-

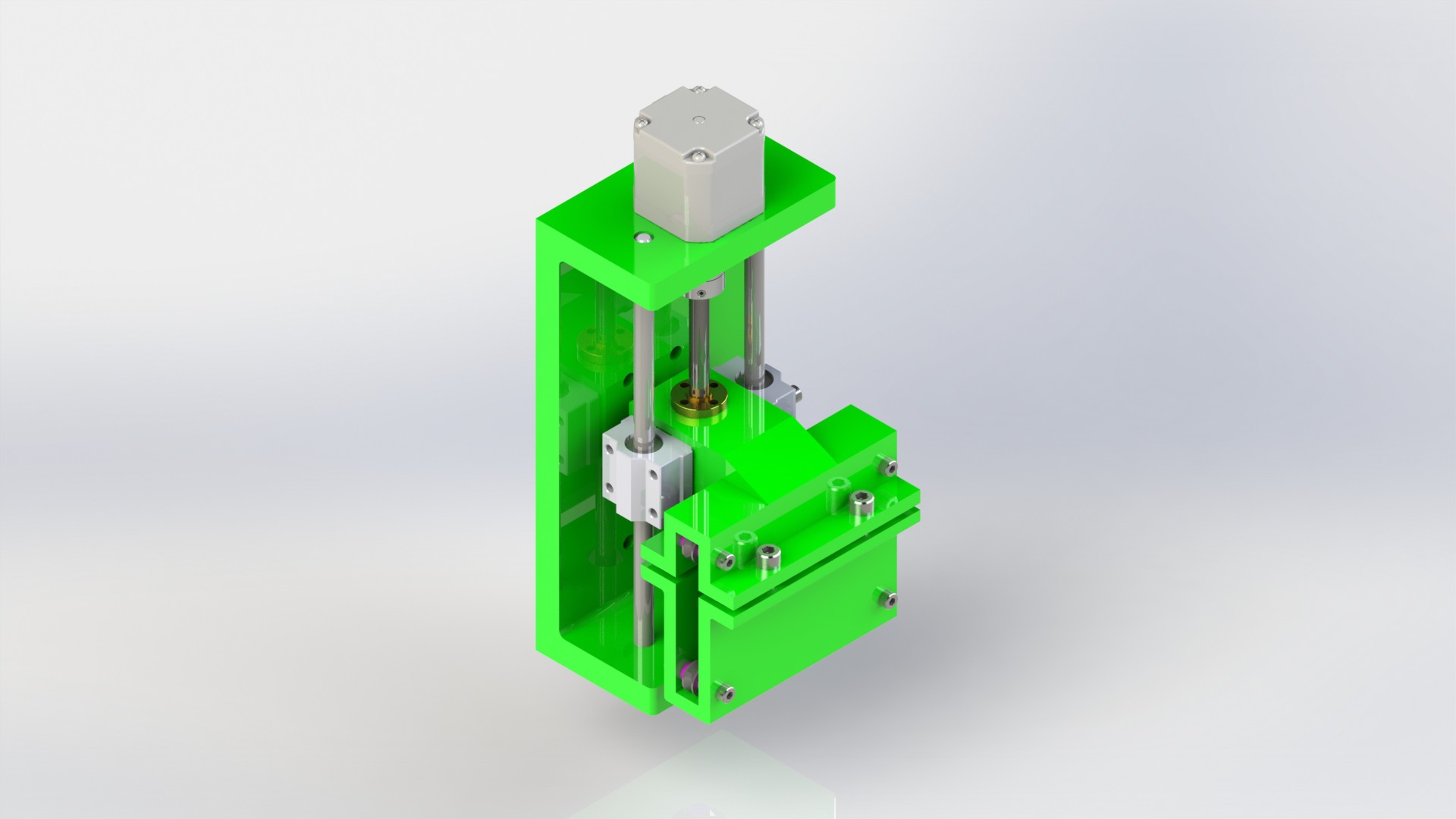

Iteration four of our desktop CNC milling machine

05/16/2016 at 17:47 • 0 commentsWe’ve been working hard for the last few weeks to iterate and design our desktop CNC machine design and here’s a rendered CAD image of where we are right now.

Before putting in the electronics, we have just over 160 parts. Compared to other desktop CNC milling machines, this is an incredibly low number (about 280-300 on the Shapeoko BOM and X Carve BOM) but we’re still working on finding ways to do more with less parts, simplifying assembly, and making repairs easy.

![machine proto v4]()

![machine proto v4 pink ed]()

-

We get a new 3D printer

05/16/2016 at 17:47 • 0 commentsWe’ve had our 3D printer, the Tevo Tarantula, for just under two months, and it has served us beautifully. I decided on picking up a new printer due to the fact that it kept breaking down and needing maintenance, and so the plan is to take apart the Tarantula and use the parts to build new machines.

The Tarantula decided to start doing weird things in the z axis and I finally pulled the trigger in purchasing a new printer.

So we purchased a new Wanhao i3 Duplicator on Friday, and Tim brought it back from Richmond Hill last night. It took about 20 minutes to set up and we were printing right away.

Besides a mishap involving the spool falling out in the middle of the night, everything has been working great! Long live the Duplicator!

![wanhao 3d printer setup]()

![new printer box]()

-

More prototyping

05/12/2016 at 17:00 • 0 commentsWe’ve put together a number of rail and gantry prototypes during the past week or so. A bunch have parts have come in for testing, and we’re excited to try them out!

We’ve had interest from a few different places to develop some linear rails for 3D printing applications, so we have created a few designs to address that. This means creating smaller and lighter versions of our current rails and exploring different setups, from belt drives to lead screw drives, angle style rails or flat bar style rails.

![3D printing motor mounts and idler mounts]()

![rail and gantry tests]()

![linear motion assembly]()

-

We recieve $5000 in funding!

05/10/2016 at 16:35 • 0 commentsWe won $5000 from yesterday's pitch competition! 18 teams presented their pitch to two of our judges, David Rose and Nada Basir, from the Conrad Business, Entrepreneurship, and Technology Center.

Special congratulations to our other pitchers who won an award:

- Aaron Cote, Polyball Studio Monolith

- Ashwin Krishnan, WeSmart Technologies

- Ron Tsang, Thyme

- Richard Norton, Edible Art Project

- Susanna Yu, BeautyTime

- Zain Kevashjee, Soko

-

We recieve $5000 in funding!

05/10/2016 at 16:35 • 0 commentsWe won $5000 from yesterday's pitch competition! 18 teams presented their pitch to two of our judges, David Rose and Nada Basir, from the Conrad Business, Entrepreneurship, and Technology Center.

Special congratulations to our other pitchers who won an award:

- Aaron Cote, Polyball Studio Monolith

- Ashwin Krishnan, WeSmart Technologies

- Ron Tsang, Thyme

- Richard Norton, Edible Art Project

- Susanna Yu, BeautyTime

- Zain Kevashjee, Soko

Program in August. We're excited to use these funds to continue

developing desktop CNC machines and linear motion systems for rapid

prototyping!

-

Printing the new parts for the machine!

04/05/2016 at 19:38 • 0 commentsOur 3D printer is up and running and has been printing furiously for the last 2 days.

Here's the setup and a Y axis gantry we got printed:

![new gantry.jpg]()

As well as some test prints:

![20160405_153556.jpg]()

-

Our 3D printer has arrived!

03/31/2016 at 22:20 • 0 commentsOur 3D printer has finally arrived here in Waterloo all the way from Guangzhou! It’s a Tevo Tarantula that we picked up for just under $400 CAD.

We’re moving into exam season so the project will be slowing down for a few weeks until we can move into working on it full time, but hopefully the 3D printer will be fully assembled and printing so we can have stuff being made while we study!

![]()

-

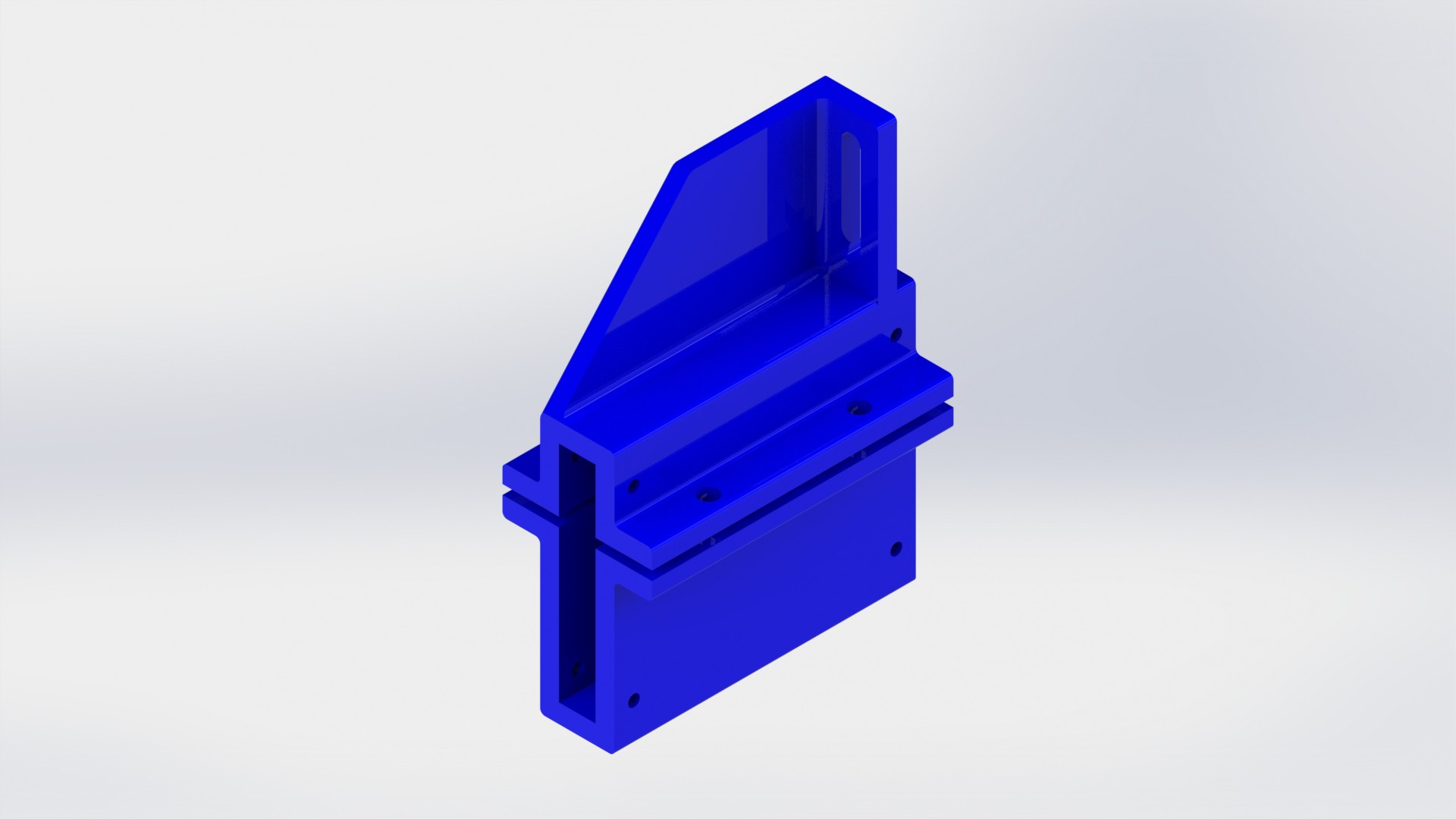

A redesign of the X and Z axis gantry

03/24/2016 at 21:58 • 0 commentsI've been working on improving stiffness in all of the axis. Here's a 3D render of the X and Z axis assembly. I found that the biggest issue with the previous iteration was that it was difficult to reach the fasteners, so it was a bit tricky to get everything as tight as possible.

We ordered linear rods and bearings, lead screws and nuts, and some other fun stuff to play around with, so this design is going to implement them. Lets hope they get here soon.

In the meantime, Chris is printing out some new parts for us to test out, and so we should know how they do in the next couple of days.

-

Design…round two

03/23/2016 at 03:36 • 0 commentsHi everyone! We’ve put together a prototype and it looks pretty, but there’s a couple of things we want to touch up to get the best performance out of our machines, so we’re going into the second full round of design. Our new 3D printer is due to come in the next week or two, and so are all the extra parts we ordered, including couplers, leadscrews, bearings, and more.

We learned a bunch of new things from our first design, and what we plan to do with our second design iteration will make Sienci 1 even better. We plan to give more support to all of the v wheels, lower the y axis gantry and raise the corner supports, and experiment with thicker or wider rail materials. We also plan to make the X axis calibration much easier by allowing it to split, as well as making all of the fasteners easier to access and tighten.

Here’s a CAD rendering of what the Y axis gantry might look like:

-

Tim and I ordered a new 3D printer!

03/23/2016 at 03:35 • 0 commentsTim and I needed a new 3D printer, so we ordered one online last night. Can’t wait to make some new prototypes and new machines!

It’s a cheap one we got online for about $310 CAD. 3D printers have gone down in price a lot over the last few years. I’m excited to see what this one can do and if it’s worth the money.

We’re going to be going into another design iteration to improve the performance on all axis with some new gantries, and this printer should help us make those parts. Also, we’re planning to take some of the parts off this guy later on and throw it on the Sienci 1 to make a GIANT 3D PRINTER.

![]()

Sienci Mill One: Simplifying Desktop CNC Milling

CNC desktop machines are expensive and complicated. This machine changes all that.

Andy Lee

Andy Lee