This is an initial log to record the progress so far on this project. Currently:

- The ShapeOko2 has been assembled mechanically

- The electronics have been mounted in the enclosure

- The electronics and main stepper motors have been tested (but not wired in permanently)

- All of the other components required for the build have been ordered

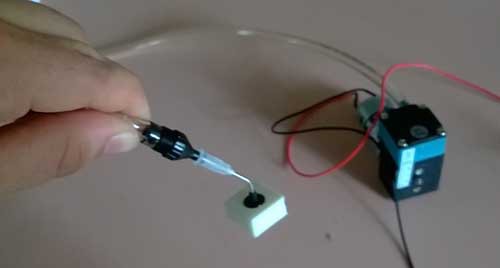

The pump selected for this project has been tested, and can successfully pick up a 20mm calibration cube:

Once all of the parts have arrived, the wiring of the ShapeOko2 frame and building of the tool head can begin.

Initial designs for the tool head have been completed; the current concept is to use the Nema 8 hollow shaft stepper motor for component placement and the 90:1 Nema 8 stepper motor for solder paste extrusion, with the micro stepper being used to raise and lower components during fast travels, and the solenoid used to actuate the tape feeders. The design of the feeders will be loosely based on industry-standard feeders, optimised for lower actuation force and lower tolerance parts.

The intent for the design of parts in this project is to allow them to either be 3D printed or CNC milled, so that a single machine can be purchased, the parts made, and then the machine modified to make a pick and place.

Alex

Alex

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.