-

Captured Photos

07/11/2016 at 13:34 • 0 commentsNo captions are necessary, just enjoy the view!

-

The Data Entry

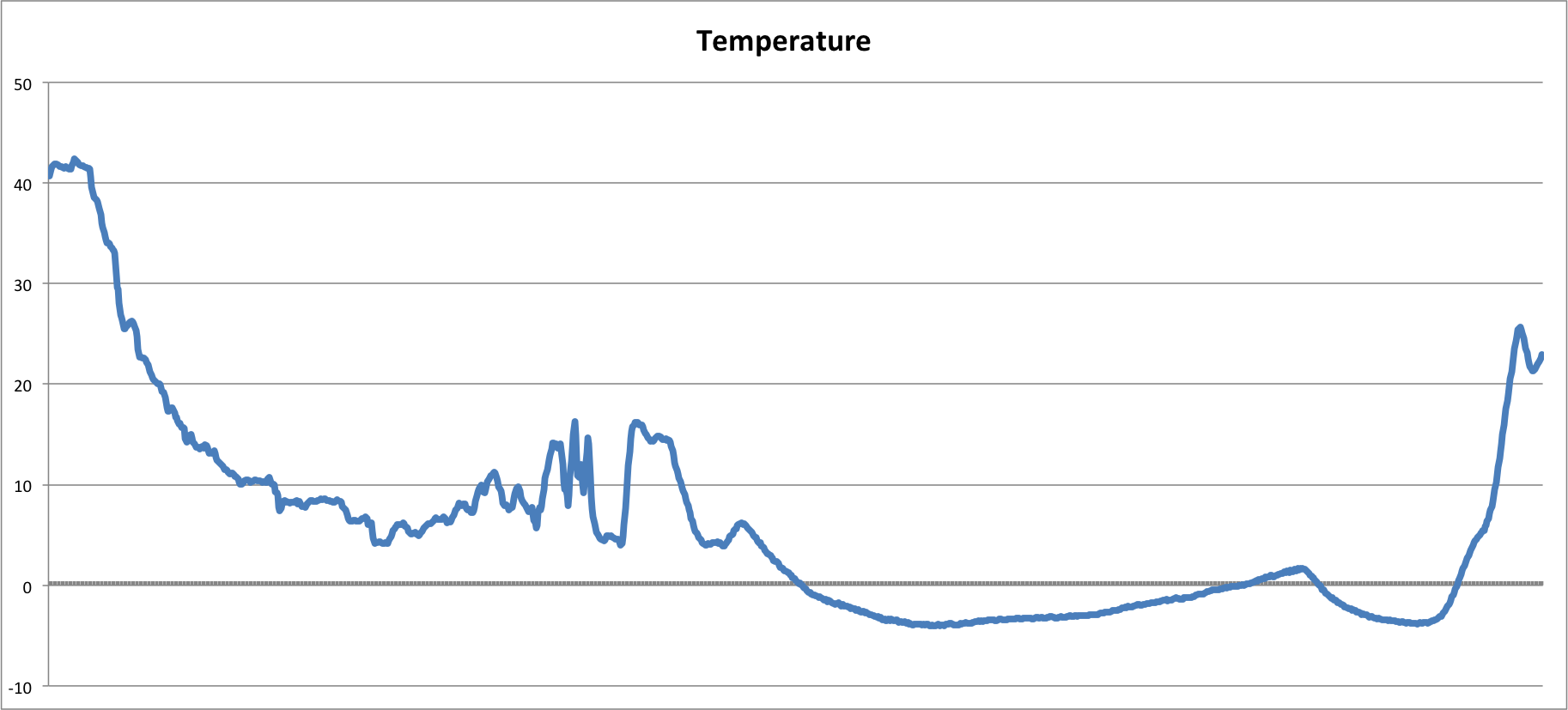

07/11/2016 at 02:19 • 0 commentsThe FlightCPU provided very interesting data throughout the flight. Unfortunately due to calibration issues, the barometer did not give us accurate results in terms of absolute altitude, but we can infer the overall flight path using relative values. Other data points from gyroscope and magnetometer were difficult to parse, and even harder to graph. We are still working on the best way to visualize this data, so any suggestions would be appreciated!

![]()

As you can see above, the temperature seems to fluctuate as the balloon rises through the atmosphere. Why is this so? Our best guess is cloud coverage (although the cameras didn't seem to indicate many clouds). It is also curious to see the temperature rise as reaches the top of the assent. Perhaps the sun had something to do with it? Note on the descent, you can see a slight change in the rate of temperature increase, we believe this lines up with the fluctuations we saw during the rise (keeping in mind the descent was much faster than the rise). One final note, the temperature starts to decrease right at the end of the graph. Because we found the payload in the woods in the shade, we believe this decrease at the end signifies the payload at rest, waiting to be found.

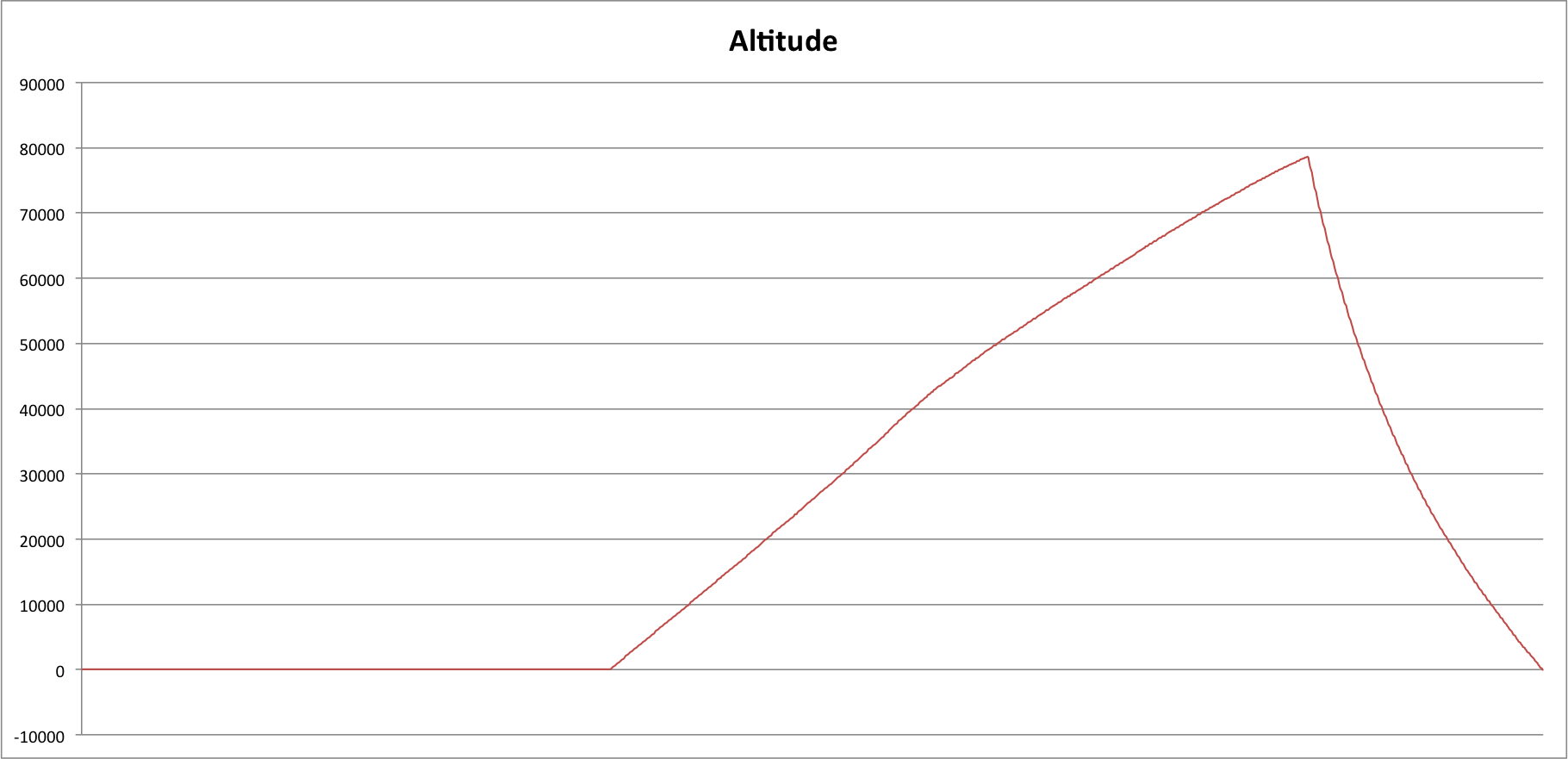

The altitude graph is about as straightforward as it gets. Unfortunately, due to calibration issues, the absolute values are invalid, but the relative height can still be analyzed. Of interest, the rate of accent looks to be pretty constant, with only one slight change about half-way up. On the descent, the rate is decreases, signifying the work of the parachute and the thickening of the atmosphere.![]()

-

Lift Off!

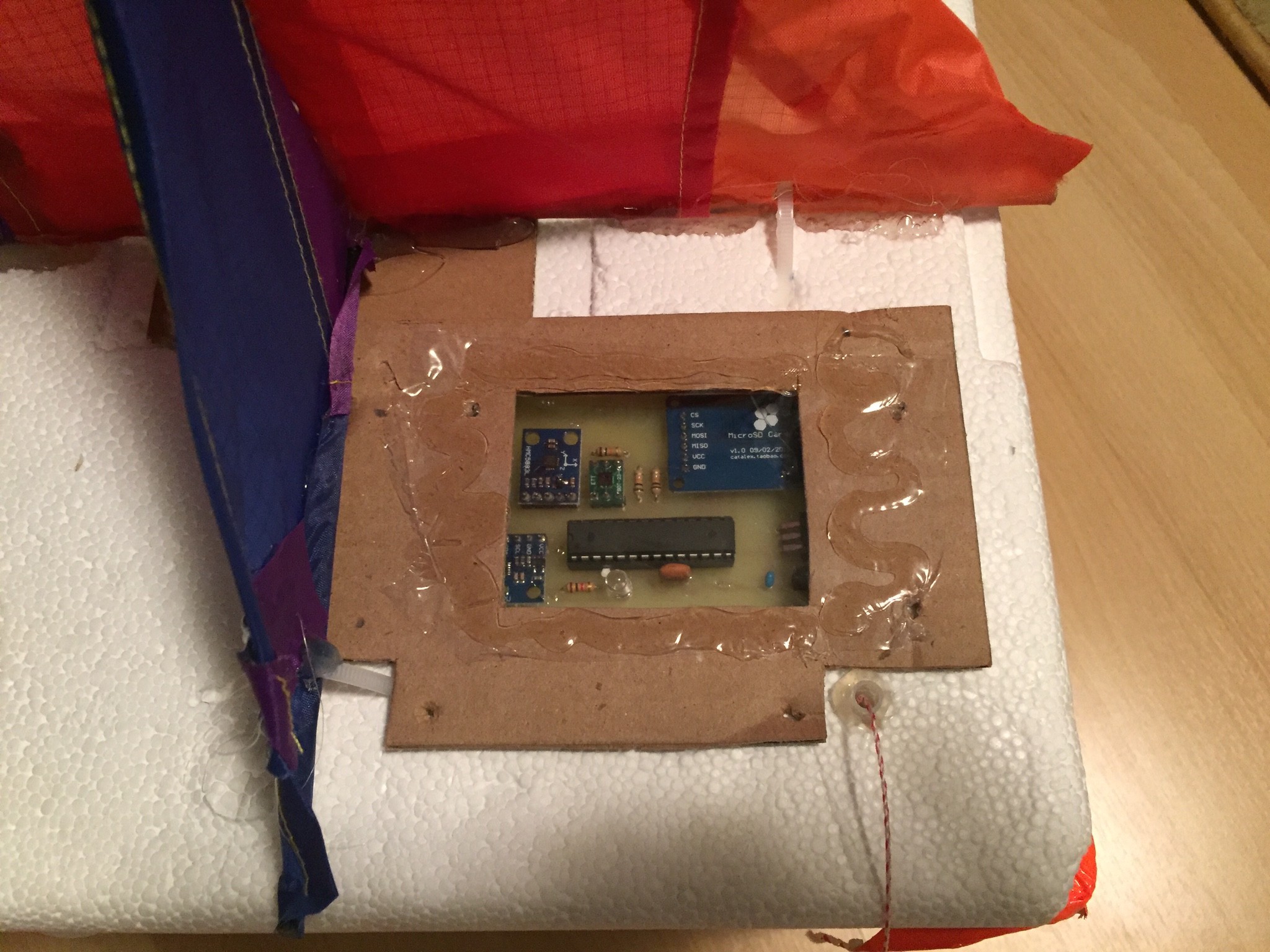

07/11/2016 at 01:40 • 0 commentsWe decided to carve out space in the lid of the payload box to secure the FlightCPU. This allowed it to be exposed to the elements, but in a way that did not damage the board. If we had placed the FlightCPU in the actual payload, we risked contaminating the data as we had included warmers to keep the cameras above freezing temperature. So placing the FlightCPU outside the payload was a must.

![]()

Here you can get a good sense for the size of the ballon and the care taken to inflate it. Notice the latex gloves being warn- even the slightest oil form your hand can cause the balloon to prematurely pop.

![]()

This picture shows the complete ballon, parachute, radar deflector (or is it reflector?), and payload. The entire flight line was about 40 ft. It was impressive to hold, as I could certainly feel the lift of the ballon on the payload.

![]()

-

Creating the PCB

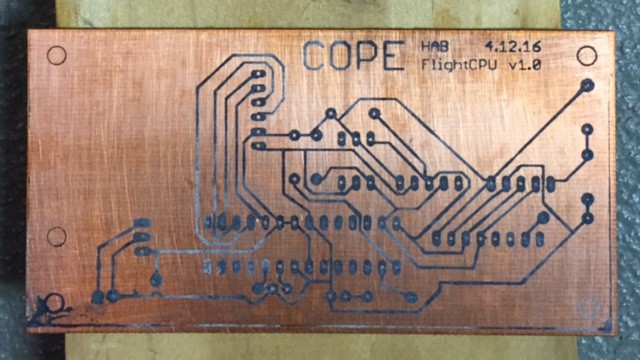

07/07/2016 at 21:31 • 0 commentsFull Disclosure: I have to give credit where credit is due. Everything I learned about home etching was from this HackADay article. I fully recommend you read it, and tailor the etching methods to your equipment and materials.

http://hackaday.com/2008/07/28/how-to-etch-a-single-sided-pcb/

PCB Etching is an art. You need the correct paper, apply right amount of pressure, create an acid bath, and have tons of patience. It took me around a dozen attempts in order to perfect the process for my environment, so by the time it came to create the FlightCPU, it only took 3 boars (1 wasted). Below is a visual walkthrough to help identify the steps it takes to home etch a PCB.

![]()

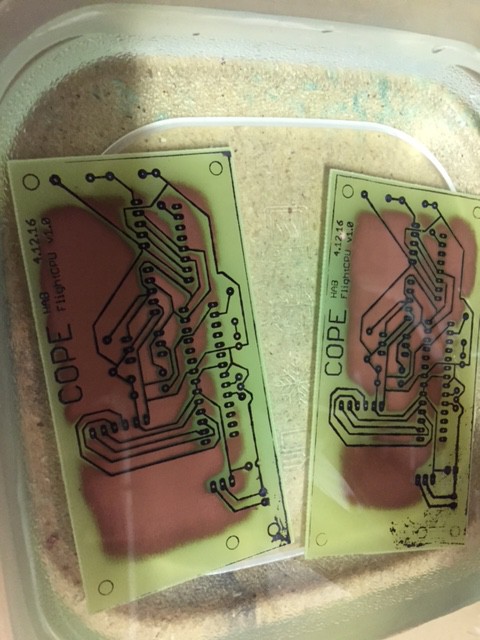

In true Contact fashion.. why build one when you can build two for twice the price.

The acid bath etches away the copper on the board, leaving only the traces applied during the ink transfer process. Here you can see the acid doing its part, eroding from the edges to the middle. I find it is best to wipe the board with a brush as it etches to help evenly distribute the acid bath.

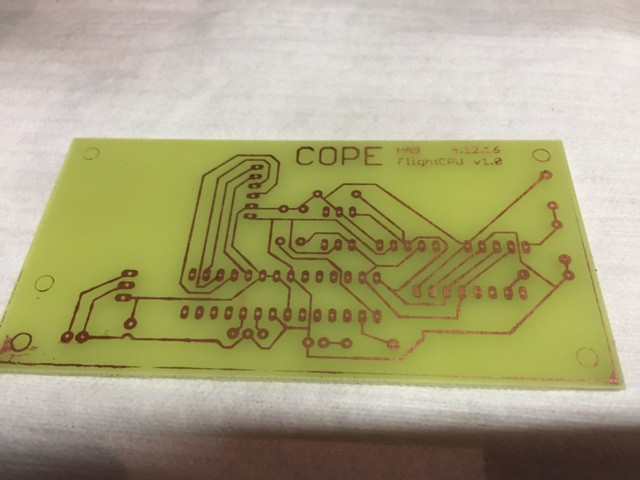

Here you can see the final product before we head over the the drill press and create holes for all the components. I used paint thiner to clean off the ink from the traces, exposing the copper lines that will be the electrical traces for the components. Not a bad job!

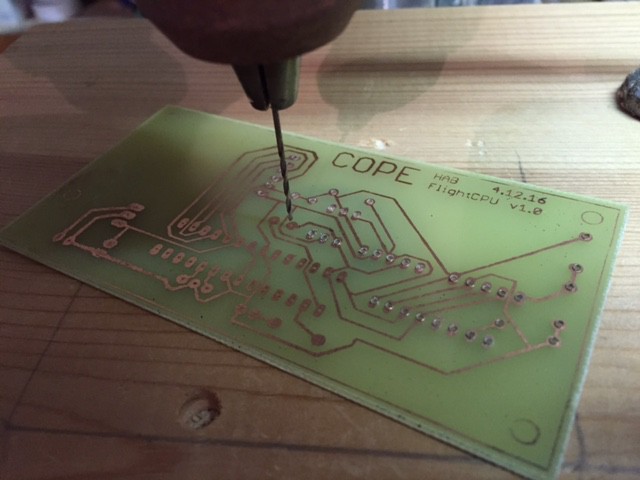

A drill press is a must if you are serious about creating your own PCBs at home. There is no other way to ensure straight perpendicular holes when drilling into PCB. Also, the copper helps guide the drill bit into the correct place, so once you get into a groove, everything just comes together.

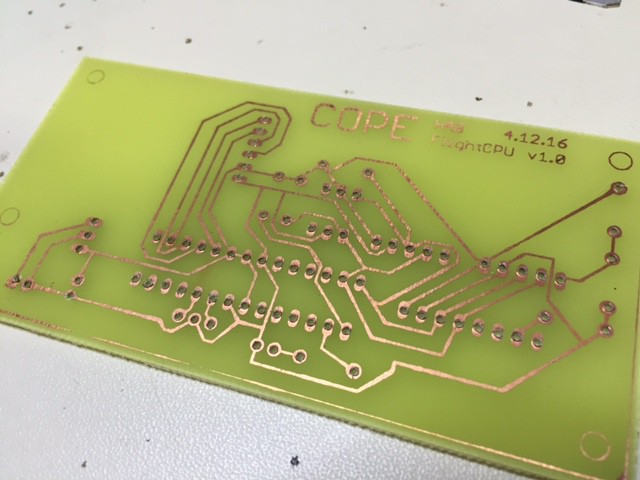

And finally, the finished product. Well, the PCB at least. We still have to assemble the components and solder every junction, but that might have to wait for another log update.

-

Rapid Prototyping

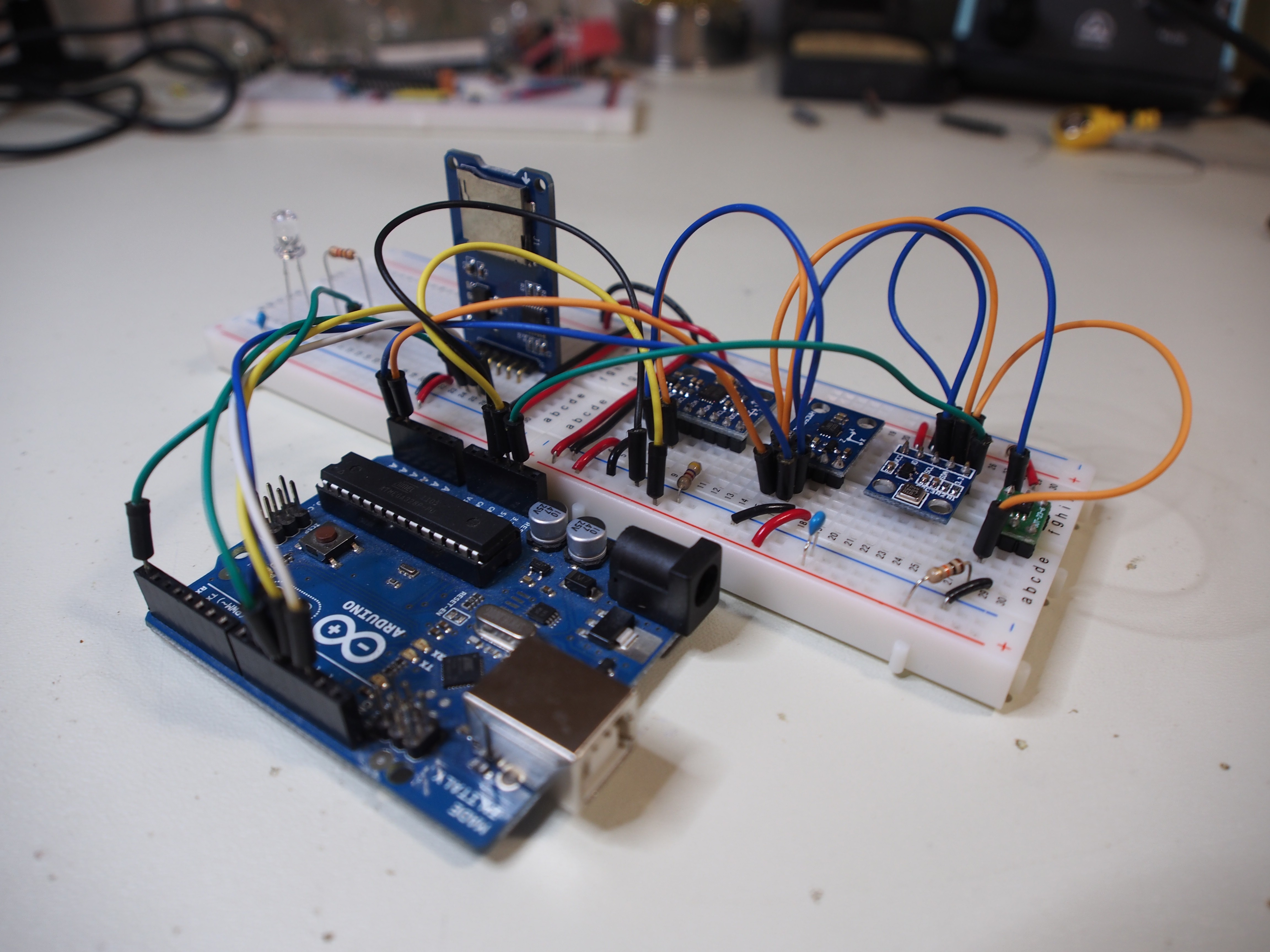

06/29/2016 at 16:08 • 0 commentsAny good hardware design needs a solid development environment to help debug and isolate issues as they arise. The final FlighCPU will be etched on a PCB, but until then, I needed to rely on breadboard and the Arduino Uno.

All sensors where purchased off of eBay for relatively inexpensive prices. If you can absorb the slow shipping speeds, this is definitely the way to go. The Humidity/Temperature sensor was a left over from an IOT project I worked on, so that sensor stands out from the rest (although it still uses I2C so I was all set on that front).

Development consisted of attached each sensor to the Arduino using the I2C bus (SDA-Pin 4, SCL-Pin 5)- and using the Wire (I2C) library to test communications. Well that was for the Humidity/Temperature sensor. For all other sensors, I was able to find open source libraries to help communicate with each sensor and pull the appropriate data.

Once I was able to confirm the Arduino could communicate independently with all sensors, it was time to daisy chain them to the I2C bus and make sure I could talk to all of them. I2C allows for devices to have unique addresses, so when you communicate on the bus, on the desired device will respond. Some I2C devices have multiple addresses, allowing you to avoid any conflict with multiple devices. Luckily, all hardware we selected had different addresses, and talking to each one while on the bus was no problem.

-

Initial Log

06/07/2016 at 22:48 • 0 commentsHi Everybody!

This past spring, my brother and I launched a weather balloon as part of the Global Balloon Challenge. It was our first endeavor in such a project, but had a complete blast designing, constructing, launching, and finally retrieving the balloon.

This project is focused on the actual Flight CPU I designed and built in an effort to log the data as the High Altitude Balloon rose through the atmosphere.

The Flight CPU is designed around the ATMEGA328P so it can easily be developed using Arduino tools. All sensor modules communicate with the uC using I2C with while the MicroSD card is accessed on the SPI buss. Data is logged on the MicroSD card at various resolutions depending on the sensor.

Sensors include: Gyroscope/Accelerometer, Compass, Temp/Humidity, Barometer.

Check back later as we update the page with build details and instructions on how to replicate. If you want to get an early jump, head over to the GitHub Repo and check out the hardware and software.

Jeremy

Jeremy