-

New video session about my plan's for XATC

09/22/2016 at 06:58 • 0 commentsNew Studio and new Design! :)

I'm just kidding, but please send me ur opinion about this video!

I'm proud to present a new video session about XATC and my plan's for the next weeks. Further i made a small 4x tool change. Please send me your opinion about this video and how can i make something better.

The XATC is not perfect at this time, but close to. I need more tests and then it's perfect. Now i come back to my XDisPlace project and try to mill a complete PCB.

Interview with Sebastian:

XATC @ G+:

-

XATC V0.2 released

09/12/2016 at 11:23 • 1 commentI'm proud to present my XATC V0.2. Without the expensive gator grips and better support for long endmills.

On the thumbnail for this video you see my improved design of the endmill Holder. The hole in the center has a diameter of 3mm and hold enmill's with 3,.175mm (1/8") Diameter.Now the summer close to end and i have to speed up my XATC cuz i want build the main project XDisplace. Now i'm proud to have a Zonestar P802N 3d printer and here is my first 3d Design for an endmill holder. This will screw under the carousel to hold the endmill in correct position :)

http://www.thingiverse.com/thing:1756051I plan to make a new video session during next weekend to describe everything about this new design, please check or subscribe my Youtube Channel and you will informed if it happend.

-

XTLS Tool Length Sensor

07/15/2016 at 08:49 • 0 commentsHi Friends,

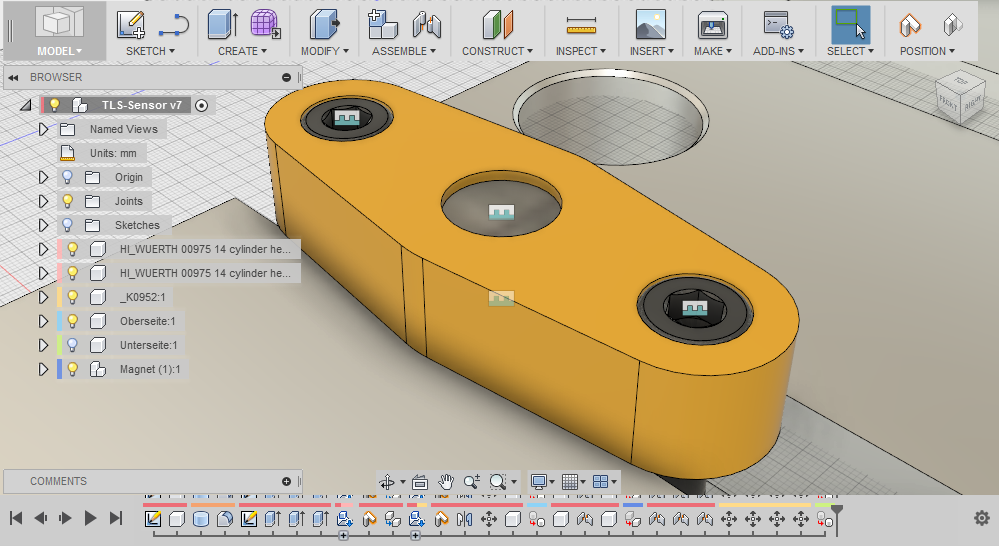

for XATC i need a Tool Length Sensor. Ok, i can buy a micro switch ... but you know ... i love to design my own, cuz i'm addicted to #Fusion360, this program is so great and i love it.

Ok, my idea ... i build a 3d print and put 2 neodym magnets (12x3mm) inside, once on the bottom and second on the top of this enclosure . They are in front with the same poles and repel each other. This will replace a springload and works in every case, the surface of the top magnet are the sensor. We need only the wire from touchprobe connected to this magnet and thats all :)

I get my prototypes in the next days, maybe i make some photos ... but my boat vacation will start at weekend ... we will see :)![]()

Hi Friends, ok this is the last message before we start the Vacation. After 2 weeks i'll send new magic things :)

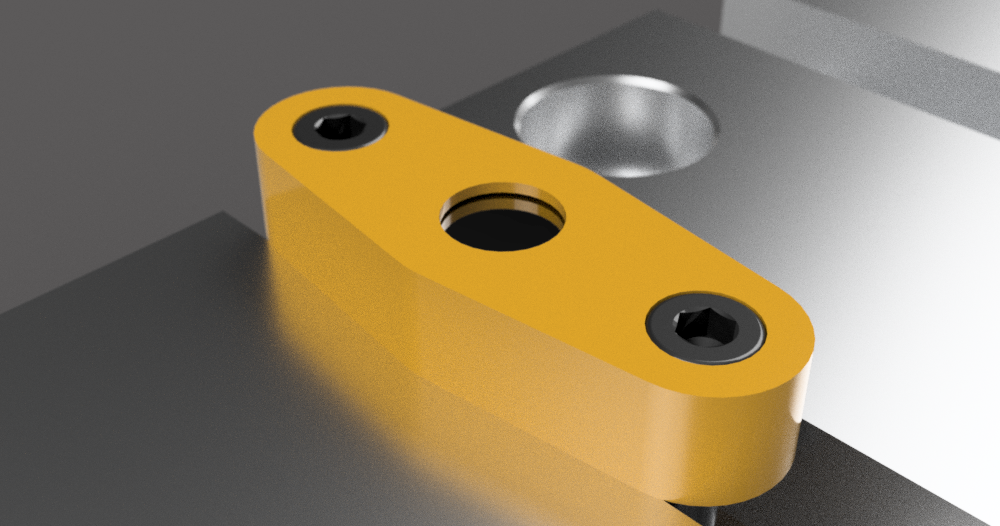

Well, my 3d printer guy was very fast and i got yesterday the first 3d Prototype. I have to say awesome quality! The funny part was, bring this 3d magnets together in this small 12x10mm hole. After some tests, i used 2 iron wrench and hold the magnets in position. Zhen it was possible to put both of them in this enclousure.

Here some Photos, first from prototype ( i need a name for this, hmm ... "XTLS" :) ) and complete on my (dusty) CNC Table.

Now i need a z-max wire, also i want to mill a aluminium top plate on the second prototype for more simple wiring.cu

Frank

-

Some patches and a new "Shake" mechanism

06/22/2016 at 11:25 • 0 commentsNew Patch:

* add 2 new commands "sav" and "rem" at XC-Console, to save the actual direction and speed. "rem" will set the spindle to this saved values after toolchange.

* use this commands in xatc macro

* add a "shake" mechanism for sure catching spindle. After a block, the spindle rotate in the opposite direction for 200ms, then back to prepar "magic move"

* use carousel.servo.level instead of zero

https://github.com/xpix/XATChttps://plus.google.com/u/0/+FrankHerrmann1967/posts/5e2Z413Qa8n

XATC (extreme simple automatic tool changer)

A very simple but cheap solution to change endmill bits on a CNC Machine.

Frank Herrmann

Frank Herrmann