Construction 3D Printing

SALEM is a form of Construction 3D printing, a relatively new method of Additive Manufacturing aimed at producing large objects for construction purposes. The general principle of Construction 3D Printing (C3DP) is the same as that of its much smaller desktop counterpart. A desired article for manufacture is designed using CAD software and is “spliced” into consecutive layers from the bottom of the model to the top using special software. These layers are then converted into manufacture instructions that tell the printer how to operate to reproduce that layer. The 3D printer then manufactures the desired article by printing out the model layer by layer according to the manufacturing instruction file (often referred to as a GCODE).

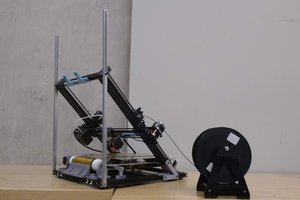

The materials printed by C3DP machines are typically cement or metals and the printers come in many shapes and varieties. These include rotary arms, robotic printers and overhead cranes to name a few styles. One of the best examples of current C3DP technology is a rotary arm printer designed by Apis Cor (see below).

Current C3DP Issues

One of the key issues with current C3DP machines is scalability. To print a larger structure, you generally need to build a larger printer which is more expensive and limits the ease of assembly or deployment of the printer. The Apis Cor printer for example, can only print within a circular envelope as wide as the print arms reach (about 8.5m).

Some C3DP companies, such as the Chinese company WinSun, have approached this issue by completing their prints in segments at a central location, then assembling the segments at location. There are two main issues with this solution. The first is that it requires transport of the segments to the final build location. This is cumbersome for large structures and prohibitive for building structures in uninhabited regions without transport infrastructure like roads and where it is difficult to erect craneage to lift and place the segments.

The second issue is that structures built in segments are inherently less structurally sound than a structure printed in one constant extrusion.

How SALEM works

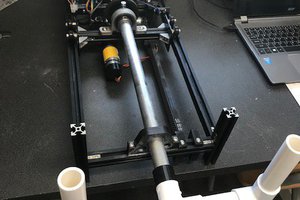

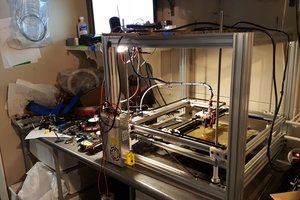

SALEM works by triangulating the position of the Extruder based on the extension length of the Hoist cables and the relative positions of each Hoist. The Hoists can traverse the length of the Support Structure and will rise gradually as more layers are added to the printed cement structure. The Hoists can extend or retract the cables and by extending some cables and retracting others, it is possible to move the relative position of the Extruder in a fully controlled manner. This allows the Printer to print any shape within a 3-dimensional print envelope. The Printer could be capable of printing with millimetre accuracy once fully developed and will be capable of printing far more complex structures than current construction methods feasibly allow.

Each of the Supporting legs are composed of several standardised pieces. By adding or subtracting these grid pieces from the support the height of the printer can be adjusted. It is permissible to secure these Support Legs at any practical length apart, from as little as 2 meters separation, to upwards of 100 meters. When erecting the printer there are several calibration operations which set the starting positions of the Hoists, Support Legs and Extruder as well as identifies ground height and slope of the print envelope. This means that it is unnecessary to position the legs perfectly square as the print envelope is entirely relative.

Why

Benefits of Construction 3D Printing

There are several benefits to construction 3D printing that have already been proven by many of the current C3D printers in development. The main benefits are:

- Cost – C3DP reduces the cost of building structures by minimising waste and significantly reducing the number of manufacturing steps...

jon.knutton

jon.knutton

Swaleh Owais

Swaleh Owais

Tim

Tim

adamfilip

adamfilip

0n37w0

0n37w0