I wish I could say otherwise, but this project looks like a failure, at least for high accuracy positioning. It's works great for torque multiplication and appears to have pretty good precision, but a 3D printer Z axis needs both precision and accuracy.

There's a problem visible in the video below: when the Z axis is moved in 1 mm intervals, every other step is right on and those in between are a little off.

UMMD 40:1 worm drive precision testing and belt stretch under load from Mark Rehorst on Vimeo.

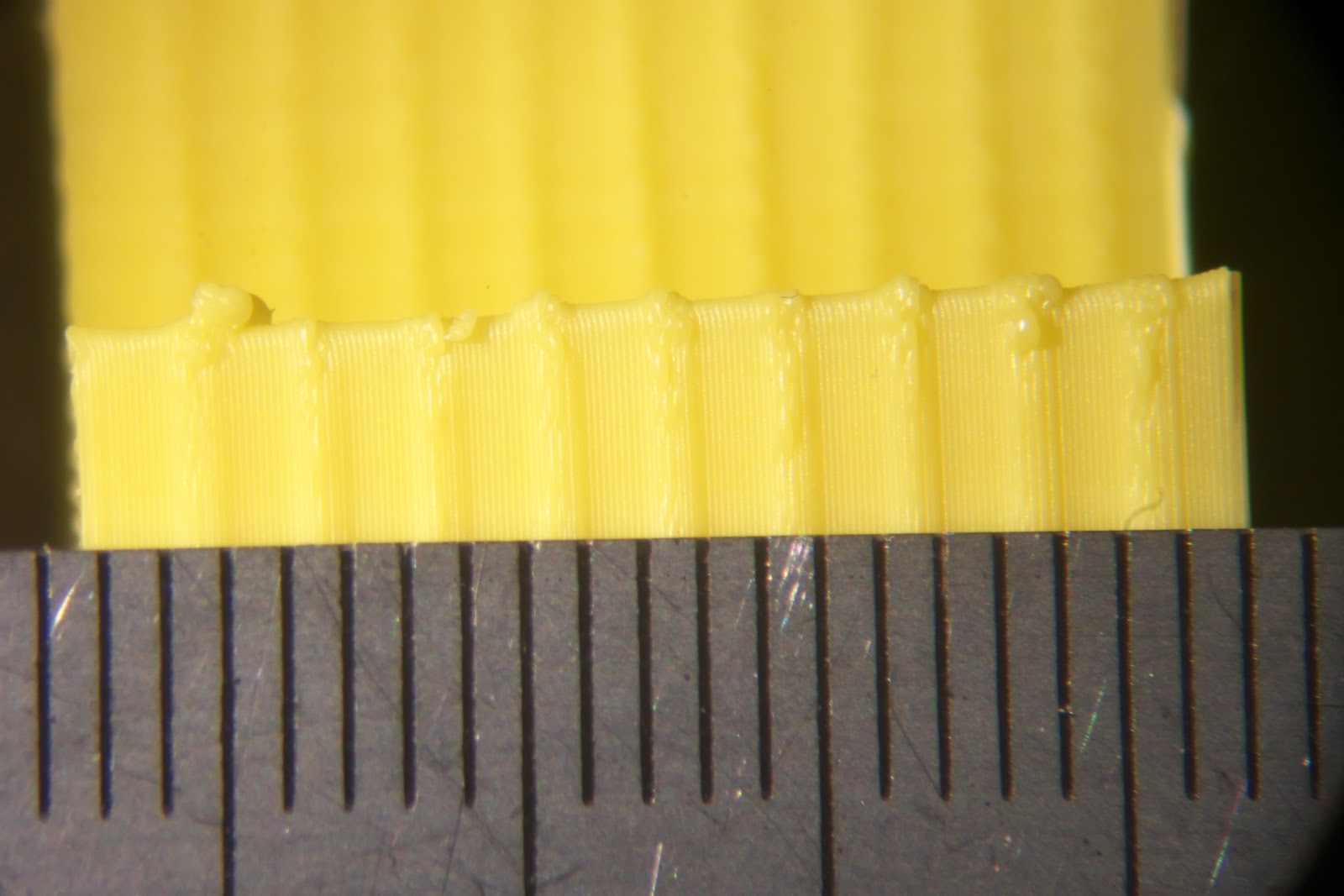

I managed to repair the extruder and ran a test print yesterday and got Z ribbing every 2 mm, most likely because of a problem with the worm gear which spins 1 revolution for every 2 mm of Z axis movement.

I don't think there's anything that can be done to fix this. I'll be putting the Rino back into the machine today.

Mark Rehorst

Mark Rehorst

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.