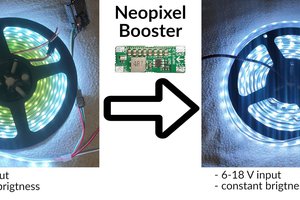

The modules are rated at 12V/2.5W each. The IC and input caps on these modules can handle up to 50V, so it makes sense to use higher voltage to decrease current and lower resistive losses. PSU delivers 19V nom. at 60W max (=~22 modules, it got overcurrent protection), each module is at about 130mA (so cheap crocodile clips are ok). Voltage drop across the whole steel cable is ca. 0.1-0.2V. I was surprised over the thin wires of the power supply, but as it is sold that way and I did not want to break the potted PSU open just to attach a few centimeters of bigger wire, I shortened the thin wires to a reasonable length to minimize losses.

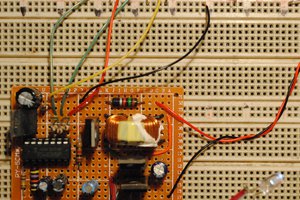

As I planned the first one of these, I was concerned over EMC (lots of small suboptimal layouted step-down converters where they left out the nF-range decoupling cap, with long, free-hangig "antenna" wires). As it turned out, there is a tiny amount of noise if I measure high impedance sources with my scope, but it is much less than the noise created from a Bosch LiIon battery charger (it is impossible to listen to FM or AM radio if it charges...). I got really expensive professional-grade LED lights in the lab benches at work - they are built into the lab benches and the power switch is at the secondary side of the SMPS - these create noise, too - but to disable the power supply it is necessary to unplug the whole lab bench.

Update after 1 year of use: received an electricity bill over 2,5kWh/day = 100Watt avg ! 40% of that is used up by the interwebs (cable modem + router + switch + webcam + DECT phone). They all run off 12V, 7V, 5V ... PSUs . Hmm... maybe I'll setup a 12V solar off-grid thingy for them...

rawe

rawe

Jan Mrázek

Jan Mrázek

Martin

Martin

Nicholas Amrich

Nicholas Amrich

bornach

bornach