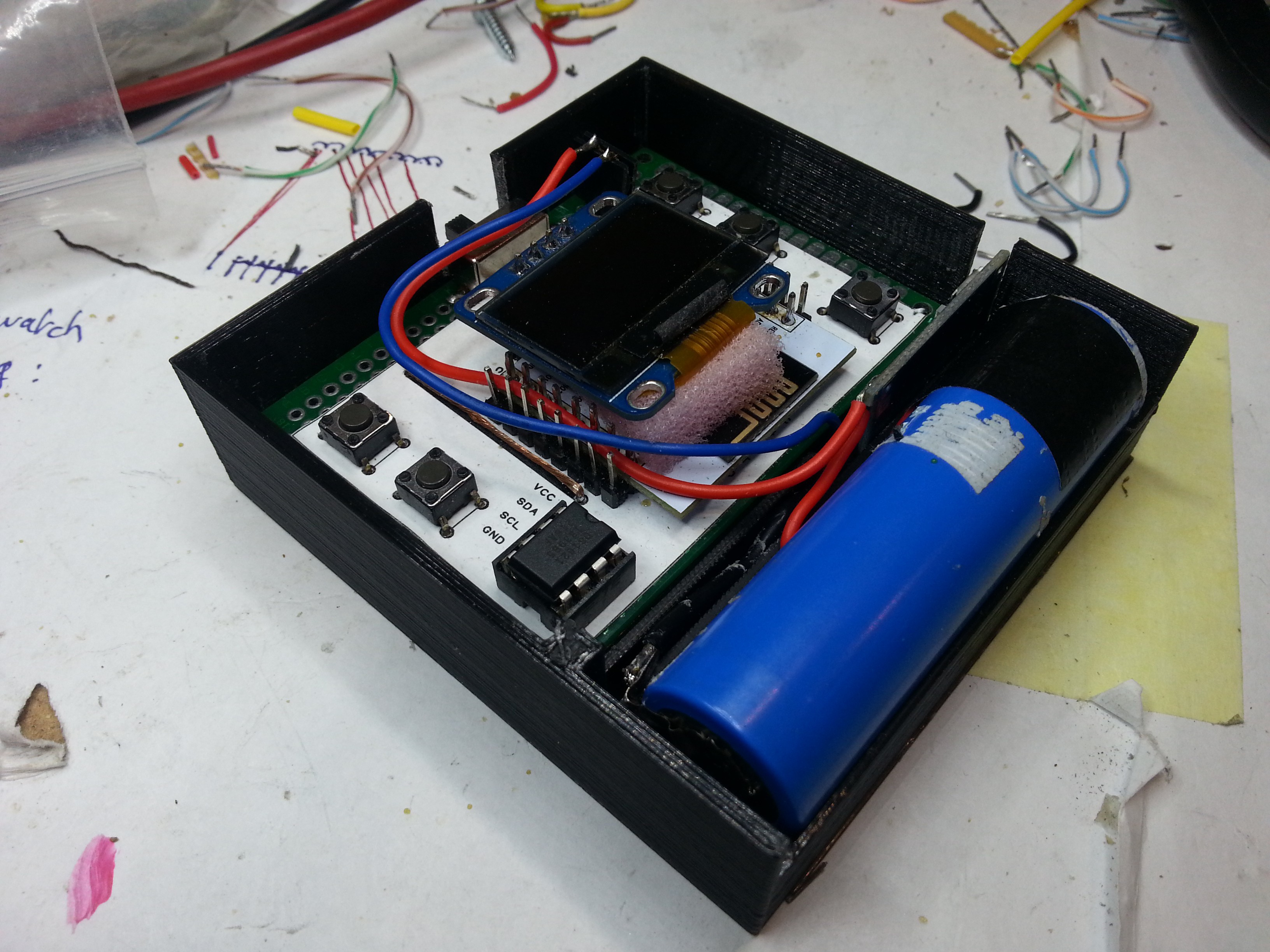

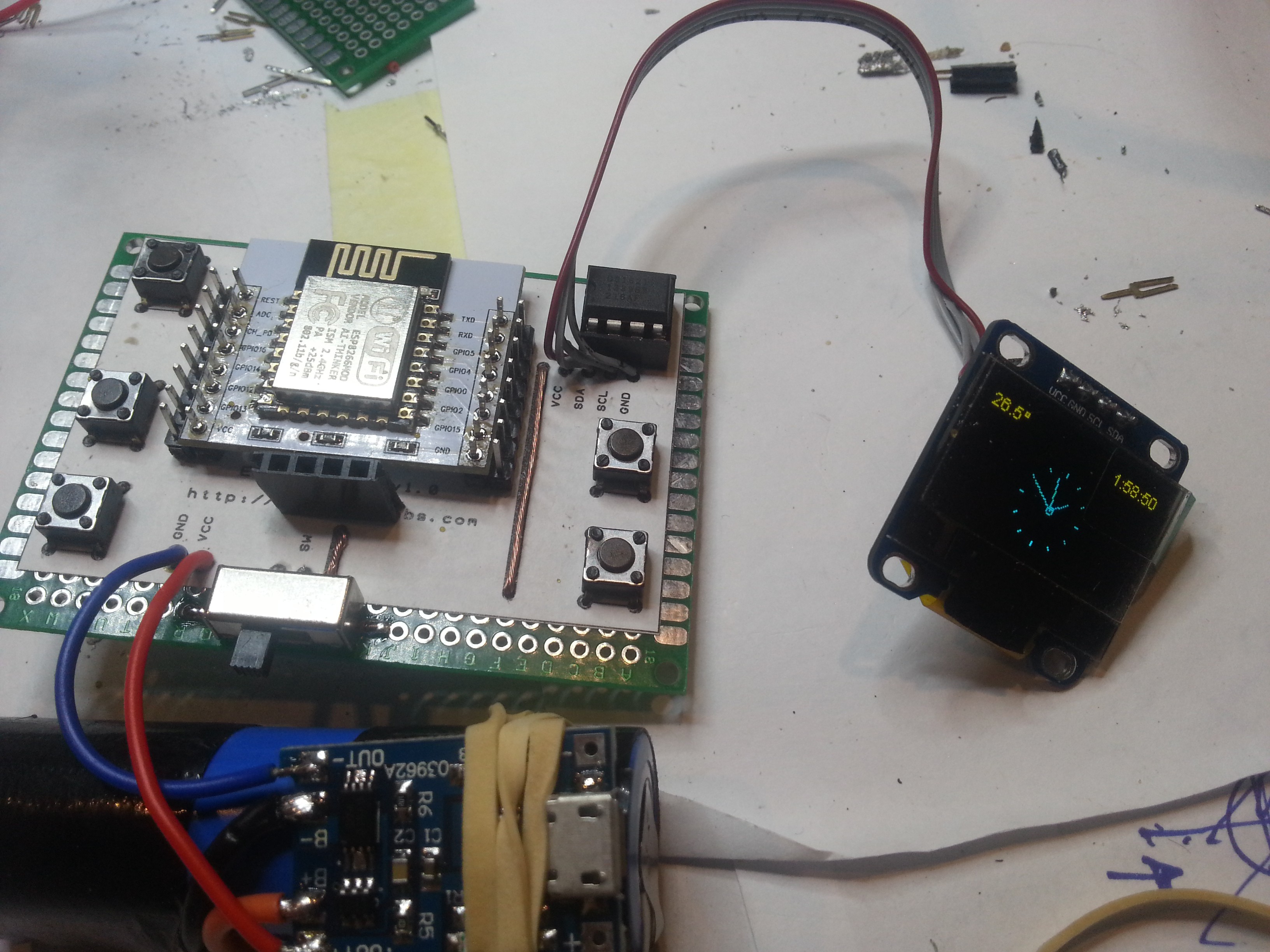

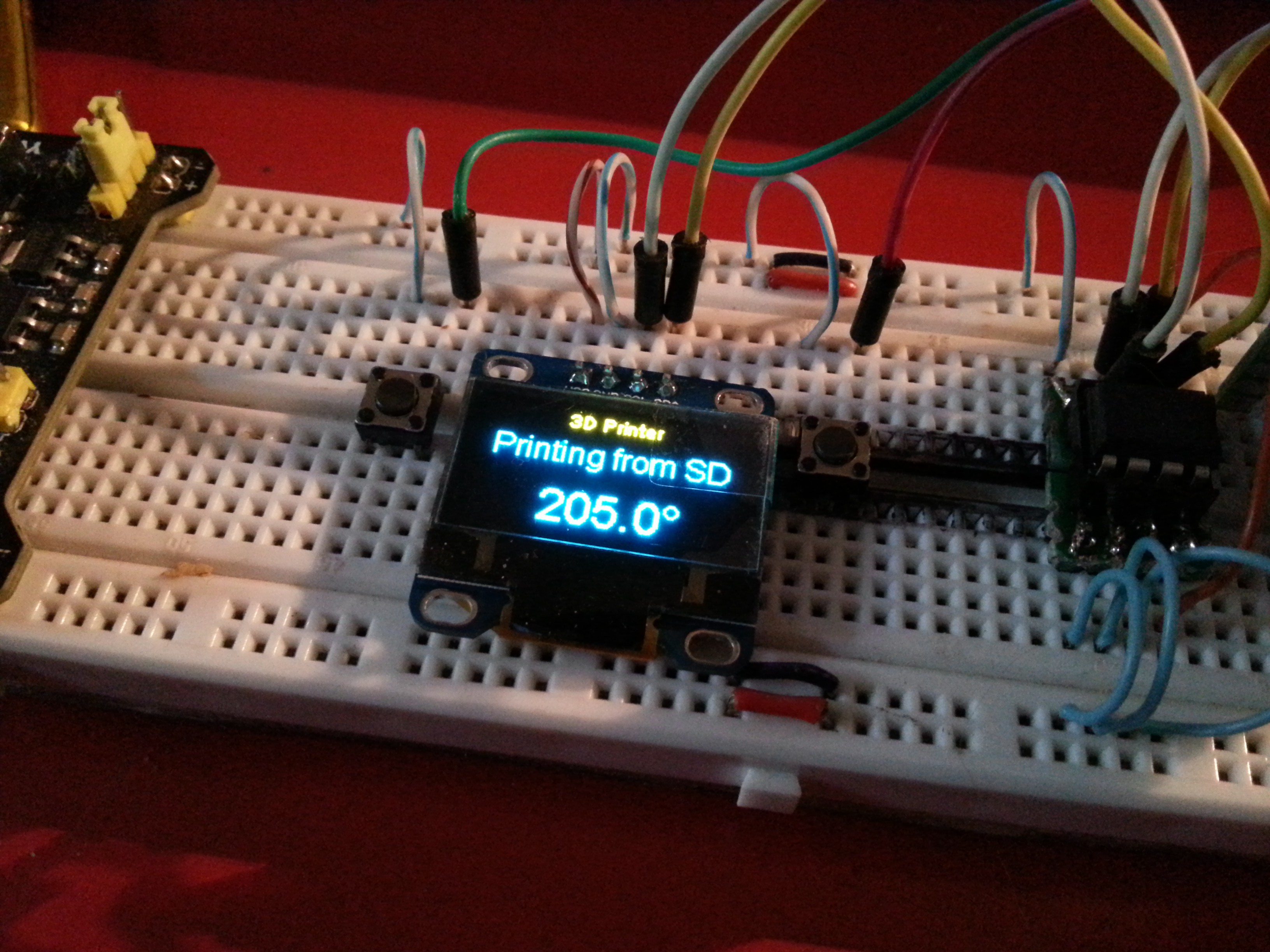

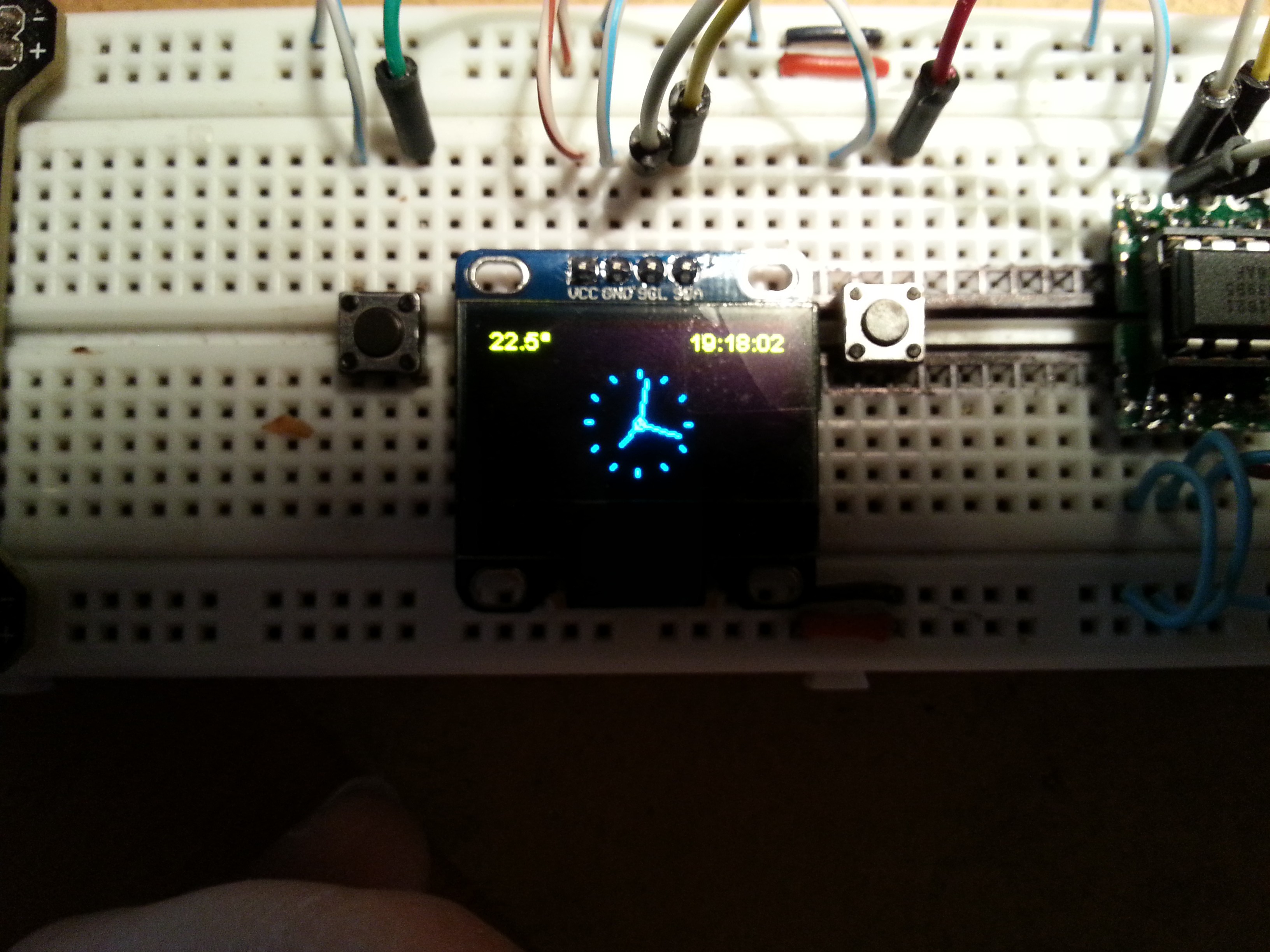

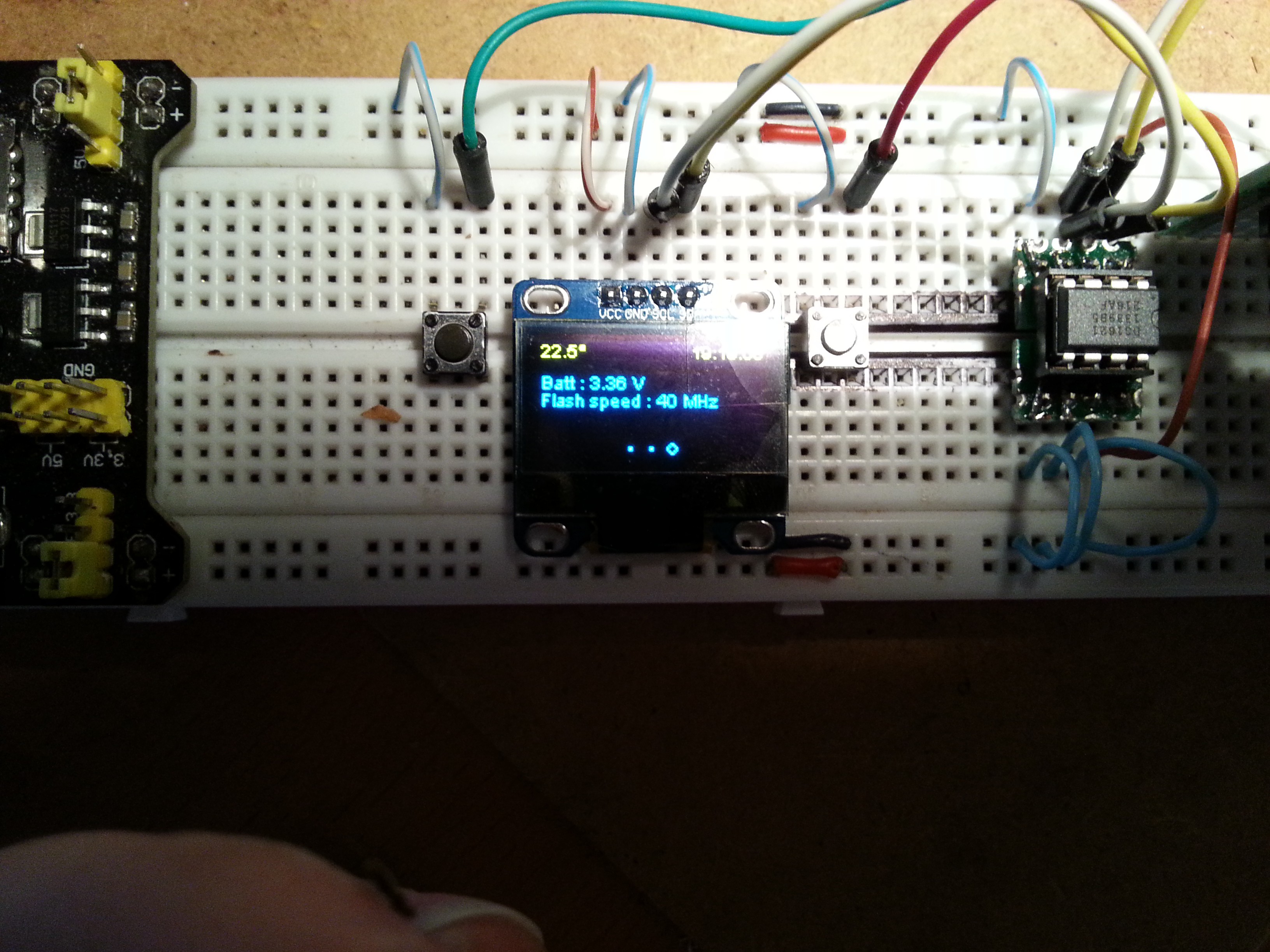

The device is built around a ESP8266 (ESP-12E actually) and a SSD1306 I2C OLED display. It is battery powered (using a 18650 cell from a dead laptop battery). 2 buttons are used to navigate the interface and activate functions.

I also plan to use an "utility socket" to expand capabilities : https://hackaday.io/project/11869/log/38691-the-utility-socket-explained

Right now, working functions are :

- some nice navigation menus

- analog and digital clock

- gets real temperature using a DS1621 I2C sensor

- connects to known networks

- checks internet connectivity

- gets current time via NTP

- gets weather forecast on timed intervals (using a php script hosted on my home server)

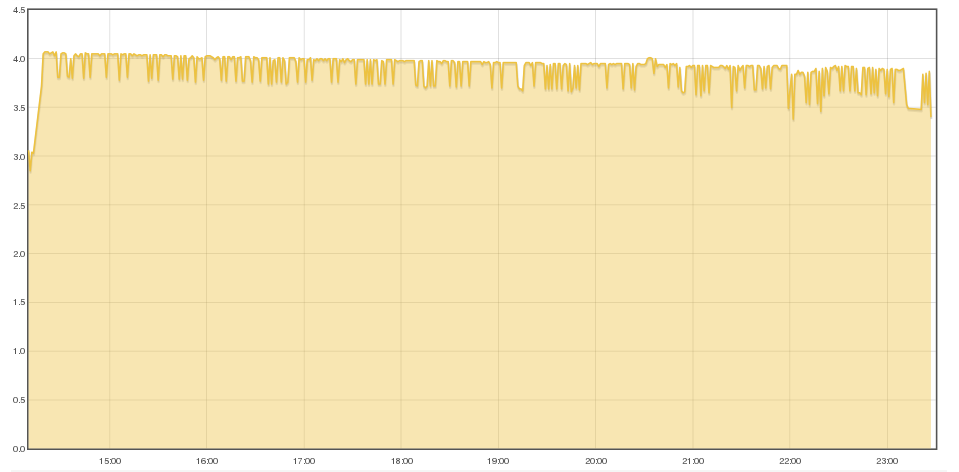

- posts real temperature and voltage to my emoncms server on timed intervals

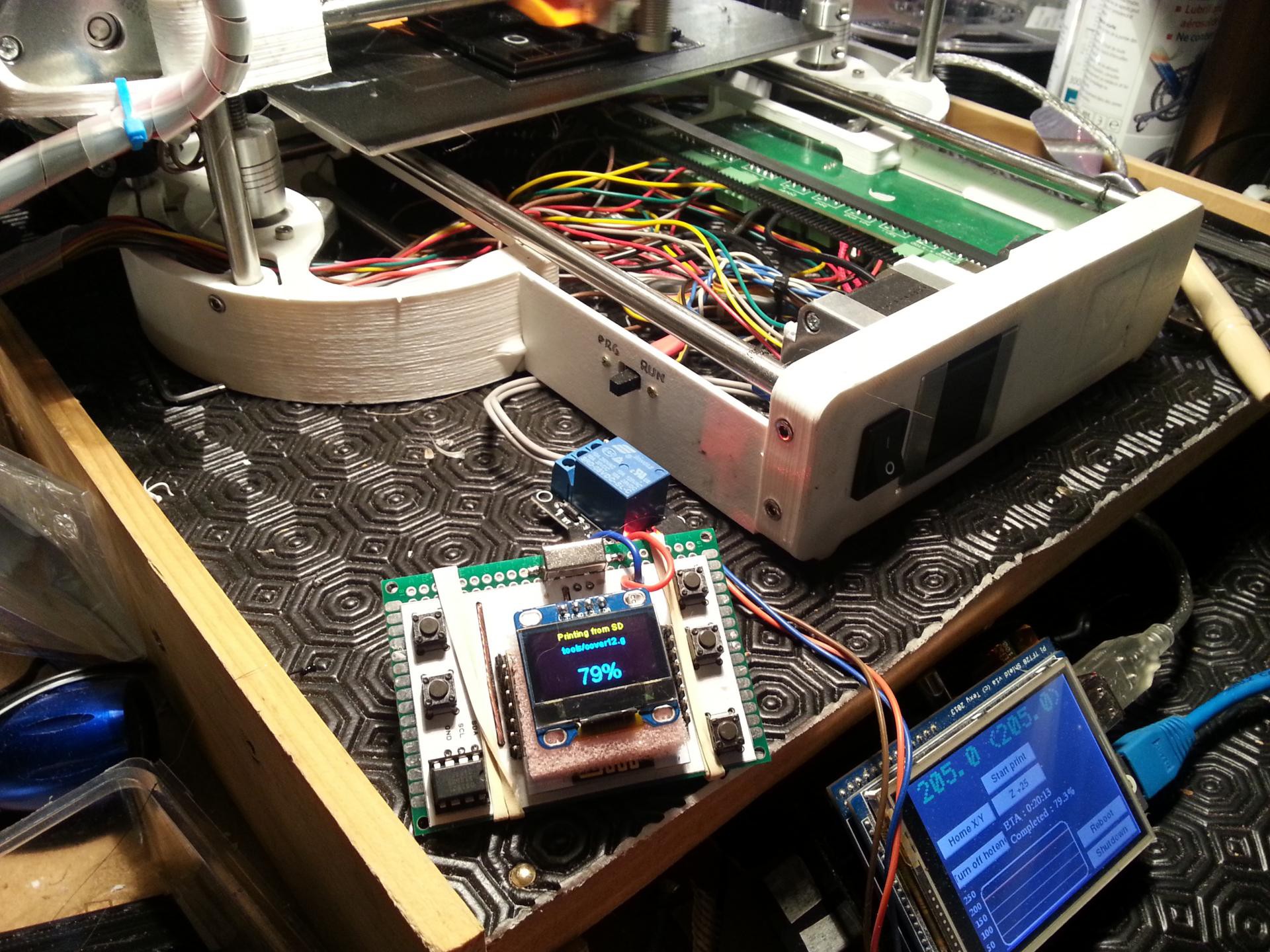

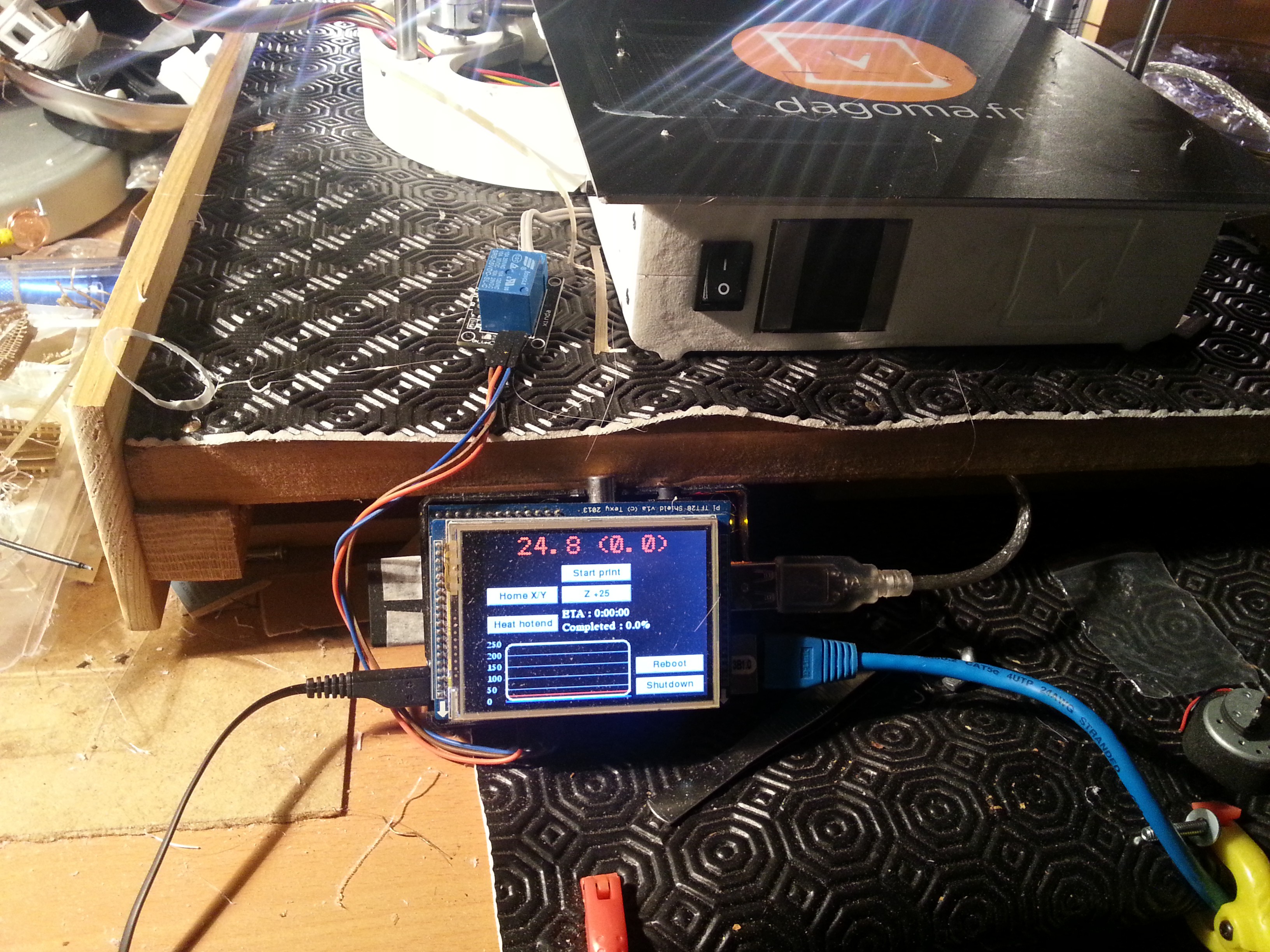

- shows my 3d printer status : on / off / disconnected, running state, hotend temperature

- gives details about the ESP chip : connectivity, ESSID, IP, free ram, battery voltage...

- On demand "WiFi smart config" : starts an AP and a webserver during 30s, allowing to add new WiFi credentials using a web interface.

- OTA firmware updates

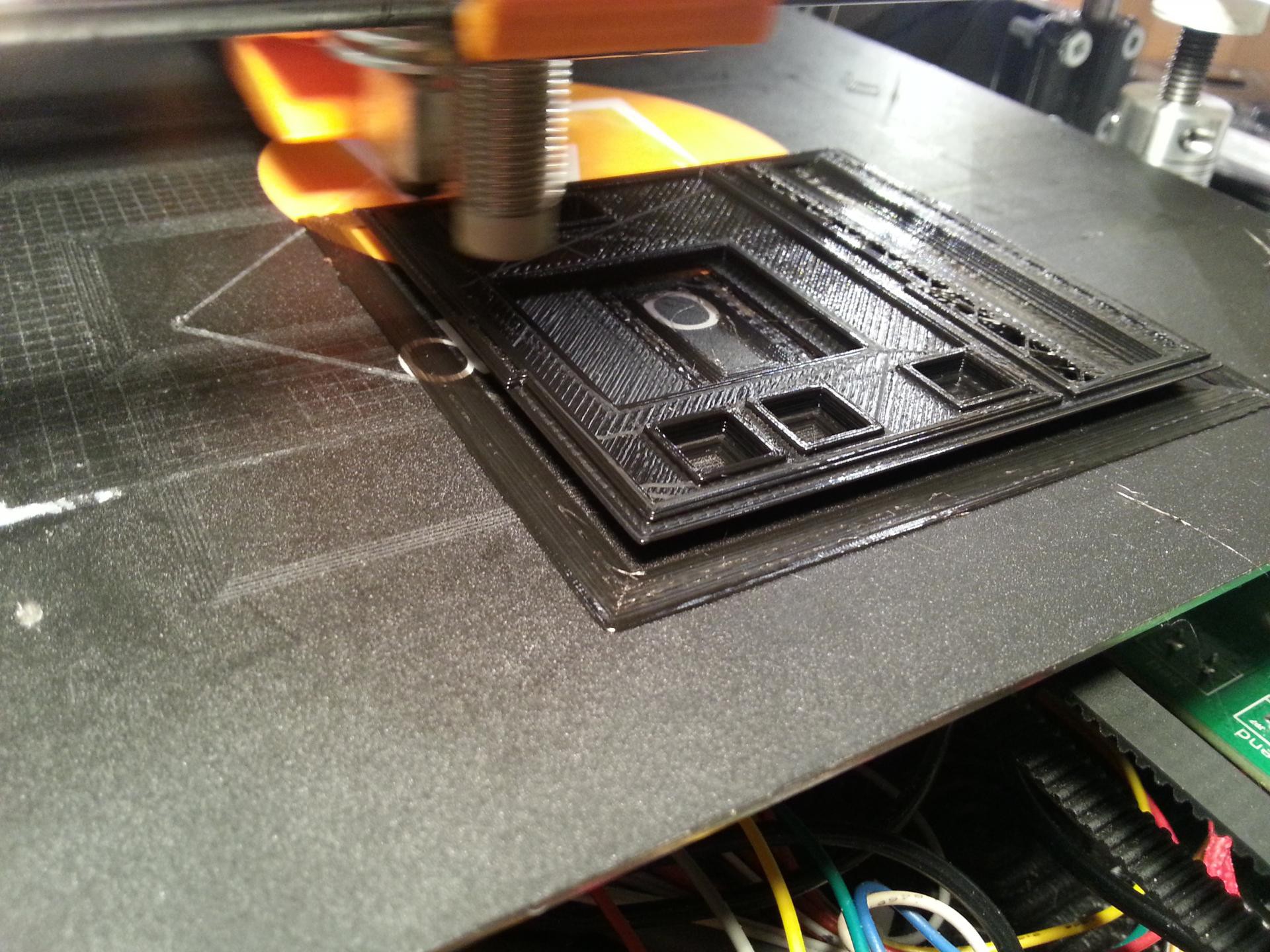

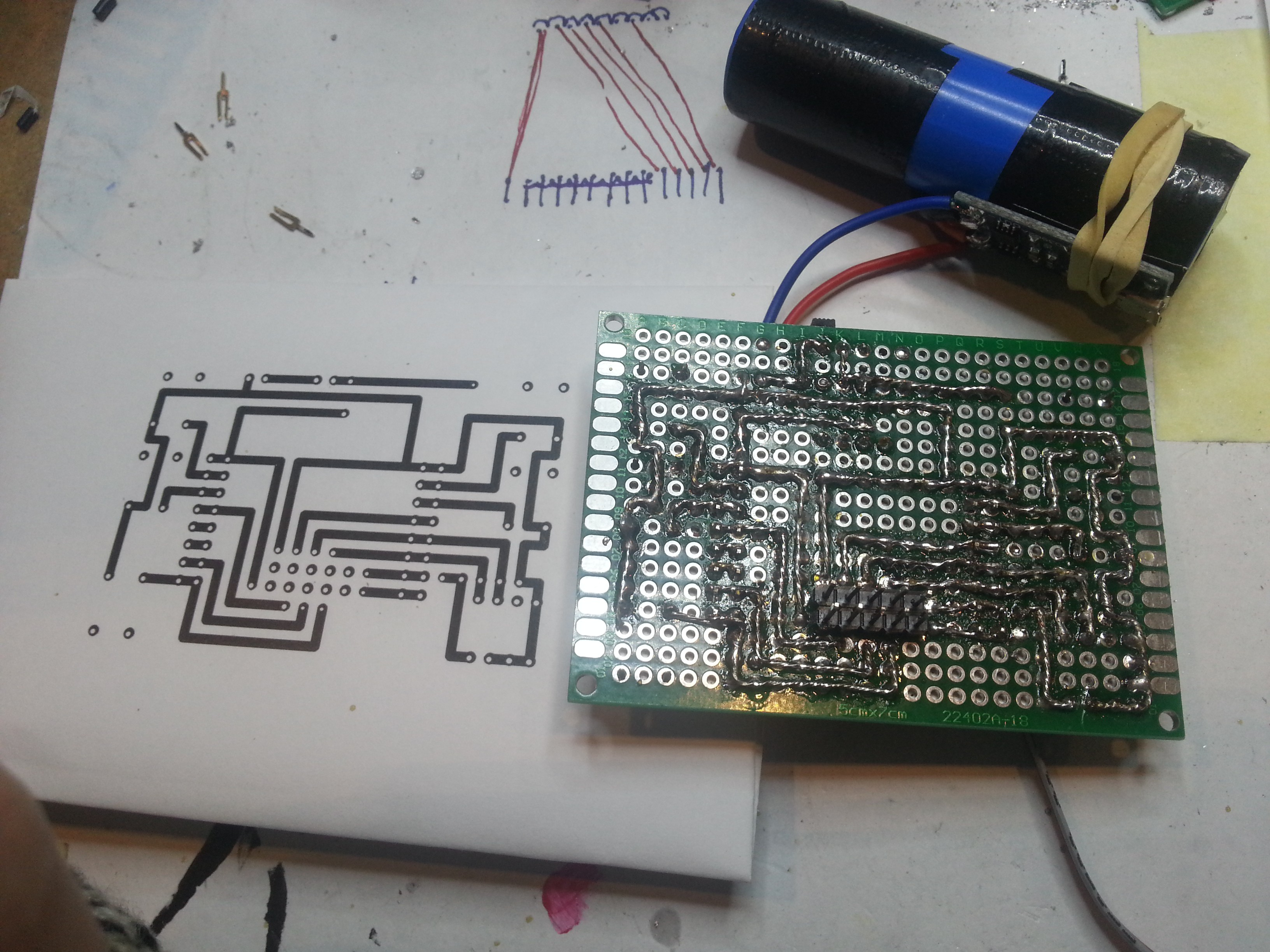

Circuit board still needs some work : it is a prototype on a perfboard, and while it is working, I now want to move to a real PCB. Problem is : I can't find how to export a working gerber from Designspark software...

Arcadia Labs

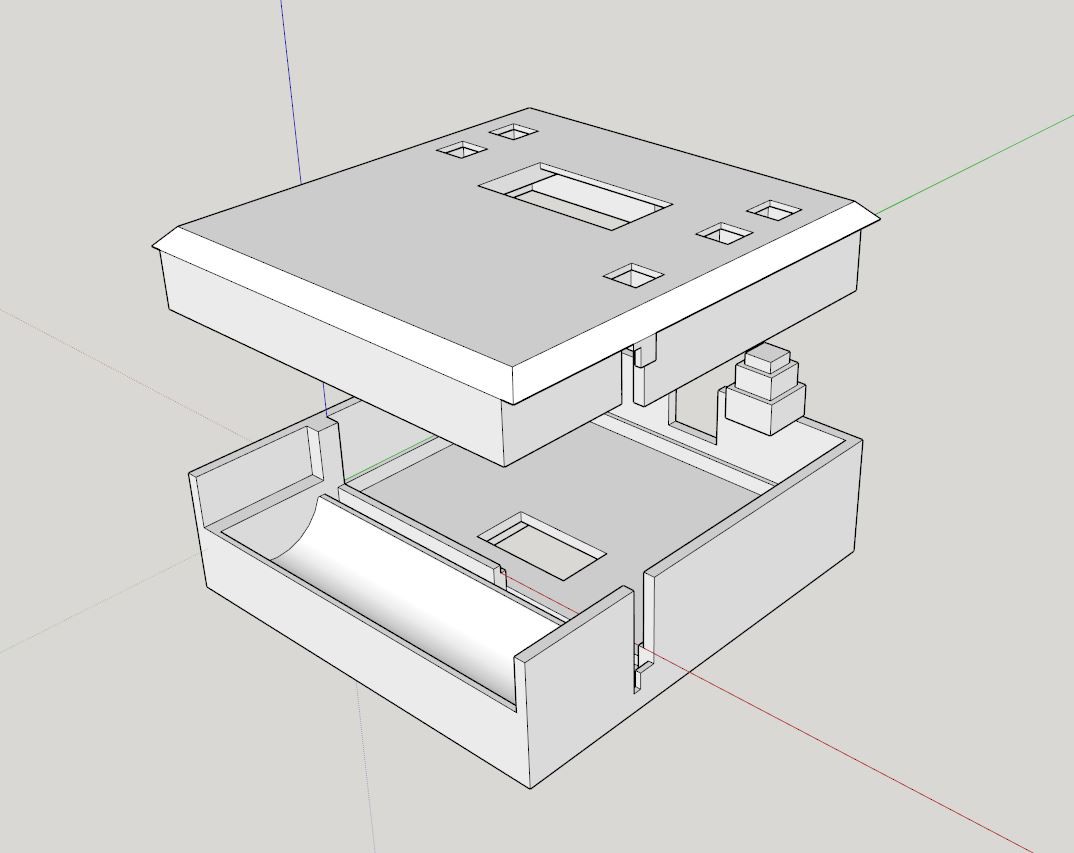

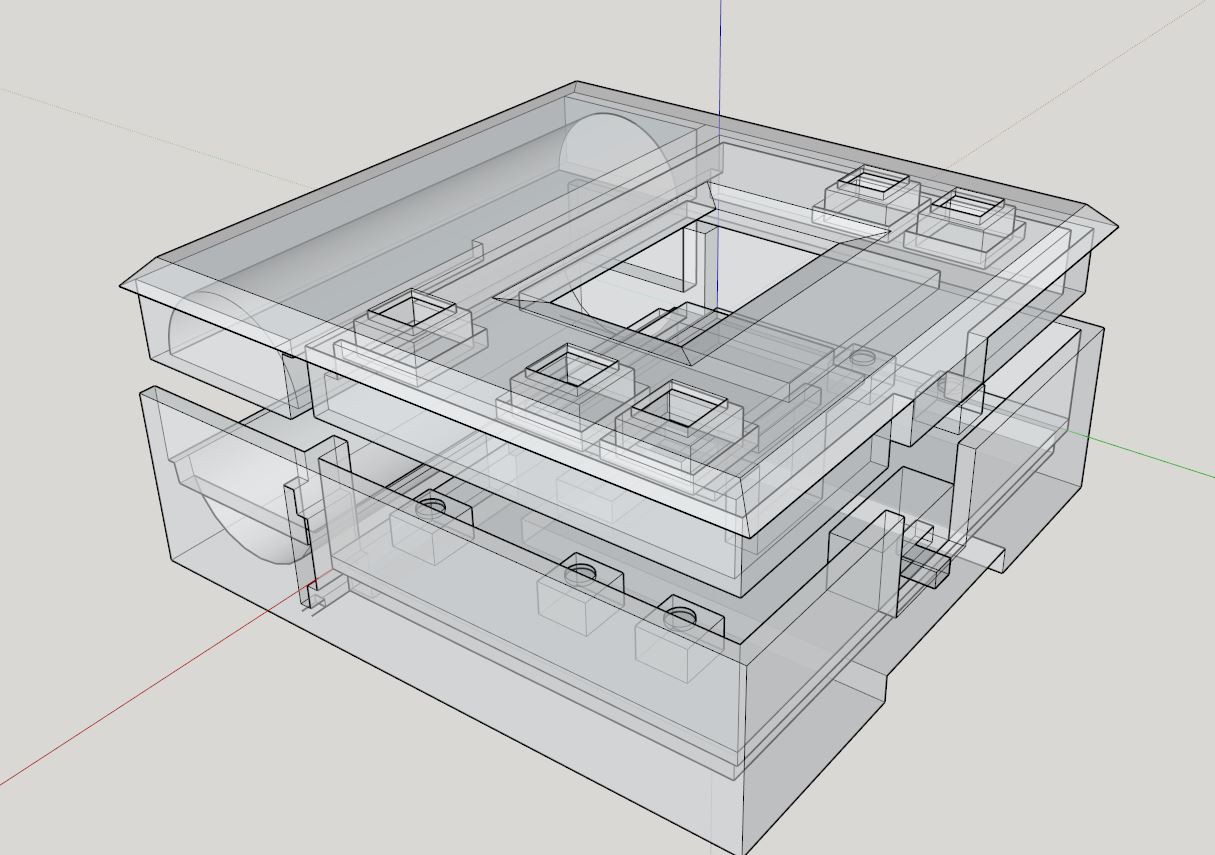

Arcadia Labs The inside

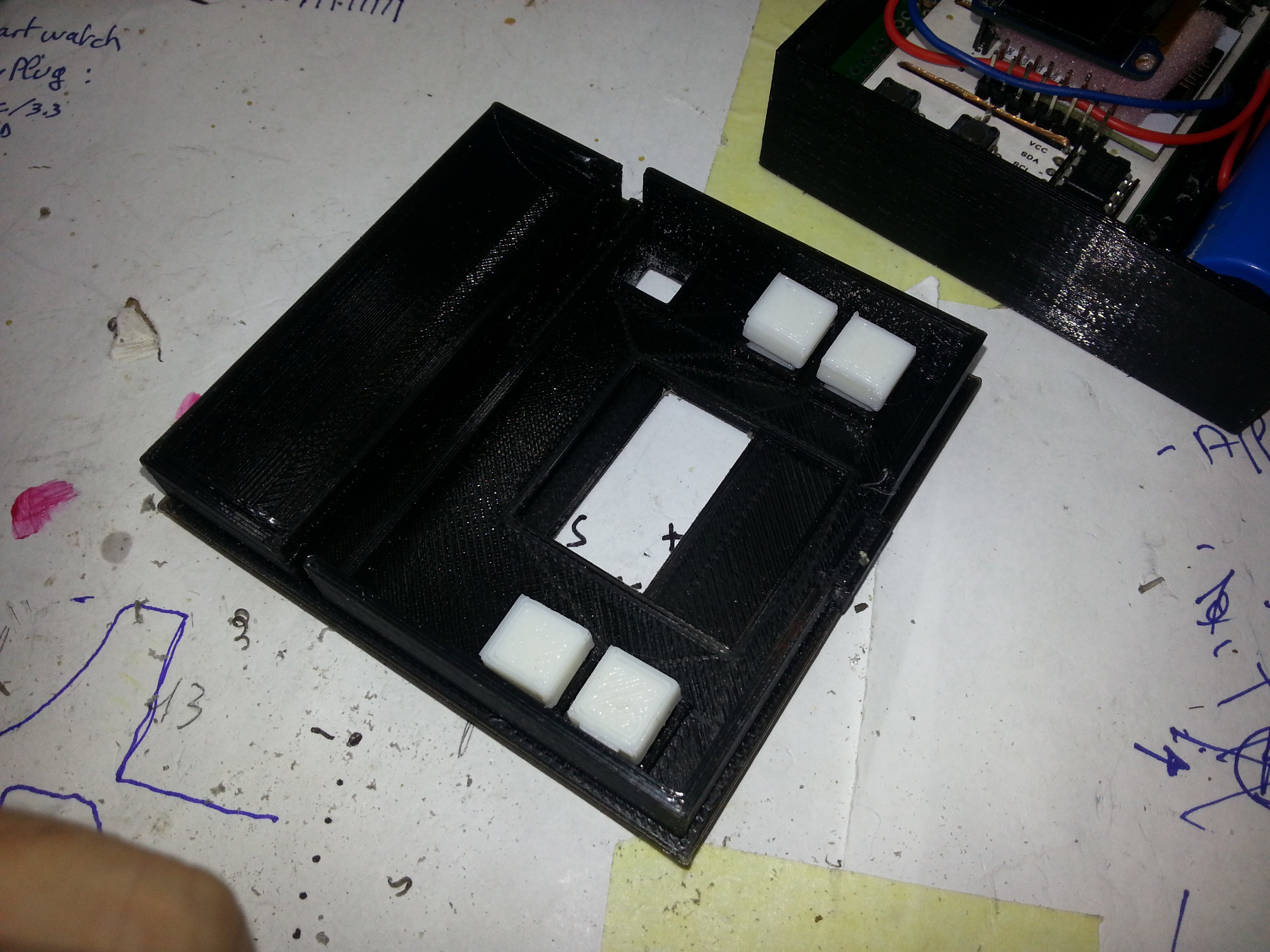

The inside Cover and buttons

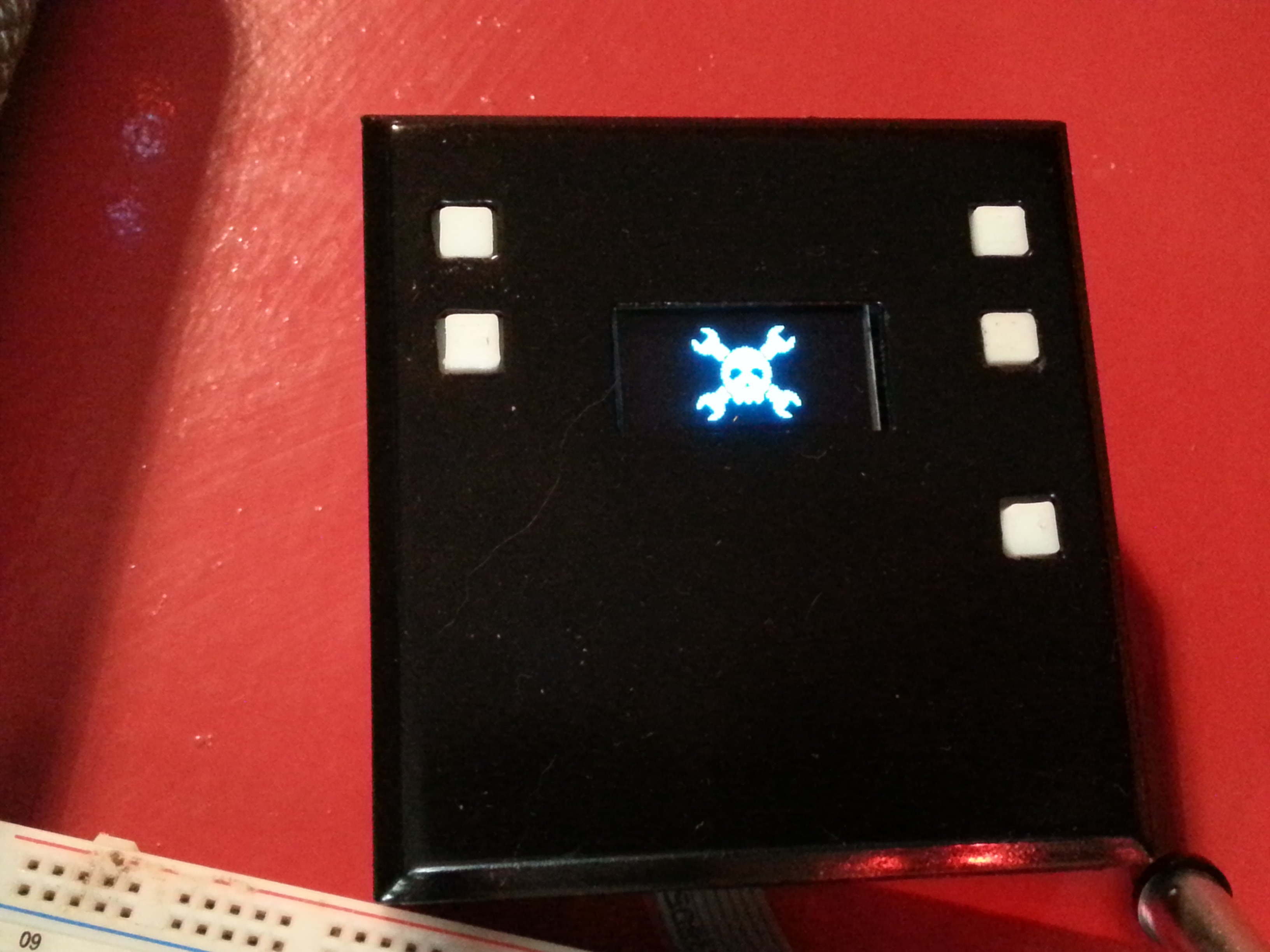

Cover and buttons Device start-up... Hello Jolly Wrencher ! :)

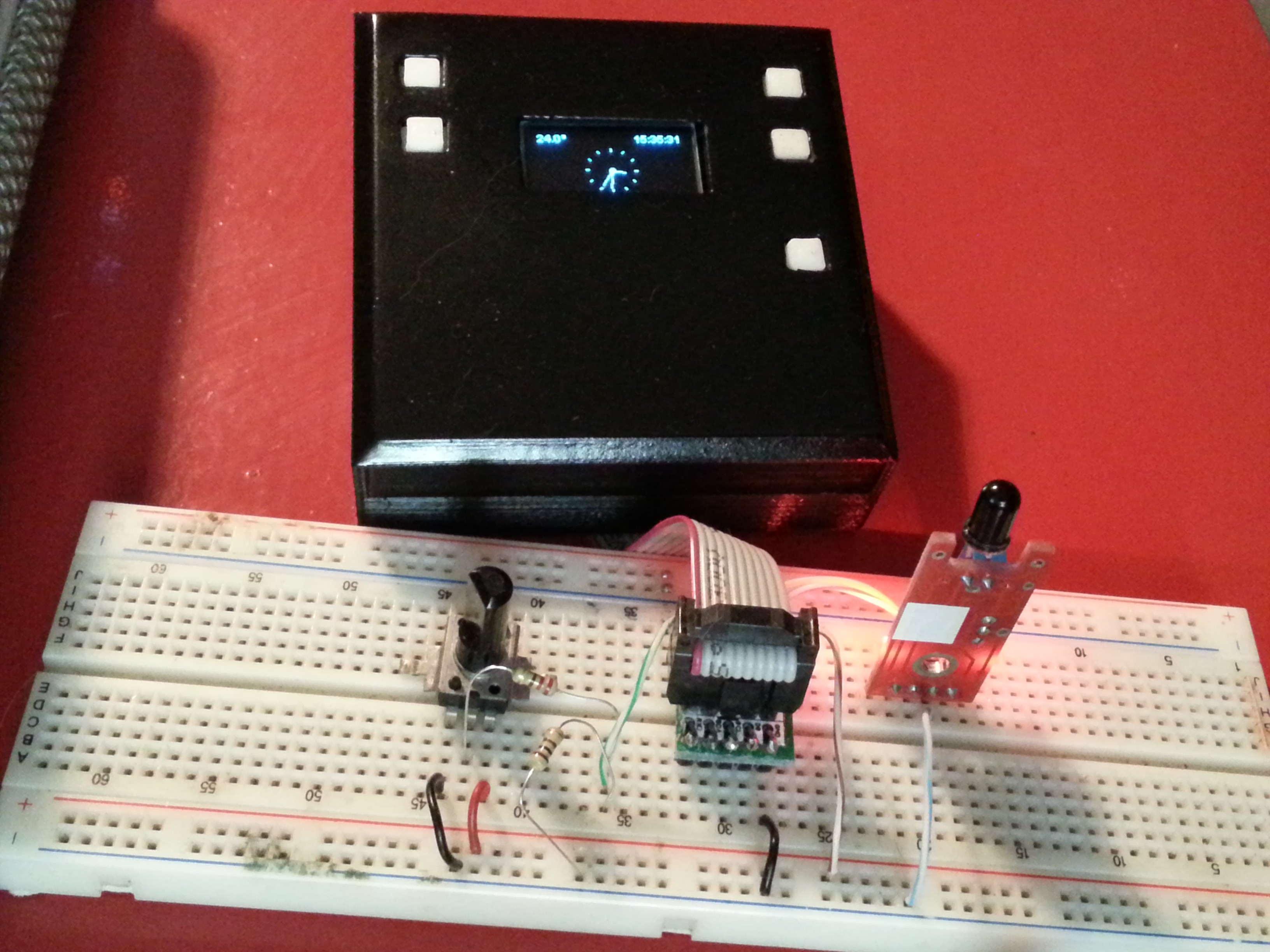

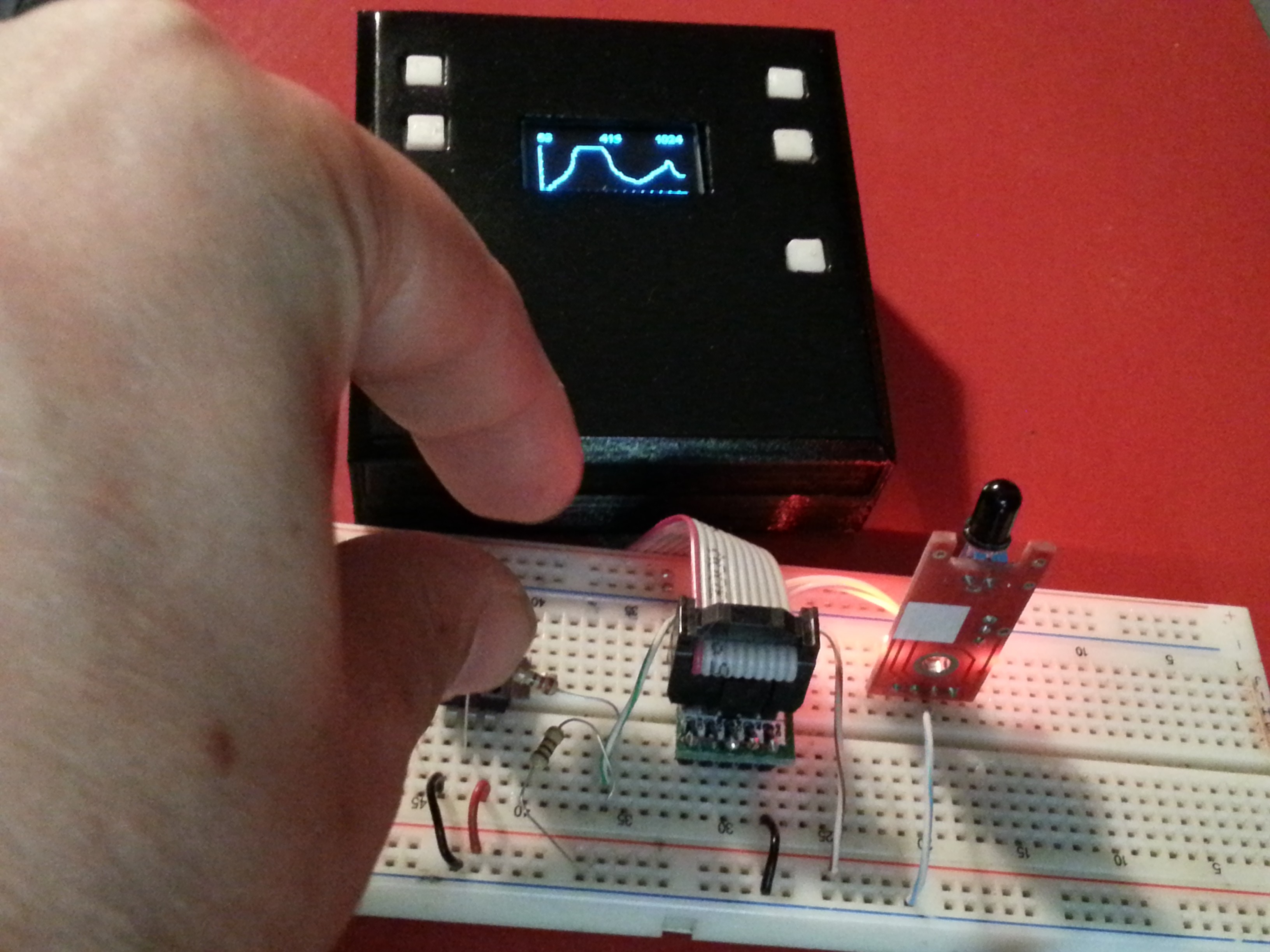

Device start-up... Hello Jolly Wrencher ! :) Test rig using the utility socket : a potentiometer to simulate analog input, and a IR receiver module to simulate digital input.

Test rig using the utility socket : a potentiometer to simulate analog input, and a IR receiver module to simulate digital input. Analog monitor, with min, actual and maximum values, while playing with the potentiometer

Analog monitor, with min, actual and maximum values, while playing with the potentiometer Digital monitor while playing with the IR receiver and a TV remote (sorry for the blur, difficult to capture). Sampling speed could be changed with 10Hz increments. Next feature will be a new running mode, starting only on a pin change, sampling during a fixed time, and then showing on a scrollable / zoomable static graph.

Digital monitor while playing with the IR receiver and a TV remote (sorry for the blur, difficult to capture). Sampling speed could be changed with 10Hz increments. Next feature will be a new running mode, starting only on a pin change, sampling during a fixed time, and then showing on a scrollable / zoomable static graph.

Seems good. I want to test the same program with metal training knife project, you can see here https://combatica.co.uk/collections/metal-blunt-training-knives