-

Project Log 4 - Focusing on the Future

05/31/2016 at 01:31 • 0 commentsJune 2016

With the core mechanics implemented, we are working to improve the speed at which the ORB can operate. With initial concepts for MultiHeat, Multi-Material, and Laser Scanner, we are excited to move to the next phase of the project, incorporating new technologies into 3D printers for faster print speeds and accessibility for the end-user.

Parallel to these mechanical improvements, we are standardizing the printed circuit boards (PCBs) for each PEASH module and incorporating the electrical components such as wiring and input/output ports into a more production-ready design.

We are developing an Alpha version of the ORB Studio software, so that we can begin testing with a small community of users. This will allow us to gather feedback so we can rapidly improve ORB Studio, making the ORB 3D printing experience as easy as using a paper printer.

We are enthusiastic about the progress we have made thus far and excited to share our project with the world, working with a growing community of users who will use 3D printing technology to shape our world.

-

Project Log 3 - Automated Fabrication

05/31/2016 at 01:30 • 0 commentsJanuary 2016

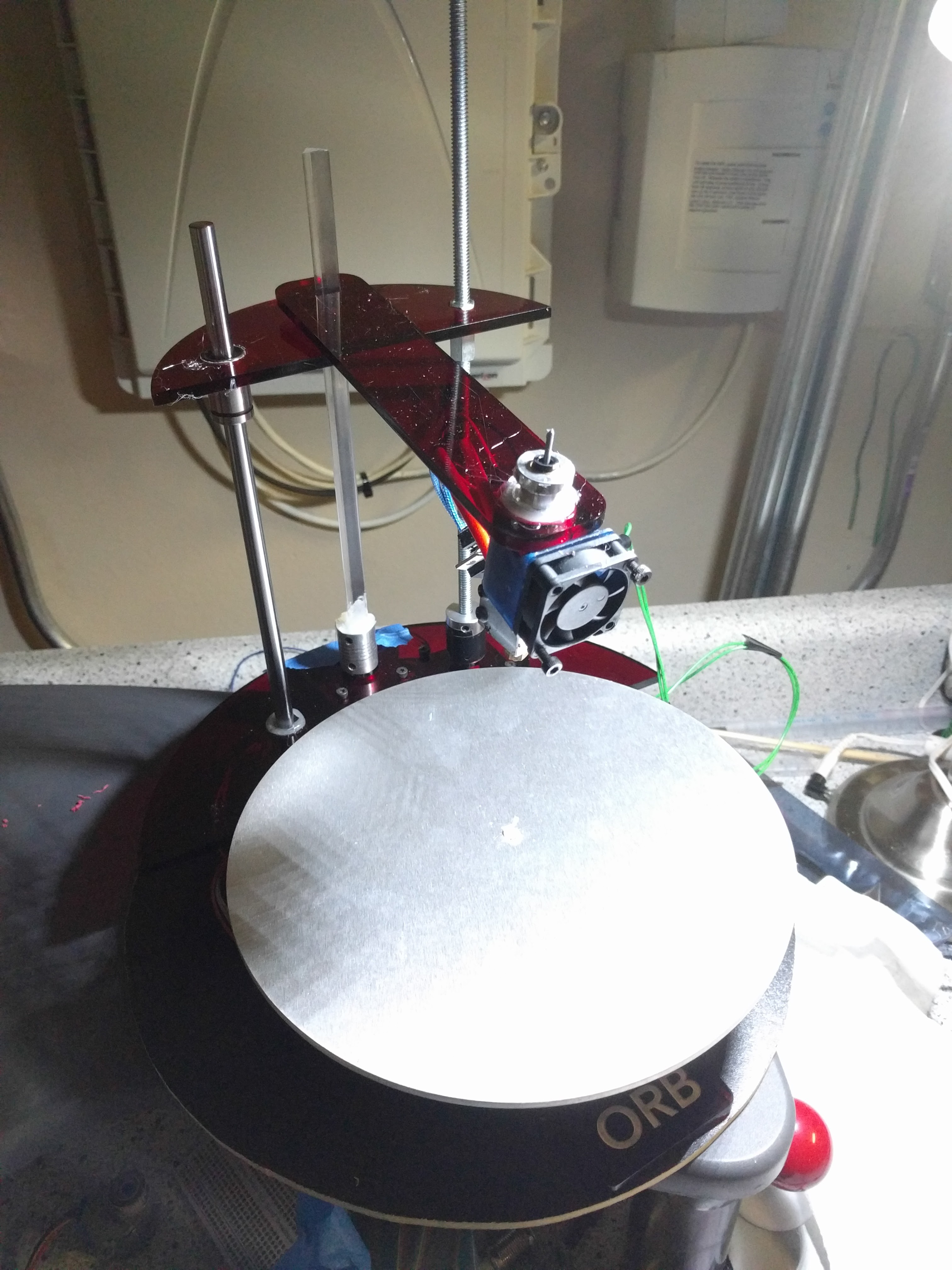

Making the giant leap from manual fabrication to automated, laser cut precision, our prototype has increased dramatically in reliability and robustness. Through CAD designed, laser cut parts, the relationship between the moving parts of the printer is now more accurately realized, producing a more elegant and robust printing experience. Thinking about ways to enhance ORB’s assemblies, we are currently aiming to accelerate print speed through both mechanical design and new software implementations.

April 2016

During this time period, we are focusing on our third major design overhaul. With most of the major mechanics working, we have turned our attention to refining all the major elements and moving towards a production/consumer model. Shifting from our purely functional prototype, the design philosophy is now to manufacture a unibody for the base, where we can nest the motors and printed circuit boards (PCBs). Additionally, we are starting work on the UI/UX for the end user. With ORB Studio, our accessible cross-platform web-app for ORB 3D modeling, users will be able to print objects directly from files and build objects with multiple materials using a simple, intuitive interface.

-

Project Log 2 - ORBuilding!

05/31/2016 at 01:29 • 0 commentsSeptember 2014

Thomas has established fully custom electrical, mechanical, software and firmware prototypes using Raspberry Pi, Arduino, AVR, and 3D printed parts. He stays focused on the goal of super fast 3D printing.

January 2015

The ORB website has launched! -- http://orbprinter.com

Introducing the PEASH Paradigm, Thomas has created independent modular components for each individual mechanical part of the printer. Each of the PEASH electronic components controls an associated motor and mechanical part: Platform, Extrude, Angle, Spin, Hotend. With the introduction of ORB Print Code, he also aims to simplify the print process for the maker and end user.

The next major focus of the ORB 3D Printer has been created: Modularity!

Realizing that today’s 3D printers are generally closed for innovation, from both hardware and software points of view, ORB aims to foster an ecosystem for modular 3D printing. By eliminating the need for extensive engineering experience to add to or change a 3D printer, he is determined to give every user all the tools they need, from simple, one material prints to complex, multi-material electronics. All on one machine.

The modification of 3D printers still remains limited to a select few of engineers due to the growing complexity of centralized CNC control. ORB Modularity solves this issue by designating every major mechanical/electrical component in the printer as an individual Module, these “Building Blocks” allow users to modify the printer, customizing its functionality. Modularity vastly reduces the risk of failure of the entire system by removing interdependencies and ‘sandboxing’ individual Modules from the rest of the system. ORB Modules (and therefore the entire printer) are built on Arduino, a strong global open-source microcontroller platform. This also means that anyone can prototype their own Modules for the ORB.

Throughout the year, Thomas prototyped many iterations of the ORB 3D Printer, updating components and designs to make them just right.

September 2015

Raymond Lo has joined the team to focus on mechanical engineering, working with Thomas to design the next phases of the ORB 3D Printer. This iteration introduces mechanical standardization and furthers the work on printer geometry and functionality. Each mechanical component is being overhauled and improved for reliability. Electrical components are being miniaturized and we are prototyping new methods for each PEASH module, determined to optimize each one for individual performance in the ORB 3D Printer.

In our first study of ORB mechanics, we created what we fondly dubbed our “Pegboard” prototype, working to flesh out a functional architecture for modular components. Accomplished fairly quickly, we soon found the limitations of this model and dove into a radical overhaul. With Thomas visiting the Tribeca Film Festival soon to gather feedback on our prototype, we aimed at delivering a demo that would show the ORB as a stable, initial concept with room for development.

-

Project Log 1 - ORBeginnings!

05/31/2016 at 01:27 • 0 commentsJanuary 2012

Thomas Suarez just received his first 3D printer, a MakerBot Replicator, and is a big fan of its open-source architecture and do-it-yourself (DIY) origin. He enjoys printing and tinkering with it, but has growing frustration with the speed of the machine. Delving into the world of 3D printing, research begins on developing other methods for object fabrication. ORB is conceived to not only increase print speeds, but also to increase end-user access. The product should be simple to use, with connectivity through multiple devices.

April 2012

Generating a multitude of concepts for the ORB 3D Printer, all with the goal of much faster 3D printing, he continues to create ideas for new, more efficient 3D printing and rapid prototyping devices. First reworking the electronics and software control of the printer, multiple new concepts are imagined, each building upon the best ideas from previous iterations.

April 2013

Focusing on the design and hardware of the machine, Thomas continues to create new 3D renders of the ORB 3D Printer, and keeps learning by experimenting with 3D software and firmware. Inspired by companies that seamlessly meld form and function, he constantly tweaks the aesthetic and works hard towards minimizing clutter and unnecessary mechanics.

April 2014

After a year of development, Thomas has documented some of his new 3D printing ideas for a United States patent application. As a supporter of the open-source community through GitHub and other online sites, Thomas wants to ensure that a major corporation in the 3D printing industry does not run with his ideas before he has a chance. His plan is to first develop ORB to a solid, integrated machine, and then open it to the worldwide community of makers.

Thomas Suarez

Thomas Suarez