-

Still going strong!

02/05/2018 at 12:58 • 0 commentsI think this is one of the geekiest posts I've ever done.

The soldering pen project is back on the table, after a trip round the moving box and then the drawer.I'm getting ready for the next (and hopefully final) firmware.

This time it's about testing the hardware and a note-to-self about AVRDUDE.

There's a lot of code snippet on this one and the formatting is getting screwed. Read the full post here:http://embryonic.dk/wordpress/?p=815

I'm not sure about the timeframe but I still really want to get this going..

Until next time!

-

Demo time!

11/25/2016 at 05:58 • 0 commentsHi everybody! I’m done. The soldering pen project is done. Well, At least in the first form where I feel I can release it to the public. A small beta-test have already given me changes that I need to implement before going to the next level and really trying to sell the pen but have a look at the video! I even found a case to ship it in.Now, I’ll let the video speak (that’s still me speaking though)

Also - Check out my blog about this project - http://www.embryonic.dk

-

Programming a lot of boards

11/17/2016 at 09:53 • 0 commentsEver wondered how I'm going to program those small boards?

I've made a video!

Also - most of the information about the project will be maintained on my own website. http://www.embryonic.dk

-

Spending money

10/27/2016 at 08:36 • 3 commentsI've just spend about 850$ on PCBs.. The soldering pen is going to production :)

I still need to tweak firmware and make a programming jig. PCB's will arrive next week.

Also this project will be further updated on my own site: http://embryonic.dk

-

Now with Casing

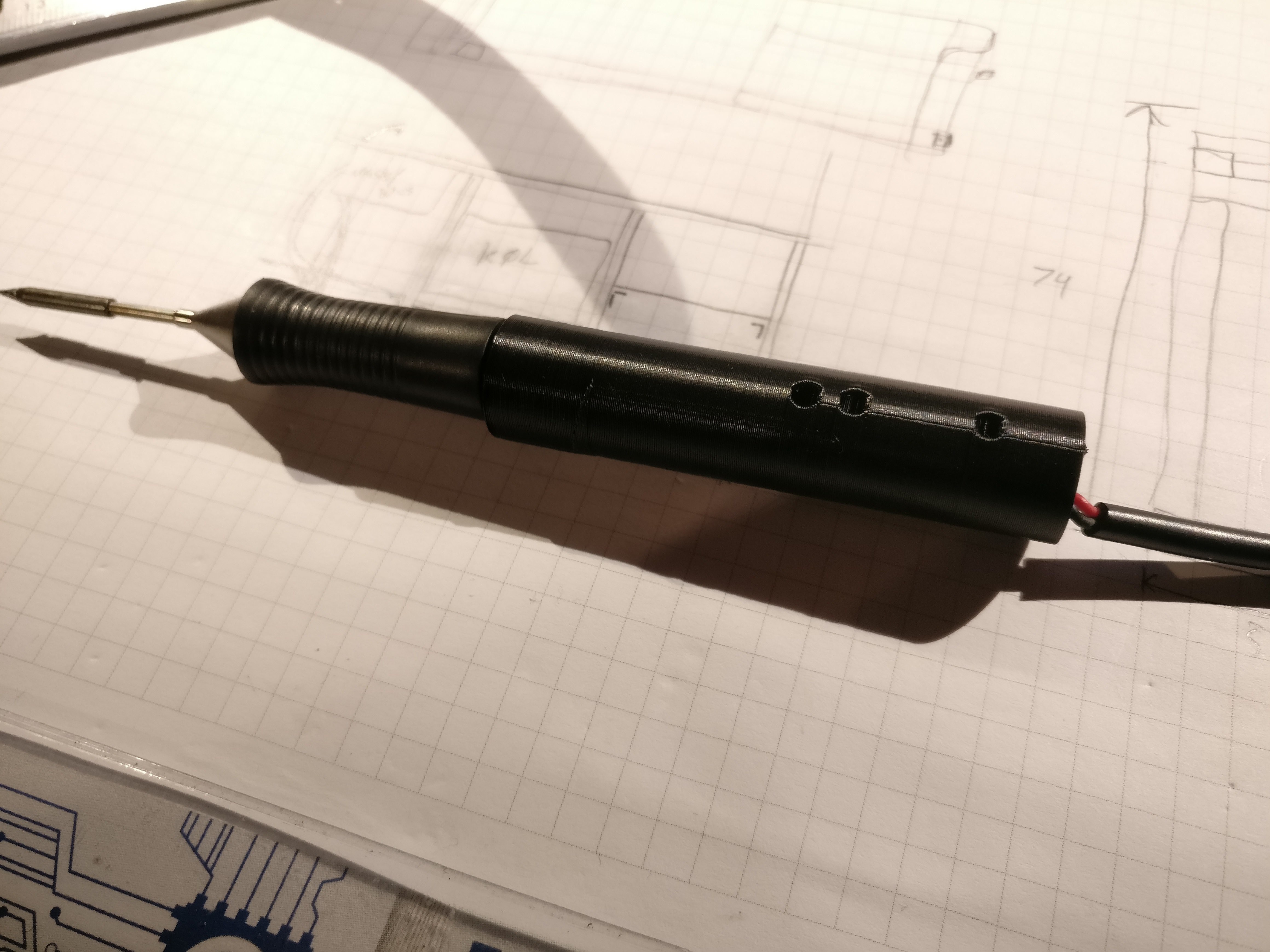

10/10/2016 at 12:02 • 11 commentsIt's been a while since I got the soldering pen to work.

Now I'm back with more good news. I've printed the first casing for the electronics! Yes it might not be much but it's there! Looking more pen-ish than ever.

![]()

What do you think?

I haven't added buttons yet - they will go in the two hoels farthest from the tip.

The hole closes to the tip is for a small light-pipe so the LED can shine through the casing. I was thinking some white PLA in 3mm would suffice.

I'm still working on buttons. I'm not convinced that my initial idea will work so adding the buttons as small pieces of plastic might be the solution.![]()

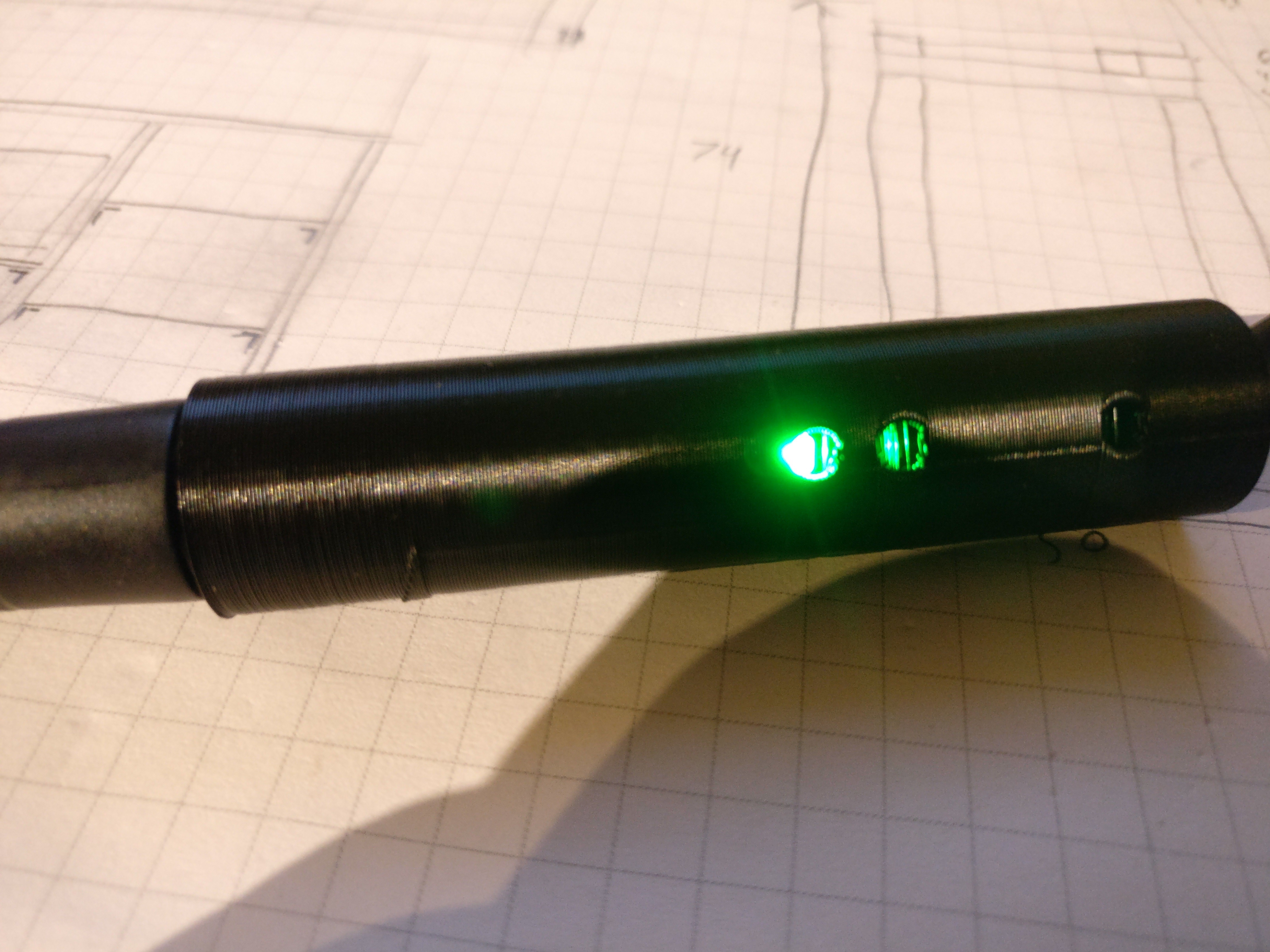

Here the pen is heating. The red LED is really bright!!

Next step is to convert all parts to 0603 so I maybe can have it produced locally. Also I will be extending the PCB beyond the 50mm limit I was currently working on, making room for a barrel jack connector for the 12V.

![]()

I should make a gif.. the green is pulsing, indicating that working temperature has been reached.

The biggest problem is now that the mini-jack connector is only rated for 1A and the tip is requiring 2A.. The connector gets warm.. I don't think I will have any luck finding a high-current low-profil mini-jack connector..Any thoughts?

-

It's alive!

09/08/2016 at 09:17 • 7 commentsI know, I know - It's been a long time seince I've written (and done) anything on this project.

A lot have happened although not that much on the project specifically. I got married, I've completed my laser cutter (at least to a stage where it can burn stuff) and a host of other things.

I kept hitting a brick wall when I attempted to communicate with the MCU on latest revision of the soldering pen. I've given up hope of getting it to work.

I considered going back to revision 2, but not having that slick low-profile mini-jack connector really bothered me.

So, two nights ago a friend wrote me. We came across the soldering pen project and we discussed problems and solutions. Just out of curiosity I tried to solder a new MCU on one of the PCBs. Using AVRDUDE I read the fuses - It worked! I then tried to put a simple blink sketch using the Arduino IDE onto the chip. Bang. Dead.

AVRDUDE couldn't see the chip anymore. Slowly it dawned that the fuse settings had to be wrong altough they were set right. To jump to the end of this: I think the unspecified fuse settings in the extended fuse caused some kind of lock-up in the chip. I don't have access to high voltage programmin equipment (such as the STK500) so trying anything like this was never in my head. I just assumed that the Arduino IDE would do the job. I have on several occasions had trouble with the right fuse settings through Arduino. Grrrrr!

Then, yesterday my friend came by. We talked a bit more and we assembled yet another board. using the default fuse settings from an online fuse calculator (engbedded) we tried one more time with AVRDUDE. Contact. then again in AVRDUDE. still working. right, now we modified the Boards.txt file and tried, with caution, to download the blink sketch from the Arduino IDE. no problems.

We read the fuses using AVRDUDE again. Still working.. wohooo!

Quickly I soldered the RGB LED to the pads. put power back on. Bang! Blindingly red light - at least blindingly bright for a LED that size! blinking! It was Blinking! YES!

Now for the Opamp and the connector to the tip. Set the temperature for 50 degrees and power on.

The system didn't have the MOSFET so of course nothing would happen. I used the tip of my soldering iron to heat up the other tip. I could se the soldering pen go from red to green indicating that the temperature was reached. success!

Now solder on the hall-sensor - Blue light indicating that the pen was hibernating was shown when I put a magnet close. Double success!

Add the LDO regulator and attach 12V.

Nothing. Quickly I disconnected the 12V again. something was wrong. I had to go to bed. dang - so close!

this morning I fired up the sytem again, after checking that all connections was right. I had a voltmeter on the 3.3V line and it came up nicely. A splitsecond later the red diode went on. I had simply not waited long enough for the 12V supply (a brick) to power on. I adjusted the sketch to 350 degress and tried again.

A quick puff of solder-smoke from the tip and a nice green glow from the 'ready' LED was shown.

YES! IT'S WORKING!!! We're back in business!

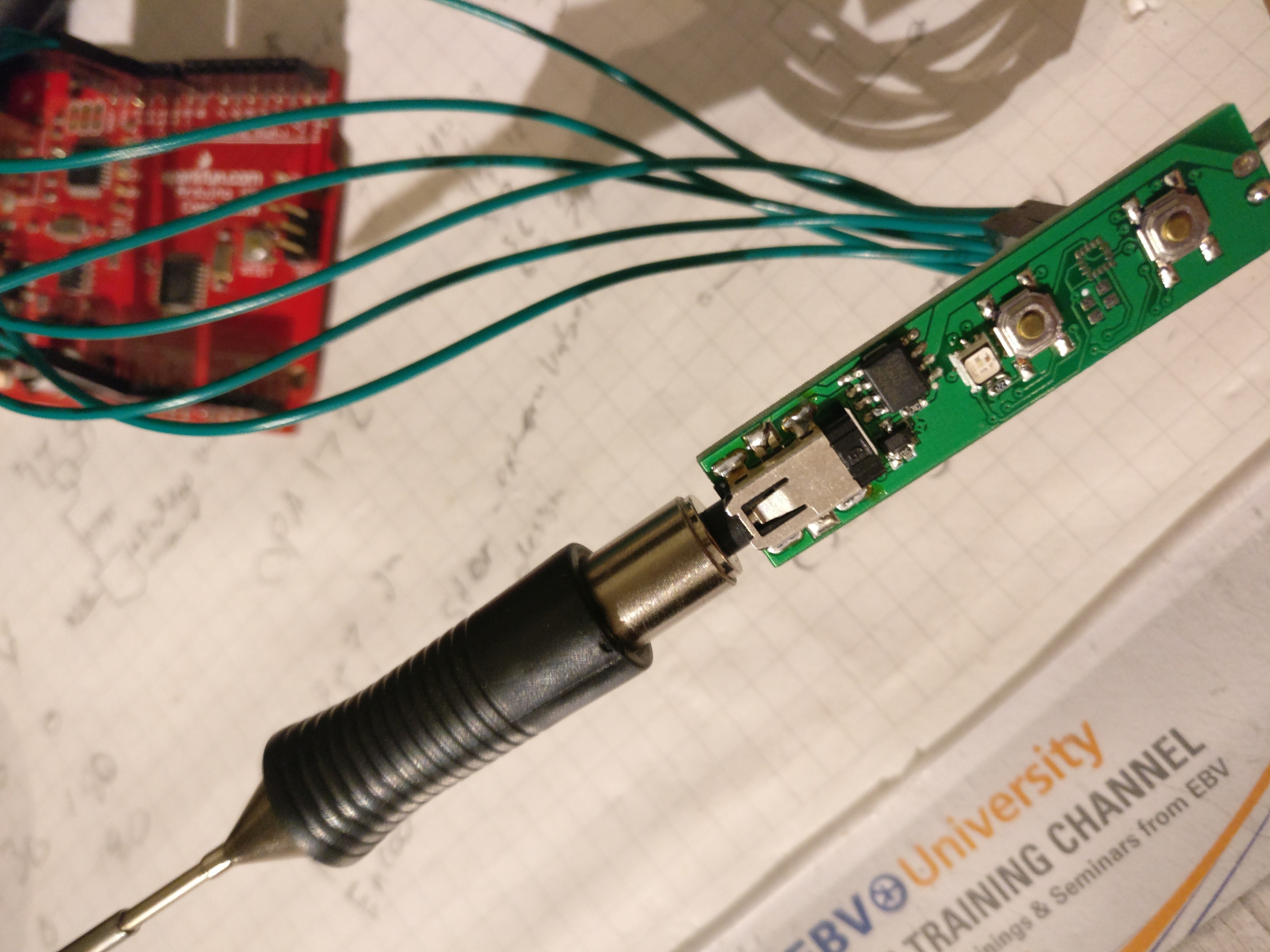

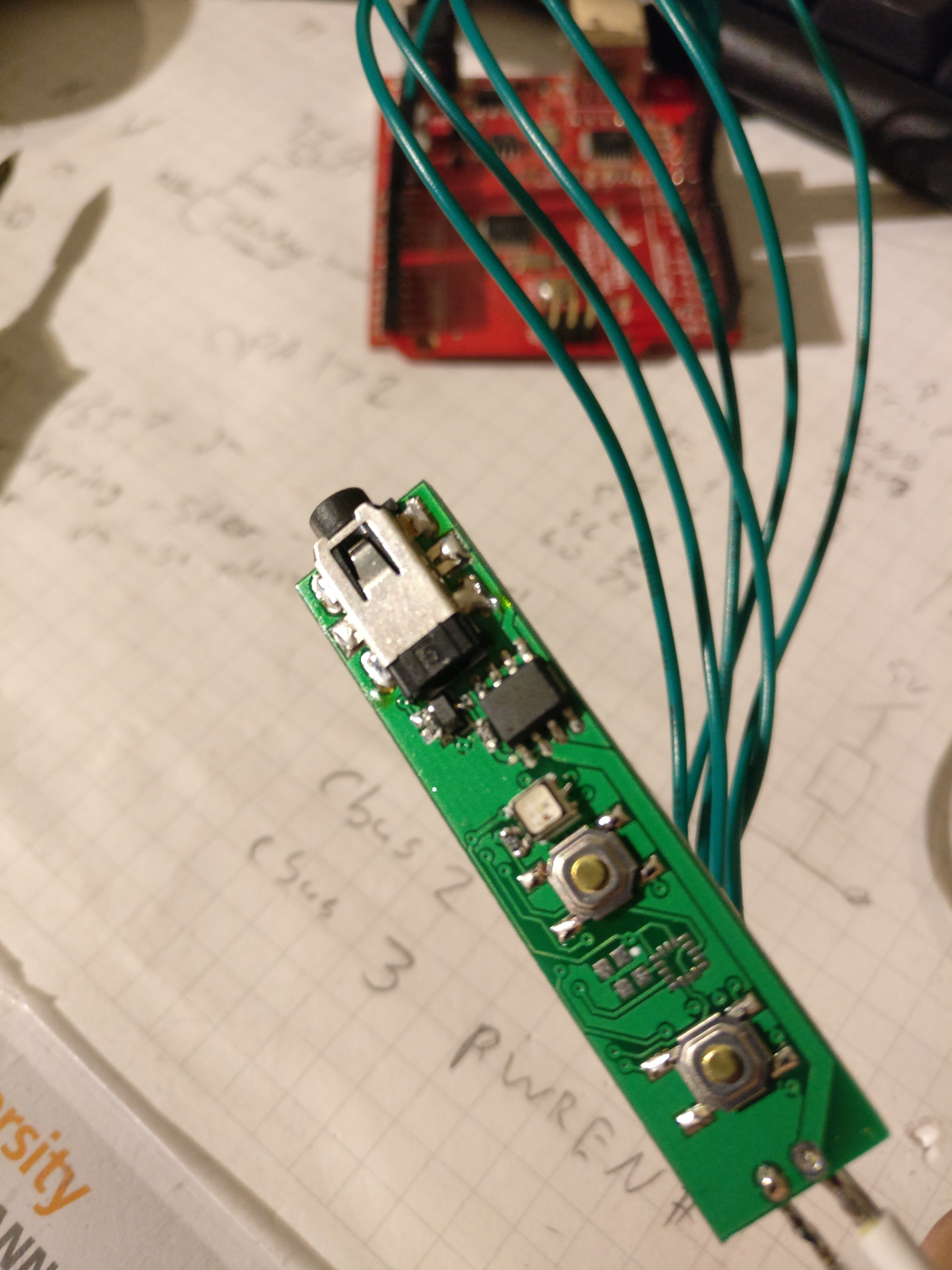

Now, since you've read so far, some pictures:

![]()

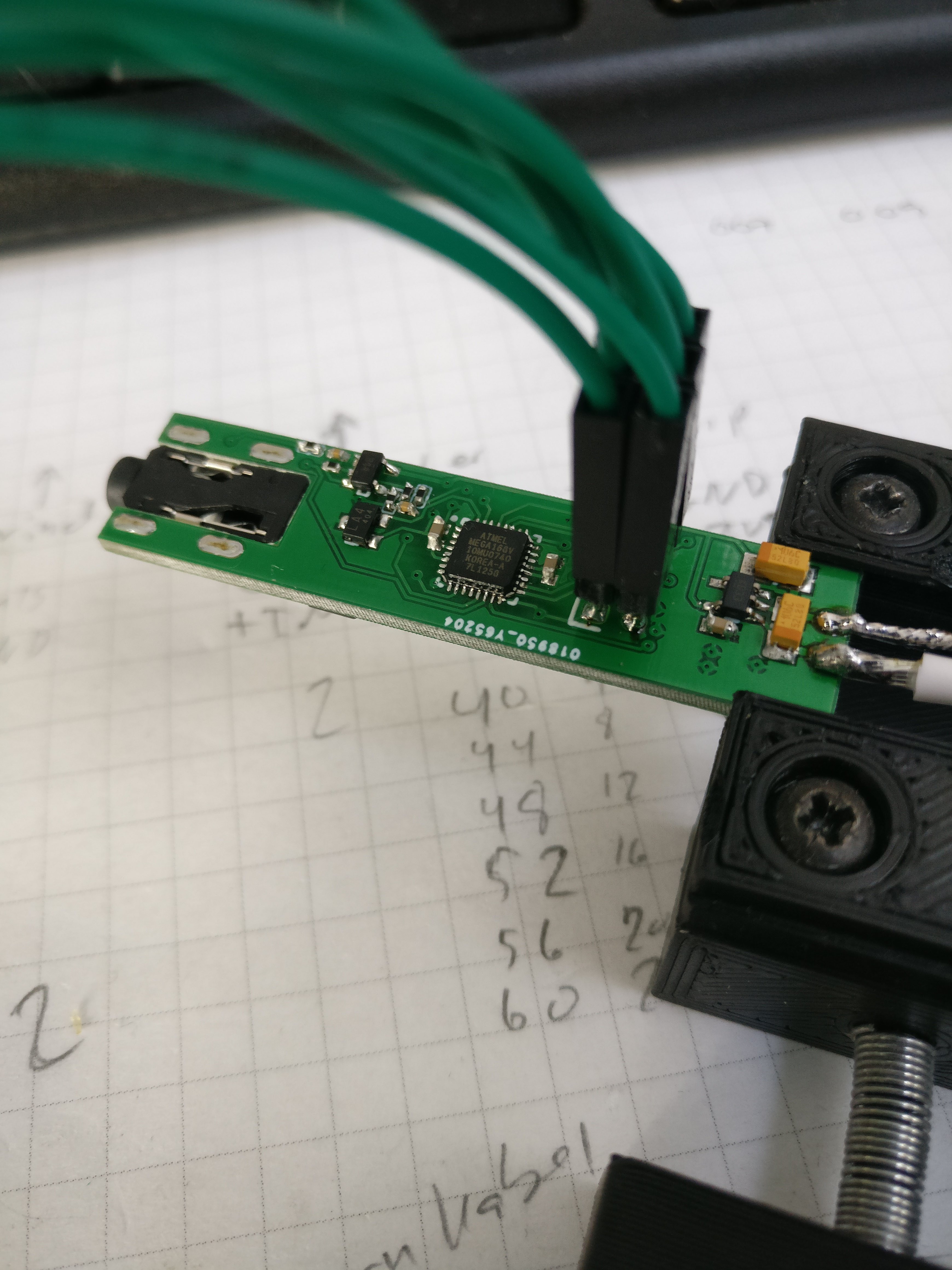

The pen from the top side. The SOIC is the P-Mos for power to the tip. The RGB LED is right next to the lowest button.

![]()

Close-up of the top-side of the PCB.

![]()

Bottom-side. Those 0402 parts are tiny! I will change them for 0603 parts and add a barrel-jack (low profile?) for the power connector.

![]()

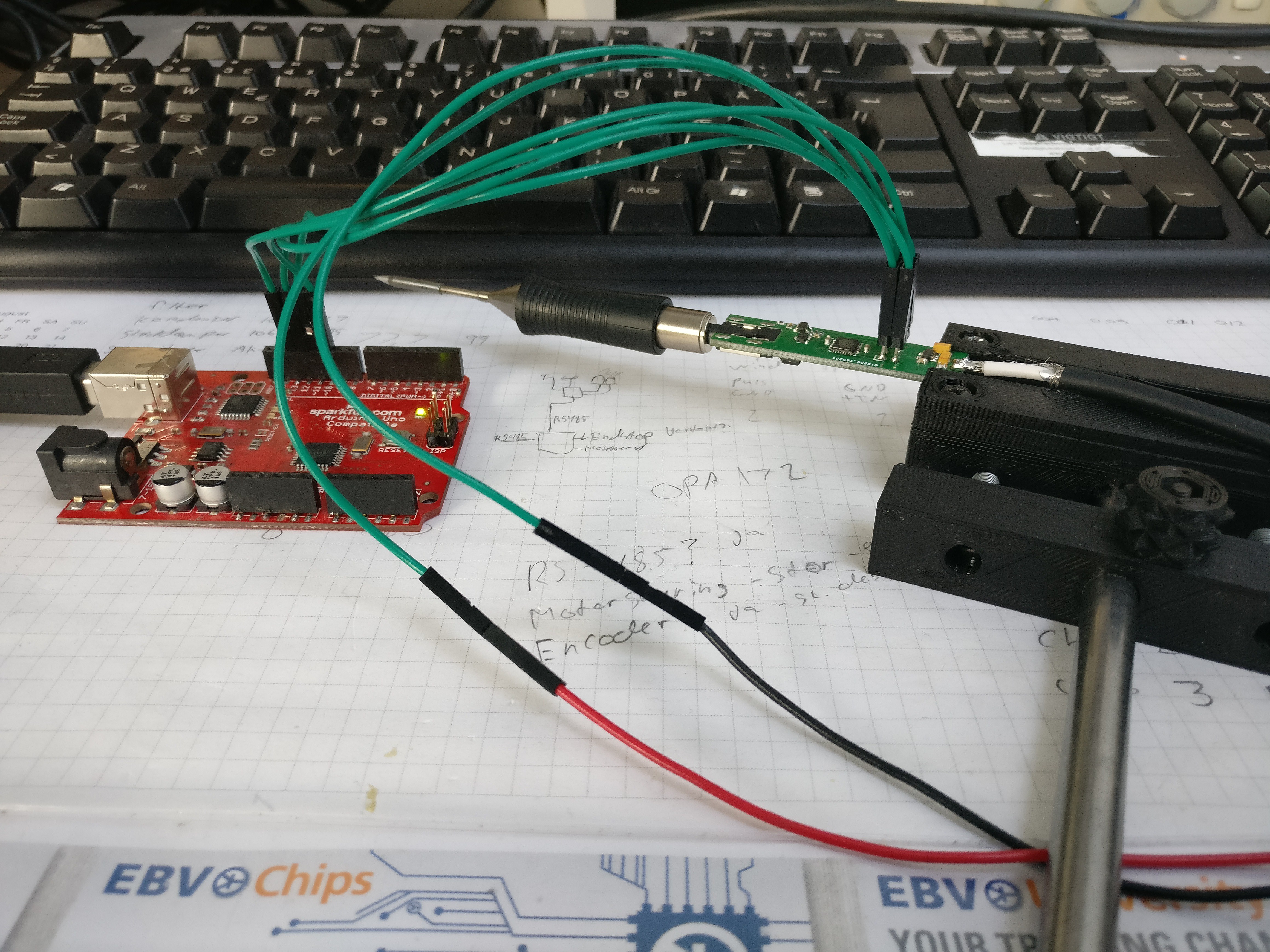

Another full-system view. The arduino-as-ISP is shown for completeness. the voltmeter connections are the black and red wires going to the right.

-

The problem with real life

06/14/2016 at 12:14 • 7 commentsThe problem with real life is that it tends to get in the way of your projects.

This update is far overdue - sorry for that! The paying projects (my job amongst other things) has been taking up most of my time. Also I'm leavning for a much needed vacation in a day. This all means that I won't be back until July to continue work on the soldering pen.

So what have I managed to get done?

Last time I wrote I was ordering PCBs. I have those - I've had them for a good month now. The trouble is programming the MCUs! I feel that I have tried everything. I have tried to solder all pins under a microscope securing all connections. I have assembled 6 boards but NO luck!

I have only put on the MCU and the ICSP header. That should give me both SPI access and power for the MCU. But I must have been doing something wrong on the design.

I have looked through the schematics but again - no luck. Everything seems to be in order - except is isnt. Could it be the MCUs? Maybe. I have them stored in a tray without any control of moisture. the tray is of the type with a small indent to keep each chip in place. a chip tray. it should be good enough, however I can't vouch for the chips. but that would mean that all my chips are fried. not a pretty thought.

I know that this project has gotten a fair amount of followers since the start. Maybe some of you would like to have a look at the design? If you find an error I will send you a working PCB :)

-

New PCB ordered - Now with accelerometer

05/03/2016 at 11:04 • 0 commentsI need a field for short updates, comment style.

I have now ordered the Rev.3 PCB. I birefly covered a change to 3.3V internal voltage but didn't tell that much about the reasons.

The reason (there is only one) is that I'm adding an accelerometer. Why you might ask? because my use-case has changed a little bit. I often find myself soldering in awkward spaces, close to the ceiling etc. therefore I might not have a magnet with me for turning the pen into standby-mode. the solution is therefore to have an accelerometer with tap detection so I can just do a double-tap and the pen will turn off. another double tap will turn it back on. The LED will provide the visual feedback I need to see if the command is received properly. In the end it's just an on/off state trigger. The hall sensor will provide the same feedback and the last input will provide the signal change.

Well, That's all for now. carry on!

-

A new PCB and a new CAD

04/26/2016 at 12:39 • 4 commentsOne of the fundamental ideas with the soldering pen was to have a small package and a 3d printed casing for the whole project. I don't know how it happened but somehow I completely missed the fact that the jack connector was not in the same plane as the board. of course. therefore I decided to look for a very low profile connector instead.

The first and second revision of the PCB showed that the principle was working. I could (easily) make a soldering pen with a small footprint and a nice set of features. Now I could focus more on the mechanics of the project.

I've found the connector: CUI SJ-3502-SMT. It's only rated for 1A but so is most of the jack connectors I can find. My biggest problem: slotted holes!

It turns out that DesignSpark PCB can't do slotted holes! Argh! Somehow I've always managed to get around this until now, but this was very much needed. What should I do? A new CAD tool is not a very funny solution.

Anyway I decided to have a look and I found CircuitMaker - the 'free' version of Altium, that in return requires that you store your project publicly. Fair enough I'm all for open source anyway and having a platform to share from is not that bad. At least I knew that I could get my slottet holes.

Fast forward 2 days and I've found out that Circuitmaker gets compoent specifications and footprints directly from octopart. this is insanely nice - crazy nice! beacuse that means that when I'm done with a component it will be shared for everybody else to use. voilá, a single global component library. wow!

Also Circuitmaker, being Altium under the hood, of course works in 3D. So almost all components have 3d models attached.

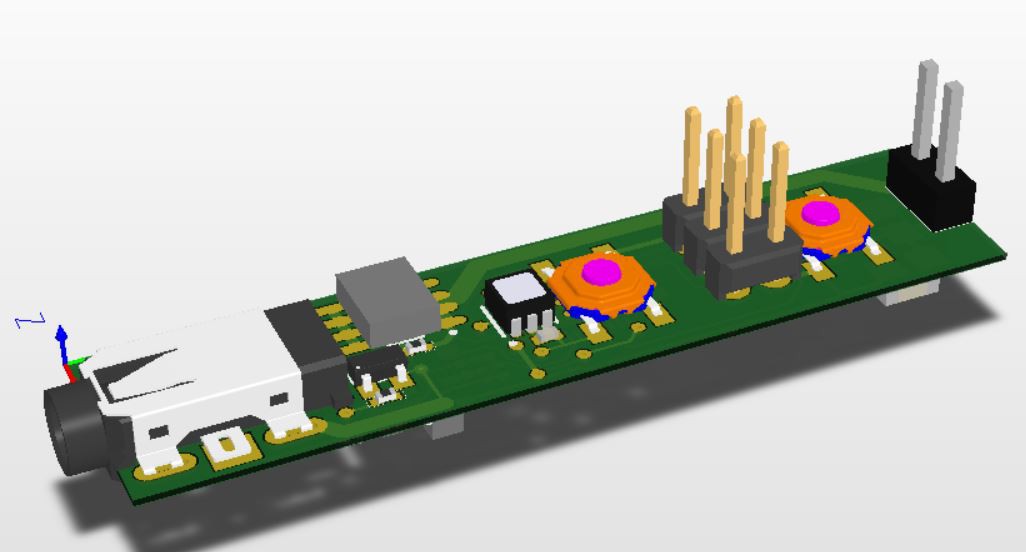

Look at this:

Isn't that beautiful?The new low-profil jack connector is clearly visible and I've changed the LED to a SMD version.

I'm really close to removing the programming header and replacing it with.... something smaller. I have an idea for something that could fit in that space..

-

Take a stand...

04/16/2016 at 12:48 • 3 commentsThis is exactly why I love 3d printers. When you have an idea you draw it and then you print it. Simple as that.

Of course the soldering pen needs a stand. And why can't it be printed?

I know that a lot of people will tell me that it will melt and maybe they're right. But I havent seen them print a stand for their soldering pen yet. So here goes:

![]()

It shows some problemswith the board layout of the pen. for example the hall sensor for standby detection is located a really stupid place - in the opposite end of the tip. Why is this a problem? Well, the support containing a magnet for the hall sensor to detect has to be really long!

For now I have chosen to move the magnet 20mm downward but of course there's no hall sensor there right now. Luckily I will do another PCB revision because I want to change the mini-jack plug to a different model that will keep the connector on the same plane as the PCB. This is another story but it will make it possible to have a round casing on the pen. it will be more pen-like.

I'll conlude this log with a picture of the stand with the pen inserted. haven't turned the thing on yet. Soon. very soon :)

![]()

HP (@banjohat)

HP (@banjohat)