I've been working on a single-pole single-throw (SPST) relay, after realising that all of the circuits that I am interested in and have been prototyping with SPDT relays can be made equally well using SPST relays (albeit using a few more than if SPDT relays are used).

Here's a photo of the relay:

The design constraints on relays mean that it is easier to make a good SPST relay than an SPDT relay. In an SPDT relay, the spring keeping the normally closed (NC) contact closed must exert enough force so that the NC contact resistance is low. But the larger this force, the greater the power required to operate the relay and make a low resistance contact at the normally open (NO) contact. Also, since I'm using PLA, the spring holding the NC contact closed tends to creep over time, even when the relay is not in use, causing the NC contact resistance to reduce.

Here is a video of the relay being tested:

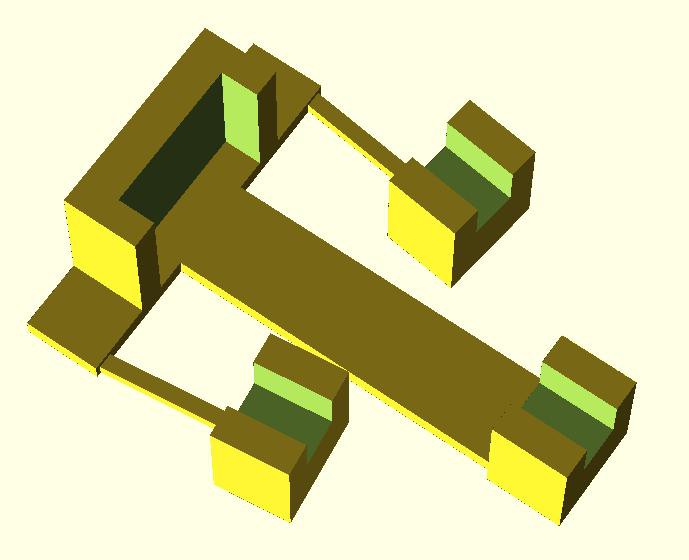

You can see that there are two pole nails, both of which close on a common NO nail. The idea behind having two pole nails is that they should be wired in parallel to reduce the chance of getting a bad contact closure (due to dust or some other problem) - only if there is a bad closure on both contacts will the relay fail. I believe that a similar idea is employed in some commercial miniature relays.

An initial manual scroll through the test data shows that the relay operated correctly for about 3000 cycles (i.e. until the test ended), with a load of 50 ohms. The contact resistance when both contacts are wired in parallel is about 0.5 ohms at the beginning of the test, and slowly increases to about 1.5 ohms by the end of the test. I don't know whether the increase in resistance is due to a mechanical change in the relay over the course of the test, or a change to the surfaces of the contacts.

Here is an image of the 3D printed part of the relay:

The OpenSCAD files for this relay are available in github: relay7c.scad

The coil is 2150 turns of 40 swg enameled copper wire wound around a 30mm long galvanized iron nail. The pole nails are 20mm long. All nails have a 3mm diameter shaft. The coil is tapered slightly and is only wound around 19mm of the nail, to allow space for the pole nails to make contact. The coil is held in place by a small 3D printed washer. The resistance of the coil is 57 ohms.

There are still a couple of problems with this relay:

- It's difficult to make relays with a consistently sized gap between the pole nail heads and the coil nail.

- Because there is no NC contact, the pole nails are not very well damped, and after the relay is deactivated they tend to oscillate for a large fraction of a second at a frequency that looks and sounds like a few dozen hertz.

will.stevens

will.stevens

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.