-

2018 in Review and New EU Webshop Open

12/30/2018 at 06:11 • 3 commentsMany of our European customers will be happy to know that the EU webshop is now officially open. Most of our products are now stocked and available from a warehouse in the UK. The shipping times to Europe should be drastically improved when ordering from there.

Now that we have reached the end of the year, I want to take the opportunity to summarise some of the highlights of the past year, and to thank each and everyone of you for the incredible support we've received.

In the beginning of 2018 we released ODrive v3.5, and with that we reached a stable hardware version. With that we were able to focus our efforts on improving the firmware, supporting software and the overall user experience.

We saw over 100 new features, improvements and fixes (full details in the Changelog). Just to lift out some highlights, we have implemented:

- Trapezoidal trajectory planner

- Switching frequency increased to 24kHz for silent operation

- Storing of configuration parameters to Non Volatile Memory

- Many encoder related improvements, including index pulse encoders and Hall sensor feedback

- RC PWM input

On top of this there are currently many excellent features waiting in Pull Requests which will be our priority to merge as soon as possible.

We love seeing so many fantastic projects come to life with the help of ODrive. Check out the Projects category on our forum to see all the ones people have chosen to share. I want to highlight two projects that I found to be particularly excellent.

The first one is a modular, heavy duty Swiss mill-turn machining center for cutting metal called SwissMak, which uses ODrive to precisely control the two spindles, and will also use ODrive for the movement axes in a future version. They successfully completed a kickstarter, and the first set of machines are being manufactured at this very moment.

![front iso view 2 jan 17]()

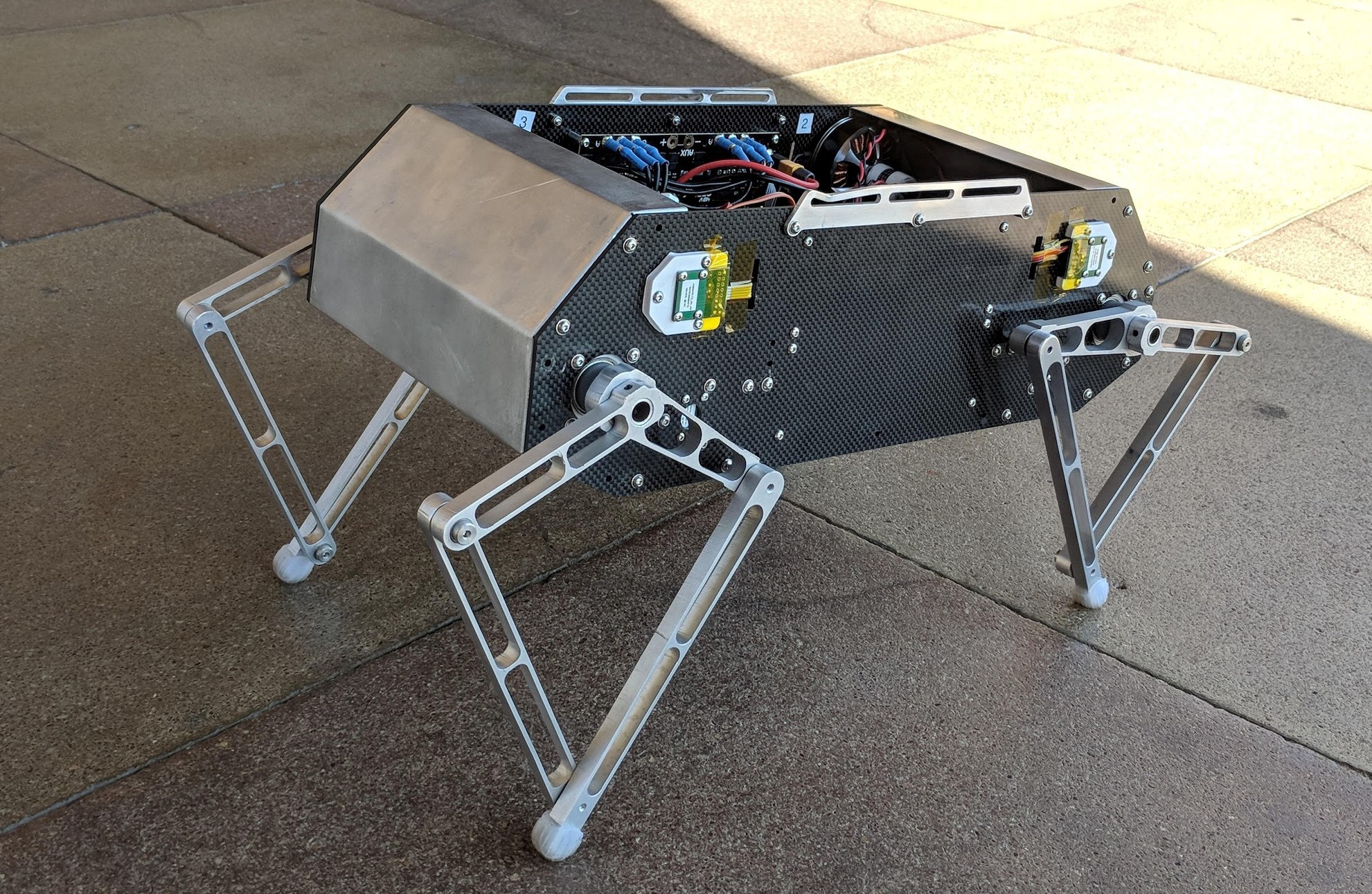

The other project I want to feature is the Stanford Doggo, a quadruped robot made by a group of students at Stanford University. Check out more photos, and watch it walk, dance and jump extremely high in their excellent video presentation here.

![Stanford Doggo Stanford Doggo]()

To all businesses and hobbyists alike that have chosen to use ODrive; a huge thanks to everyone that have helped to make this possible.

On top of that we want to specially thank all the direct contributors to the project. For your code contributions, test data, documentation improvements and for providing help to other users on our forum and Discord. Thank you so much, your contributions are invaluable.

In 2018 ODrive went from a promising project to a successful product and business. We hope to continue on this trend and make ODrive even better.

-

Jan 2018

01/15/2018 at 09:49 • 0 commentsRobot Arm and More

The ODrive project has been very fortunate to attract such a strong community of enthusiasts. Today we want to feature the excellent work done by Richard Parsons, who's been very active on the ODrive Community. In the video below he demonstrates his direct-drive robot arm, how he built and wired up the servo axes, his step/dir tests and finally his high speed pen plotter.

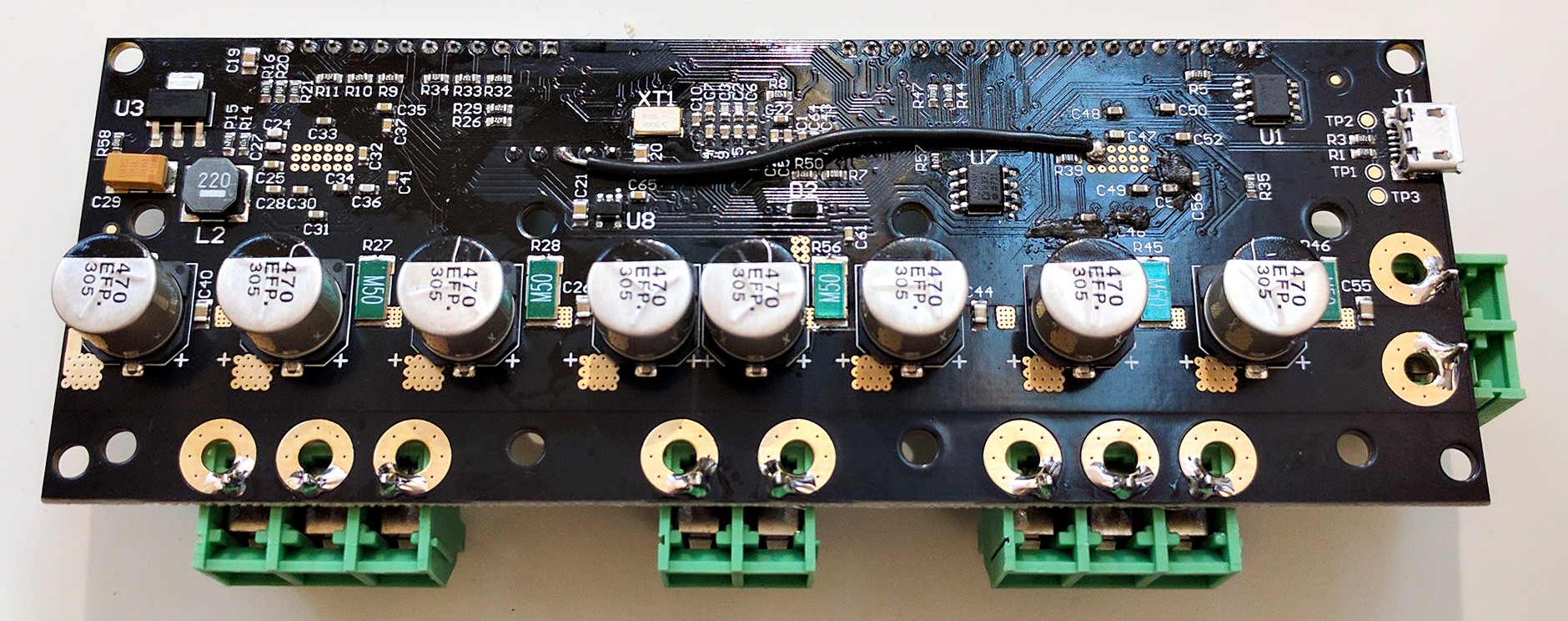

ODrive v3.4

Since the last newsletter update, ODrive v3.4 has become available. From a user-perspective, not much of the design has changed from v3.3. However, we now have a 48V version available. It has the same current handling capacity as the 24V version, hence it has twice the power. We are talking around 3kW peak power per axis.

We can't wait until the videos of projects with this kind of power show up!

New Encoder

We now stock the CUI AMT102 encoder in the ODrive Shop. This is a compact 8192 counts/rev encoder with index pulse. It comes with a custom 2m shielded cable that matches the pin-out for the ODrive.

![]()

The increased resolution will help with smoother motion and less "hunting" vibration when holding position. Also, in a couple of weeks, when we expect have the index pulse feature finished, it should enable the ODrive to restore the encoder calibration. This means that the encoder calibration only has to run once to commision the drive, and then skipped every run from then on.

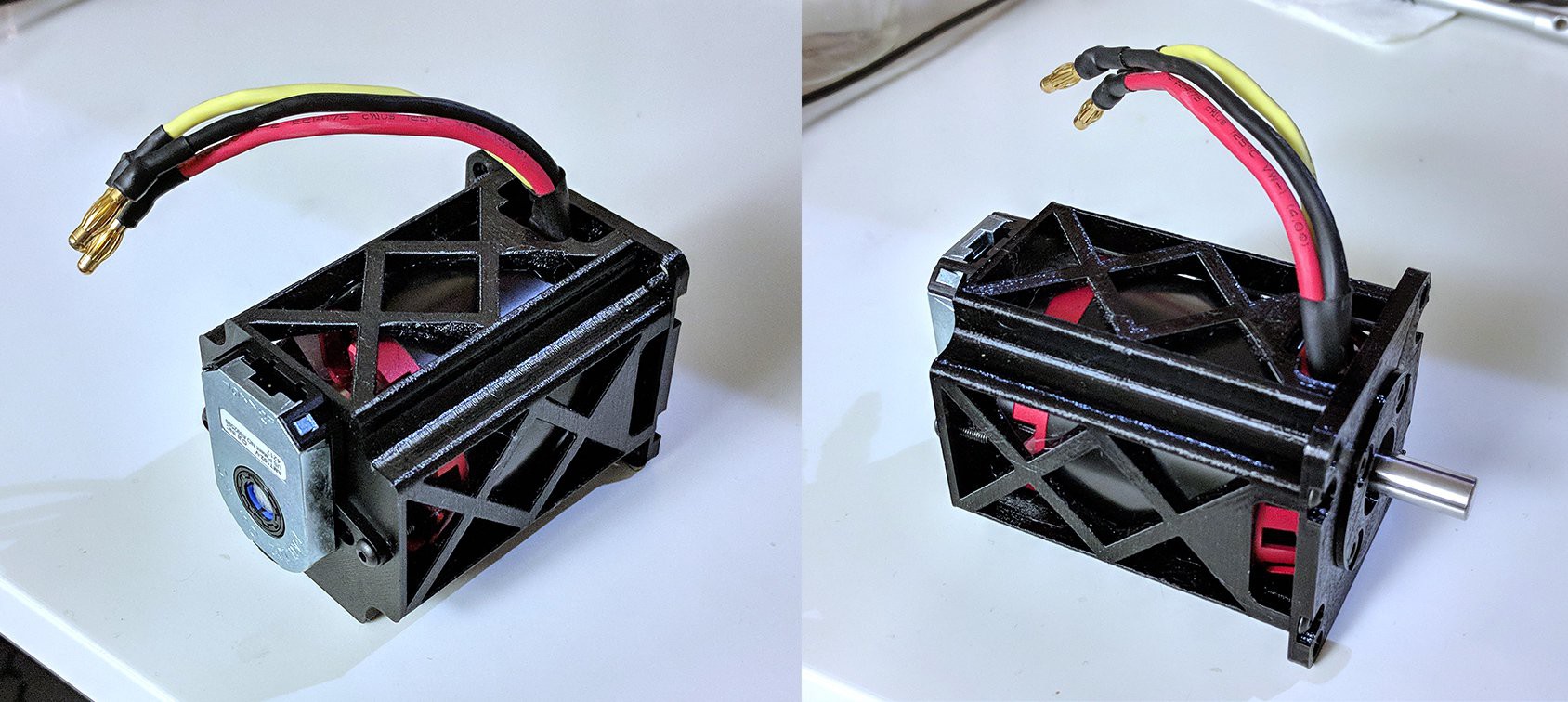

![]()

Above is a design by [Wetmelon] on the ODrive Community. It uses the 1.6kW N5065 motor and the aforementioned AMT102 encoder, to make a NEMA23 compliant compact and high performance servomotor. The above prototype is printed in PET-G filament, that has a glass transition temperature of 88C, so despite using a 3D printed part it should be ok for applications that don't run the motors too hot. If you are interested, he also made a design that uses a 10:1 gearbox, check it out.

Your Project

If you also have a project that you are working on that uses the ODrive, or even one that could make good use of an ODrive, we'd love if you shared some pictures with us.

-

ODrive v3.4 Ready Soon

11/24/2017 at 01:09 • 0 commentsWe have managed to sell out of ODrive v3.3, thank you everyone who has shown such support! The batch of ODrive v3.4 are due to arrive in about a week from now, and we hope to have them tested and available to ship in the beginning of December.

As you might be aware, we used to have a restriction asking you to not order more than two drives at a time. Now we are able to order much bigger batches, so this restriction is lifted: order as many ODrives as you would like. With this batch and going forward, I think we should be able to keep ODrive from going out of stock.

On that note: If you are an OEM or Distributor, please get in touch, as we now have the capacity to take large orders.

Thanks to everyone who has helped to make this possible,

Cheers,

Oskar.

-

Announcing 48V ODrive Board

11/06/2017 at 23:05 • 2 commentsMany of you have requested that there should be available a 48V version of ODrive. I'm happy to announce that this is expected to become available in the beginning of 2018. To be notified when it will be possible to order, please sign up here: https://goo.gl/forms/EUJP726GsLaBf5YN2.

Some things to note:

- The price is expected to be $149.

- The current handling capacity will not decrease, hence the power handling capacity will in principle be double that of the 24V version.

- We will keep offering the 24V version at the same price as before: $119

-

Cogging Torque Compensation

11/06/2017 at 22:55 • 0 commentsInexpensive hobby brushless motors are powerful, but they are not built for precision applications. One of the undesirable characteristics of less expensive motors is cogging torque. This is the torque generated by the permanent magnets in the rotor being attracted to the iron in the stator in an unbalanced way.

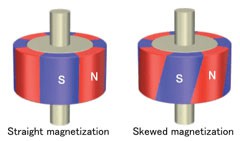

In more expensive motors this is avoided by skewing the rotor magnets, as shown below. This balances the reluctance torque across the skew angle, which eliminates most cogging torque.

![]()

Straight and skewed rotor magnets.

Interestingly, the cogging torque exhibited by the motor is a constant function of the rotor angle. That means that if we can figure out what it is, we can improve the performance by simply compensating for it.

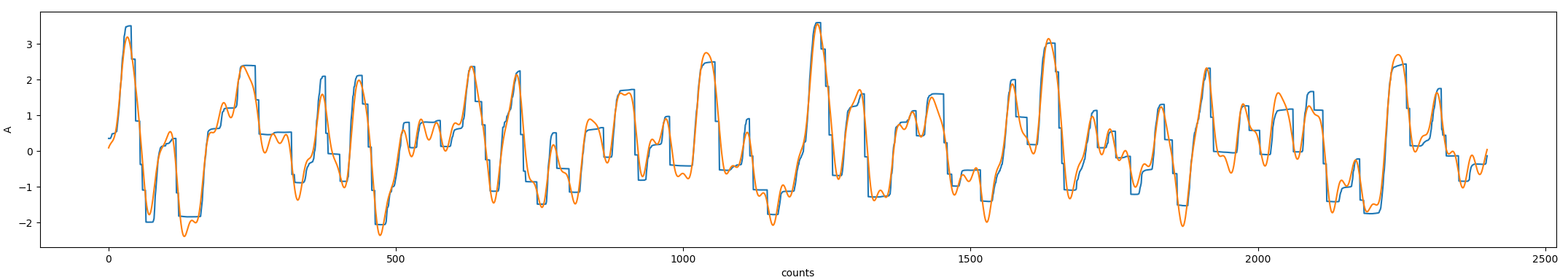

And that is exactly what we did. Thanks to the implementation of a calibration and compensation algorithm by @Wetmelon on the ODrive forums, we can estimate and cancel the cogging torque.

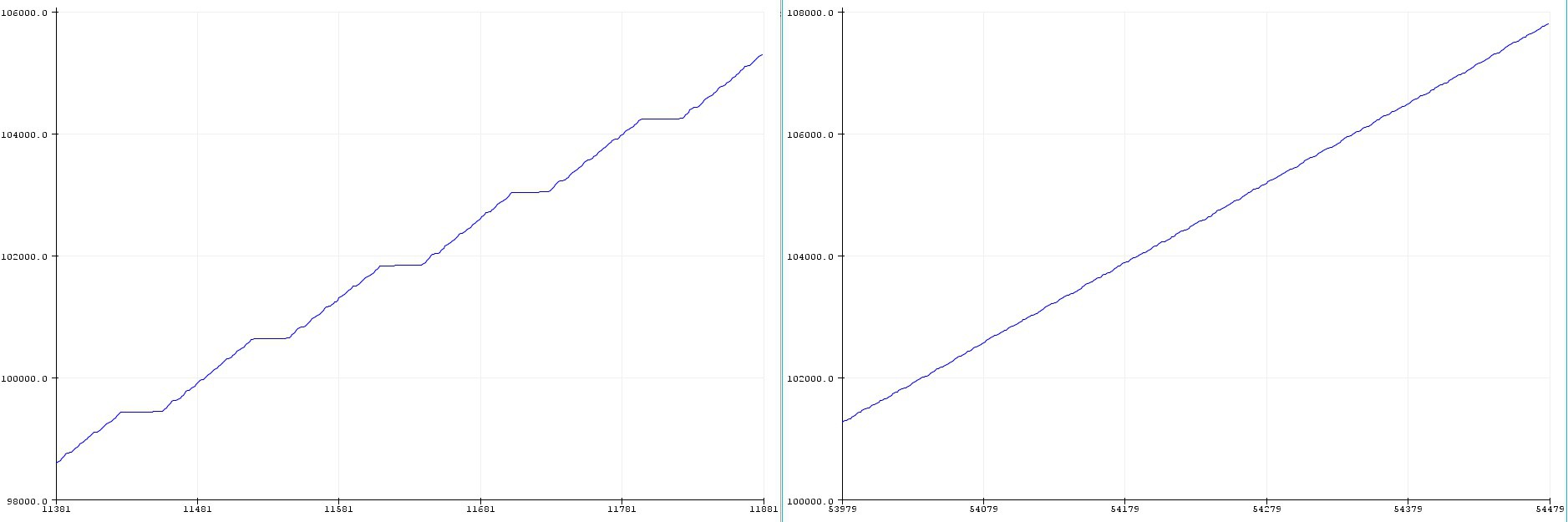

Cogging torque map: Current as a function of encoder count. Measured values in blue, fitted values in orange.

![]()

Without and with anticogging, showing rotor position at 25 RPM commanded velocity. Note that the feedback gains were not very stiff for this test.

Note that the above is just an excerpt of the full writeup, please see that for more detail, and full resolution plots.

This algorithm is already merged to the devel branch of the ODrive firmware, and after sufficient testing will be available in the next release. -

UART and Arduino Library

10/18/2017 at 01:43 • 1 commentThe UART feature is now ready for testing.

Many of you have been waiting for the ability to control the ODrive from another microcontroller, and so this feature complements the USB and let's you do exactly that.

I have also made a first revision of an Arduino library that lets those of you who wish to use Arduino get started quickly. If you don't use Arduino, you can still have a look at the library to see how the communication is implemented, and copy that to your platform.

The UART feature is currently in a pull request, which means that the documentation on the master branch hasn't updated yet. Please check the documentation on the uart branch instead. Here are some of the important things that are new for UART:

If you have any problems, or if everything worked perfectly, or anything in-between: please help us with feedback. Once this feature has been confirmed to work for enough people, we will merge it to the devel and hence master branch in the next release.

-

Three Demos

10/02/2017 at 04:09 • 0 commentsIt's so awesome to see what kind of cool stuff people are doing with the ODrive. Here are 3 demos of fairly different nature. I think they are awesome, I hope you do too!

Willam Osman put ODrive on a PowerWheels. This video is actually a few months old now, and I probably should have posted it earlier. Anyway, watch that thing do doughnuts:The Arduino library and UART communication is under way, a usable release should be ready in a couple of weeks. Check out the first demo:

Bauerslab posted his awesome Skittle Sorter on the ODrive forum. It's really awesome to see the diverter teleporting around. If you wanna skip to the action, it starts at 6:15.

-

Which voltage in your application?

08/25/2017 at 03:40 • 0 commentsIt’s good to know what voltage range people want to use ODrive for in their application. Right now the voltage rating is for 24V, but it’s fairly easy to change. There is a current handling penalty to increase it though, so it might be useful to offer two versions. To help us decide between the different options, please answer the poll about what supply voltage would be the most ideal in your application. You may check multiple options if they apply to you.

Thanks!

-

Electrical issue discovered

08/13/2017 at 07:57 • 0 commentsThanks to the help from the community, recently we uncovered a hardware bug that affects all ODrives manufactured to date (v3.3 and earlier).

This bug is described in more detail here, and the fix is described in detail here.

In short, the bug means that the GND on the GPIO pins and the M1 motor gate driver has significant spikes of electrical noise. This causes glitches on the control signals on the GPIO pins, and motor control glitches on M1.

If you plan on using M1, it is strongly advised that you apply this fix. You can follow the instructions as linked above. If you do not feel comfortable applying the fix, you can also send the board to me (San Jose, CA, USA), and I will apply the fix for you, free of charge (you pay shipping to me, I pay shipping back to you). If you need help to apply the fix to your board, please email info@odriverobotics.com, and we can arrange it.

We have already started applying the fix to all the ODrive v3.3's:

![]()

The fix applied to an ODrive v3.3.

![]()

Applying the fix to all the ODrive v3.3.

-

Sensorless Mode

08/04/2017 at 23:50 • 0 commentsQuite a few of you have requested sensor-less operation: running the motor without an encoder. This is now a reality:

Video shows open-loop startup speed-ramp followed by switching to closed loop FOC velocity control.

The main limitation of this mode is that it's not able to provide precise control at very low speeds (it can however spin up to speed using not-so-precise control). Therefore, this mode is great for applications where the primary operational regime is at speed. So not great for CNC machines or polargraphs, but great for electric skateboards and conveyor belts.

If you are interested in the technical details, or have an ODrive and want to try this out, please see the Sensorless mode post on the forum for more detail.

ODrive - High performance motor control

Hobby brushless motors are incredibly cheap and powerful. However we need a way to make robots out of them. ODrive is that way.

Oskar Weigl

Oskar Weigl