Energy harvesting is the process by which energy is captured from environment and stored or used to feed low-power circuits (e.g. LED lighting a lamp). It is an alternative to environmentally harmful and life-limited batteries in embedded systems. Kinetic, thermal, solar, and electromagnetic energy can be transformed into electricity using appropriate harvesting transducers (respectively piezoelectric, thermoelectric, photovoltaic and microbial fuel cell).

Energy harvesting from ambient sources can offer a sustained source of power, suitable for many applications. Yet the output from available energy storage devices and transducers, used to extract that energy, can fall below levels suitable for typical components. In building efficient energy-harvesting designs, engineers can draw on available boost converter devices able to operate with input voltages well below 1 V, offered by manufacturers including Intersil, Linear Technology, Maxim Integrated, Microchip, and Texas Instruments, among others.

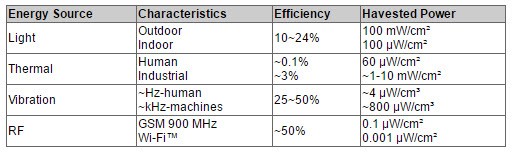

Ambient energy sources pervade the environment, yet typically provide a trickle of power at microwatt levels (Figure 1). In a typical energy-harvesting design, transducers needed to convert solar, mechanical, thermal, or RF energy consequently might produce hundreds or even just tens of millivolts on a consistent basis. Many DC/DC converters, such as those designed for use with multicell battery sources, offer high-efficiency operation, but could easily require input voltage levels above the levels generated in typical energy-harvesting applications. Other specialized boost converters are able to operate from low input voltages – maximizing energy extraction and delivering sufficient power to enable operation of application circuitry from even the weakest sources of ambient energy.

Figure 1: Common ambient energy sources are estimated to yield power at microwatt levels. (Courtesy of Texas Instruments.)

Low-voltage input devices

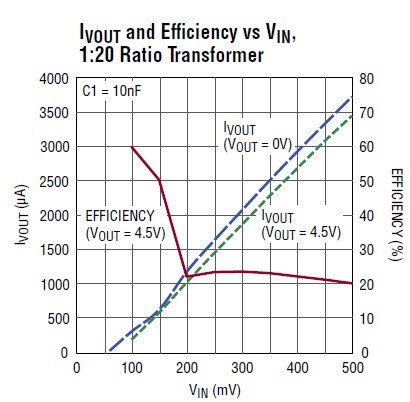

Designers can find a variety of boost converters designed to operate with voltage sources below 1 V. The LTC3108 is the most appropriate for our project. By working with MFC it entails that have obtained a few millivolts for Vin. The LTC3108 offers a minimum operating voltage of 20 mV. The device requires only a few additional components, including a transformer specified with ratio: 1:100, 1:50 or 1:20 and achieves efficiency values ranging from 20 percent to mor than 80 percent, depending on input voltage and output current (figure 2).

Figure 2.

The LTCR3108 is a highly integrated DC/DC converter ideal for harvesting and managing surplus energy from extremely low input voltage sources such as TEGs (thermoelectric generators), thermopiles and small solar cells.

Using a small step-up transformer, the LTC3108 provides a complete power management solution for wireless sensing and data acquisition. The 2.2V LDO powers an externalmicroprocessor, while the main output is programmed to one of four fixed voltages to power a wireless transmitter or sensors. The power good indicator signals that the main

output voltage is within regulation. A second output can be enabled by the host. A storage capacitor provides power when the input voltage source is unavailable. Extremely

low quiescent current and high efficiency design ensure the fastest possible charge times of the output reservoir capacitor.

Able to operate with input voltages below 1 V, specialized boost converters play a key role in energy-harvesting designs. Using switching topologies and minimal external components, these devices step up low voltage levels from transducers and energy storage devices to levels required for application circuits. By taking advantage of available boost converters, engineers can design highly efficient energy-harvesting applications able to maintain full operation despite the very low voltage levels often available from ambient energy sources.

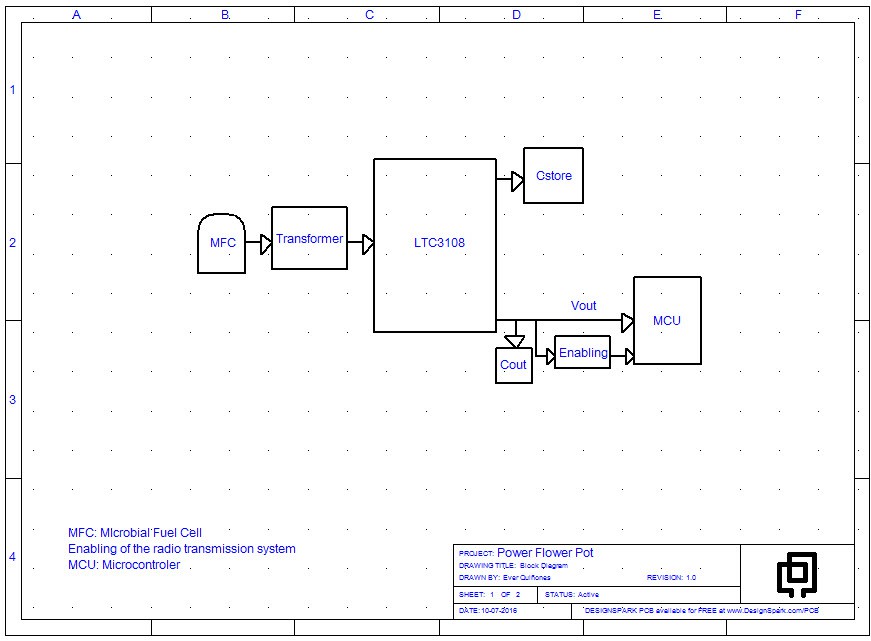

Based on the theoretical approach presenter achievement here is to design the block diagram to achieve the objectives of the project Figure 3. Block diagram of project.

Ever

Ever

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Can i replace the 1:100 TRANSFORMER WITH 1:20.IN THE FIRST EXAMPLE CIRCUIT GIVEN IN LTC3108 DATASHEET.

Are you sure? yes | no

hi

i was working on MFC as hobby project wanted to know the design of the Energy harvesting system.I was referring to the ltc3108 datasheet example designs so which one to choose out of those designs specifiedin the datasheet.

Are you sure? yes | no