-

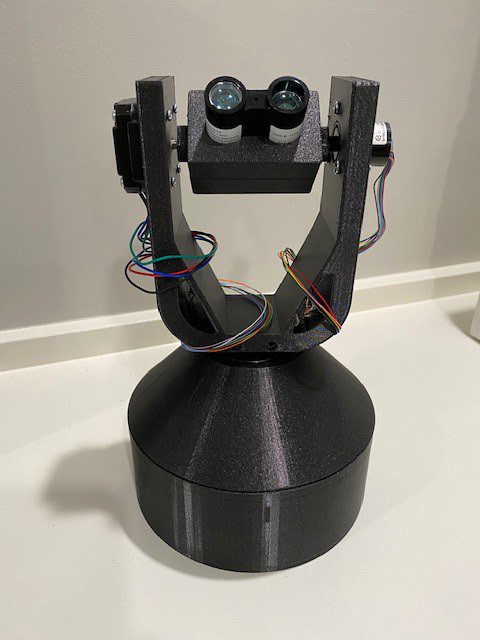

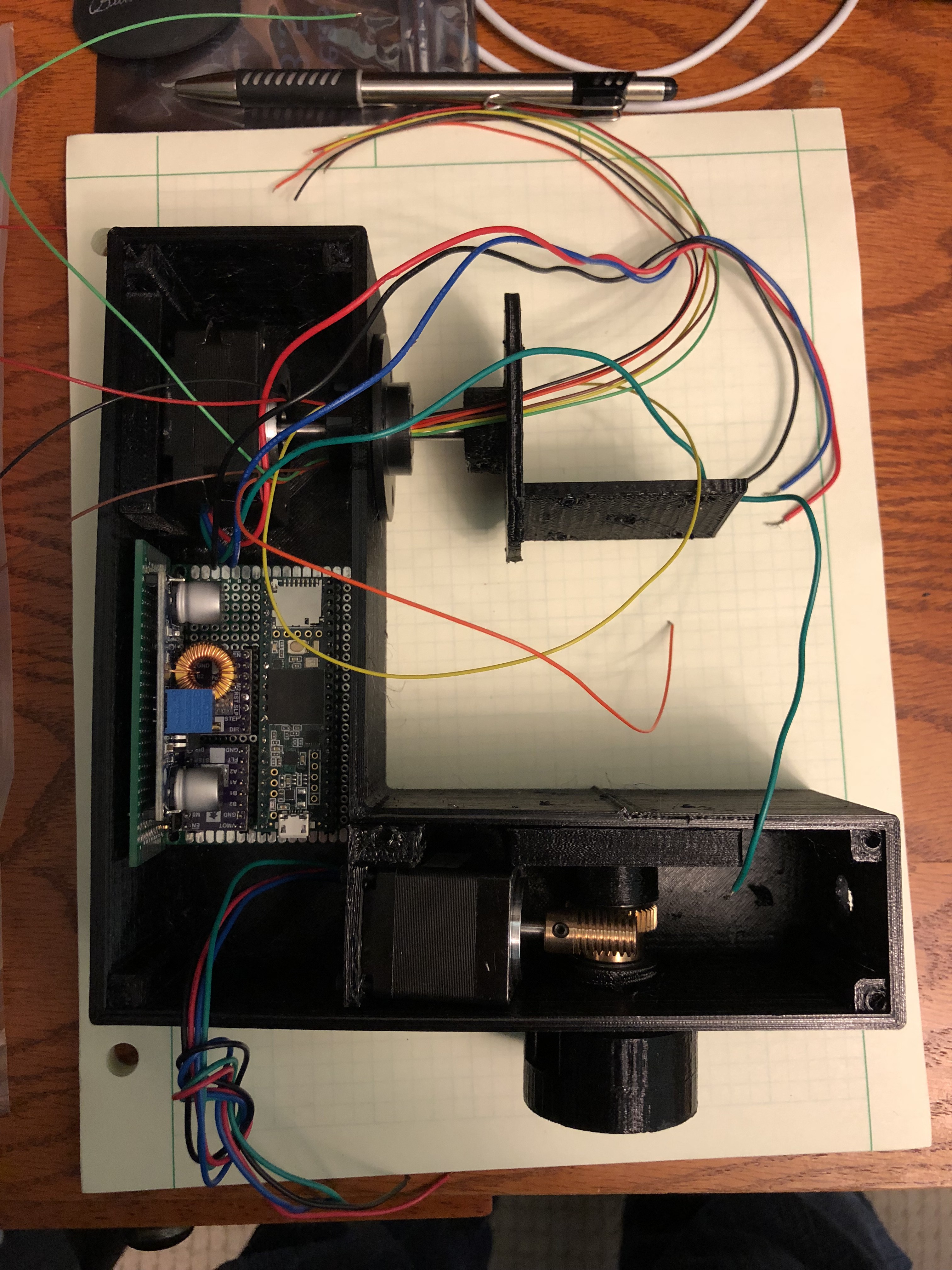

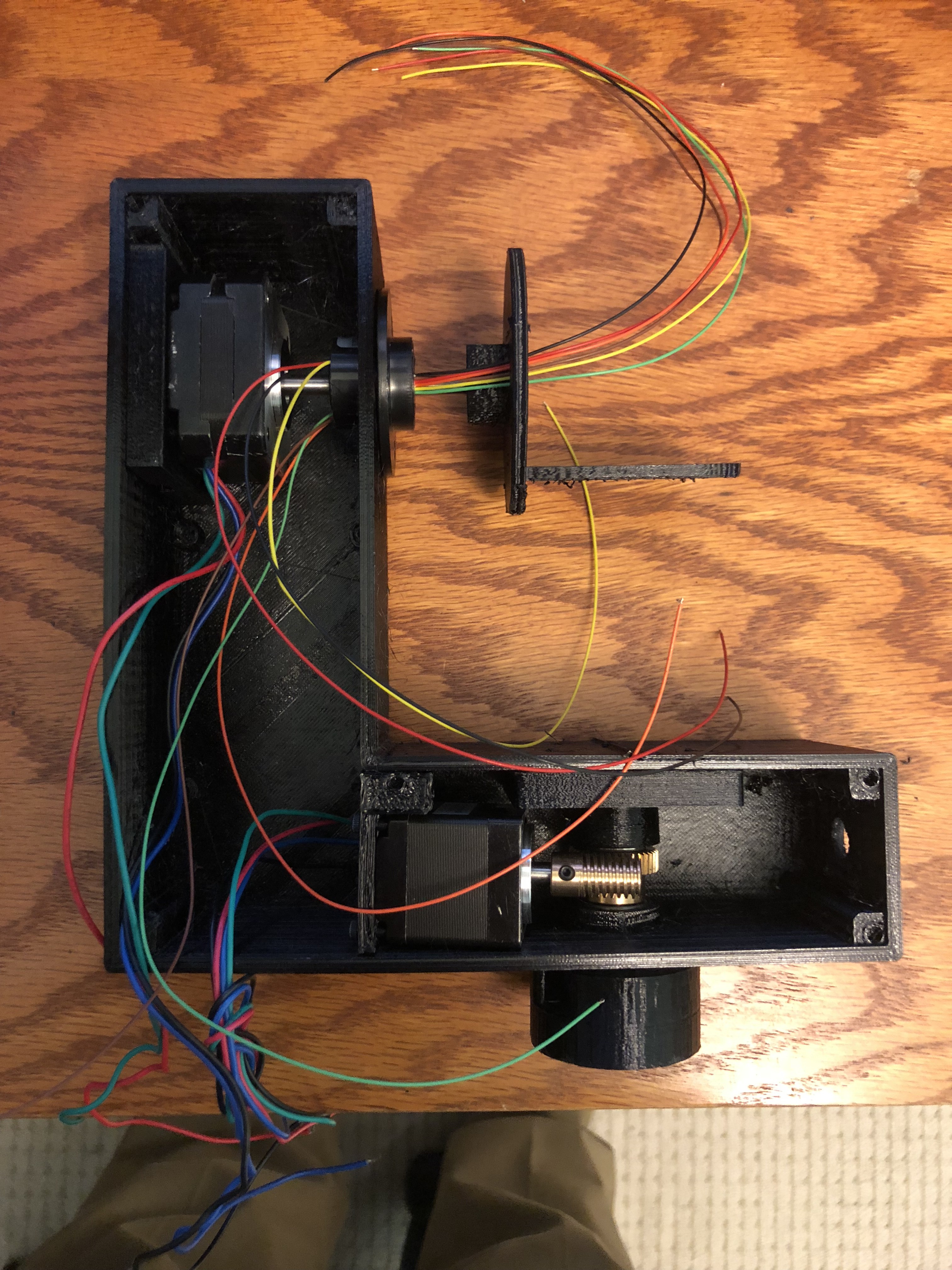

Functional Components Printed

08/04/2021 at 00:56 • 0 commentsToday I finished printing the functional components. I'm going to have to wait for a new spool of filament before I can print the wire covers for the fieldgoal. But when i have time I can begin assembling this.

Next step is to use a 3mm tap to tap the screw holes. Once that's done I can assemble the body and start on the electronics. One thing I don't really love is that it is a bit difficult to get the motor gear attached at the correct height to match the shaft gear. But it is just a bit of trial and error to complete. I'm considering modelling a simple spacer to assist though.

Last time I made the cavity in the body a very tight fit and it was a problem...this time I may have made the body too big. At least it will hold everything and I can decide after testing it whether it is worth purchasing a shrink-ray.

![]()

-

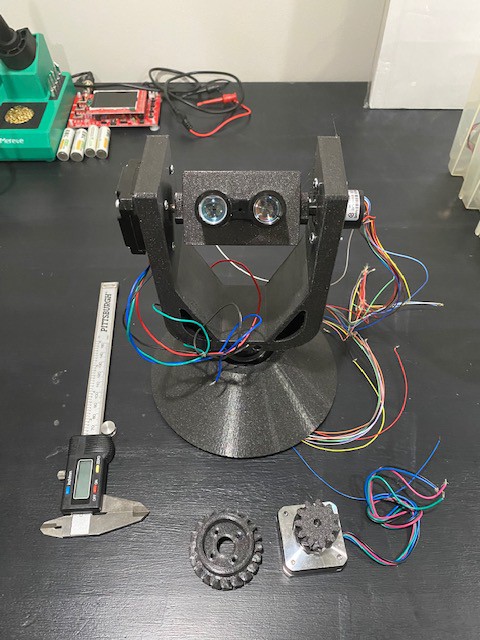

CAD Progress Continues

08/03/2021 at 03:18 • 0 commentsA few more parts printed. So far there have been a couple press-fits that are a bit loose. I've updated the CAD models to make them tighter, but in the meantime I can make do on the prototype with loose friction fits. A little thread-locker glue will take care of it.

So far I'm really liking the new yaw shaft. It is MUCH more stable than the old design and moves very smoothly. The next print will have the motor mount so I can test the gear. But the gear seems to fit excellent when hand fit.

![]()

-

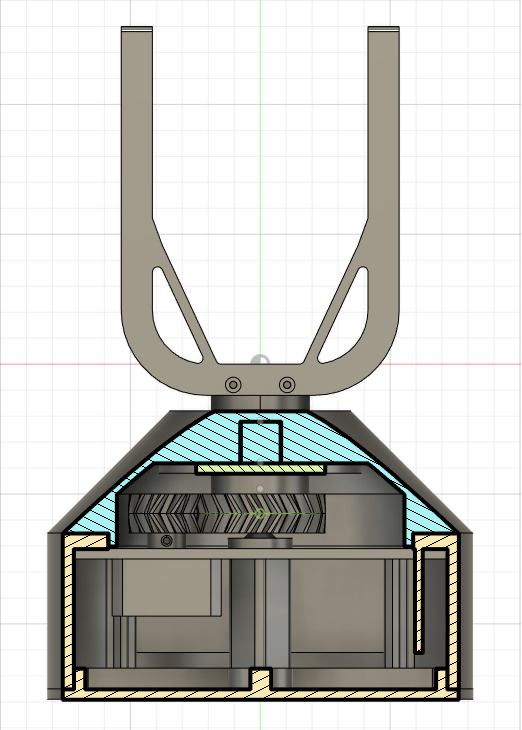

CAD Progress

07/30/2021 at 20:28 • 0 commentsI've been making progress on the CAD modelling for the project. I've got a draft model of all of the hardware at this point. This weekend I'll start printing/testing components.

I decided to go with a double herringbone gear for connecting the yaw motor to the shaft passing through the bearing. This made the assembly a bit more difficult because the gears have to come together as a specific angle, but I think the strength will be worth it. I also decided to use a prime number of teeth on the gear which is going to make the possible angles a bit odd in the programming but should drastically reduce wear on the 3d printed gears.

![]()

Based on the field-goal portion so far, it looks like this design is going to be a lot more stable than the last one. I worry a bit that I may have gone a bit overkill on the size of the body, but it should have plenty of space for the bearing, motor, gears, and electronics.

-

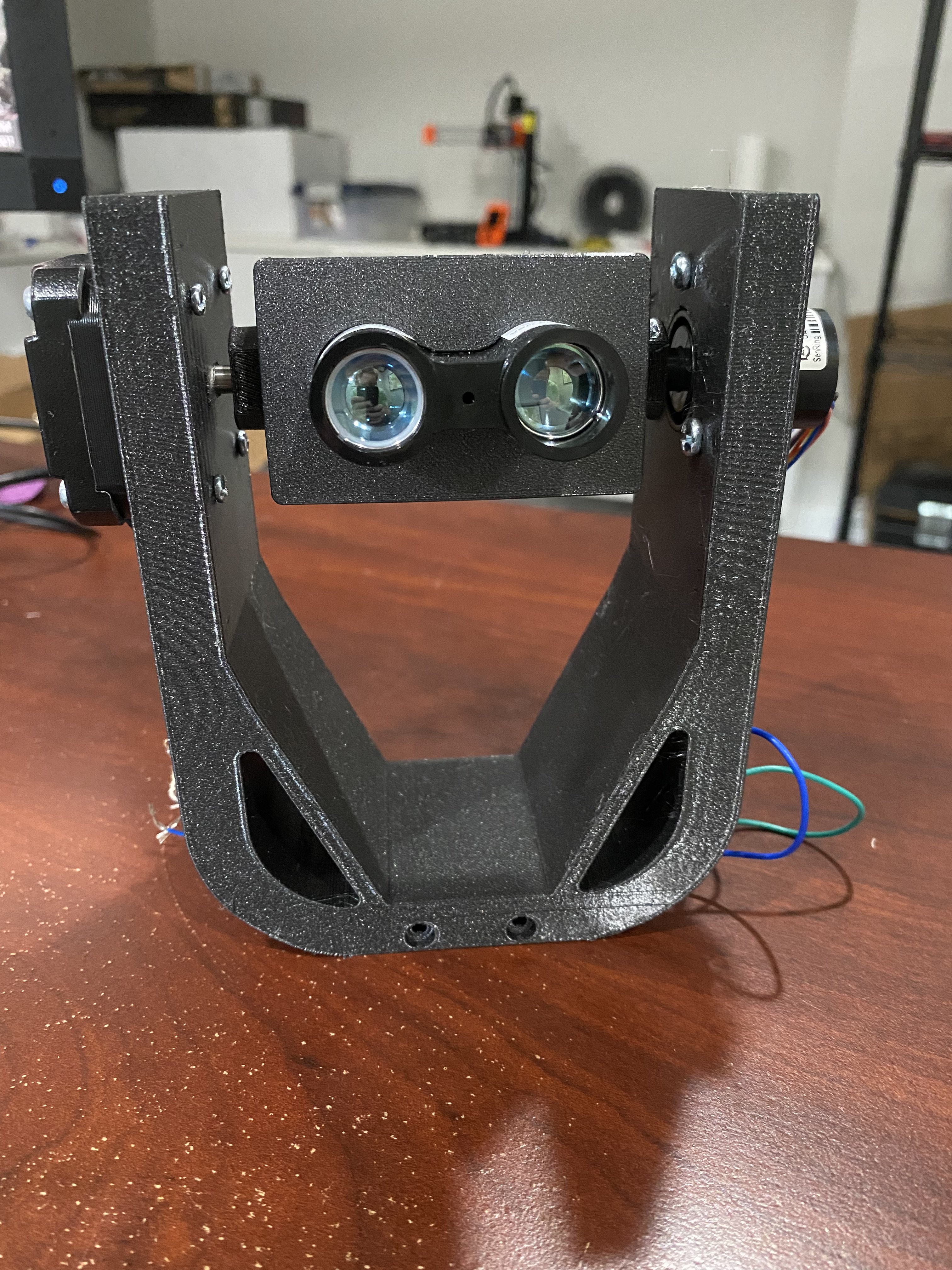

Version 3 Progressing

07/06/2021 at 02:26 • 3 commentsMy last version of the 3d lidar scanner had a few significant problems that I've come up with fixes for. One issue was that the pitch motor needed to have a longer shaft added and once I finished there was too much friction and the new motor shaft started slipping. Another problem was that the yaw connection point was far too weak. Finally, the power supply was having overheating issues.

The new version uses a "field-goal" configuration with a stock Nema 17 motor on one side and a slip ring on the other side. This allows me to use stock components and reduces friction.In addition, I'm now using S42B stepper drivers that mount on the back of the motors and allow precise control. This removes the need for me to populate a circuit board with motor drivers and allows me to spread out the electronics to reduce the chance of overheating.

For the yaw control I'm now using a 30mm shaft which is press fit into a substantial bearing. This should add the rigidity needed to the yaw axis that was completely missing in the last version.

Finally, I will be powering the device with an 18V off the shelf dewalt battery which will remove the need for a boost converter in the circuitry.

Today I finished printing the "field-goal". I need to convert the sketch of the yaw shaft and circuitry body to CAD still. It's going to take a while longer to complete, but this new version is substantially better planned out than the version 2.

![]()

-

First Run

08/30/2018 at 03:56 • 2 commentsTried a first run today of the mostly assembled project.

Two issues showed up.

First, the yaw axis is very jerky. I need to find a better way to turn it on the axis. It's doing too much balancing on the small shaft.

Second, about 1/3rd of the way through the scan the LM7805CV overheated. I need to see about adding a heat sink onto that. Otherwise I'll have to re-design the 5V side of the project (medium). Or lower the 18V side of the project to 12V (easy)

-

Getting close

08/24/2018 at 11:56 • 0 commentsOpenLidar has made a bunch of progress in the last week. Now the motors are working, the Bluetooth control is working, and the lidar module is taking measurements.

Need to get the SD card working (to have somewhere to store data) and then program the basic algorithm for capturing a room. Also need to get the battery box printed (difficulty with the 3d printer currently).

-

Electronic mock-up

08/11/2018 at 03:29 • 0 commentsPut the electronics into headers on a protoboard and put them in the case. I’m concerned that the second board is too close to the motor drivers. I think the motor drivers can’t be placed on headers and will have to be soldered in even for the prototype stage. Unfortunate, but I’ll just have to commit sooner than planned. Also having trouble with the teensy damaging the headers. Looks like I might be going hard soldered quickly.

![]()

-

Updated yaw motor mount works!

08/10/2018 at 06:34 • 0 commentsgot the 3d printer repaired and printed the new yaw motor mount. Fits like a charm and the worm gear makes a great connection.

Next step is to start assembling the circuit and simultaneously finishing the remaining non-functional parts such as the battery box and the lid for the whole case.

![]()

-

Re-designed the yaw motor mount

08/06/2018 at 15:26 • 0 commentsFortunately, I was able to re-design the yaw motor mount. I designed the part originally from the Amazon description of the worm gears that I used...and I messed up the dimensions. Didn't figure it out until I had printed the main box for the project. Fortunately, I left some wiggle-room in the box so that I can just tilt the motor 7 degrees and fix spacing problem. Planning to print/verify the fix tonight.

-

Delayed again

07/12/2018 at 19:49 • 0 commentsUgh. Took a delay because we were on a 2 week vacation and then got back and got sick. I'm missing this project, but there's no way I'm braving the 90F / 60%RH in the Garage while I'm sick.

I seriously want to get these motor shafts replaced and the replacement nema10 mount printed.

Open LIDAR

This project is to build a motorized gimbal mount to convert a laser distance module into a 3d LIDAR.

caver.adam

caver.adam