Problem

By far the most popular 3D printer technology for hackers on the market today is fused deposition modeling (FDM): it's cheap, it's customizable, and the materials are easy to acquire and generally safe to work with. There are several limitations to the design, two of which stick in my mind the most: they only work with thermoplastics, and the deposition of many small layers limits the types of shapes that the printer can make.

The printer technologies that enable a wide range of materials end up being quite expensive and not very hacker-friendly. And technologies that can handle more diverse shapes like STL or SLA require highly specialized materials to work. I think this holds back the 3D printing community. As such I've been searching for a new 3D printer technology that meets all the criteria for the maker/hacker community:

- Inexpensive

- Open Source

- Easy to understand & modify

- Supports a wide range of materials

Solution

Many formable materials are self-hardening: two-part resins and epoxies, cement, plaster, silicone, etc. However, getting them to keep their shape requires a mold. My idea is to take advantage of shape-retaining nature of many gels to act as a mold as a part is printed, injecting a hardening material into the gel where it will retain its shape until hardened.

This design requires a 3-axis, precision motion arm, common with any FDM 3D printer, enabling the reuse of an already popular and open source technology. The only additional needs are a vat for the gel and a pump/needle mechanism. In the future, the design can include a material-mixing system.

From a software perspective, the majority of tooling created for FDM can also be reused, although it may very well prove to be different enough to warrant new slicing techniques, etc.

Proof of Concept

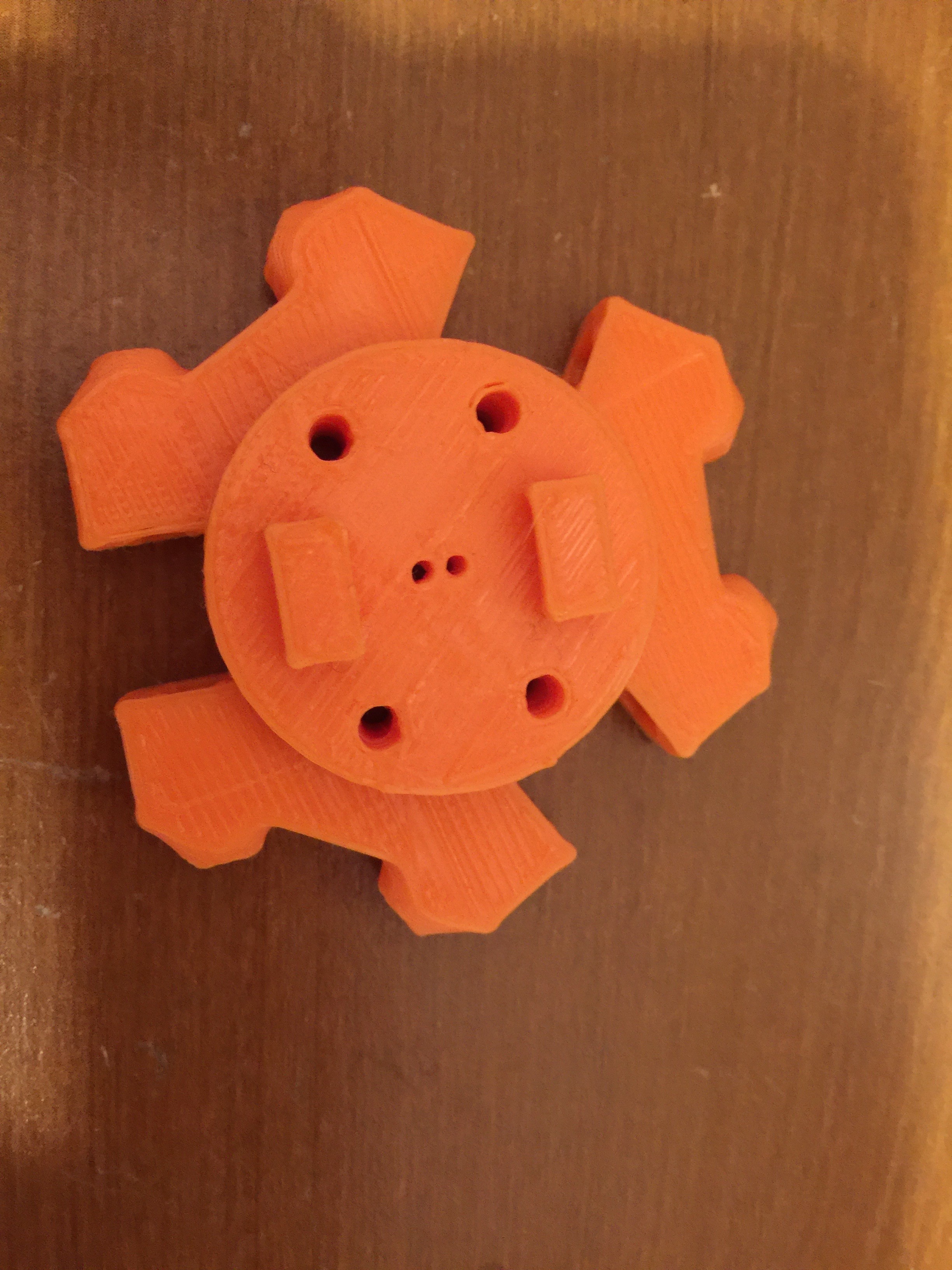

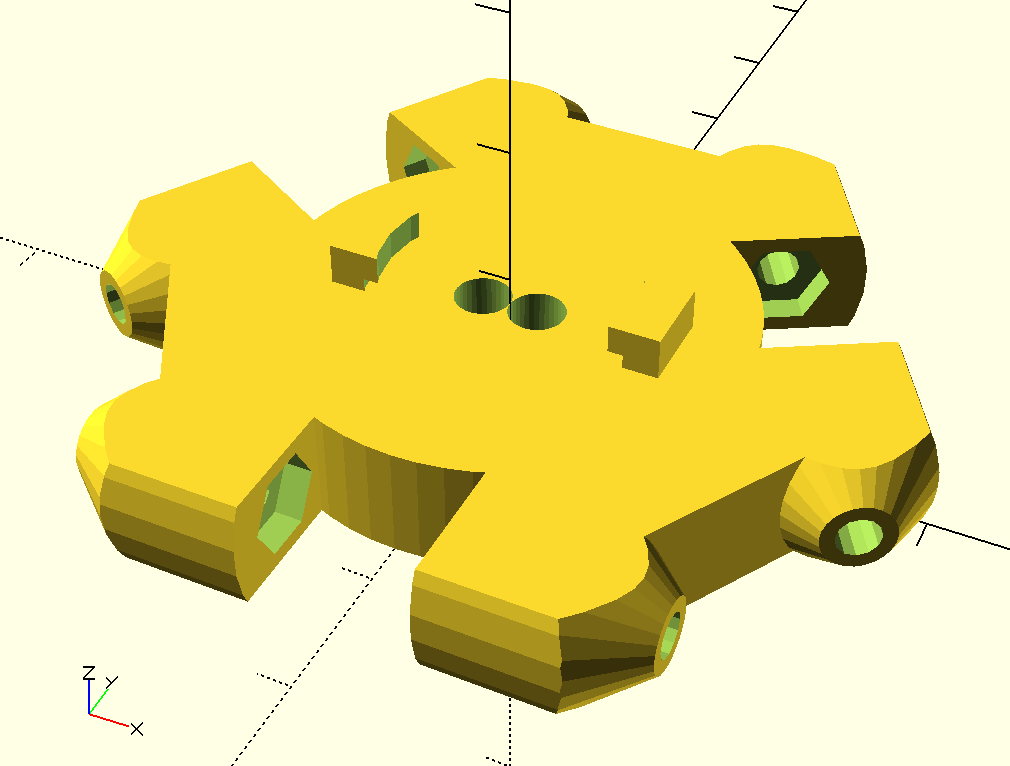

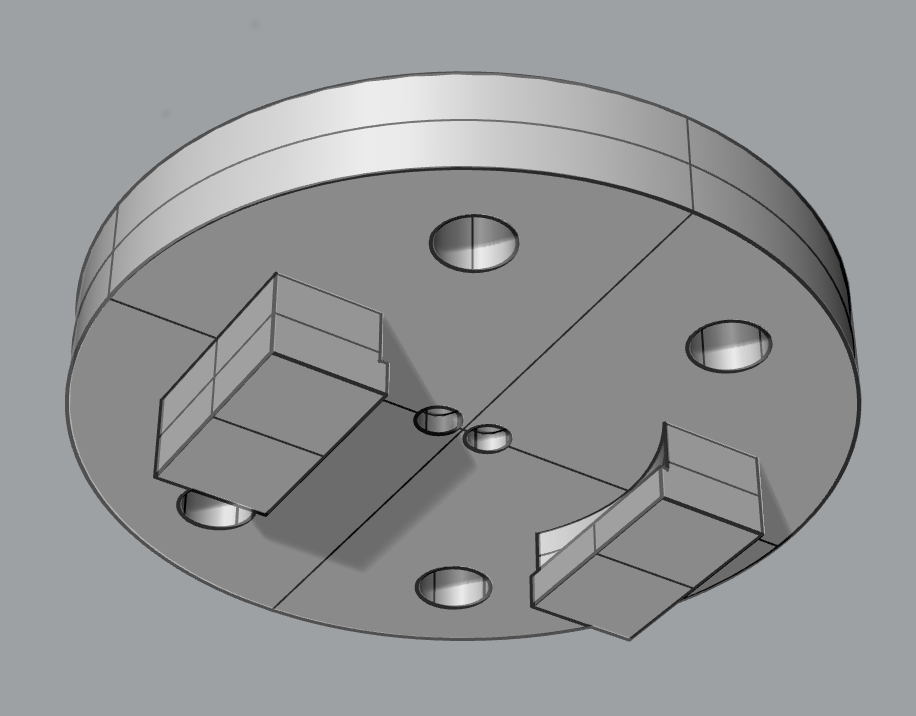

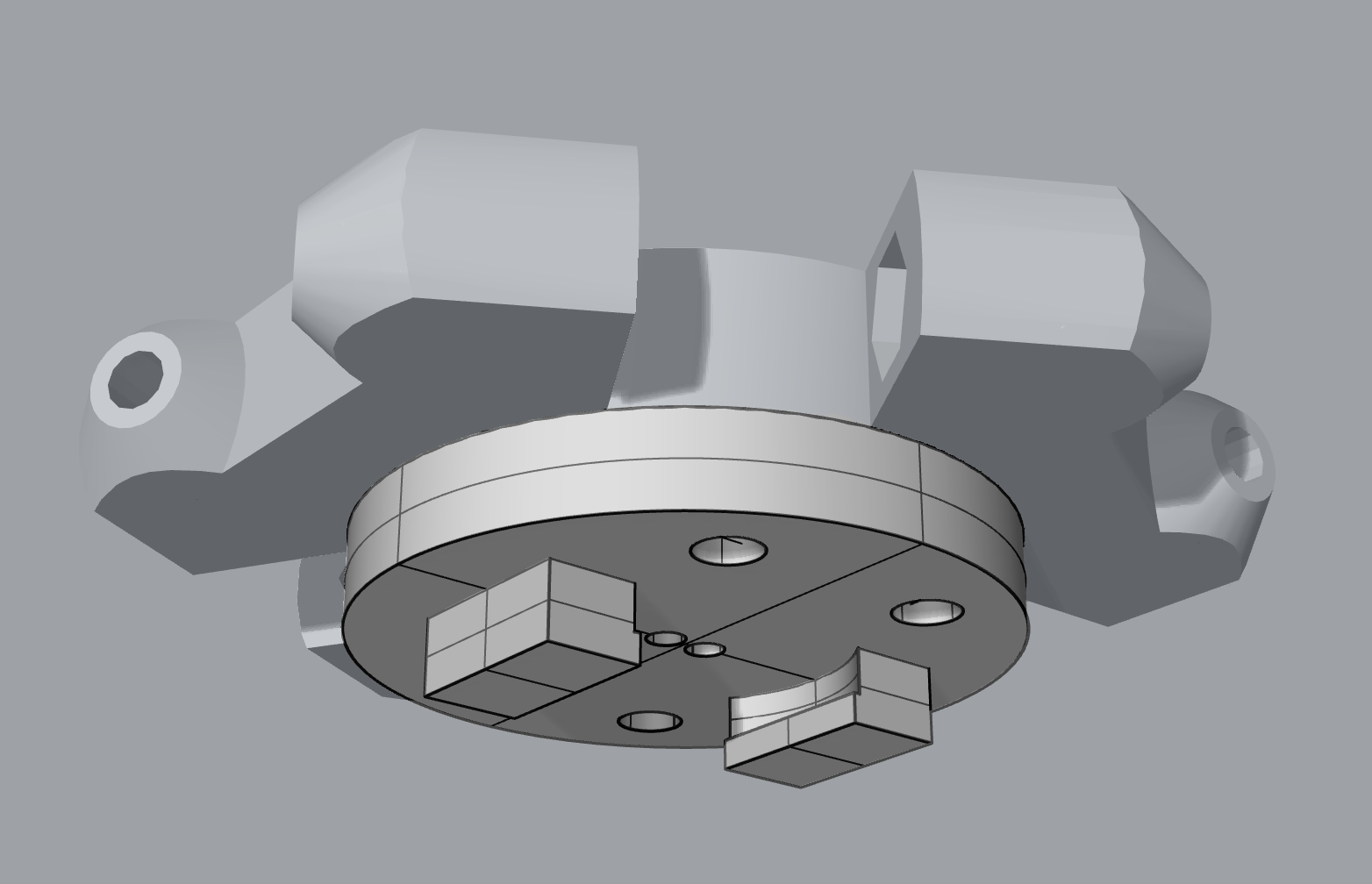

To prove out the idea, I intend to take a standard fused deposition 3D printer, replace the extruder with a needle head, and place a vat of inert gel on the build plate. Material will be pumped through the needle using a peristaltic pump to provide fine-grained flow control. I've found a great 3D printed implementation of a pump that works with a stepper motor. By rewiring the pump motor to the control board, the 3D printer can drive the pump like it would the extruder head, minimizing/eliminating any major firmware/controller modifications. I've accomplished this before in an attempt to make a 3D printer for clay.

Materials

Materials suitable for injection must have the following properties:

- Chemical curing process, e.g. thermoset resins

- Capable of curing in an airless environment

- Curing times of at least 2-3 minutes

In selecting a material, it's also important to select an appropriate gel medium that won't negatively impact the curing process of the material. For instance, some resins react poorly to moisture and may need an oil-based medium. Other resins are the exact opposite, and would need something water-based or an exotic solution.

So far I've identified four off-the-shelf materials that I think will work nicely for experimentation:

- Plaster is cheap and should be relatively versatile. This will probably be the first material I'll try. My major concern is grit blocking the needle. So I'll need to filter the powder with a pretty fine mesh with hole size of a fraction of the needle inner diameter. Since it cures when wet, my initial concern was using a water-based medium, however I think that the plaster will remain cohesive and not leak out into the medium too much.

- Portland Cement is also cheap and relatively versatile, but would be even more susceptible to grit issues and will need to be filtered.

- Silicone Caulk cures using moisture and would create flexible prints. The down side is that it's pretty thick, so I'll need to investigate ways to thin it. I've heard of mixing water to accelerate hardening - unsure how much water can be added before it negatively impacts the material properties.

- Two-part epoxy could provide really solid prints. There's such a wide variety of options...

Michael

Michael

Great project. I am currently to devellop exaltly the same project with an extruder attach to a robot arm. Would you have any suggestion to get thicker resine and cheap gel ?