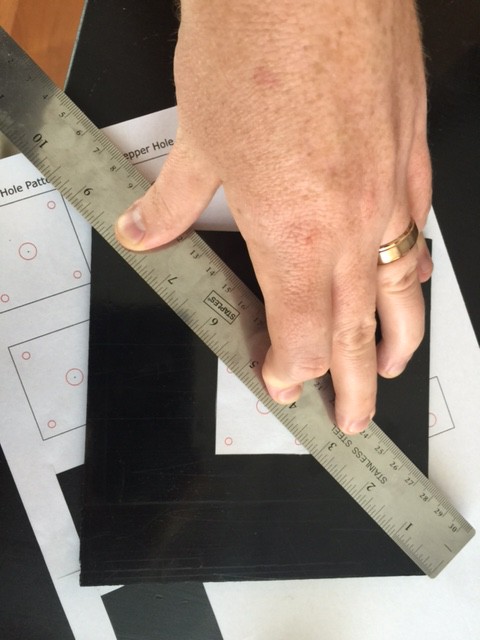

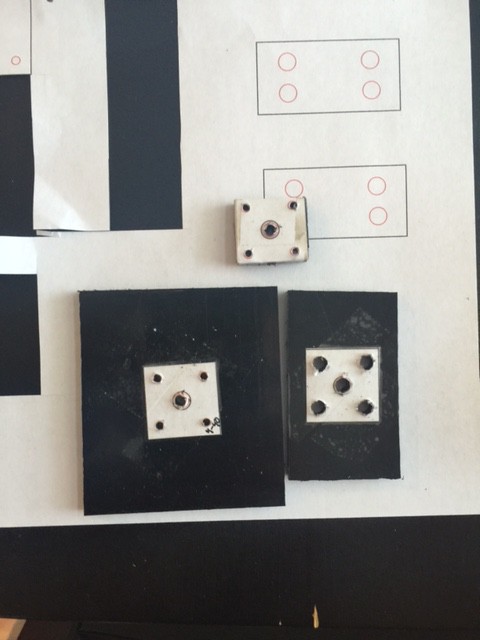

Today I went into the drilling and assembly phase. I used Inkscape to create drill patterns for each of the pieces. I measured and then taped the drill patterns to the base.

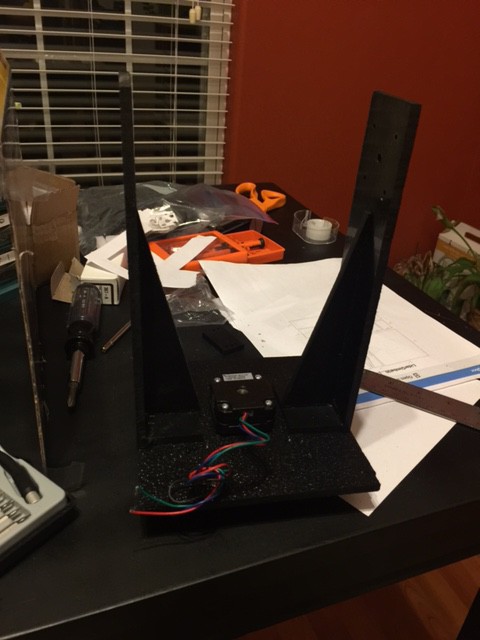

Then I drilled pieces in the order that will be discussed in a later instruction. I also tapped each piece immediately after I drilled it. Although, that was more so I could see the assembly coming together. It's going to take me some time to put more information up on the assembly portion into the instructions section. The alignment of the shaft with the lazy susan is off and is creating increased resistance during rotation (and noise). I'm going to need to fix the alignment issue another day. Maybe on Tuesday when I go down to the Lvl1 hackerspace.

The base portion which connects the yaw motor to the tripod is complete (except that one alignment fix). I've also made the uprights and drilled most of the holes. I need to drill the 3 remaining holes and alight the uprights next before I start working on the LIDAR carriage.

Here's a short video just because:

caver.adam

caver.adam

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I'm seriously tempted to remove the lazy susan and see what happens.

Are you sure? yes | no