After the experiments with resin, I recognized that the pot time was way to short to mix the material before starting a print. As such, I need an easy setup that will mix the two part resin just before injection.

Thankfully this is a problem that's been solved multiple times. My favorite solution is the disposable static mixer - particularly these from Loctite as they are cheap and have technical specification diagrams on their website. Thank you Loctite.

The end of the mixer is a luer slip adapter, so the needles I've been using will slip right on. So then the next challenge is how to get this mixer attached to the 3D printer where the hotend would normally be.

Thanks to advice from @ear0wax, I recognized that most 3D printers that move the build plate would probably burn out a motor moving around a big vat of gel. As such I've decided the best printer type is a delta printer, particularly the Kossel.

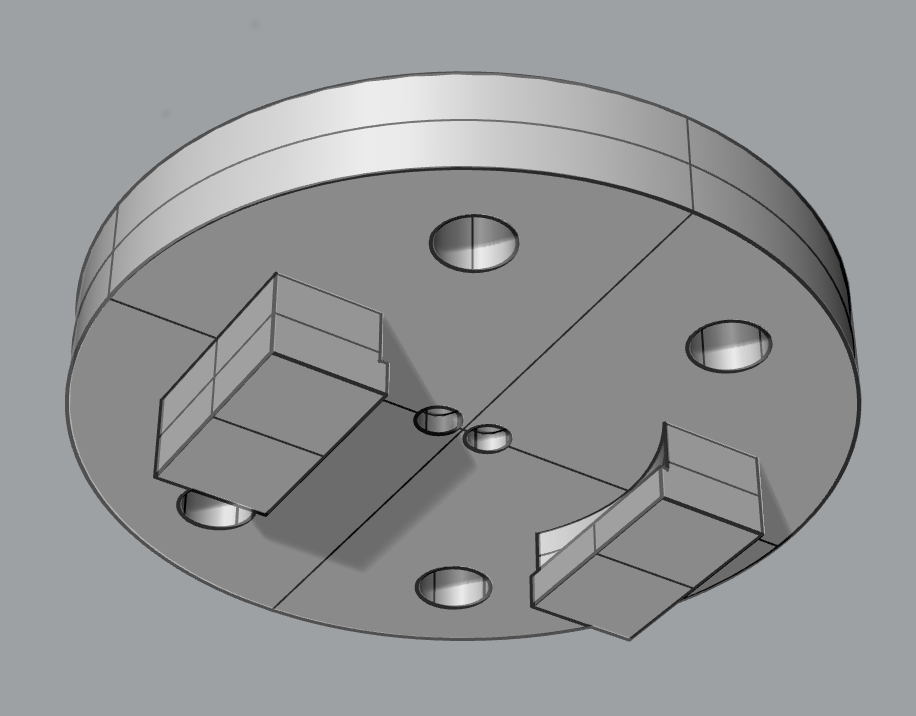

I've designed an adapter plate that I can easily attach a static mixer to and insert the tubing for the resin parts. Here's the part, which I've included in the files section of the project:

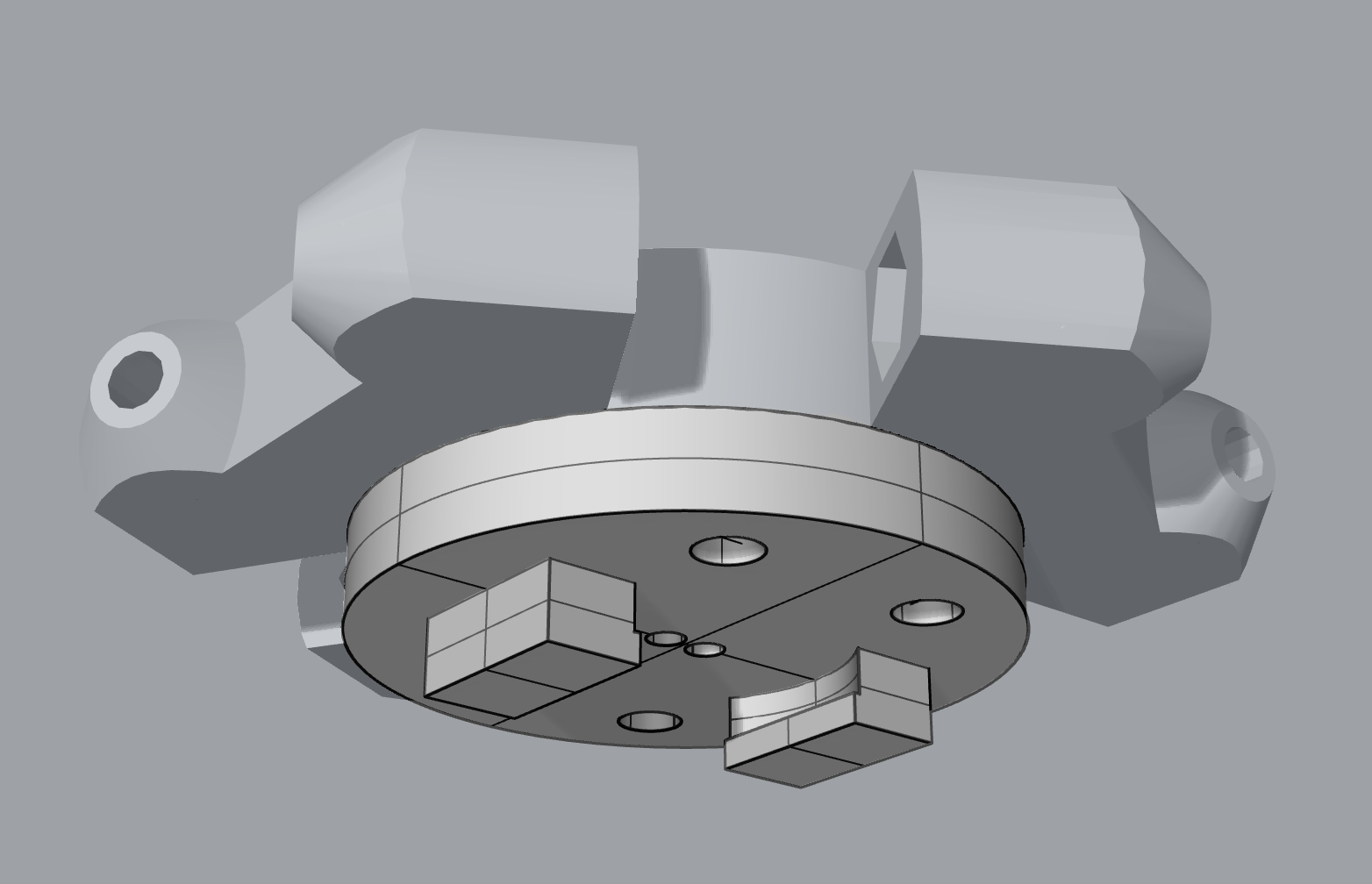

Here's what it looks like attached to the "effector" - the plate that floats at the vertex of the delta arms:

Of course I'll need to tweak this thing a bunch to account for 3D print tolerances, etc. That will require getting a Kossel printer, both to make the part and fit the part to the printer. If I'm chosen for any of the early rounds for the Hackaday prize this year, I intend to use the prize money to buy the printer for this stage. Otherwise, I'll need to beg/borrow one. Wish me luck!

Michael

Michael

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I could print parts for you if you like.

Are you sure? yes | no

Heck yea! That would be awesome, thanks! I'll DM you.

Are you sure? yes | no