-

On the Kindness of Strangers

05/26/2016 at 16:02 • 0 commentsHi all,

Sorry for the delay in updates - for the past month, I've been in the process of selling my home which has significantly hindered my ability to hack.

I've decided to move to a delta printer for the prototype, but I have a problem: I don't own a delta printer, and considering all my moving about I'm not in a place to buy a bunch of equipment yet. In the next few weeks I'll be settled into my new place with plenty of garage space, but how do I keep moving on my project when I have to keep my current place looking like a showroom? Enter the awesome @Ryan Shill.

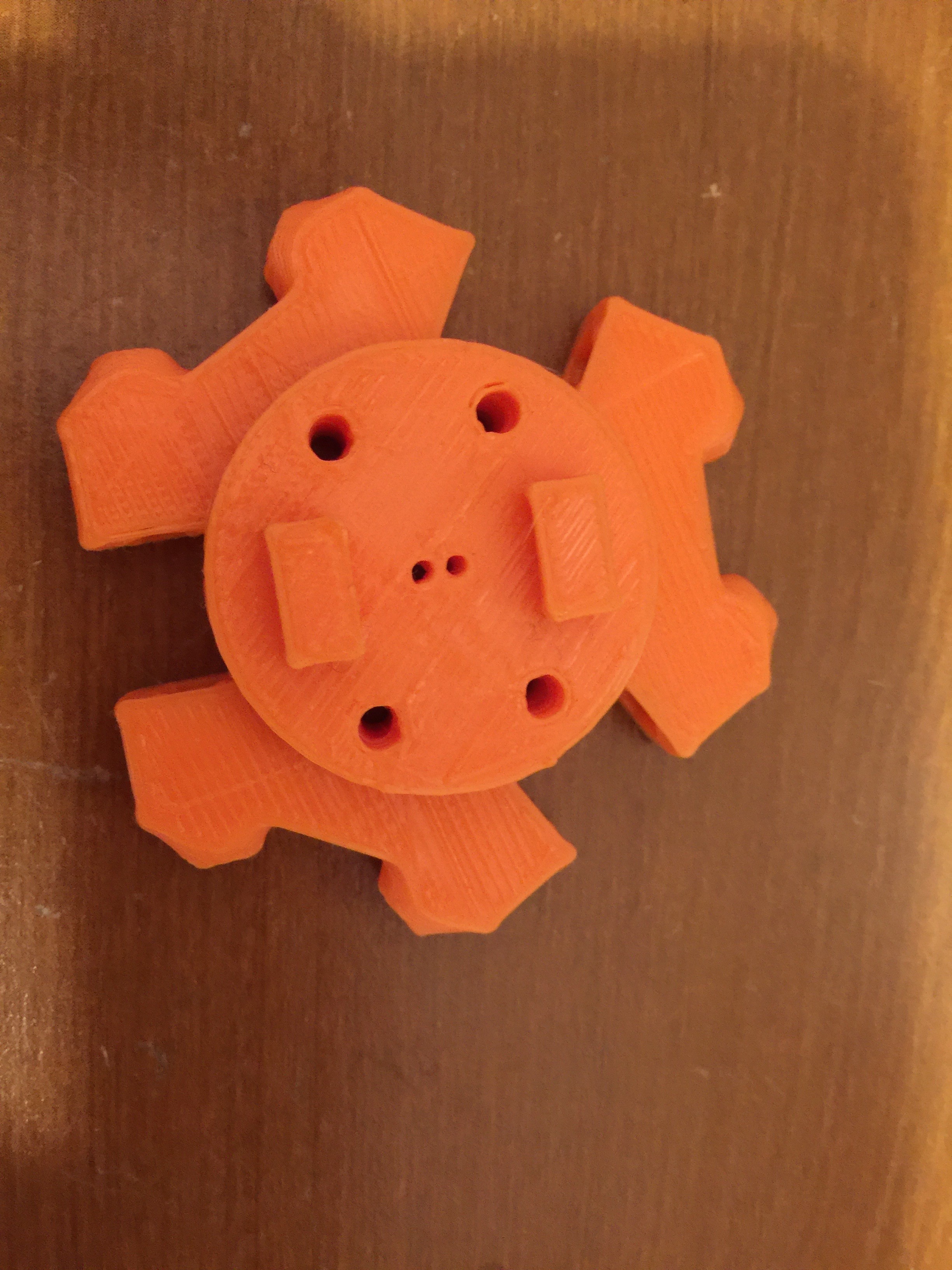

Ryan generously offered to print my adapter part so I could validate that my design would fit all the correct parts - in particular the silicone tubing and static mixer. Here's the printed part, sitting on top of a printed effector plate he also printed for me to check sizing:

![]()

In trying out the dimensions I've found a number of issues, the biggest being that the hole through the standard effector plate just doesn't give me enough space to fit the silicone tubes I needed. Furthermore, I chose too small of silicone tubing.

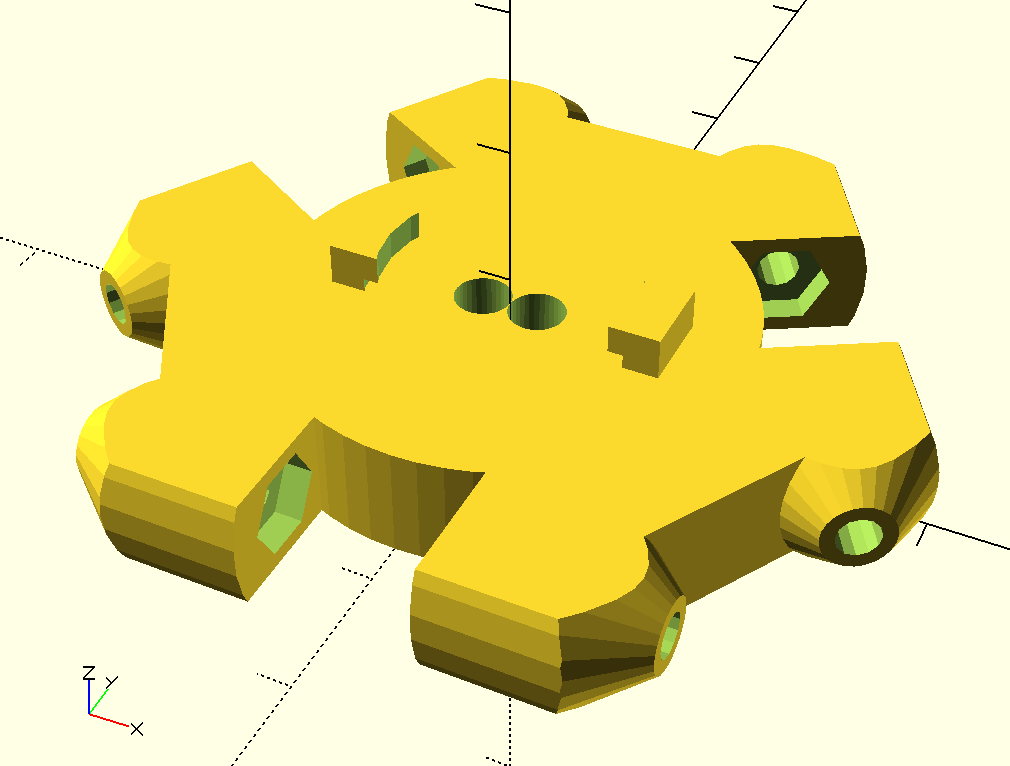

So I've pulled the original OpenSCAD for the effector plate, and modified it to match the right dimensions for everything, in the effector plate itself. This way to make the printer work as a suspension printer, you need to replace the whole effector plate. This has the advantage that you don't need to disassemble your extruder to modify the printer, so that's a big plus!

Here's the new part:

![]()

You'll find the modified OpenSCAD file attached to the project.

Next steps, I will be trying to actually get a printer to modify. I have a clever idea for how to get my hands on one very, very quickly...stay tuned to find out my plan!

-

Mixing & Matching

04/13/2016 at 04:13 • 2 commentsAfter the experiments with resin, I recognized that the pot time was way to short to mix the material before starting a print. As such, I need an easy setup that will mix the two part resin just before injection.

Thankfully this is a problem that's been solved multiple times. My favorite solution is the disposable static mixer - particularly these from Loctite as they are cheap and have technical specification diagrams on their website. Thank you Loctite.

The end of the mixer is a luer slip adapter, so the needles I've been using will slip right on. So then the next challenge is how to get this mixer attached to the 3D printer where the hotend would normally be.

Thanks to advice from @ear0wax, I recognized that most 3D printers that move the build plate would probably burn out a motor moving around a big vat of gel. As such I've decided the best printer type is a delta printer, particularly the Kossel.

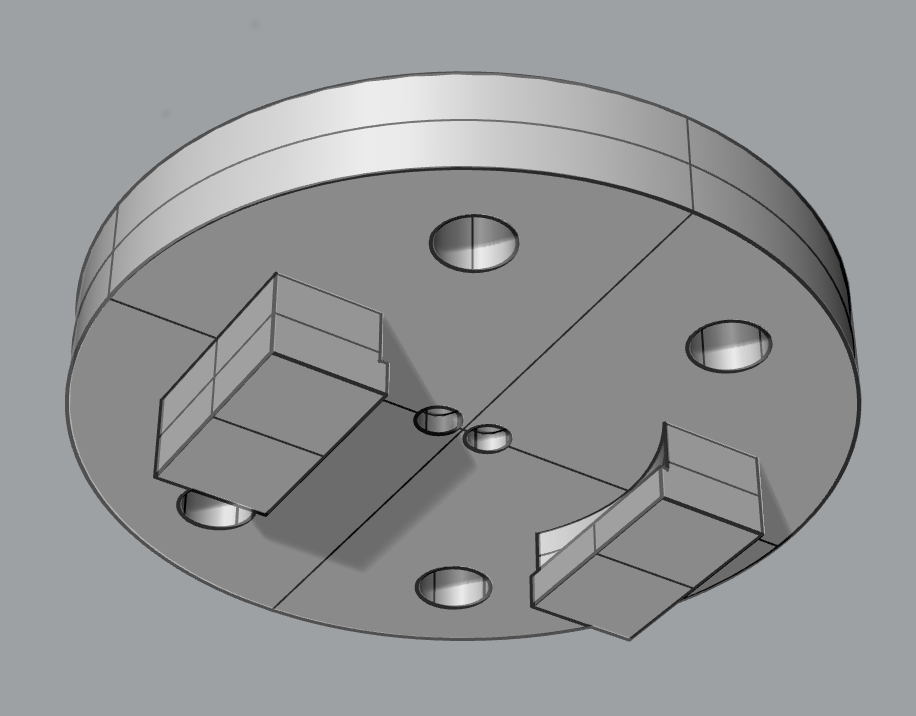

I've designed an adapter plate that I can easily attach a static mixer to and insert the tubing for the resin parts. Here's the part, which I've included in the files section of the project:

![]()

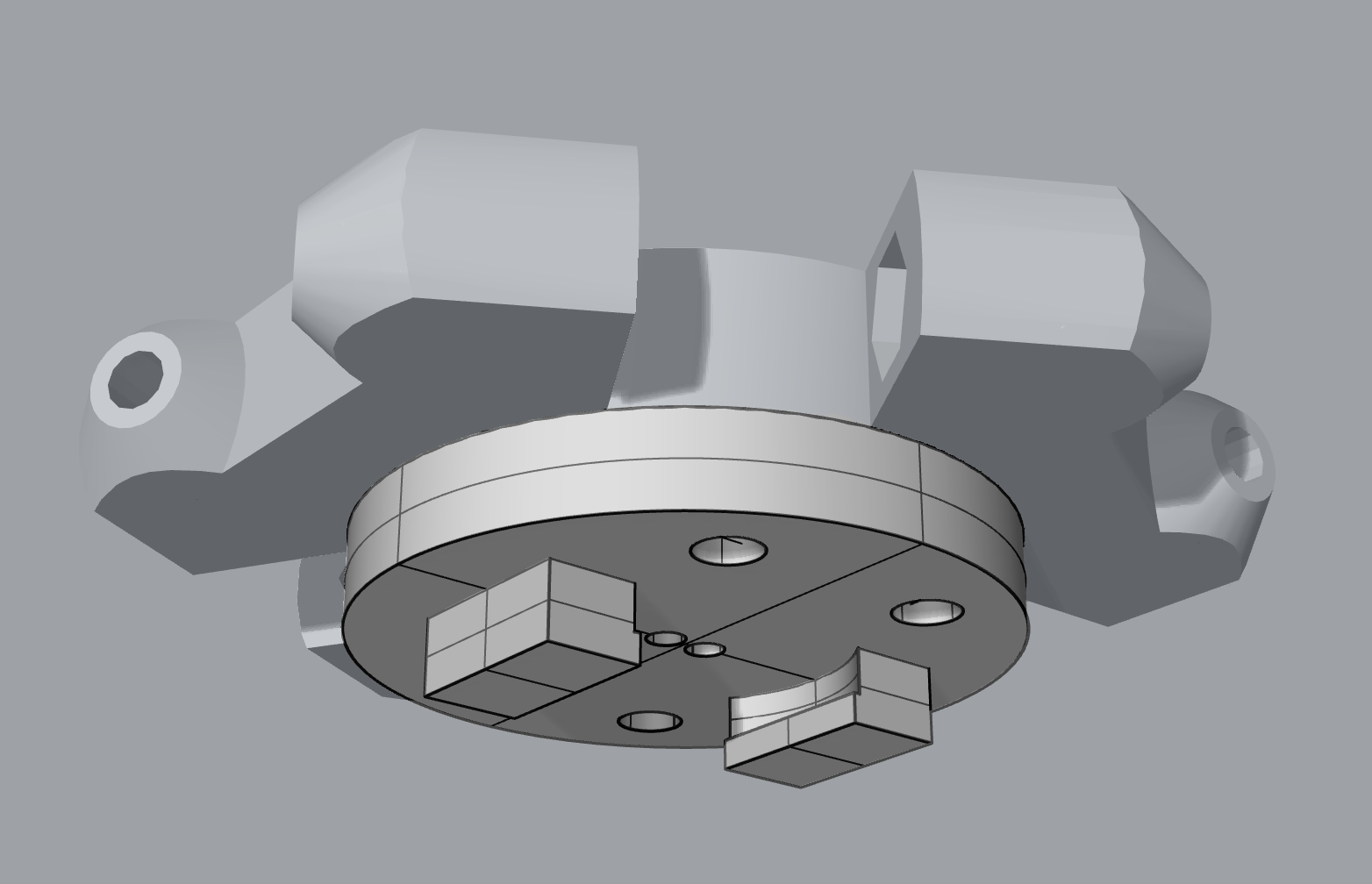

Here's what it looks like attached to the "effector" - the plate that floats at the vertex of the delta arms:

![]()

Of course I'll need to tweak this thing a bunch to account for 3D print tolerances, etc. That will require getting a Kossel printer, both to make the part and fit the part to the printer. If I'm chosen for any of the early rounds for the Hackaday prize this year, I intend to use the prize money to buy the printer for this stage. Otherwise, I'll need to beg/borrow one. Wish me luck!

-

Weird Science

03/30/2016 at 15:50 • 0 commentsI just got in the Smooth-on resin and supplies. I tried a few tests to see what kind of issues I'd run into using a resin like this in a water-based gel. I injected mixed resin into a shallow container of gel, mostly to make sure that the combination didn't cause major issues in curing, etc. The results were promising, if a little primitive. Here are some examples of what came out from simple injections:

The resin cured fine in a water-based gel, considering all the issues I've heard you can have with curing urethane resins in high moisture environments. So that's one issue I don't need to worry about.

I also found that, for the most part, injecting resin into a gel will allow some extrusion of shapes. That being said, I encountered two big issues I wasn't too thrilled about:

- Resin Leaks occurred when I first tried to inject into the gel - the resin would travel up through the hole made by the needle and create a small pool at the surface of the gel.

- The Resin Hardened Too Quickly as its pot time is only a few minutes. Those minutes go by fast. I think for future tests I'm going to need a resin with a longer pot time, and for the final proof of concept, I'll need to build something that mixes the resin just as it's going into the gel.

The resin leak issue was bugging me. The major issue was that the resin was too fluid, and the gel was too viscous. The gel held its shape too well, keeping holes open when it should have filled them in. The resin wanted to flow everywhere.

So I thought I'd try to test some different materials that I could tweak the viscosity of, to see if there was a balance of material to gel that worked well. The solution was to mix flour and water to act as the material, and whisk the gel with water to make it less viscous. And it worked great.

Now I could easily inject bubbles, lines, etc. into the gel. It was so much fun to extrude into the gel that I made some GIFs :)

![]()

![]()

![]()

Next steps are to get some more gel, some materials for thickening the resin, and some plaster. Wish me luck!

-

First Steps

03/26/2016 at 00:30 • 1 commentOkay Hackaday community, I'm starting some first steps towards the proof of concept. I've ordered a bunch of syringes, a bunch of water-based gel (the kind used for ) and per the recommendation of @Jarrett, some Smooth-on 300 two part resin. The first test will be to hand-inject some mixed resin into the gel to see how the two interact and experiment with shape, movement, flow rate, etc.

I'm also going to pick up some plaster for testing as well, as I realized that if I can use plaster to print, it could be a great way to make low-temp metal casting molds.

While I wait for supplies to arrive, I'm doing research into a good 3D printer for this project. So far the best candidate seems to be the Prusa i3 or some variant, and I've mocked that up in the header image. I considered a few other models including delta printers, would love any thoughts you might have on the subject

Suspension 3D Printing

A unique approach to 3D printing that injects curing resin into a gel. The rig is designed to be added to most hackable 3D printers.

Michael

Michael