There are lots of manuals of cleaning nozzle inside (my favorite is cold pull with nylon). Generally, the outside is easier to clean, and is not as important.

However, when leveling bed and calibrating gap, the residue of plastic can significantly affect the results. Also, for aesthetic purposes... Clean extruder can lower the amount of ooze, too.

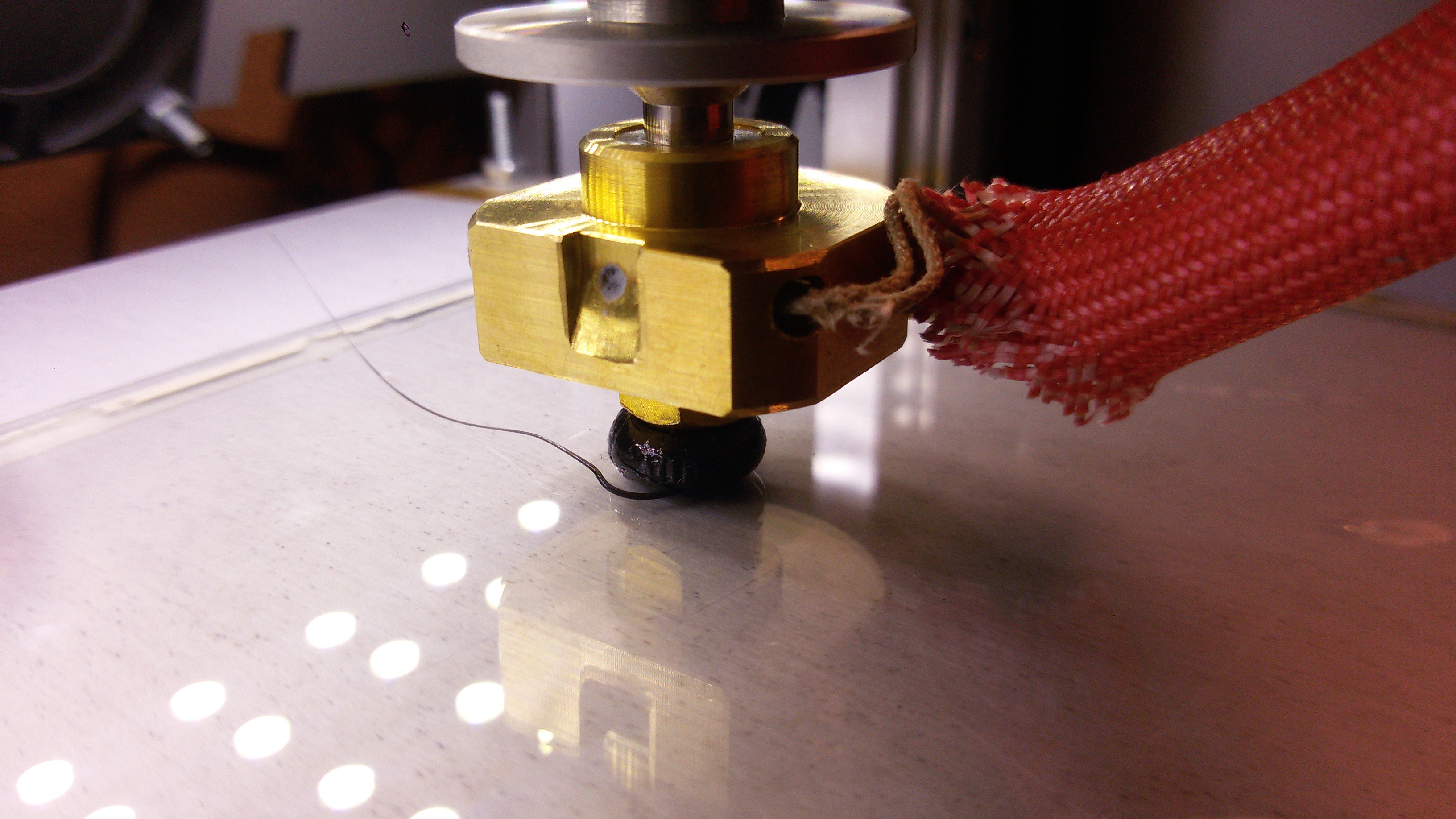

So, after each run, I lower the nozzle to be just above the bed, and let it extrude as much as it can while it cools down. This results in a nice blob that is stuck to the nozzle.

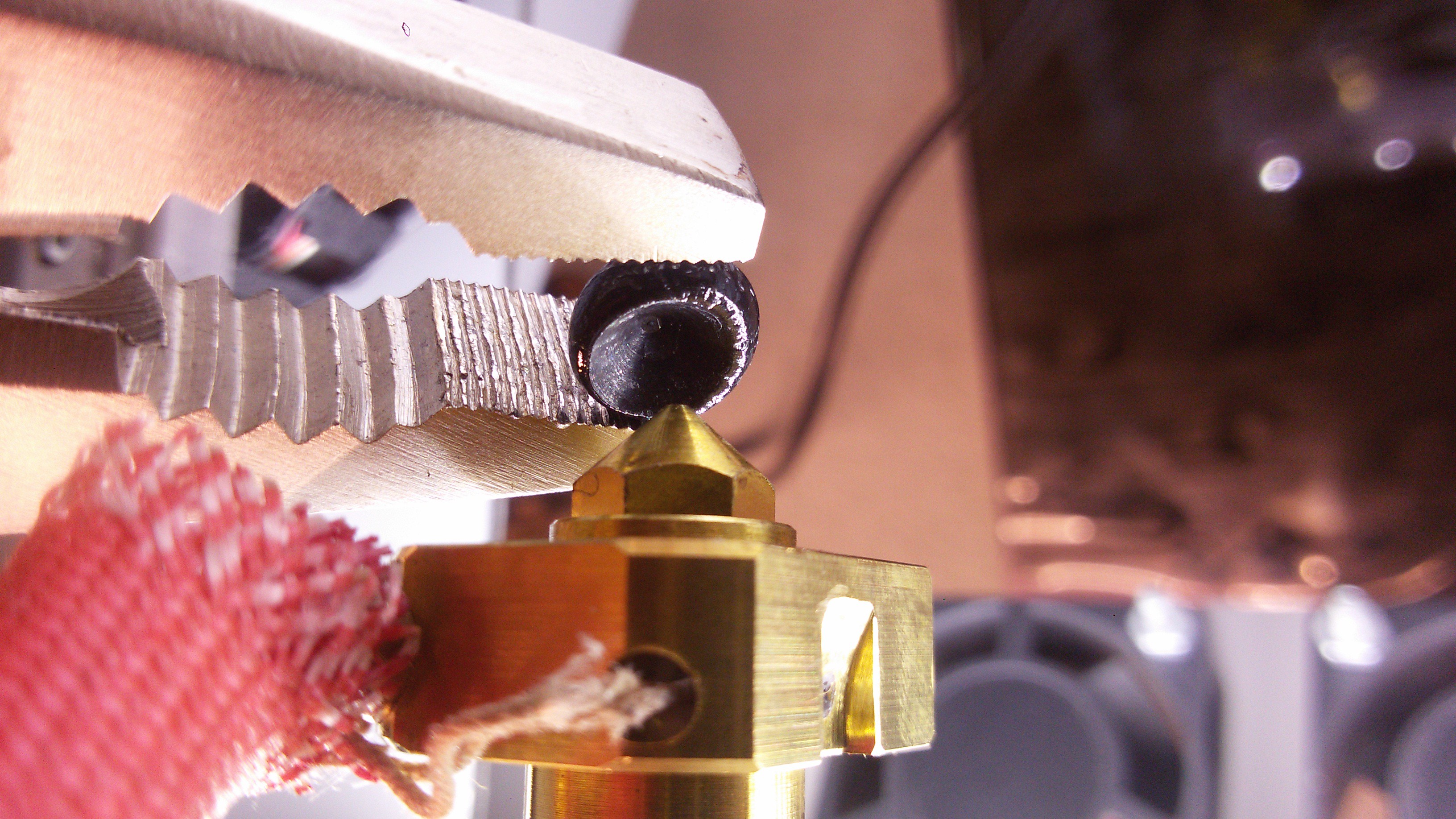

And then, when nozzle is cool, I rip the blob off using pliers, and a plenty of force.

And then, when nozzle is cool, I rip the blob off using pliers, and a plenty of force.

Note: the extruder on these photos looks good as new, because it is ... new! I have just replaced it, and did one test print to verify it's all working properly.

DeepSOIC

DeepSOIC

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.