-

Castellated Edges

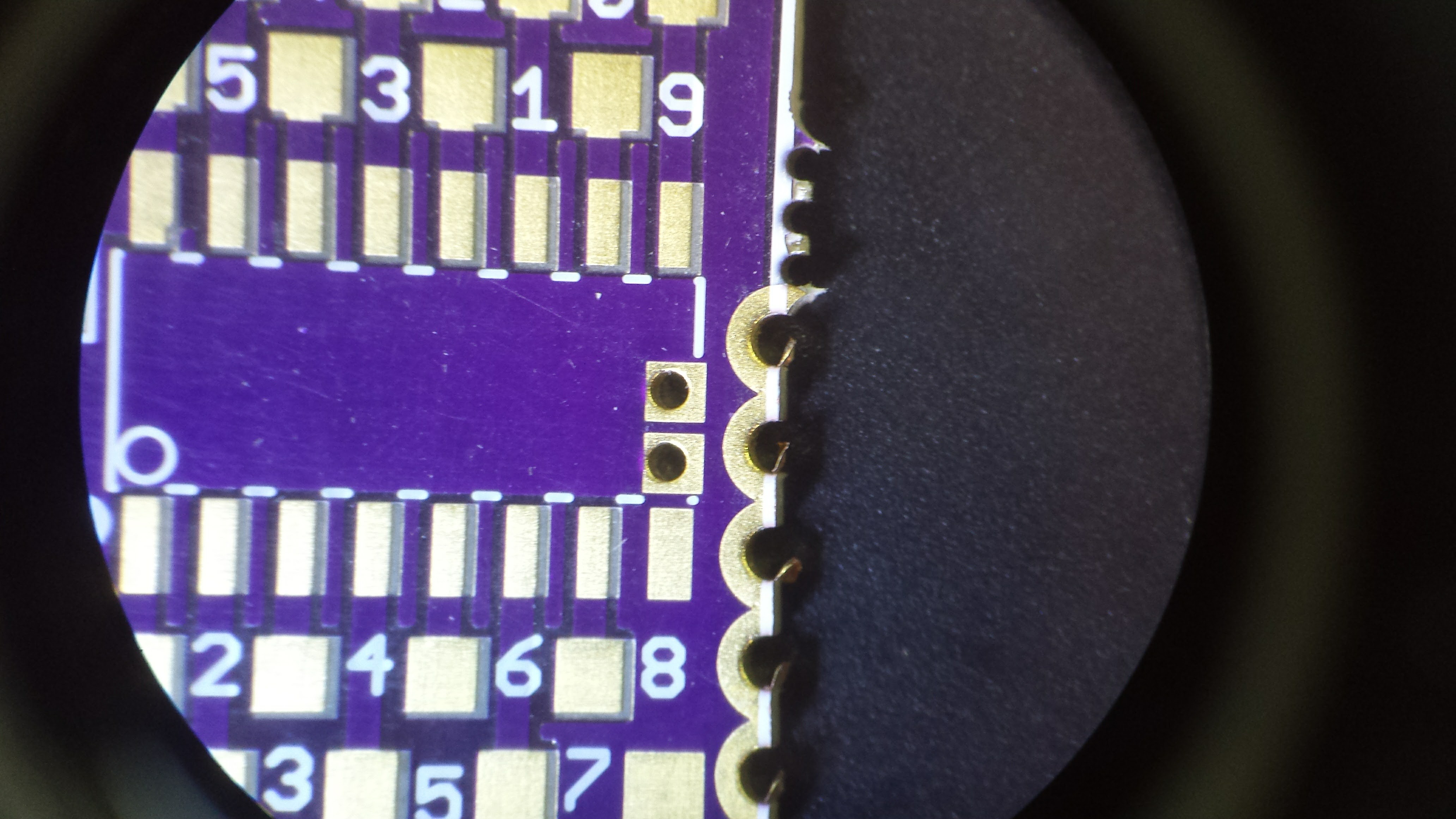

01/15/2017 at 00:27 • 0 commentsI haven't been good about updating this project, but I've been using these adapters very successfully. Most recently, I've started adding castellated edges for soldering to the ground plane. Here's a look at some under the 10x inspection microscope:

![]()

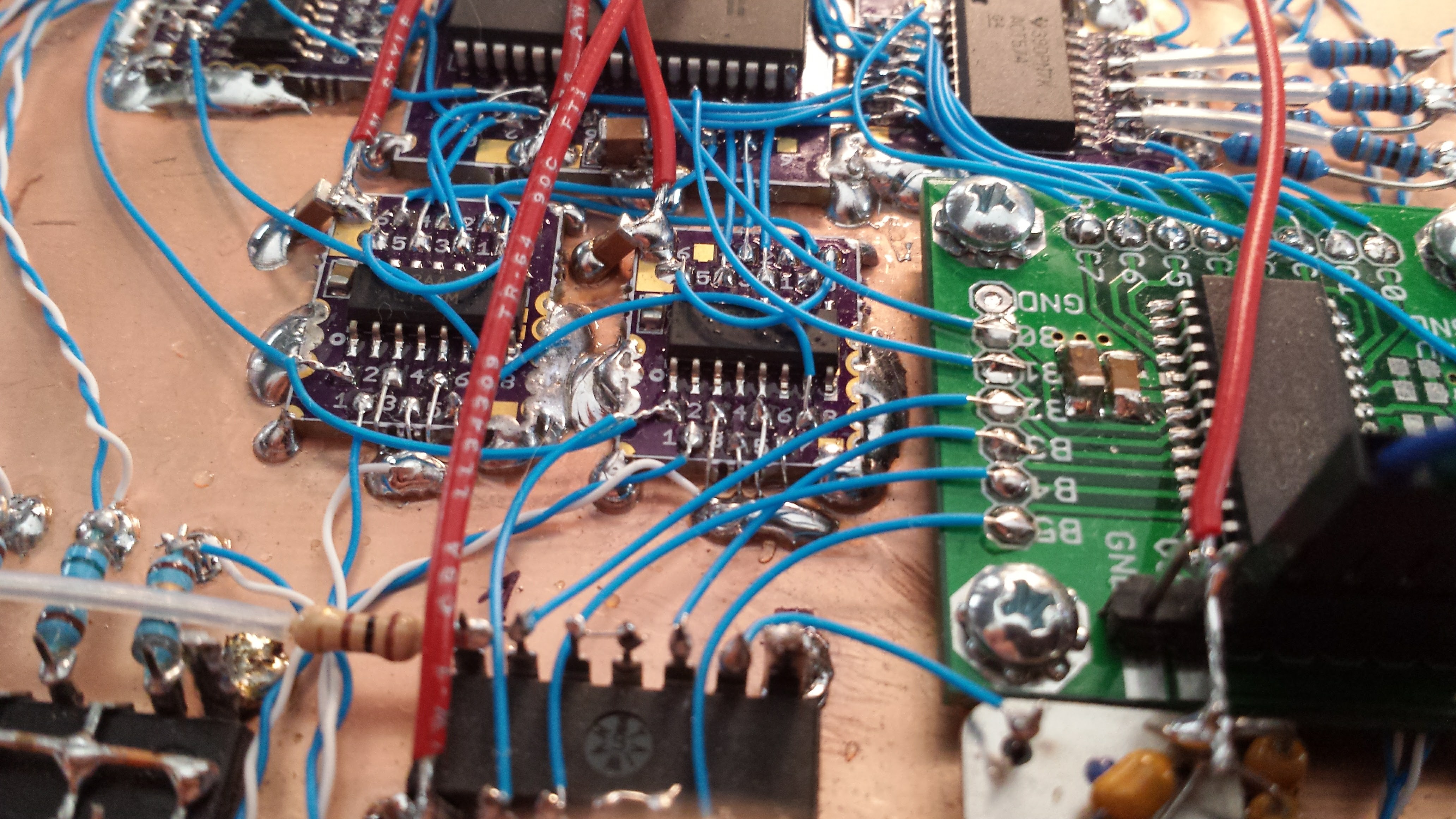

This board was (obviously) made at OSH Park, using their castellation guidelines. As you can see, the outer cut can leave a little bit of extra copper foil attached to the hole. This is easily removed with a knife, a file, or sandpaper. If you were using these for connecting individual signals to a base board, you would probably want to remove them before soldering to avoid possible bridges. Since I'm using them for ground connections, I didn't bother, and just soldered them to the ground plane as is. The result isn't particularly attractive, but it works:

![]()

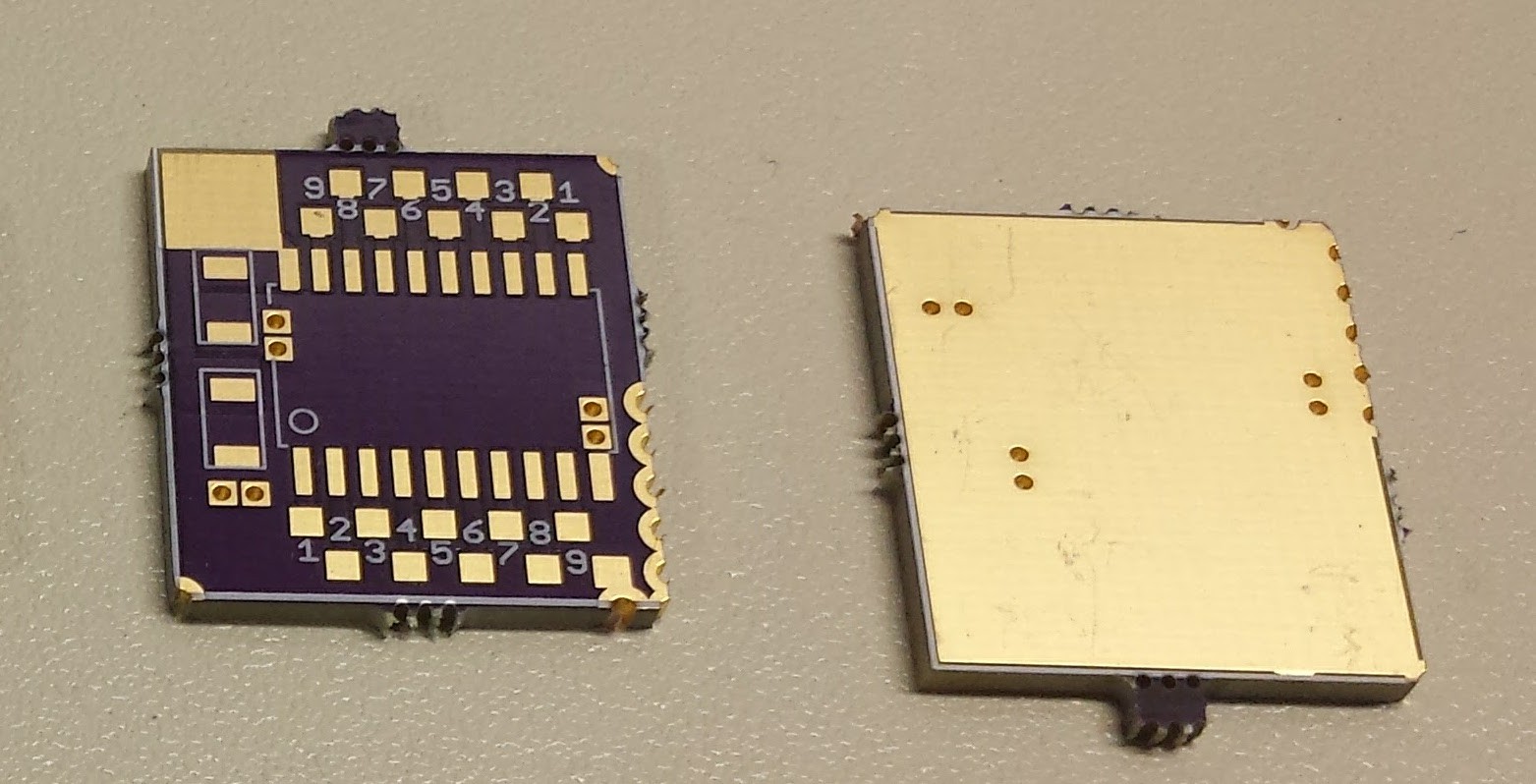

These particular adapters were made for SOIC logic packages for the #PIC Graphics Demo. The project uses 74AC logic, which has a reputation for causing trouble with ground bounce and with signal reflections due to very fast edge rates. As a result, systems built with 74AC can be more sensitive to layout than other logic families. I wasn't sure how well the castellated ground connections would work, so I also removed the soldermask from the bottom ground plane on the adapters:

![]()

The idea is that you could reflow these adapters to the solid copper clad ground plane if you wanted. As it turned out, just connecting the grounds with the castellations worked for this particular project - although the bare gold is right next to the bare copper, closely coupled capacitively, if not conductively. I don't know if it would work for everything. For 74HC gates, there should be no issues just connecting the castellations.

As you can see in the image, there are sites for bypass capacitors on the boards; they assume the standard corner power-pin layout of logic ICs. In that sense, they're not totally general-purpose, but they could be used for any logic gates in standard packages.

The solder pads are 50 mils square, and spaced 100 mils apart. This is a comfortable pitch for me to hand-wire boards with wire-wrap wire - the 50 mil pitch of the SOIC parts is just a little too small.

One thing I want to try is making adapters for wire-wrapping SOIC gate packages. Some ICs are no longer available in DIP packages, and wire wrap sockets are very expensive. Adapters that mounted SOIC parts and 25-mil square gold header pins would solve both problems. Also, the low-profile of the SOIC parts would let you mount the pins on the top side of the board, with room to wire-wrap over the ICs - where did I see this around here? No more reversing the pin layout in your head!

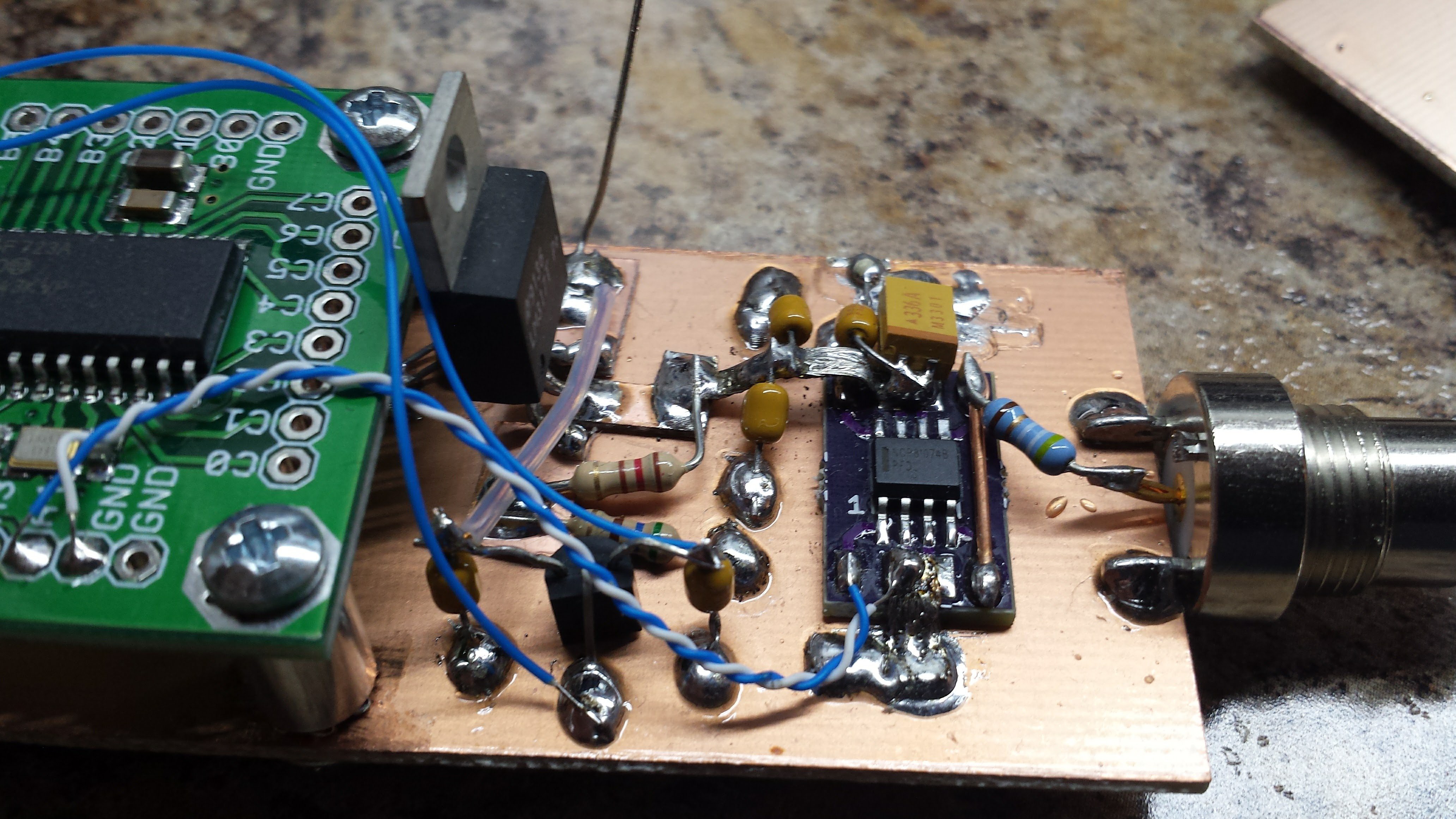

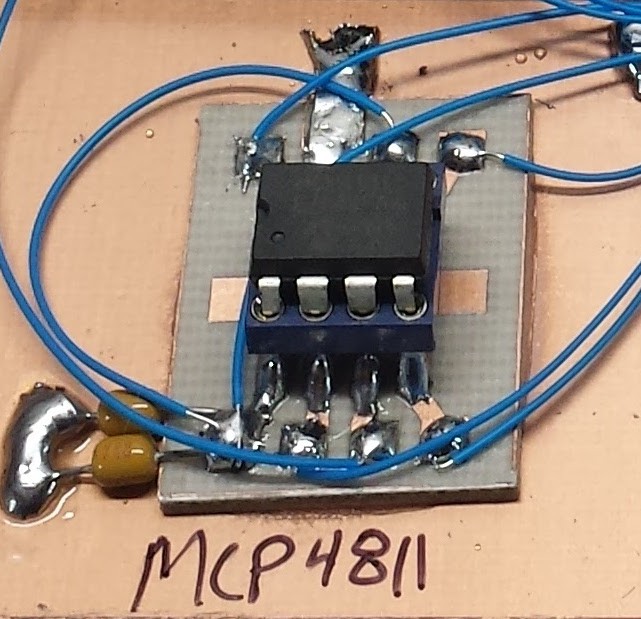

Finally, here's a completely unrelated board that shows how easily the original adapters mix with more traditional prototyping.

![]()

-

First batch (twice!)

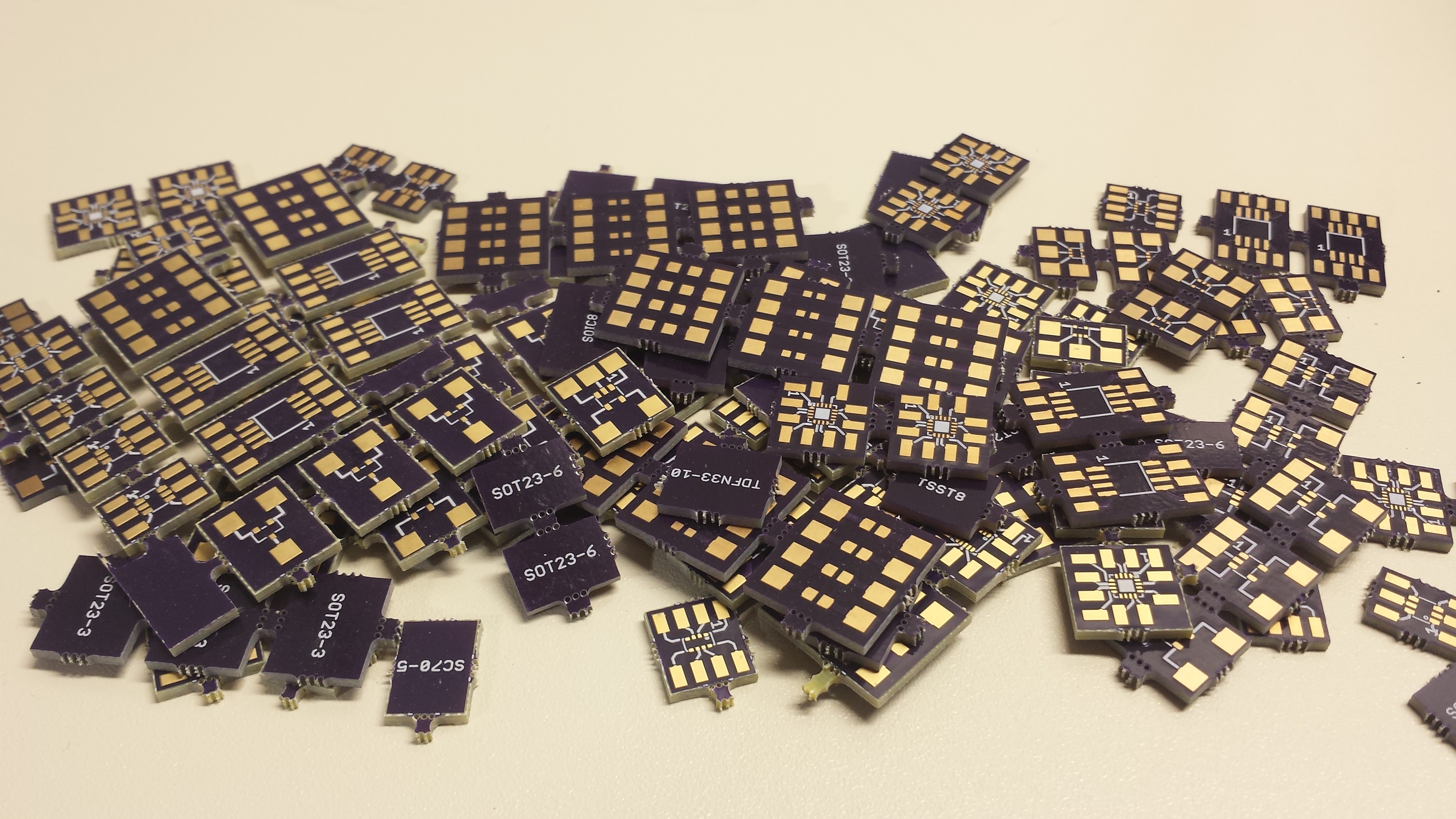

08/23/2016 at 17:26 • 1 commentThe first batch of test boards arrived. Actually two batches did: USPS "misplaced" my first shipment for ten days, but found them again just after OSH Park rush-ordered a replacement set. Here they are:

![]()

I have a few projects that have been on hold until these arrived, so I'm excited to test them out. I'll post progress as I do.

These first boards must be glued to the copper-clad backplane. As a next step, I'm going to try some boards with three different ways of soldering to the plane:

- bare pad bottoms skillet-reflowed onto the plane with solder paste

- an outside ring of through-holes to solder to the plane

- castellations around the board perimeter

It turns out that OSH Park supports castellations, so that sounds like the most promising approach, but I'd still like to test all three.

Next Up

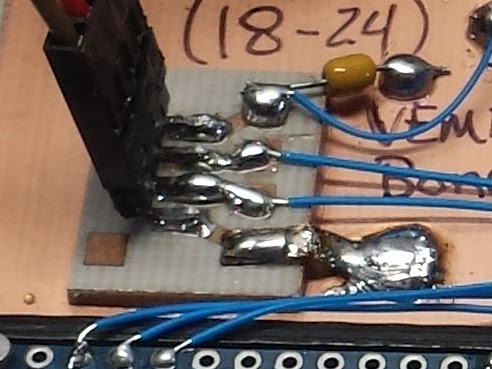

As to which packages to support next, I'm running out of small DIP adapters. Here's a few I used this past weekend:

![]()

![]()

(Left) A 10-bit DAC is plugged in while I wait for a 12-bit unit to arrive; the adapter board makes mounting a socket on the plane easy. (Right) Half of a DIP8 adapter board makes a convenient mount for a 4-pin header for connections to a daughterboard.

Stay-Clean Boards

I used another trick on the above prototype to preserve the copper ground plane. I cleaned the copper clad with "Barkeeper's Friend," a scouring powder containing a fine abrasive, then rinsed it thoroughly. Once it dried, I spray painted it with a light coat of clear enamel. This coating protects the copper from corrosion, but is easy to solder through when connecting to the plane: it will keep the boards looking pretty for years to come. I read about this technique a few years ago on Charles Wenzel's site, but haven't been that good about actually doing it. I finally got motivated, and coated a few large pieces of copper-clad, so I can just cut them up with a shear as I need pre-coated pieces.

Ted Yapo

Ted Yapo