-

It's finally DONE! Well, for now!

03/13/2017 at 01:07 • 0 commentsPhew. All done and ready for the Maker Faire. And it runs and runs great! In the end, I learned:

1) My choice for track works well in one direction only. Going in reverse throws a track

2) 2.5HP is not enough

3) I over engineered it in the effort to make it 'Heavy Duty'. I should have stuck to a metal body

4) I would use straight through axles for the road wheels. I have 16 pillow block bearings there. Each weights close to 3lbs. I could do fine with axles and 8 bearings instead.

5) The lexan sprung bogie is not strong enough for heavy duty work. I have to switch to metal

6) Electric is not the way to go for something this heavy. The motors are way too heavy and the 8 batteries are killer in terms of weight.

But...I love it!

![]()

-

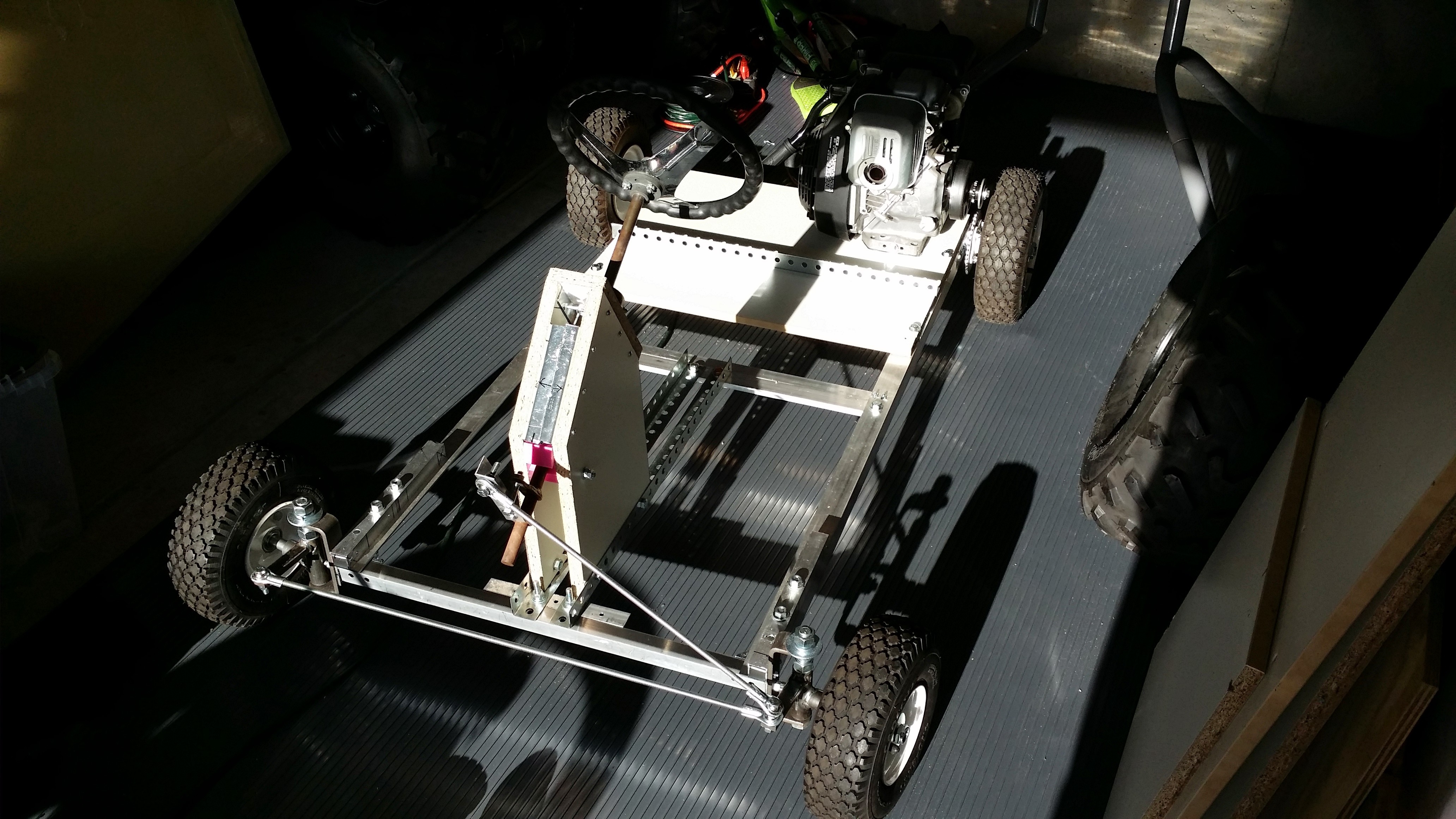

How does it look?

04/26/2016 at 12:41 • 0 commentsOk, it really still looks like a Go Kart, but we are not far away now. My next step is to complete the wiring and run the track. Once done, I will ride it around a bit before I convert to full tank.

![]()

-

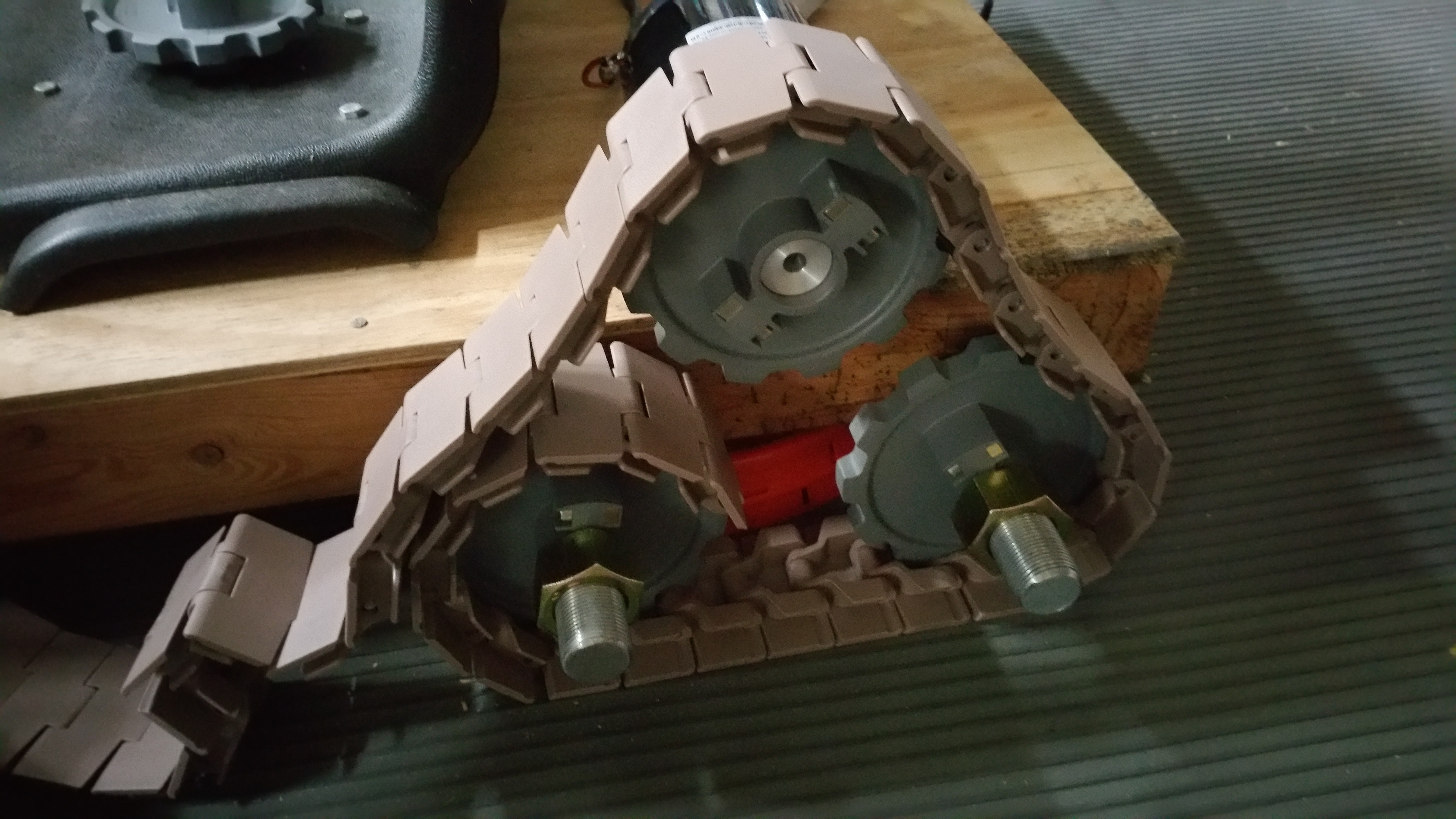

Test Fit the Drive/Track System

04/26/2016 at 12:36 • 0 commentsTime to test locate the motor and install the drive sprocket. Notice the metal cylinder in the drive sprocket. A set screw is being used to secure it to the motor shaft. As you can see, it's pretty simple to do this, it's also pretty simple to replicate this architecture up front and make it a a 4 point tracked system (hybrid) or full tank, by just extending the track all the way to the front and adding more wheels. When I go full tank, I will want to raise the ground clearance.

![]()

-

Install the Axles and Test Fit the Idlers/Road Wheels

04/26/2016 at 12:33 • 0 commentsI originally wanted to put in suspension, but for now that is not going to work. Instead, if I go full tank, I will look at a bungee-cord based torsion bar suspension mechanism I have come up with based on what I have seen on some older aircraft. At that point I would probably need to double up on the tracks. For now, though, the idler sprockets are also the road wheels. Bonus: with differential power, I will be able to steer the tank with throttle controls alone and they motors have electrical braking.

![]()

-

Axle Holes

04/26/2016 at 12:29 • 0 commentsI found that I had to force the large threaded rod axles in very gingerly. I didn't want to wreck the wooden frame. I also realized I should cover the wooden frame in fiberglass when I was done. I made sure that the distance between the 2 rear axles was short, because I didn't want to add 'guide teeth' or something similar to the plastic track and I had decided to do a triangular drive system to conserve space. This meant that any flex in the track was constrained by the sprockets.

![]()

-

Initial Steps

04/26/2016 at 12:25 • 0 commentsPretty simply, I had originally built my goKart out of metal I bought at Home Depot. The way it worked was that it had one drive wheel (rear right when facing the back of the Kart) and one wheel with a drum brake (rear left).

![]()

The Kart was doing close to 30mph at half throttle, so it was scary. Instead it was converted to use a wooden (heavier) frame. Once the decision was made to convert it to a Half Track, the same decision was made to make it a full tank.

Steps:

1) Removed the engine, rear axle and rear wheels

2) Measured and inserted a pair of 1.25" threaded rods, 36" long each

3) Cut a set of metal cylinders to fit the bore of 2 drive sprockets (from InterLox), which in turn fit the shafts of a pair of electric motors

Go Kart Tank (formerly Half Track)

Go Kart Tank. Used to be a gas powered Go Kart, became a Half Track and then became a fully tracked vehicle.