-

One small step back.

06/12/2018 at 03:48 • 0 commentsStarted to assemble and apparently I should've waited for my amazon order of the worm gear to come in so I could measure it...doesn't quite fit. Not a large problem. Should take about an hour to redesign the yaw motor mount and another hour to print it. Should be fixed by the weekend.

Also having trouble replacing the rod in the stepper motor. Man those pieces are on snug. Need to figure out a better way to get them off.

-

Hardened Steel is Hard to Cut

06/11/2018 at 13:43 • 0 commentsSo, it turns out that I don't have a tool capable of cutting 5mm hardened steel rod. Admittedly, most of my tools are for electronics (or basic woodworking and home repair). I've got a family member nearby that will let me use his Dremel.

Otherwise, I've printed all the body elements required to make a functional skeleton of the open lidar. Once I get the rods cut to length I can retrofit my stepper motor and get the skeleton assembled. Really want to get the skeleton done. I still need to print lids and the battery box, but those won't stop the device from working.

I still need to finish the new schematic that uses the Teensy 3.5, but the Teensy has so darn many pins that you can practically throw a wire at it from across the room and be plugged into a pin that will work. That's going to make it a lot easier to get a good layout. I've looked at the schematic and it's going to be pretty easy to get a clean layout with the new circuit.

-

First 3D Print

05/31/2018 at 10:58 • 0 comments![]()

Set up the printer to print PETG and got the first component off. Still need to dial in the settings because I’m getting a bit of stringing, but the roll motor mount is serviceable. The stringing is making it hard to print more than one part at the same time though.

-

PETG or Nylon?

05/29/2018 at 21:16 • 0 commentsNeed to figure out what material to use to print the body for the Open Lidar. My printer doesn't have an enclosure, so there's some extra work involved in getting Nylon to work. Guess I'll try PETG to start and if it doesn't work I'll switch to Nylon.

Still need to make a case for the batteries, but I can design that while I'm waiting for the other prints...

-

3D model update

05/29/2018 at 01:40 • 0 commentsI've updated the 3d model files with a better design. This design has room to add magnetic rotary encoders on both shafts. The motor mount for the NEMA 11 yaw motor has been turned into a stand alone piece so that the motor can be hooked up and then the whole piece connected to the main body. There are also holders for the yaw bearings that are spaced so that a pair of washers and the worm gear assembly will hold the bearings in place and prevent the shaft from shifting up and down. Some minor improvements were made to the hole spacing for the battery pack (and the case for the battery pack is not yet fully designed). The lidar lite mount has been updated to include a cover to protect the lidar module a bit more.

Updates are available on GitHub.

-

Reboot!

05/21/2018 at 03:13 • 0 commentsIt's time to update and continue this project. Since my last update I've started and finished my seconds Master degree and started a new career... hence the big delay on this project. But there are also some new products available since I started this project that are going to make it a lot easier.

New plan for this project is to 3d print the body that holds the parts. The body itself is estimated at 150g of PLA based on the newest concept. Going to add a bit more than that by the time I get the mount designed to hold the lidar module. I've added the first edition of the stl files but I haven't had a chance to print them and check for fit yet.

Another update is that the newest lidarlite module is out and is capable of 1k readings per second at better than centimeter accuracy. I've got the lidarlite v3 (capable of 500 readings per second) to get started with and will upgrade once I have everything else working.

Also, I'm going to be using the Teensy 3.5 which has a boatload of memory on board (which was a major problem with my previous design) and also has an SD card mount ready to store files.

I've obtained some better motor drivers from Pololu because the old ones got rather hot and were quite noisy. Better to spend a few extra bucks on better drivers.

I've left space in the case to add a rotary encoder like the mechaduino. I'm hoping I won't need to use one and can save the $50 bucks...but I wanted to have the option to upgrade later.

I've also changed the yaw motor to connect to a worm gear so that the whole unit doesn't spin like crazy when the motor is off. It should also help the motor generate the torque needed to turn the entire unit on the base station. The other motor shouldn't need the help because it's only controlling the tilt of the lidar module.

-

Reviewing Project

05/25/2017 at 15:16 • 0 commentsWhen I left off the status was that I had accidentally back-volted my circuit and damaged every component (including the sensor).

I've been too busy with my Master program to tear apart the sensor to find and replace the burnt out components, but I now have a LidarLiteV3.

As I've been looking at the components that I burnt out, I'm realizing there are some improvements I can make. First, the Teensy 3.5 had a firmware update and now supports the LidarLite (and I presume the SF30). I've compiled the code for the Teensy and it compiles! This solves all my issues with not having enough memory to bulk-write to the SD card!!!

Another thing that I can fix while I'm at it is the motor whine. The motors were whining while using the knock-off motor drivers I had. Instead I can splurge for some $10 Pololu drivers that should work a lot nicer.

Also, there are now other people that have validated that the point cloud for these sensors looks awesome. Good enough for cave survey (but not for historical cateloging of archeological sites). So I'm also looking at my old plan to have this kit laser cut out of ABS. The devices I've seen so far were not stand-alone and had wires hanging everywhere to a computer.

-

Lesson: headers are not secure

10/09/2016 at 19:41 • 0 commentsI've been working to recover from accidentally pulling my Arduino out of the female header pins. Since it reconnected when it landed and burned itself up...it also burned up a number of other components. I've replaced the motor drivers, the 5V regulator and the Arduino. Next I need to replace the microSD module which also burned out. Also, the serial portion of the SF30 was damaged, but the USB side still works. So I can either switch to the LidarLite 3 which has arrived now, or I can get a usb to serial module to put between the SF30 and the Arduino (I'll eventually do both so I can compare the two sensors). I'll probably work on the LidarLite portion while I wait for a USB module to come.

That being said...It took all of 2 seconds to accidentally yank that cable, but it will take 2 weeks to repair the damage. I had used headers to try to make it easier to switch parts and to prototype...but that seriously backfired here.

-

Conversion to XYZ works

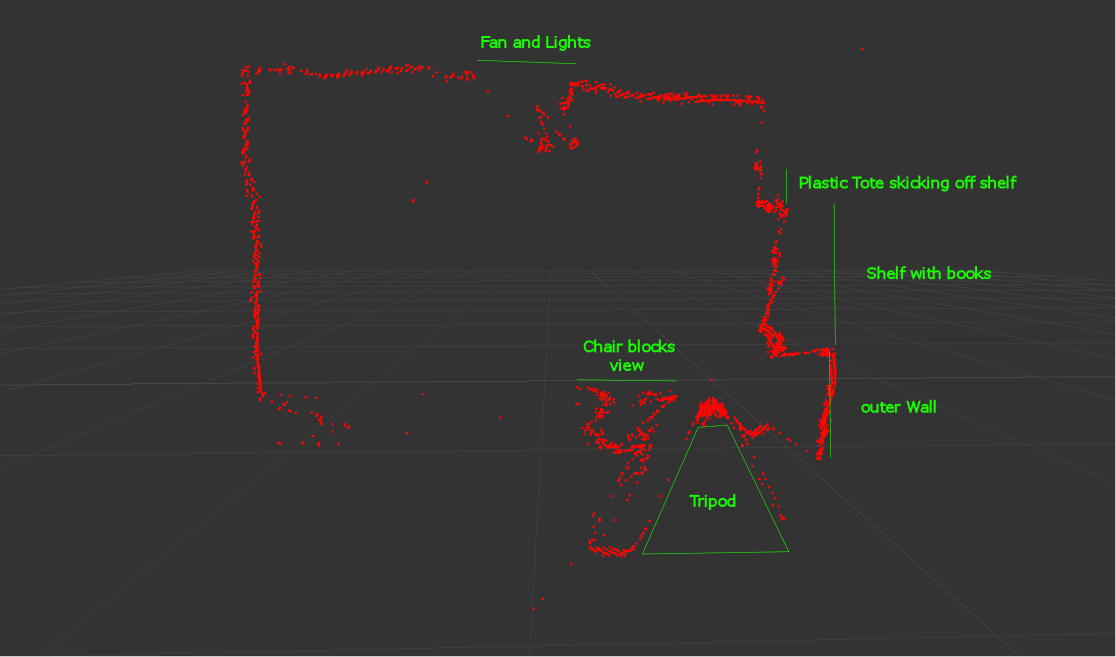

10/06/2016 at 01:49 • 0 commentsMy processing sketch now converts from RAE to XYZ. I used a single azimuth scan to prove that the conversion works.

Then CloudCompare imports the file and can clean it up and save it as needed (I used e57).

Once I saved it in an LAS file it opened in ReCap without a problem.

I'm noticing a lot of waviness in the scan. However, I'm wondering how much of that is due to the jerking motion being made because of the frequent SD card delays. Without outputting to the SD card this is MUCH more smooth running. Oh well, a problem for another day.

![]()

Also, my LidarLite v3 arrived today. I hooked up all the electronics.

My replacement Adafruit Trinket arrives tomorrow. Fingers crossed that the SD card module didn't get burned out. If everything else survived then it should be ready to upload the sketch and get my first scan.

And my 8K FRAM chip arrived today. But I'm out of time...so it will have to wait until another night.

-

Update

10/05/2016 at 15:53 • 0 commentsMaking progress slowly. Last night I was ready to try a first room scan...but I picked up the unit with the USB still connected. The arduino was pulled out of the female header socket and when I set the tripod back down the pins shorted and burned out the arduino (battery power was still on). Didn't have time to check whether any other parts were damaged. New arduino arrives Thursday.

I'm also getting strange results when I convert my spherical RAE file to Cartesian XYZ. My scan only had two pitch scans all the way around and azimuth varies 0.225 degrees. But converted to XYZ the angle appears much larger. Also, the pitch results appear to be repetitive. I suspect I may have an algorithm problem with the pitch calculation, and I may have a sin/cos decimal error with very small angles. Will try to work on the processing sketch more tonight.

[Edit: ...and...my angles are in degrees but sin is in radians...that explains that.]

Open LIDAR

This project is to build a motorized gimbal mount to convert a laser distance module into a 3d LIDAR.

caver.adam

caver.adam