almost every way

|

![]() @Ferdinand Sanchez C-mount lenses are tricky. There is quite the variability in image circle coverage and it facies from series to series and manufacturer. There is also the CS mount which is aimed at scientific applications and has a slightly larger image circle. Your best bet is to hunt down lens datasheets. They absolutely exist! Rodenstock / linos, schneider etc... all produce datasheets with mtf curves and image circle information

@Ferdinand Sanchez C-mount lenses are tricky. There is quite the variability in image circle coverage and it facies from series to series and manufacturer. There is also the CS mount which is aimed at scientific applications and has a slightly larger image circle. Your best bet is to hunt down lens datasheets. They absolutely exist! Rodenstock / linos, schneider etc... all produce datasheets with mtf curves and image circle information

|

![]() @Ferdinand Sanchez for example:

https://schneiderkreuznach.com/application/files/9716/7879/2629/JADE_28_16_C_1099214_datasheet.pdf

@Ferdinand Sanchez for example:

https://schneiderkreuznach.com/application/files/9716/7879/2629/JADE_28_16_C_1099214_datasheet.pdf

|

![]() @Ferdinand Sanchez I believe there were cinema specific cs lenses made by schneider or another large lens vendor, I forgot the name.

@Ferdinand Sanchez I believe there were cinema specific cs lenses made by schneider or another large lens vendor, I forgot the name.

|

![]() Any tips on dealing with loose focus grips? The rubber ring on one of my old primes is getting a bit loose.

Any tips on dealing with loose focus grips? The rubber ring on one of my old primes is getting a bit loose.

|

![]() @cho16888ol Absolutely! My two favorites are mikeno62 on youtube and listening into the duclos-lens livestreams. Matthew Duclos is incredibly knowledgeable on lens repair and at this point, has seen the inside of nearly every cinema lens in existence.

https://www.youtube.com/@mikeno62

@cho16888ol Absolutely! My two favorites are mikeno62 on youtube and listening into the duclos-lens livestreams. Matthew Duclos is incredibly knowledgeable on lens repair and at this point, has seen the inside of nearly every cinema lens in existence.

https://www.youtube.com/@mikeno62

|

![]() Anthony, have you serviced or come across radioactive glass?

I was shocked to learn my Super-Takumar 50mm F1.4 used Thoriated glass and sent my DIY geiger kit off the charts.

(I don't use it and would certainly never open it myself)

Anthony, have you serviced or come across radioactive glass?

I was shocked to learn my Super-Takumar 50mm F1.4 used Thoriated glass and sent my DIY geiger kit off the charts.

(I don't use it and would certainly never open it myself)

|

![]() @Anthony Kouttron Thank you! I am working on a action camera setup that uses M4/3 sensor, so i am hunting down quality wide angle C mount lens(of course not fisheye one - i am searching for low distortion one)

@Anthony Kouttron Thank you! I am working on a action camera setup that uses M4/3 sensor, so i am hunting down quality wide angle C mount lens(of course not fisheye one - i am searching for low distortion one)

|

![]() @Andrew Smith did you know you can un-yellow thoriated lens's with UV? https://richardhaw.com/2021/05/30/repair-bleaching-radiated-lenses/

@Andrew Smith did you know you can un-yellow thoriated lens's with UV? https://richardhaw.com/2021/05/30/repair-bleaching-radiated-lenses/

|

![]() @Evan Rubber grips are tricky. Rubber that has aged or become impregnated by oil is hard to recover back to original shape. I have not found a solution that works. My 12-35mm f2/8 lenses that I use from panasonic have the exact issue you state and I have not found a fix other than removing the rubber lens grip adding heatshrink below where the rubber ring goes and reinserting the stretched out rubber grip. The grip diameter will be larger, but it will at least not feel sloppy when in use. Digikey is a great resource for heatshrhink. Adhesive heatshrink works best. Take your time when selecting heatshrink sizes, it's easy to measure wrong :D. If the lens you have is still recent, buy a new grip from aliexpress / taobao

@Evan Rubber grips are tricky. Rubber that has aged or become impregnated by oil is hard to recover back to original shape. I have not found a solution that works. My 12-35mm f2/8 lenses that I use from panasonic have the exact issue you state and I have not found a fix other than removing the rubber lens grip adding heatshrink below where the rubber ring goes and reinserting the stretched out rubber grip. The grip diameter will be larger, but it will at least not feel sloppy when in use. Digikey is a great resource for heatshrhink. Adhesive heatshrink works best. Take your time when selecting heatshrink sizes, it's easy to measure wrong :D. If the lens you have is still recent, buy a new grip from aliexpress / taobao

|

![]() @Andrew Smith I have a few radioactive pentax lenses. They are fantastic to use and ironically I have not had to tear them down yet. I don't fuss over a bit of dust inside a 1970s-80s lens. Unless there is fungus or substantial internal problems with a film lens, I will not tear it down for a full "CLA" Clean, Lubricate and Adjustment

@Andrew Smith I have a few radioactive pentax lenses. They are fantastic to use and ironically I have not had to tear them down yet. I don't fuss over a bit of dust inside a 1970s-80s lens. Unless there is fungus or substantial internal problems with a film lens, I will not tear it down for a full "CLA" Clean, Lubricate and Adjustment

|

![]() @Andrew Smith I have too many other lenses calling for my attention :D

@Andrew Smith I have too many other lenses calling for my attention :D

|

![]()

![]()

|

![]() @transistor--man Yes I've seen that UV technique.

Mine is definitely yellowing

@transistor--man Yes I've seen that UV technique.

Mine is definitely yellowing

|

![]() @Andrew Smith woah

@Andrew Smith woah

|

![]() @transistor--man This technique is something I'd like to do myself! Don't tempt me to grab a few yellowing lenses....Oh well too late.

@transistor--man This technique is something I'd like to do myself! Don't tempt me to grab a few yellowing lenses....Oh well too late.

|

![]() 🤔 I wonder if the radiation makes fungus less likely

🤔 I wonder if the radiation makes fungus less likely

|

![]() or stronger

or stronger

|

![]() Thanks Anthony, thanks Dan.

Gotta run but will check back in the chat later. Cheers

Thanks Anthony, thanks Dan.

Gotta run but will check back in the chat later. Cheers

|

![]() @Andrew Smith Thanks for stopping in :D

@Andrew Smith Thanks for stopping in :D

|

![]() @Evan The 200-500 zoom repair you linked looks pretty straight forward and easy!. I'd go for it. The fellow sugests using electrical tape instead of the yellow looking tape nikon used

@Evan The 200-500 zoom repair you linked looks pretty straight forward and easy!. I'd go for it. The fellow sugests using electrical tape instead of the yellow looking tape nikon used

|

![]() no luck with that quick 200-500 repair process (none of the screws he mentioned seem loose), will have to research more, might have to take off the whole shroud

no luck with that quick 200-500 repair process (none of the screws he mentioned seem loose), will have to research more, might have to take off the whole shroud

|

![]() @Evan I would highly suggest not to use electrical tape for this application. It will become gummy after a week. Use doublesided 3m tape. Hmm.

@Evan I would highly suggest not to use electrical tape for this application. It will become gummy after a week. Use doublesided 3m tape. Hmm.

|

![]() it looks like kapton tape to me. I've got a roll of 1" kapton that I can use to replace it.

it looks like kapton tape to me. I've got a roll of 1" kapton that I can use to replace it.

|

![]() when I watched the video I thought he was talking about that tape being used to hold the rubber grip down, but as far as I can tell it's just single-sided tape that holds the little metal covers in place

when I watched the video I thought he was talking about that tape being used to hold the rubber grip down, but as far as I can tell it's just single-sided tape that holds the little metal covers in place

|

![]() @Evan I have not worked on that specific lens, but zoom lens repair can get hairy. The fellow made it seem like the kapton tape was doublesided. Zoom lenses often have many interlocking segments and they are not always accessible from one side of the lens

@Evan I have not worked on that specific lens, but zoom lens repair can get hairy. The fellow made it seem like the kapton tape was doublesided. Zoom lenses often have many interlocking segments and they are not always accessible from one side of the lens

|

![]() and the rubber grip is just held in place with friction

and the rubber grip is just held in place with friction

|

![]() yeah I'd go find a bunch more content before digging any further for sure.

yeah I'd go find a bunch more content before digging any further for sure.

|

![]() @Evan That makes sense. sometimes the front half of the lens is screwed in to the bayonet half, and the front lens beauty ring hides screws or a threaded collar

@Evan That makes sense. sometimes the front half of the lens is screwed in to the bayonet half, and the front lens beauty ring hides screws or a threaded collar

|

![]() @Evan in that case, you;ll need a lens spanner to disassemble the front element group or a cylindrical rubber grippy bit to remove the front lens facia. I linked a photo of what they look above.

@Evan in that case, you;ll need a lens spanner to disassemble the front element group or a cylindrical rubber grippy bit to remove the front lens facia. I linked a photo of what they look above.

|

![]() @Anthony Kouttron have you looked at the signaling for camera lens attachments, like M4/3 or E-Mounts?

@Anthony Kouttron have you looked at the signaling for camera lens attachments, like M4/3 or E-Mounts?

|

![]() Dan Maloney 2:51 PMHey Anthony, welcome aboard!Anthony Kouttron 2:52 PMThanks!

Dan Maloney 2:51 PMHey Anthony, welcome aboard!Anthony Kouttron 2:52 PMThanks!![]() Dan Maloney 2:53 PMWe'll give it a few more minutes to let people filter in then we'll kick it off

Dan Maloney 2:53 PMWe'll give it a few more minutes to let people filter in then we'll kick it off![]() Dan Maloney 3:00 PMOK, hello everyone and welcome to the Hack Chat! I'm Dan, I'll be moderating today along with Dusan as we welcome Anthony Kouttron to the Hack Chat to talk about busted cameras and lenses and how to make them un-busted

Dan Maloney 3:00 PMOK, hello everyone and welcome to the Hack Chat! I'm Dan, I'll be moderating today along with Dusan as we welcome Anthony Kouttron to the Hack Chat to talk about busted cameras and lenses and how to make them un-busted![]() Dusan Petrovic 3:00 PMHi Dan

Dusan Petrovic 3:00 PMHi Dan![]() Dusan Petrovic 3:00 PMwelcome everyone!

Dusan Petrovic 3:00 PMwelcome everyone!![]() Dan Maloney 3:01 PMThanks for joining us today, Anthony. THe reason I asked you on with us today was that cool repair of the Sigma lens that you pulled off. I thought it had a lot of neat tips and tricks:Anthony Kouttron 3:01 PMGlad to be here!

Dan Maloney 3:01 PMThanks for joining us today, Anthony. THe reason I asked you on with us today was that cool repair of the Sigma lens that you pulled off. I thought it had a lot of neat tips and tricks:Anthony Kouttron 3:01 PMGlad to be here!![]() Dan Maloney 3:01 PMhttps://hackaday.com/2024/05/13/broken-lens-provides-deep-dive-into-camera-repair/!

Dan Maloney 3:01 PMhttps://hackaday.com/2024/05/13/broken-lens-provides-deep-dive-into-camera-repair/!![]() Dusan Petrovic 3:01 PMWelcome Anthony!

Dusan Petrovic 3:01 PMWelcome Anthony!![]() Dan Maloney 3:02 PMAnd I harped a bit about how much camera repairs scare me, but it's true -- I always shied away from trying to fix any of my SLR gear, even though I'll try fixing most anything else. Is that a rational fear?Anthony Kouttron 3:03 PMThe biggest risk when tearing apart a camera is the flash trigger circuit and the sensor block.Anthony Kouttron 3:03 PMWhen disassembling a camera with a flash, the integrated capacitor will hold charge for a long time. There is not usually a bleed resistorAnthony Kouttron 3:04 PMso you have to properly discharge the capacitor before continuing with the teardown. The camera manufacturers actually talk about this on the first page of the service manual. Taking a 5w resistor and a few jumper leads takes care of it no problemEvan Nonebut it is an essential step. I forgot to discharge the flash capacitor one time and my right angle tweezers touched the wrong place. my poor knipex tweezer tips were no moreAnthony Kouttron 3:06 PMIn regards to the sensor, if the camera does not have 5-axis stabilization, there are usually 4-6 spring loaded screws that are adjusted to make the sensor planar to the lens bayonet

Dan Maloney 3:02 PMAnd I harped a bit about how much camera repairs scare me, but it's true -- I always shied away from trying to fix any of my SLR gear, even though I'll try fixing most anything else. Is that a rational fear?Anthony Kouttron 3:03 PMThe biggest risk when tearing apart a camera is the flash trigger circuit and the sensor block.Anthony Kouttron 3:03 PMWhen disassembling a camera with a flash, the integrated capacitor will hold charge for a long time. There is not usually a bleed resistorAnthony Kouttron 3:04 PMso you have to properly discharge the capacitor before continuing with the teardown. The camera manufacturers actually talk about this on the first page of the service manual. Taking a 5w resistor and a few jumper leads takes care of it no problemEvan Nonebut it is an essential step. I forgot to discharge the flash capacitor one time and my right angle tweezers touched the wrong place. my poor knipex tweezer tips were no moreAnthony Kouttron 3:06 PMIn regards to the sensor, if the camera does not have 5-axis stabilization, there are usually 4-6 spring loaded screws that are adjusted to make the sensor planar to the lens bayonet![]() ump 3:06 PMWhat is the proper way to discharge the capacitor once identified?transistor--man Nonethese screws are calibrated at the factory before the camera is shipped. you do not want to unscrew these are you will not be able to verify sensor flatness without speciality tools. I'm sure it can be done, but you will likely need a light projector and some kind of light measuring device

ump 3:06 PMWhat is the proper way to discharge the capacitor once identified?transistor--man Nonethese screws are calibrated at the factory before the camera is shipped. you do not want to unscrew these are you will not be able to verify sensor flatness without speciality tools. I'm sure it can be done, but you will likely need a light projector and some kind of light measuring device![]() Andrew Smith 3:07 PMHi Dan Hi Anthony, I've been collecting film cameras with a bit of repair for a while. I learned a lot from the books of Thomas Tomosy. Saddened to learn he passed in 2023 https://vancouversunandprovince.remembering.ca/obituary/thomas-tomosy-1088995731Anthony Kouttron 3:07 PMI use a 10ohm 5w resistor with insulated leads. I simply put the resistor across the capacitor and it safely discharges the cap

Andrew Smith 3:07 PMHi Dan Hi Anthony, I've been collecting film cameras with a bit of repair for a while. I learned a lot from the books of Thomas Tomosy. Saddened to learn he passed in 2023 https://vancouversunandprovince.remembering.ca/obituary/thomas-tomosy-1088995731Anthony Kouttron 3:07 PMI use a 10ohm 5w resistor with insulated leads. I simply put the resistor across the capacitor and it safely discharges the cap![]() transistor--man 3:08 PMThanks for hosting a hack chat, whats the best series of cameras in terms of repairability?Anthony Kouttron 3:08 PMobviously do not touch any bare metal wire leads, make sure the leads are indulated

transistor--man 3:08 PMThanks for hosting a hack chat, whats the best series of cameras in terms of repairability?Anthony Kouttron 3:08 PMobviously do not touch any bare metal wire leads, make sure the leads are indulated![]() Dan Maloney 3:09 PMI've got a Canon A1 that I left the battery in for too long and it leaked. I've heard the battery box replacement is pretty straightforward, so I should probably start with that. The camera has a lot of memories for meAnthony Kouttron 3:09 PM

Dan Maloney 3:09 PMI've got a Canon A1 that I left the battery in for too long and it leaked. I've heard the battery box replacement is pretty straightforward, so I should probably start with that. The camera has a lot of memories for meAnthony Kouttron 3:09 PM![]() Anthony Kouttron 3:09 PMHey @Andrew Smith Thanks for the info! I did not know him personally, but I'll check out his work! Camera repair is an interesting industry and it is even thereputic. Yes it can get involved, but it's fun.Anthony Kouttron 3:10 PMI started repairing lenses by tearing down the many 1970s clone lenses that were available at retailers like jc.penny, sears etc...Anthony Kouttron 3:11 PMthey were usually dubious quality but similar build construction was found on fancier lenses. It's a way where you don't have to care about making mistakes on a lens with little value

Anthony Kouttron 3:09 PMHey @Andrew Smith Thanks for the info! I did not know him personally, but I'll check out his work! Camera repair is an interesting industry and it is even thereputic. Yes it can get involved, but it's fun.Anthony Kouttron 3:10 PMI started repairing lenses by tearing down the many 1970s clone lenses that were available at retailers like jc.penny, sears etc...Anthony Kouttron 3:11 PMthey were usually dubious quality but similar build construction was found on fancier lenses. It's a way where you don't have to care about making mistakes on a lens with little value![]() ump 3:12 PMWhen starting with lens and body deconstruction, did you purchase dead cameras and lenses to do so, or were your encounters more based on "Wow my device is dead and I guess I should try to fix it"

ump 3:12 PMWhen starting with lens and body deconstruction, did you purchase dead cameras and lenses to do so, or were your encounters more based on "Wow my device is dead and I guess I should try to fix it"![]() Dan Maloney 3:12 PMYOu can pick up lenses like that for super cheap online and in the few remaining IRL camera storesAnthony Kouttron 3:12 PM@transistor--man That's a tough question, most of the manufacturers have service manuals, but olympus and fujifilm in particular do not have many service manuals floating around on the interwebs, which makes the repairs more difficult.

Dan Maloney 3:12 PMYOu can pick up lenses like that for super cheap online and in the few remaining IRL camera storesAnthony Kouttron 3:12 PM@transistor--man That's a tough question, most of the manufacturers have service manuals, but olympus and fujifilm in particular do not have many service manuals floating around on the interwebs, which makes the repairs more difficult.![]() Andrew Smith 3:13 PMI've got a sticky Mamiya-Sekor 80mm lens for the Mamiya C330 TLR Have you worked on those before? Any tips or suggestions?

Andrew Smith 3:13 PMI've got a sticky Mamiya-Sekor 80mm lens for the Mamiya C330 TLR Have you worked on those before? Any tips or suggestions?![]() Evan 3:13 PMthe timing of this hack chat is apropos - my 200-500 just stopped being able to zoom in. Apparently it's a common problem and an easy fix.Anthony Kouttron 3:13 PM@ump A bit of both! I came across a lot of 1970s/ 80s film lenses in poor condition and I started tearing these down and servicing them back to working order. It's amazing how old grease will make an aperture completely stuck.

Evan 3:13 PMthe timing of this hack chat is apropos - my 200-500 just stopped being able to zoom in. Apparently it's a common problem and an easy fix.Anthony Kouttron 3:13 PM@ump A bit of both! I came across a lot of 1970s/ 80s film lenses in poor condition and I started tearing these down and servicing them back to working order. It's amazing how old grease will make an aperture completely stuck.![]() transistor--man 3:14 PMive had issues with cameras in the cold, are there ways to keep them working on cold nights of astro photos?Anthony Kouttron 3:14 PM@Evan 200-500mm from which vendor?

transistor--man 3:14 PMive had issues with cameras in the cold, are there ways to keep them working on cold nights of astro photos?Anthony Kouttron 3:14 PM@Evan 200-500mm from which vendor?![]() Evan 3:14 PMnikon

Evan 3:14 PMnikon![]() Evan 3:14 PMhttps://youtu.be/kvKOVVnlNakAnthony Kouttron 3:17 PM@Andrew Smith I have not worked on any mamiya-sekor lenses yet but being leaf-shutter lenses, they are more complicated to service. Folks do service them though! THe sekor-c lenses are highly coveted lenses because they can cover medium-format sensors well. They are often rehoused by TLS, zero-optik etc...Anthony Kouttron 3:17 PMhttps://www.greenwoodcine.com/rentals/p/mamiya-sekor-tls-rehoused-ff-lenses

Evan 3:14 PMhttps://youtu.be/kvKOVVnlNakAnthony Kouttron 3:17 PM@Andrew Smith I have not worked on any mamiya-sekor lenses yet but being leaf-shutter lenses, they are more complicated to service. Folks do service them though! THe sekor-c lenses are highly coveted lenses because they can cover medium-format sensors well. They are often rehoused by TLS, zero-optik etc...Anthony Kouttron 3:17 PMhttps://www.greenwoodcine.com/rentals/p/mamiya-sekor-tls-rehoused-ff-lenses![]() transistor--man 3:17 PMhas lens construction gotten better over time or worse? are newer lens's less accessible for repair?Anthony Kouttron 3:19 PM@transistor--man That's a good question. I'd say, overall, lens construction has improved. There were pain periods where the main manufacturers experimented with composites and non-glass reinforced plastics and yielded to broken lens mounts and collars, but in comparison to the very sloppy, very poorly machined lenses in the 1970s, lens construction has improvedAnthony Kouttron 3:20 PMwhat I will say is there is a stark contrast between proper cinema lens innerds vs consumer lenses.

transistor--man 3:17 PMhas lens construction gotten better over time or worse? are newer lens's less accessible for repair?Anthony Kouttron 3:19 PM@transistor--man That's a good question. I'd say, overall, lens construction has improved. There were pain periods where the main manufacturers experimented with composites and non-glass reinforced plastics and yielded to broken lens mounts and collars, but in comparison to the very sloppy, very poorly machined lenses in the 1970s, lens construction has improvedAnthony Kouttron 3:20 PMwhat I will say is there is a stark contrast between proper cinema lens innerds vs consumer lenses.![]() transistor--man 3:21 PMDo cinema lens's ever end up surplus? Ive only ever seen consumer stuff on ebay, but the large TV camera lens's are pretty rareAnthony Kouttron 3:21 PMcinema lenses often required parts to torqued town to specification and require the use of calibrated screwdrivers like the wiha TorqueVario ScrewdriversAnthony Kouttron 3:22 PMthe mounts are torqued down like a car wheel. there are also offset cam lobes for fine adjustment of elements and lens assemblies in more expensive lenses that are not present on inexpensive consumer lenses

transistor--man 3:21 PMDo cinema lens's ever end up surplus? Ive only ever seen consumer stuff on ebay, but the large TV camera lens's are pretty rareAnthony Kouttron 3:21 PMcinema lenses often required parts to torqued town to specification and require the use of calibrated screwdrivers like the wiha TorqueVario ScrewdriversAnthony Kouttron 3:22 PMthe mounts are torqued down like a car wheel. there are also offset cam lobes for fine adjustment of elements and lens assemblies in more expensive lenses that are not present on inexpensive consumer lenses![]() Dan Maloney 3:23 PM"the very sloppy, very poorly machined lenses in the 1970s" That was all I could afford ;-( Although I did pick up a nice 135mm Canon lens used at a camera shop back in the 80s. Best lens I ever had. f 1.4, I think. Nice portrait lensAnthony Kouttron 3:24 PMmore attention to focus consistency is placed on cinema lenses like the zeiss master prime / supreme lenses. the lens helicoid will often be one CNC machined piece of brass with dampening bits to provide a very dampened but solid feel. Focus slop is not a desirable trait on any cinema lens.

Dan Maloney 3:23 PM"the very sloppy, very poorly machined lenses in the 1970s" That was all I could afford ;-( Although I did pick up a nice 135mm Canon lens used at a camera shop back in the 80s. Best lens I ever had. f 1.4, I think. Nice portrait lensAnthony Kouttron 3:24 PMmore attention to focus consistency is placed on cinema lenses like the zeiss master prime / supreme lenses. the lens helicoid will often be one CNC machined piece of brass with dampening bits to provide a very dampened but solid feel. Focus slop is not a desirable trait on any cinema lens.![]() cho16888ol 3:24 PMI am newbie to the camera and lens repair, any suggestion on how to get started besides the books from Thomas Tomosy suggested by Andrew?

cho16888ol 3:24 PMI am newbie to the camera and lens repair, any suggestion on how to get started besides the books from Thomas Tomosy suggested by Andrew?![]() Ferdinand Sanchez 3:25 PMIs there precise range of image circle size defined for C mount lenses?Anthony Kouttron 3:28 PM@Dan Maloney Hahaha. Let me rephrase that: there was a great divergence in lens mechanics between large lens manufacturers and the clone manufacturers in the 1970-80s. I had a "best" brand canon FL breach lock style lens. The lens was assembled in two aluminum halves that did not even line up when assembled properly and the threaded screw holes stripped if you looked at them the wrong way. The nikon, canon etc... lenses of the 1970s features far better assembly standards and did not rely on guessing alignment. there were proper machined sholders and threaded rings that held down lens elements. Ironically, canon K35 lenses from the 1970s are insanely desirable even though modern lenses are better in almost every wayAnthony Kouttron 3:30 PM@Ferdinand Sanchez C-mount lenses are tricky. There is quite the variability in image circle coverage and it facies from series to series and manufacturer. There is also the CS mount which is aimed at scientific applications and has a slightly larger image circle. Your best bet is to hunt down lens datasheets. They absolutely exist! Rodenstock / linos, schneider etc... all produce datasheets with mtf curves and image circle informationAnthony Kouttron 3:31 PM@Ferdinand Sanchez for example: https://schneiderkreuznach.com/application/files/9716/7879/2629/JADE_28_16_C_1099214_datasheet.pdfAnthony Kouttron 3:31 PM@Ferdinand Sanchez I believe there were cinema specific cs lenses made by schneider or another large lens vendor, I forgot the name.

Ferdinand Sanchez 3:25 PMIs there precise range of image circle size defined for C mount lenses?Anthony Kouttron 3:28 PM@Dan Maloney Hahaha. Let me rephrase that: there was a great divergence in lens mechanics between large lens manufacturers and the clone manufacturers in the 1970-80s. I had a "best" brand canon FL breach lock style lens. The lens was assembled in two aluminum halves that did not even line up when assembled properly and the threaded screw holes stripped if you looked at them the wrong way. The nikon, canon etc... lenses of the 1970s features far better assembly standards and did not rely on guessing alignment. there were proper machined sholders and threaded rings that held down lens elements. Ironically, canon K35 lenses from the 1970s are insanely desirable even though modern lenses are better in almost every wayAnthony Kouttron 3:30 PM@Ferdinand Sanchez C-mount lenses are tricky. There is quite the variability in image circle coverage and it facies from series to series and manufacturer. There is also the CS mount which is aimed at scientific applications and has a slightly larger image circle. Your best bet is to hunt down lens datasheets. They absolutely exist! Rodenstock / linos, schneider etc... all produce datasheets with mtf curves and image circle informationAnthony Kouttron 3:31 PM@Ferdinand Sanchez for example: https://schneiderkreuznach.com/application/files/9716/7879/2629/JADE_28_16_C_1099214_datasheet.pdfAnthony Kouttron 3:31 PM@Ferdinand Sanchez I believe there were cinema specific cs lenses made by schneider or another large lens vendor, I forgot the name.![]() Evan 3:32 PMAny tips on dealing with loose focus grips? The rubber ring on one of my old primes is getting a bit loose.Anthony Kouttron 3:33 PM@cho16888ol Absolutely! My two favorites are mikeno62 on youtube and listening into the duclos-lens livestreams. Matthew Duclos is incredibly knowledgeable on lens repair and at this point, has seen the inside of nearly every cinema lens in existence. https://www.youtube.com/@mikeno62

Evan 3:32 PMAny tips on dealing with loose focus grips? The rubber ring on one of my old primes is getting a bit loose.Anthony Kouttron 3:33 PM@cho16888ol Absolutely! My two favorites are mikeno62 on youtube and listening into the duclos-lens livestreams. Matthew Duclos is incredibly knowledgeable on lens repair and at this point, has seen the inside of nearly every cinema lens in existence. https://www.youtube.com/@mikeno62![]() Andrew Smith 3:33 PMAnthony, have you serviced or come across radioactive glass? I was shocked to learn my Super-Takumar 50mm F1.4 used Thoriated glass and sent my DIY geiger kit off the charts. (I don't use it and would certainly never open it myself)

Andrew Smith 3:33 PMAnthony, have you serviced or come across radioactive glass? I was shocked to learn my Super-Takumar 50mm F1.4 used Thoriated glass and sent my DIY geiger kit off the charts. (I don't use it and would certainly never open it myself)![]() Ferdinand Sanchez 3:35 PM@Anthony Kouttron Thank you! I am working on a action camera setup that uses M4/3 sensor, so i am hunting down quality wide angle C mount lens(of course not fisheye one - i am searching for low distortion one)

Ferdinand Sanchez 3:35 PM@Anthony Kouttron Thank you! I am working on a action camera setup that uses M4/3 sensor, so i am hunting down quality wide angle C mount lens(of course not fisheye one - i am searching for low distortion one)![]() transistor--man 3:36 PM@Andrew Smith did you know you can un-yellow thoriated lens's with UV? https://richardhaw.com/2021/05/30/repair-bleaching-radiated-lenses/Anthony Kouttron 3:36 PM@Evan Rubber grips are tricky. Rubber that has aged or become impregnated by oil is hard to recover back to original shape. I have not found a solution that works. My 12-35mm f2/8 lenses that I use from panasonic have the exact issue you state and I have not found a fix other than removing the rubber lens grip adding heatshrink below where the rubber ring goes and reinserting the stretched out rubber grip. The grip diameter will be larger, but it will at least not feel sloppy when in use. Digikey is a great resource for heatshrhink. Adhesive heatshrink works best. Take your time when selecting heatshrink sizes, it's easy to measure wrong :D. If the lens you have is still recent, buy a new grip from aliexpress / taobaoAnthony Kouttron 3:38 PM@Andrew Smith I have a few radioactive pentax lenses. They are fantastic to use and ironically I have not had to tear them down yet. I don't fuss over a bit of dust inside a 1970s-80s lens. Unless there is fungus or substantial internal problems with a film lens, I will not tear it down for a full "CLA" Clean, Lubricate and AdjustmentAnthony Kouttron 3:38 PM@Andrew Smith I have too many other lenses calling for my attention :D

transistor--man 3:36 PM@Andrew Smith did you know you can un-yellow thoriated lens's with UV? https://richardhaw.com/2021/05/30/repair-bleaching-radiated-lenses/Anthony Kouttron 3:36 PM@Evan Rubber grips are tricky. Rubber that has aged or become impregnated by oil is hard to recover back to original shape. I have not found a solution that works. My 12-35mm f2/8 lenses that I use from panasonic have the exact issue you state and I have not found a fix other than removing the rubber lens grip adding heatshrink below where the rubber ring goes and reinserting the stretched out rubber grip. The grip diameter will be larger, but it will at least not feel sloppy when in use. Digikey is a great resource for heatshrhink. Adhesive heatshrink works best. Take your time when selecting heatshrink sizes, it's easy to measure wrong :D. If the lens you have is still recent, buy a new grip from aliexpress / taobaoAnthony Kouttron 3:38 PM@Andrew Smith I have a few radioactive pentax lenses. They are fantastic to use and ironically I have not had to tear them down yet. I don't fuss over a bit of dust inside a 1970s-80s lens. Unless there is fungus or substantial internal problems with a film lens, I will not tear it down for a full "CLA" Clean, Lubricate and AdjustmentAnthony Kouttron 3:38 PM@Andrew Smith I have too many other lenses calling for my attention :D![]() Andrew Smith 3:38 PM

Andrew Smith 3:38 PM![]()

![]() Andrew Smith 3:38 PM@transistor--man Yes I've seen that UV technique. Mine is definitely yellowing

Andrew Smith 3:38 PM@transistor--man Yes I've seen that UV technique. Mine is definitely yellowing![]() transistor--man 3:39 PM@Andrew Smith woahAnthony Kouttron 3:39 PM@transistor--man This technique is something I'd like to do myself! Don't tempt me to grab a few yellowing lenses....Oh well too late.

transistor--man 3:39 PM@Andrew Smith woahAnthony Kouttron 3:39 PM@transistor--man This technique is something I'd like to do myself! Don't tempt me to grab a few yellowing lenses....Oh well too late.![]() Evan 3:39 PM🤔 I wonder if the radiation makes fungus less likely

Evan 3:39 PM🤔 I wonder if the radiation makes fungus less likely![]() transistor--man 3:40 PMor stronger

transistor--man 3:40 PMor stronger![]() Andrew Smith 3:42 PMThanks Anthony, thanks Dan. Gotta run but will check back in the chat later. CheersAnthony Kouttron 3:42 PM@Andrew Smith Thanks for stopping in :DAnthony Kouttron 3:44 PM@Evan The 200-500 zoom repair you linked looks pretty straight forward and easy!. I'd go for it. The fellow sugests using electrical tape instead of the yellow looking tape nikon used

Andrew Smith 3:42 PMThanks Anthony, thanks Dan. Gotta run but will check back in the chat later. CheersAnthony Kouttron 3:42 PM@Andrew Smith Thanks for stopping in :DAnthony Kouttron 3:44 PM@Evan The 200-500 zoom repair you linked looks pretty straight forward and easy!. I'd go for it. The fellow sugests using electrical tape instead of the yellow looking tape nikon used![]() Evan 3:44 PMno luck with that quick 200-500 repair process (none of the screws he mentioned seem loose), will have to research more, might have to take off the whole shroudAnthony Kouttron 3:44 PM@Evan I would highly suggest not to use electrical tape for this application. It will become gummy after a week. Use doublesided 3m tape. Hmm.

Evan 3:44 PMno luck with that quick 200-500 repair process (none of the screws he mentioned seem loose), will have to research more, might have to take off the whole shroudAnthony Kouttron 3:44 PM@Evan I would highly suggest not to use electrical tape for this application. It will become gummy after a week. Use doublesided 3m tape. Hmm.![]() Evan 3:45 PMit looks like kapton tape to me. I've got a roll of 1" kapton that I can use to replace it.

Evan 3:45 PMit looks like kapton tape to me. I've got a roll of 1" kapton that I can use to replace it.![]() Evan 3:46 PMwhen I watched the video I thought he was talking about that tape being used to hold the rubber grip down, but as far as I can tell it's just single-sided tape that holds the little metal covers in placeAnthony Kouttron 3:46 PM@Evan I have not worked on that specific lens, but zoom lens repair can get hairy. The fellow made it seem like the kapton tape was doublesided. Zoom lenses often have many interlocking segments and they are not always accessible from one side of the lens

Evan 3:46 PMwhen I watched the video I thought he was talking about that tape being used to hold the rubber grip down, but as far as I can tell it's just single-sided tape that holds the little metal covers in placeAnthony Kouttron 3:46 PM@Evan I have not worked on that specific lens, but zoom lens repair can get hairy. The fellow made it seem like the kapton tape was doublesided. Zoom lenses often have many interlocking segments and they are not always accessible from one side of the lens![]() mark Noneand the rubber grip is just held in place with friction

mark Noneand the rubber grip is just held in place with friction![]() Evan 3:47 PMyeah I'd go find a bunch more content before digging any further for sure.Anthony Kouttron 3:47 PM@Evan That makes sense. sometimes the front half of the lens is screwed in to the bayonet half, and the front lens beauty ring hides screws or a threaded collarAnthony Kouttron 3:49 PM@Evan in that case, you;ll need a lens spanner to disassemble the front element group or a cylindrical rubber grippy bit to remove the front lens facia. I linked a photo of what they look above.

Evan 3:47 PMyeah I'd go find a bunch more content before digging any further for sure.Anthony Kouttron 3:47 PM@Evan That makes sense. sometimes the front half of the lens is screwed in to the bayonet half, and the front lens beauty ring hides screws or a threaded collarAnthony Kouttron 3:49 PM@Evan in that case, you;ll need a lens spanner to disassemble the front element group or a cylindrical rubber grippy bit to remove the front lens facia. I linked a photo of what they look above.![]() transistor--man 3:49 PM@Anthony Kouttron have you looked at the signaling for camera lens attachments, like M4/3 or E-Mounts?

transistor--man 3:49 PM@Anthony Kouttron have you looked at the signaling for camera lens attachments, like M4/3 or E-Mounts?![]() Dan Maloney 3:49 PMGood point -- what's the basic toolkit look like to get started in lens and camera repair?Anthony Kouttron 3:50 PM

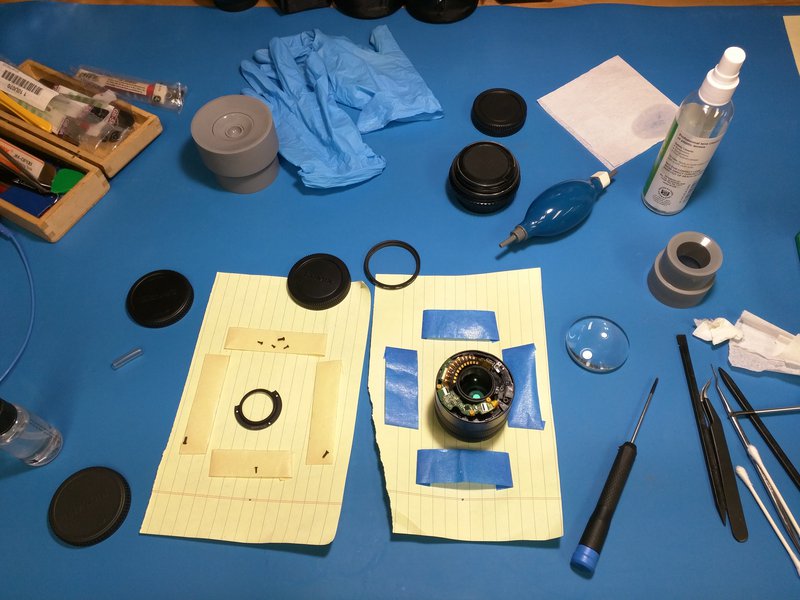

Dan Maloney 3:49 PMGood point -- what's the basic toolkit look like to get started in lens and camera repair?Anthony Kouttron 3:50 PM![]() Anthony Kouttron 3:50 PM@evan. Good luck with it! Make sure you have an empty table, some tape and a bunch of patience before your lens dissection

Anthony Kouttron 3:50 PM@evan. Good luck with it! Make sure you have an empty table, some tape and a bunch of patience before your lens dissection![]() chuisco Nonehas anyone had success fixing a gear in a dslr lens? i have one with chipped teeth and those things are tiny. not sure if i could 3d print them accurately.Anthony Kouttron 3:51 PM

chuisco Nonehas anyone had success fixing a gear in a dslr lens? i have one with chipped teeth and those things are tiny. not sure if i could 3d print them accurately.Anthony Kouttron 3:51 PM![]() Anthony Kouttron 3:52 PM@Dan Maloney I'd definitely recommend pointed and lens spanners, a silicone rubber cylindrical lens set and a cheap lens thread reshaping tool. These are invaluable. Nice lens spanners can be found on ebay from time to time. I think edmund optics used to make some

Anthony Kouttron 3:52 PM@Dan Maloney I'd definitely recommend pointed and lens spanners, a silicone rubber cylindrical lens set and a cheap lens thread reshaping tool. These are invaluable. Nice lens spanners can be found on ebay from time to time. I think edmund optics used to make some![]() Ferdinand Sanchez 3:52 PMAny rubber grips that are distorted from hard use can be restored to original shape by using naphtha. But you need to experiment with different types of rubber how long to expose them to naphtha in order to return them in original shape; Too long exposure can shrink them too much, and this can not be undone.

Ferdinand Sanchez 3:52 PMAny rubber grips that are distorted from hard use can be restored to original shape by using naphtha. But you need to experiment with different types of rubber how long to expose them to naphtha in order to return them in original shape; Too long exposure can shrink them too much, and this can not be undone.![]() Evan 3:52 PM@Ferdinand Sanchez do you do that in situ or remove them from the lens?Anthony Kouttron 3:53 PM@transistor--man I have not yet looked into camera lens signaling, but it is definitely an interesting attack vector for 3rd party adapter making. I have a feeling all the camera manufacturers use similar lens communication protocols considering the lenses use similar microcontrollers across the board.

Evan 3:52 PM@Ferdinand Sanchez do you do that in situ or remove them from the lens?Anthony Kouttron 3:53 PM@transistor--man I have not yet looked into camera lens signaling, but it is definitely an interesting attack vector for 3rd party adapter making. I have a feeling all the camera manufacturers use similar lens communication protocols considering the lenses use similar microcontrollers across the board.![]() Ferdinand Sanchez 3:54 PM@Evan remove them, of course

Ferdinand Sanchez 3:54 PM@Evan remove them, of course![]() Ferdinand Sanchez 3:54 PM@Evan you need to completely submerge desired rubber part in naphtha

Ferdinand Sanchez 3:54 PM@Evan you need to completely submerge desired rubber part in naphtha![]() Evan 3:55 PMwas just gonna ask that, thanks

Evan 3:55 PMwas just gonna ask that, thanks![]() Dan Maloney 3:55 PMQuickly read that as "napalm"Anthony Kouttron 3:56 PM@mark That sounds like a job for an SLA 3d printer. The added resolution should work great for your application. If it's small, the up front cost should not be too bad. Go for it!Anthony Kouttron 3:56 PM@Ferdinand Sanchez I have not tried naphtha, but I'll give it a shot. Thanks for the suggestion.Anthony Kouttron 3:57 PMAnthony Kouttron 3:57 PM@mark I was luckily able to reshape the focus gear in a 20mm f1.7 lens I had

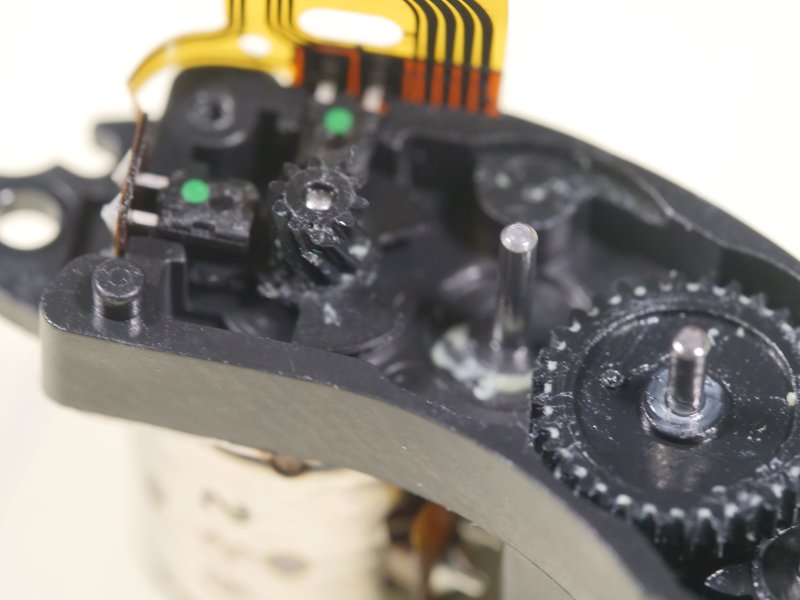

Dan Maloney 3:55 PMQuickly read that as "napalm"Anthony Kouttron 3:56 PM@mark That sounds like a job for an SLA 3d printer. The added resolution should work great for your application. If it's small, the up front cost should not be too bad. Go for it!Anthony Kouttron 3:56 PM@Ferdinand Sanchez I have not tried naphtha, but I'll give it a shot. Thanks for the suggestion.Anthony Kouttron 3:57 PMAnthony Kouttron 3:57 PM@mark I was luckily able to reshape the focus gear in a 20mm f1.7 lens I had![]() Dan Maloney 3:58 PMSeems like you have to have the correct greases and oils too. I can see the wrong products doing some very bad things

Dan Maloney 3:58 PMSeems like you have to have the correct greases and oils too. I can see the wrong products doing some very bad things![]() Ferdinand Sanchez 3:58 PM@Anthony Kouttron it is used in camping lanterns, so it is easy to get your hands on itAnthony Kouttron 3:58 PMA pair of needle files cleaned it up enough that it reliably kept working. No teeth were broken off, just two were slightly deformed. Possible from dirt / debris. The repair worked

Ferdinand Sanchez 3:58 PM@Anthony Kouttron it is used in camping lanterns, so it is easy to get your hands on itAnthony Kouttron 3:58 PMA pair of needle files cleaned it up enough that it reliably kept working. No teeth were broken off, just two were slightly deformed. Possible from dirt / debris. The repair worked![]() Evan 3:59 PM@transistor--man Here's a description of the nikon F-mount signaling: https://web.archive.org/web/20140216033445/http://nikonhacker.com/wiki/Lens_Serial_Interface -- unfortunately this nikonhacker website returns 404s for all its content now, so you have to use the wayback machine :(

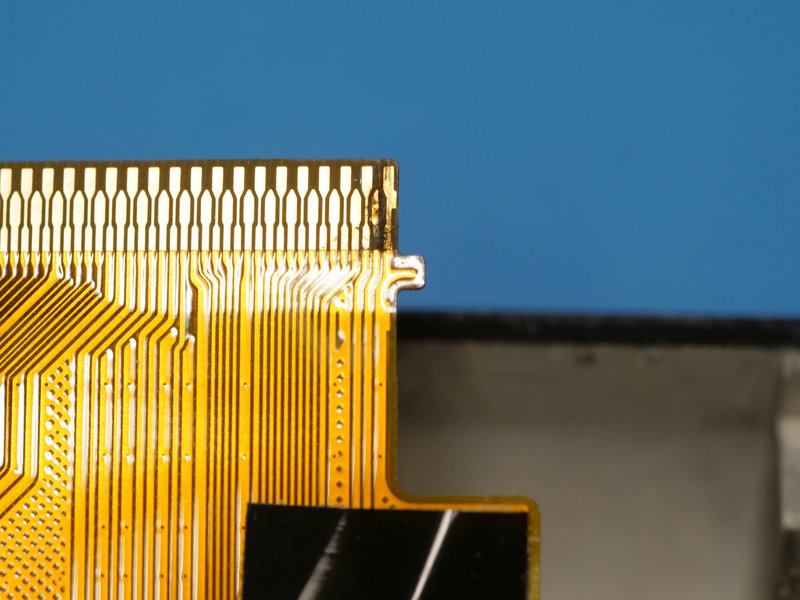

Evan 3:59 PM@transistor--man Here's a description of the nikon F-mount signaling: https://web.archive.org/web/20140216033445/http://nikonhacker.com/wiki/Lens_Serial_Interface -- unfortunately this nikonhacker website returns 404s for all its content now, so you have to use the wayback machine :(![]() transistor--man 4:00 PM@Evan thanks!Anthony Kouttron 4:01 PMcamera lens flex repairs are super common in today's AF lenses, but unfortunately, solder bridges and tiny-wire bridges are intermittent fixesAnthony Kouttron 4:01 PMAnthony Kouttron 4:02 PMIf you can solder it up to the point where the mylar doesn't fail, tiny wires act as a great solution, but often do not work because that failure point is a necessary bend radius. The added rigidity of the wire prevents the cable from bending and the lens will not reassemble properly

transistor--man 4:00 PM@Evan thanks!Anthony Kouttron 4:01 PMcamera lens flex repairs are super common in today's AF lenses, but unfortunately, solder bridges and tiny-wire bridges are intermittent fixesAnthony Kouttron 4:01 PMAnthony Kouttron 4:02 PMIf you can solder it up to the point where the mylar doesn't fail, tiny wires act as a great solution, but often do not work because that failure point is a necessary bend radius. The added rigidity of the wire prevents the cable from bending and the lens will not reassemble properly![]() Evan 4:02 PMnow that the various cheap PCB manufacturers can do flex PCBs, I wonder at what point it becomes more feasible to just recreate it in kicadAnthony Kouttron 4:02 PMYeah, I experimented and did that exact same thing with my 12mm olympus lens repair: https://salvagedcircuitry.com/olympus-12mm.html

Evan 4:02 PMnow that the various cheap PCB manufacturers can do flex PCBs, I wonder at what point it becomes more feasible to just recreate it in kicadAnthony Kouttron 4:02 PMYeah, I experimented and did that exact same thing with my 12mm olympus lens repair: https://salvagedcircuitry.com/olympus-12mm.html![]() Ferdinand Sanchez 4:03 PM@Evan that would be greatAnthony Kouttron 4:03 PMI didn't need to make the flex, but the pricing on flex manufacturing is so cheap it's hard to passAnthony Kouttron 4:03 PMit was in a region where point-to-point wiring, a staple of 1970s-90s film cameras, worked swimmingly

Ferdinand Sanchez 4:03 PM@Evan that would be greatAnthony Kouttron 4:03 PMI didn't need to make the flex, but the pricing on flex manufacturing is so cheap it's hard to passAnthony Kouttron 4:03 PMit was in a region where point-to-point wiring, a staple of 1970s-90s film cameras, worked swimmingly![]() Evan 4:04 PMnice

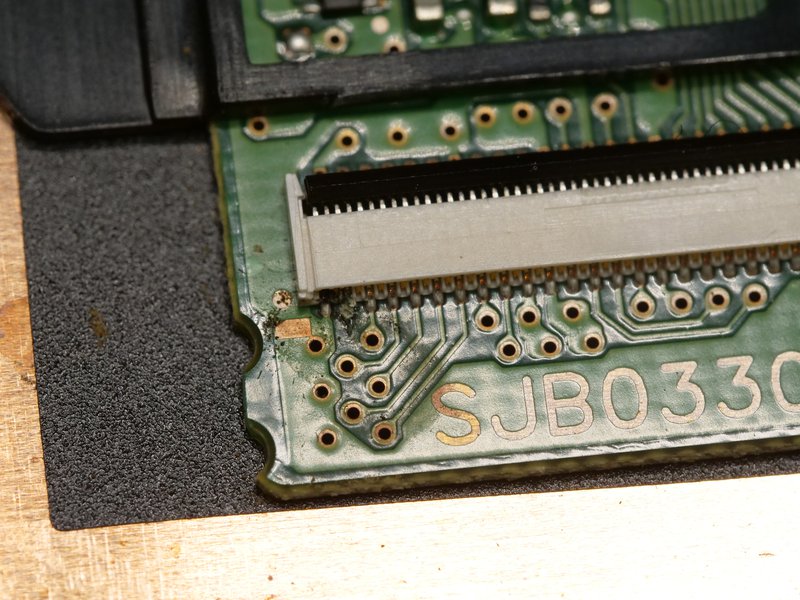

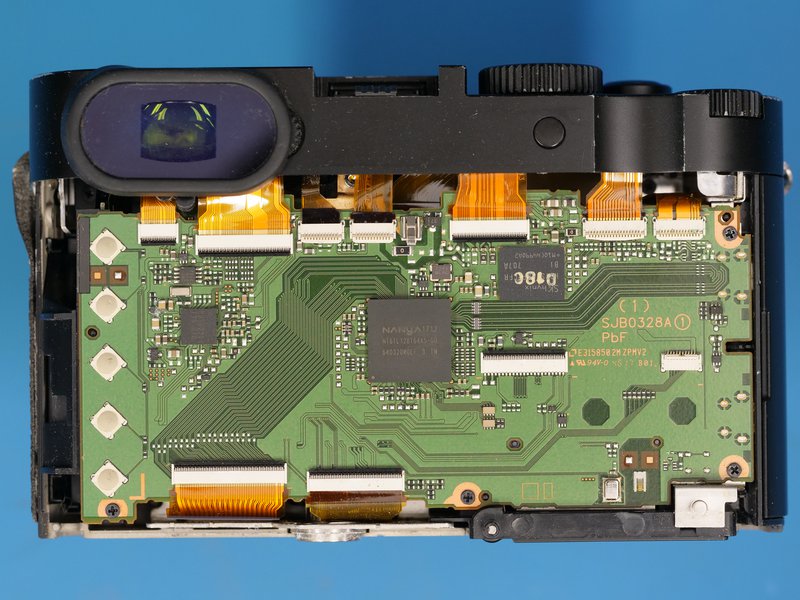

Evan 4:04 PMnice![]() Ferdinand Sanchez 4:05 PMIs there way to re-bond fogged up cemented lens group?Anthony Kouttron 4:05 PMSometimes you do get lucky with camera repair. I had a leica Q that had water damage. The LCD connector somehow harbored saltwater and shorted the power to the rear lcd. Because leica didn't put a power indicator light on, the seller did not realize the camera still worked, it just didn't output to the displayAnthony Kouttron 4:06 PMAnthony Kouttron 4:06 PMLookie hereAnthony Kouttron 4:06 PMThat's one sad looking flex cable.Anthony Kouttron 4:06 PMAnthony Kouttron 4:07 PMI ultrasonically cleaned the PCB near the fPC cable, bypassed the flex cable and hardwired the lcd power and the camera chooched againAnthony Kouttron 4:07 PMAnthony Kouttron 4:08 PMOne reassembled leica Q

Ferdinand Sanchez 4:05 PMIs there way to re-bond fogged up cemented lens group?Anthony Kouttron 4:05 PMSometimes you do get lucky with camera repair. I had a leica Q that had water damage. The LCD connector somehow harbored saltwater and shorted the power to the rear lcd. Because leica didn't put a power indicator light on, the seller did not realize the camera still worked, it just didn't output to the displayAnthony Kouttron 4:06 PMAnthony Kouttron 4:06 PMLookie hereAnthony Kouttron 4:06 PMThat's one sad looking flex cable.Anthony Kouttron 4:06 PMAnthony Kouttron 4:07 PMI ultrasonically cleaned the PCB near the fPC cable, bypassed the flex cable and hardwired the lcd power and the camera chooched againAnthony Kouttron 4:07 PMAnthony Kouttron 4:08 PMOne reassembled leica Q![]() Dan Maloney 4:09 PMWell, we're up past the top of the hour again, so time to wrap things up -- mostly so I can rummage in the closet and find an old camera body to start playing with. I want to thank Anthony for dropping by today and sharing his experience with lenses and cameras, and to everyone for a great discussion. And +1 for the AvE reference -- skookum as frigAnthony Kouttron 4:09 PMAnthony Kouttron 4:09 PM@Dan Maloney Thanks for having me! I'll be here for a bit more so if anyone has some more questions, feel free to ask!

Dan Maloney 4:09 PMWell, we're up past the top of the hour again, so time to wrap things up -- mostly so I can rummage in the closet and find an old camera body to start playing with. I want to thank Anthony for dropping by today and sharing his experience with lenses and cameras, and to everyone for a great discussion. And +1 for the AvE reference -- skookum as frigAnthony Kouttron 4:09 PMAnthony Kouttron 4:09 PM@Dan Maloney Thanks for having me! I'll be here for a bit more so if anyone has some more questions, feel free to ask!![]() Dusan Petrovic 4:09 PMThanks @Anthony Kouttron, was very interesting, and thank you all for participating!Anthony Kouttron 4:10 PM@Dusan Petrovic Thanks!

Dusan Petrovic 4:09 PMThanks @Anthony Kouttron, was very interesting, and thank you all for participating!Anthony Kouttron 4:10 PM@Dusan Petrovic Thanks!![]() Evan 4:10 PM👏👏👏

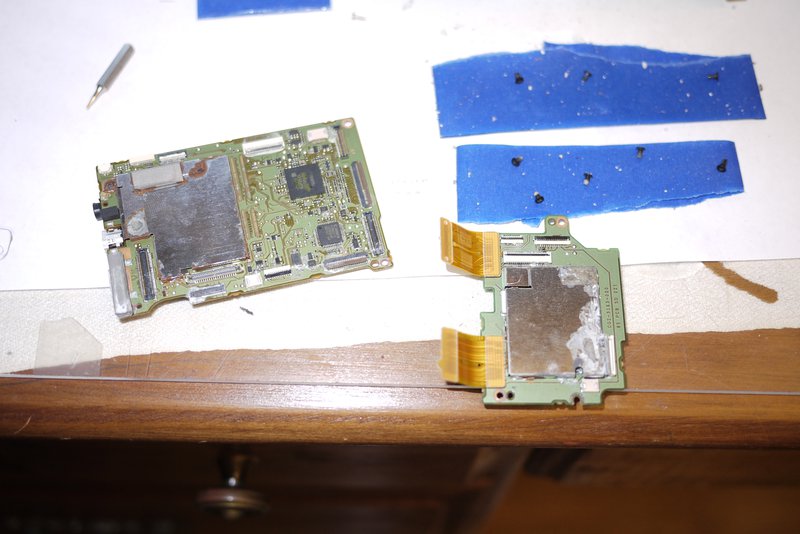

Evan 4:10 PM👏👏👏![]() Dan Maloney 4:10 PMNo problem at all, we'll wait a few minutes to pull the transcript. Thanks all!Anthony Kouttron 4:10 PMLeica camera does not service water damaged cameras, which was how I was able to score the camera at discount. I think it was $400 at the time. a $3000 camera. Saltwater can cause some invasive damage thoughAnthony Kouttron 4:11 PMAnthony Kouttron 4:11 PMJust look at the carnage. IT was well worth cleaning the entire main PCB in IPAAnthony Kouttron 4:12 PMyes, ipa has a flash point and yeah you should use something like alconix or branson EC, but you know what's environmentally friendly? Not those two.

Dan Maloney 4:10 PMNo problem at all, we'll wait a few minutes to pull the transcript. Thanks all!Anthony Kouttron 4:10 PMLeica camera does not service water damaged cameras, which was how I was able to score the camera at discount. I think it was $400 at the time. a $3000 camera. Saltwater can cause some invasive damage thoughAnthony Kouttron 4:11 PMAnthony Kouttron 4:11 PMJust look at the carnage. IT was well worth cleaning the entire main PCB in IPAAnthony Kouttron 4:12 PMyes, ipa has a flash point and yeah you should use something like alconix or branson EC, but you know what's environmentally friendly? Not those two.![]() mark 4:12 PM@Anthony Kouttron i have a friend with a resin printer. i'll talk to him. thank you!Anthony Kouttron 4:13 PMIf you watch your ultrasonic and do not let the solution become too hot, ipa does work well. Again, watch your ultrasonic if you use IPA because it will catch and it is dangerous. If you are careful it works great.Anthony Kouttron 4:13 PM@mark Good luck with it!Anthony Kouttron 4:15 PMI have found ultrasonic machines are incredibly invaluable for water damaged repair work. Louis rossman, a very famous repair / right to repair person on youtube also has a series of videos on ultrasonic cleaningAnthony Kouttron 4:17 PMYou can take boards like this and make them usable again. It doesn't always work, but it sure gives a second chance to otherwise toast control PCBs.Anthony Kouttron 4:17 PM

mark 4:12 PM@Anthony Kouttron i have a friend with a resin printer. i'll talk to him. thank you!Anthony Kouttron 4:13 PMIf you watch your ultrasonic and do not let the solution become too hot, ipa does work well. Again, watch your ultrasonic if you use IPA because it will catch and it is dangerous. If you are careful it works great.Anthony Kouttron 4:13 PM@mark Good luck with it!Anthony Kouttron 4:15 PMI have found ultrasonic machines are incredibly invaluable for water damaged repair work. Louis rossman, a very famous repair / right to repair person on youtube also has a series of videos on ultrasonic cleaningAnthony Kouttron 4:17 PMYou can take boards like this and make them usable again. It doesn't always work, but it sure gives a second chance to otherwise toast control PCBs.Anthony Kouttron 4:17 PM![]() Dan Maloney 4:19 PMLove that tape trick for keeping track of screwsAnthony Kouttron 4:19 PMAnthony Kouttron 4:19 PMThis was definitely one of the worst salt water damaged cameras I came across. The shell deteriorated on disassembly. It was a true goner. That is one of the downsides of a magnesium-alloy camera frame. Magnesium is very reactive.Anthony Kouttron 4:21 PM@Dan Maloney Thanks! I started using tape from the beginning because not all screws are magnetic. Also, dropping 000 sized screws is not very pleasant. They disappear far too easily!Anthony Kouttron 4:22 PMThanks for stopping buy everybody! I had a great time. Good luck with all your projects! :D

Dan Maloney 4:19 PMLove that tape trick for keeping track of screwsAnthony Kouttron 4:19 PMAnthony Kouttron 4:19 PMThis was definitely one of the worst salt water damaged cameras I came across. The shell deteriorated on disassembly. It was a true goner. That is one of the downsides of a magnesium-alloy camera frame. Magnesium is very reactive.Anthony Kouttron 4:21 PM@Dan Maloney Thanks! I started using tape from the beginning because not all screws are magnetic. Also, dropping 000 sized screws is not very pleasant. They disappear far too easily!Anthony Kouttron 4:22 PMThanks for stopping buy everybody! I had a great time. Good luck with all your projects! :D Lutetium

Lutetium