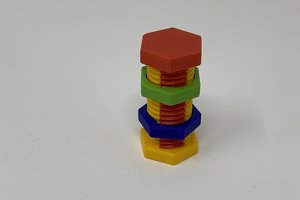

Print-Arm 3d is an Open Source 3d printing machine designed to use small, low torque, dc motors instead of stepper motors to create motion suitable for 3d printing. Several options were considered; but eventually I decided a properly programmed closed loop robot arm would be the most efficient way to print. By adding one linear axis as well we gain a very large potential print area.

I hope that by adding feedback to a cheap robot arm (I’m using an OWI toy arm) I can achieve the necessary precision needed for good printing. Using the idea in this instructable: http://www.instructables.com/id/Modifications-to-Robot-Arm-for-Opto-Coupler-Feedba/ I will add optointerrupters to the inside of the gear box. After this I plan on implementing a PID loop to control the joints of the arm.

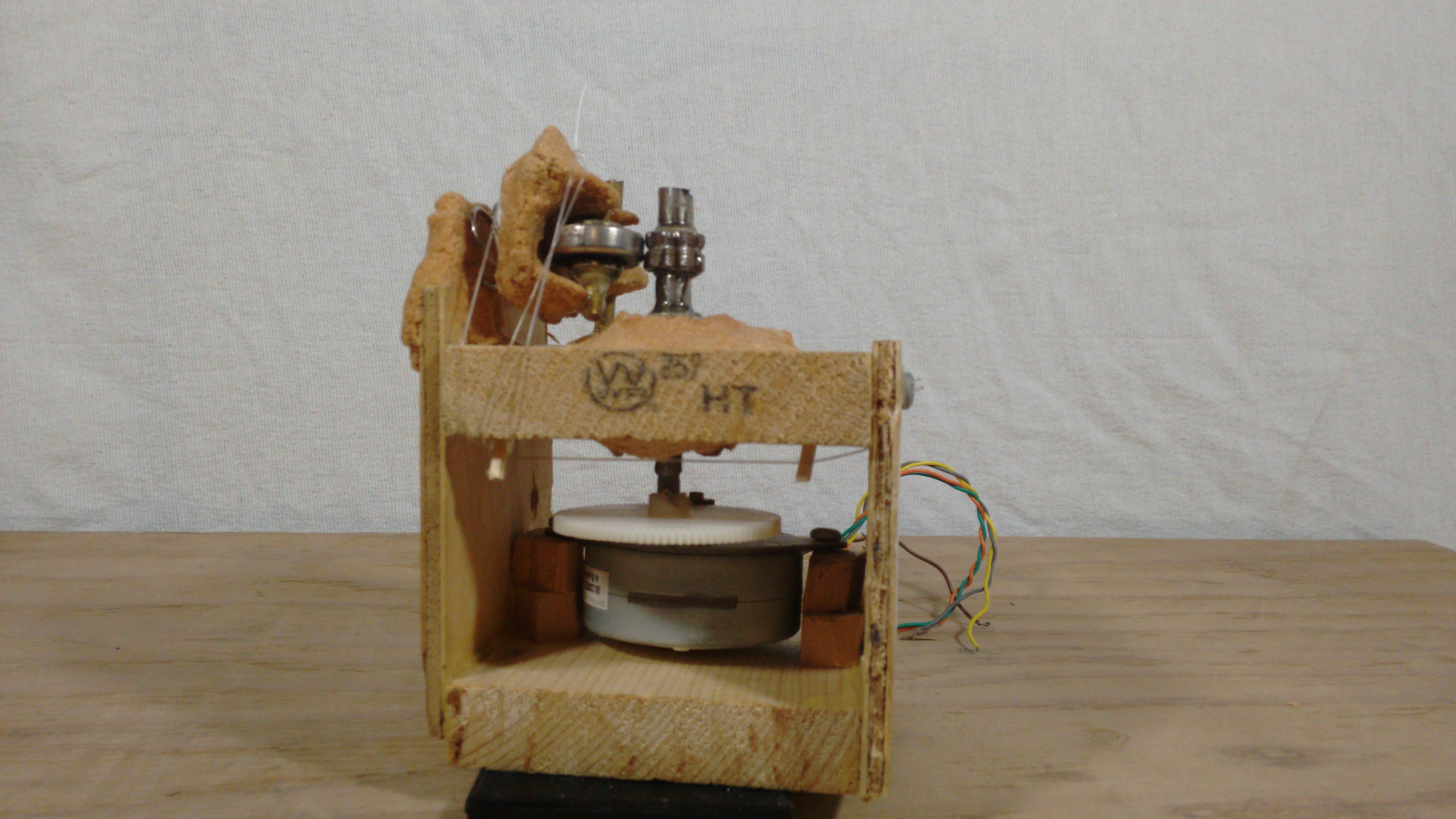

In order to use smaller, cheaper motors Print-Arm 3d uses a Bowden style extruder to reduce the weight the arm needs to move. The extruder consists of a mechanical end which pushes plastic filament through a Teflon tube to the heated extruder end on the arm.

Print Arm 3d was designed to be hand made. All of the custom parts are made of a mixture of sawdust and wood glue that was additively sculpted and pressed to form a strong composite material. Also, only basic tools are required to assemble it.

The most complex part of the project is going to be in the software. I will try to write as much of the code as I can from scratch in C++.

jon.knutton

jon.knutton

MasterOfNull

MasterOfNull

leumasyerrp

leumasyerrp

Greg Zumwalt

Greg Zumwalt

Love the handcrafted extruder! :D