-

New batch

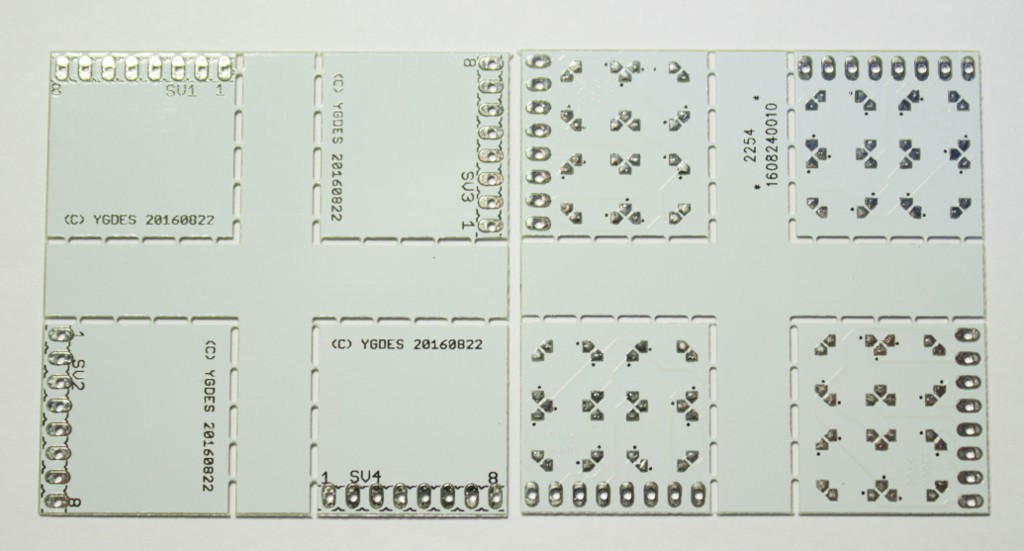

08/01/2018 at 03:17 • 0 commentsThanks to the HAD prize seed fund, I could afford more PCB !

I ordered more #DYPLED boards in .8mm thickness and white soldermask. And this time I successfully "tented" my vias, which greatly helps with assembly :-)

As previously written, I used Zener-less LEDs. This is clearly indicated in the marks at the back of the module. I'll have to solder a few... Overall, I could solder 44 modules, more than I can use now, so who is interested to get/use some ? Should I open a Tindie store ? :-)

-

Settling for Zener-less LEDs

11/17/2016 at 16:08 • 14 commentsThis project was on hold for a while, for various reasons, but I am resuming it (along with #DYPLED) thanks to the delivery of a new batch of warm white LEDs. I just tested them and they have no Zener or protection diode (like the previous warm white batch). It seems the cold white LEDs have the Zener, despite coming from the same seller.

This means that I don't intent do waste time on the Zener'ed LEDs (at least for digit display purposes). I'll stick to version 1 with series resistors and parallel connexion.

Time to order more PCBs...

-

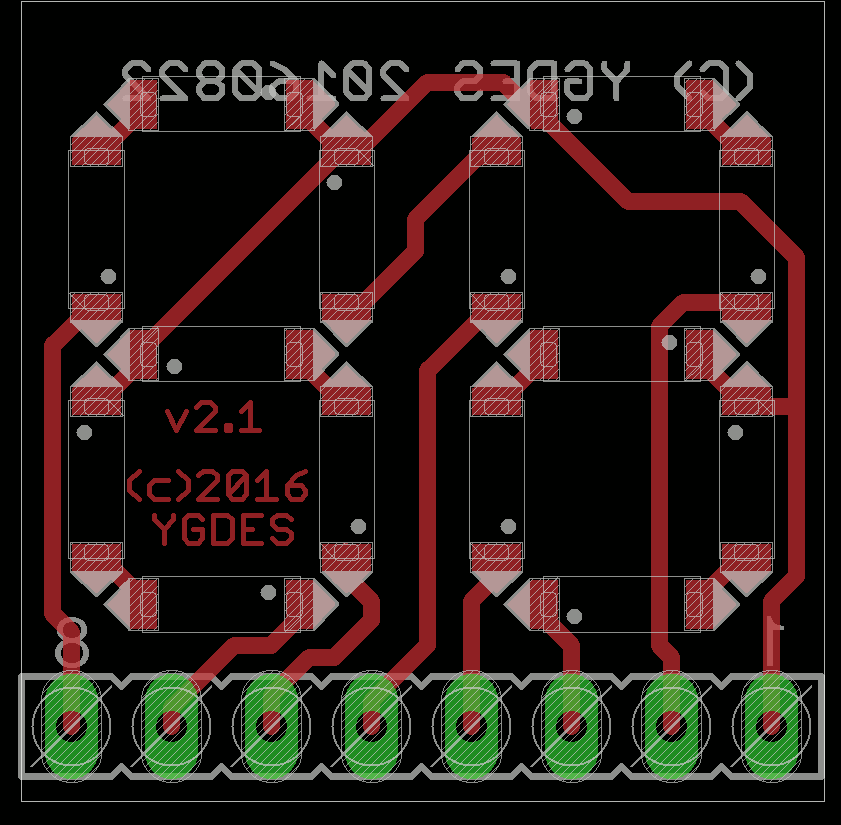

My first v2 boards

09/15/2016 at 02:19 • 0 commentsThe DirtyPCBs package is here and the boards are just as expected.

The experience gained with the previous runs has been useful, look at my page describing the tiny differences between DirtyPCBs and DangerousPrototypes: Dangerous Prototypes vs DirtyPCB : same maker, different process

In this case : no via, so no tented via problem, the milling has not been modified (much better for soldering the LEDs while still attached), the serial number marking is manually located in a blank place (thanks !)

The only defect is the one found yesterday by @al1 (see a second prototype - and some bugs (by al1))and it's just a matter of reversing F1.

Note: this board is good only for LEDs WITH an internal reverse diode.

Time to solder a few now...

Between the v1 and v2 boards, I must have enough digits to prototype a first #Discrete YASEP ;-) Which will I choose ? v2 is great because there is less wiring (easier routing) and no series resistor but the matching LEDs I have are cold white, and warm white goes to v1 boards...

If you are interested to get some of these boards, send me a message !

-

Team work on HaD

09/13/2016 at 23:14 • 0 comments@al1 found a stupid error I made in the v2.0 so I reversed the segment F1 on the new v2.1.

I uploaded the new .brd as well.

It won't go in production before a while. Meanwhile, the precedent versions can be coerced into working :-)

-

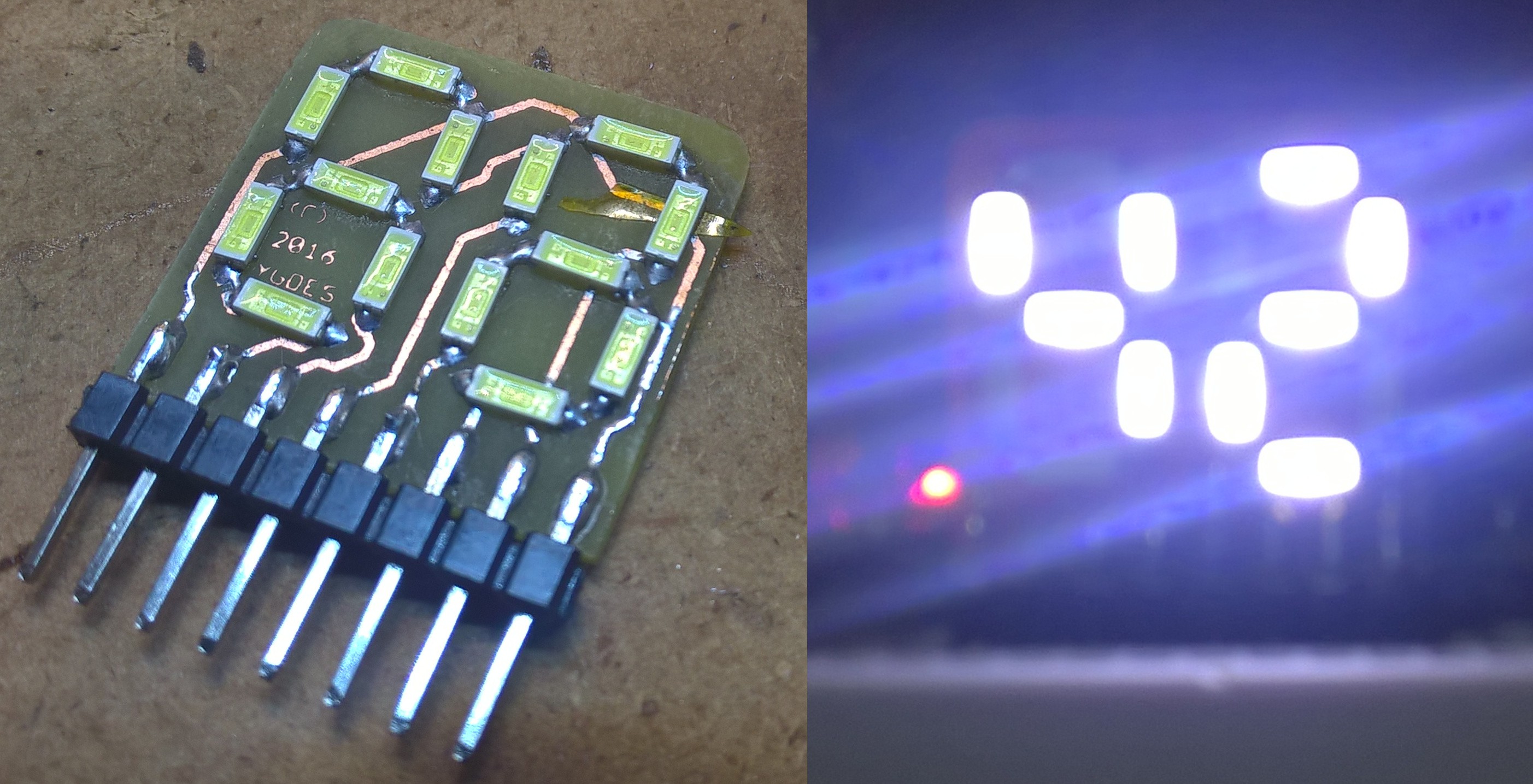

a second prototype - and some bugs (by al1)

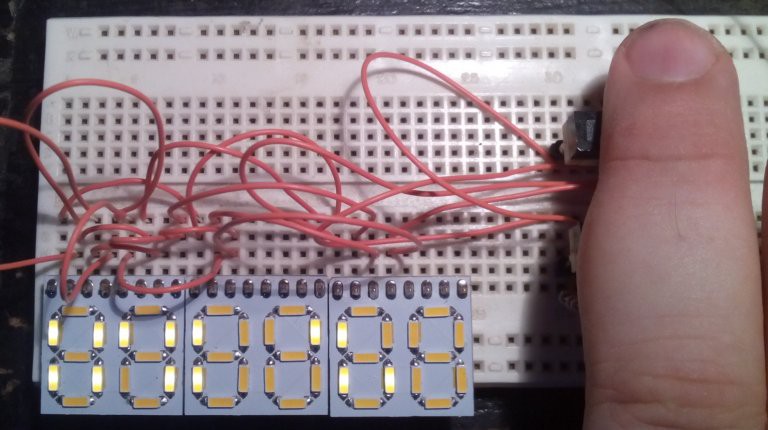

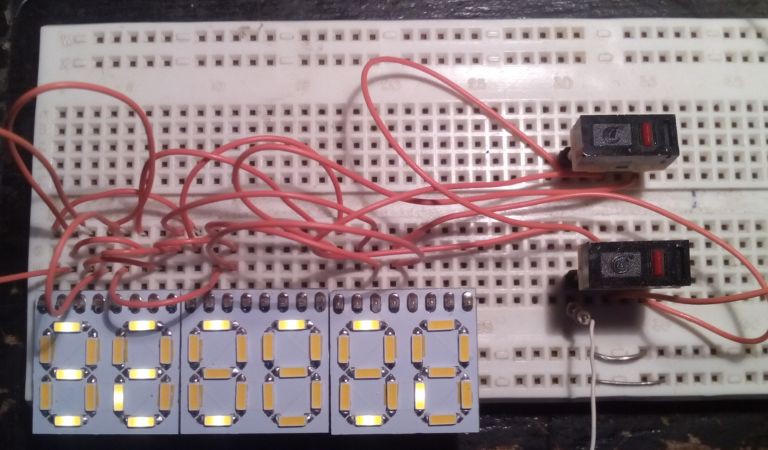

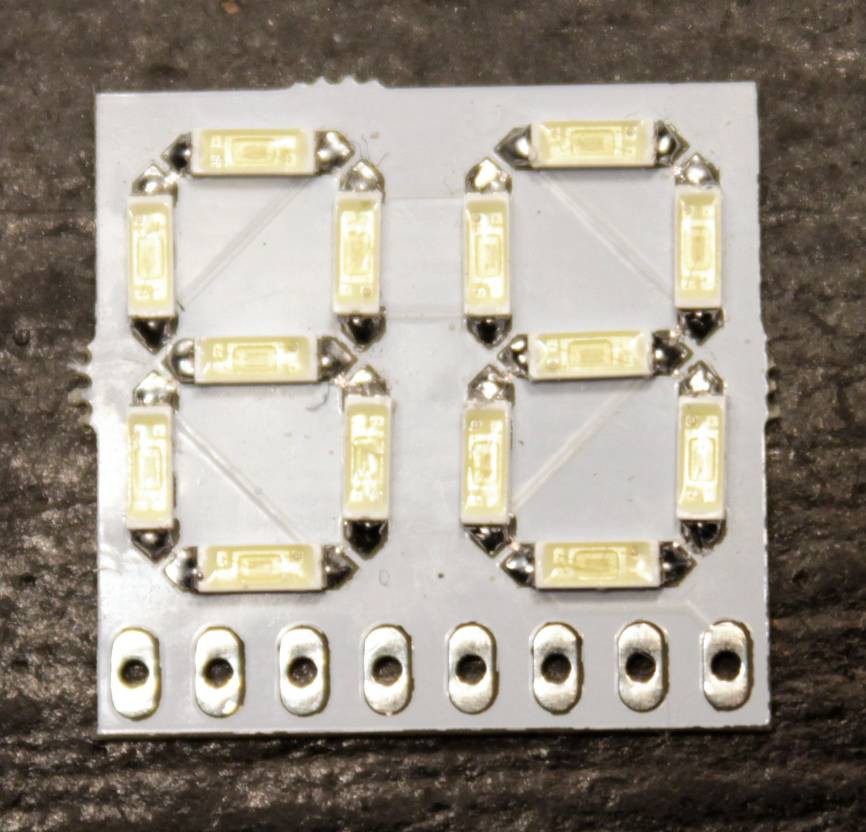

09/13/2016 at 16:28 • 2 commentsI did some home etching the last weekend and I thought that would be a opportunity to throw also some 4014 module PCBs in. This is the result a first rev2 board:

Beside that one trace with the capton tape the design is quite good to etch yourself.

I used the same software I uploaded in the files section with adapted port defines. But when reviewing my code I found something bad: I do not know why I did that, but the code does do some multiplexing to much, and lights only one LED on at the same time, must fix that later.

A second bug is in the schematic: On of LED B1 (1=left digit) or F2 is the wrong way around. So far I did saw B1 as wrong (only important for the software).The boards I order at OSH-park arrived also today. Will make some photos and soldering one soon. I did changed my order successfully to the rev2 boards so it should work with my type of LED.

-

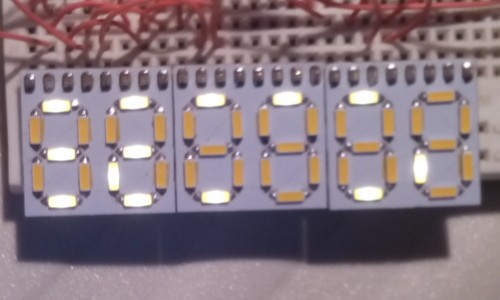

Contrast enhancement with a diffusion layer

09/06/2016 at 21:07 • 8 commentsSince the beginning of the #DYPLED project, I've been wondering how to provide a better aspect with the least means. The display is nice as it is but it can still get better. Today I could finally test my hypothesis :-)

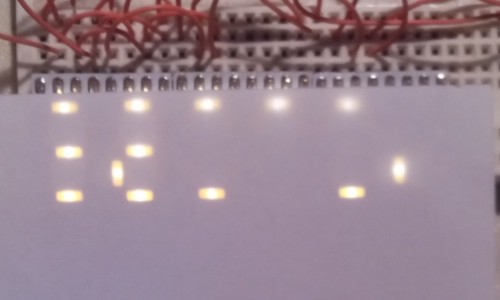

This is the display modules, shot with my crappy smartphone camera :

Adding a simple, dumb sheet of white paper in front makes it look like this :

This is obviously visually more pleasing, I think.

Now, there are many problems to solve:

- Paper is not durable. What plastic foil/film/sheet is best suited ?

- The dots don't all appear nicely because the sheet could not stick to the surface of all the LEDs. Conclusion : the surface diffusor must be adhesive...

- Does the PCB's soldermask color matter anymore ? Could black further enhance the contrast ?

I'll test more ideas, meanwhile, I'd love to read yours in the comments :-)

20160909:

I tried various diffusion sheets from broken LCD screens. The results are not as expected. LCD diffusors do their best to not waste photons and spread light as much as possible.

Paper OTOH absorbs quite a lot of light, which increases the contrast. I'll have to find a very thin adhesive label...

-

First working units

09/06/2016 at 18:37 • 0 commentsAfter yesterday's discovery while assembling the first #DYPLED prototype, I couldn't resist trying this other type of 4014 LED on the rev. 0 boards that I thought would be useless.

I couldn't wire all the segments but you get the idea from this crude setup:

I have noticed that the luminosity is very high at 3.3V and 1K series. Apply PWM ! Instead I lowered the voltage to around 2.7V to get a comfortable contrast.

-

a prototype

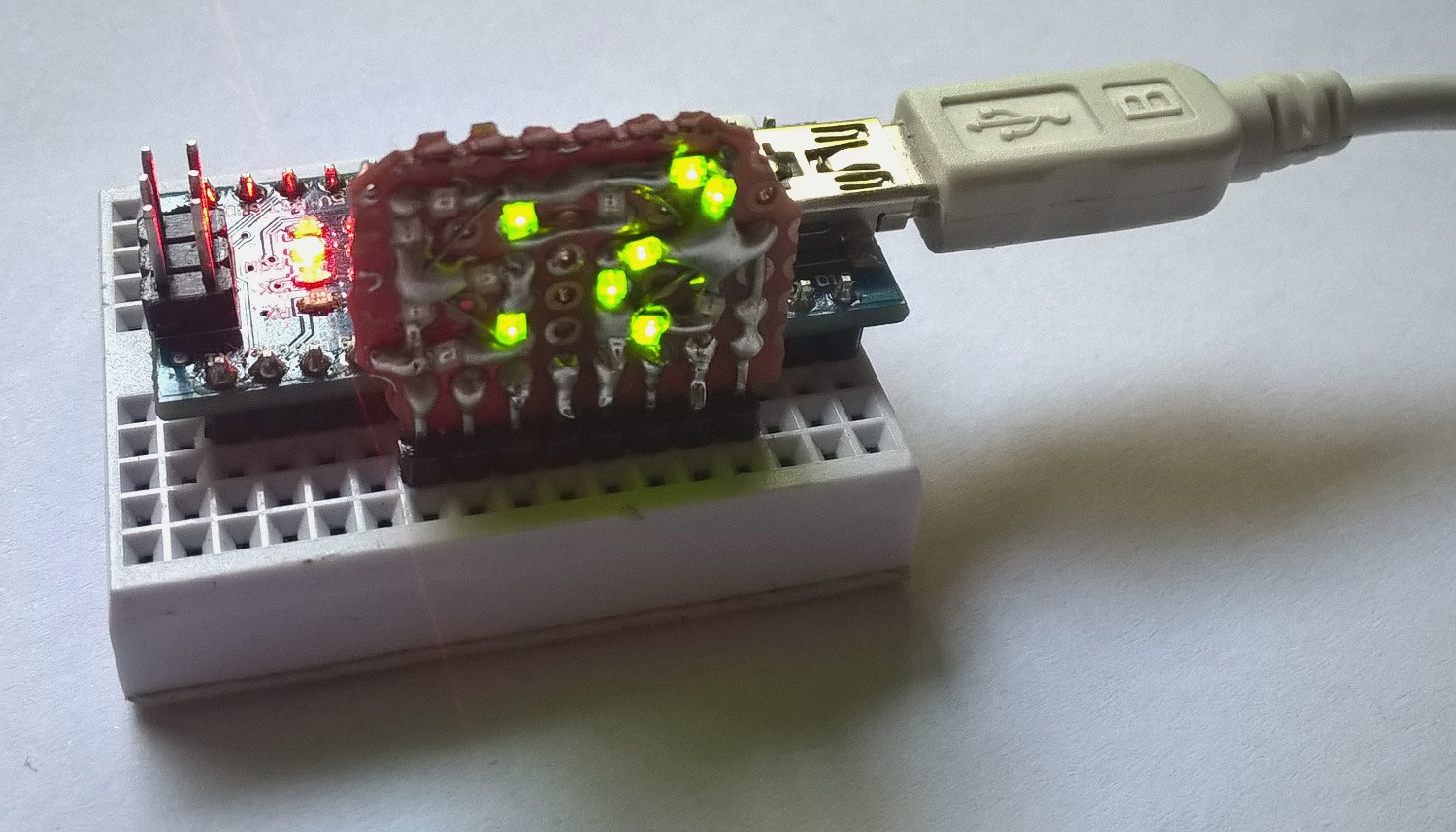

09/06/2016 at 16:34 • 4 commentsIn the file section you can now find my (al1's) AVR test code for rev0. To test this code I made this little quick prototype out of some prototype board and green 0805 SMD LEDs. It should be compatible to rev0.

With 0805 you can read it not good (should be much better with 4014 LEDs). This is a "12".

-

There are two types of 4014 LEDs !

09/06/2016 at 06:57 • 2 comments@al1 found that his 4014 LEDs have a reverse protection diode. I found the same and made the v.2 layout.

Today, I started to solder the #DYPLED prototype so I opened a new batch of LED (warm white instead of neutral) and... NO DIODE !

Alex, don't throw your PCB away, I'll solder mine and see what can be done. I'll see if I could send you a few diodeless LEDs :-)

So in the end, there are 2 types of LEDs, hence 2 types of PCB...

-

Rev.1 PCB arrived

08/29/2016 at 16:49 • 2 commentsI received the very first order recently, and it won't be of much use...

We already know that the circuit is wrong because of the protection diode (which could also be a Zener but at this point, who cares ?).

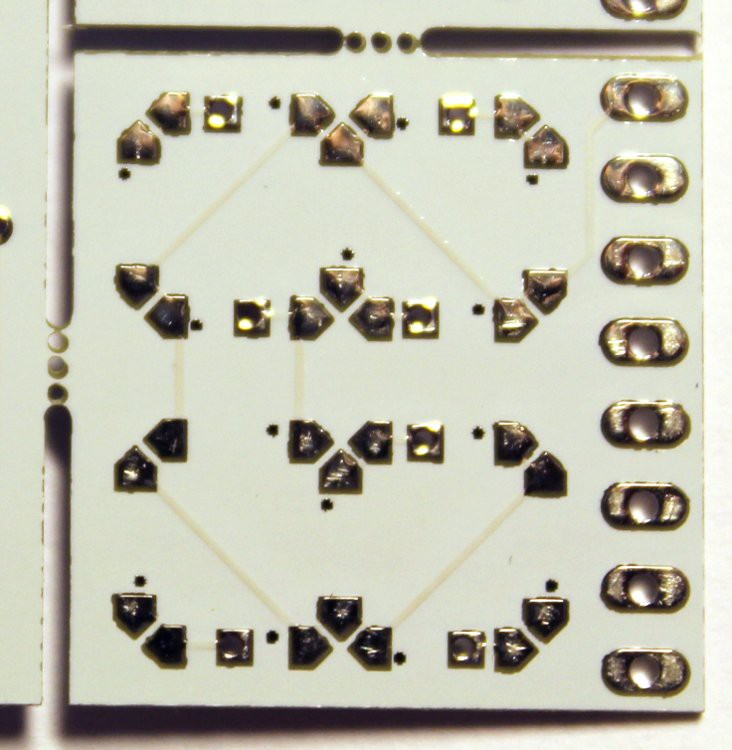

Now, it's time to examine the PCB of the first version and look at other problems.

The PCB did not get my "tented vias" and there are exposed signals under the LEDs.

I have put the vias under the LEDs because I didn't want visual distractions.

However the LEDs have heatsink pads that are electrically connected so short circuits will happen.

Even worse: the HASL treatment increases the height of the via and adding insulating Kapton will make the part unsolderable because the pads won't touch the contacts...

Fortunately, Rev.2 indirectly solved this problem because it's a single-sided PCB. No via.

The diameter of the connectors seems to be ok and standard pins can go through it.

I should try to solder a few LEDs, now...

20160902:

I soldered a few LEDs and it's not for beginners but it's not hard either. Just use very thing soldering wire, and apart from the problems with the vias etc., the layout and the footprints don't need to be modified. That's a relief :-)

(yes, I didn't care much about the quantity of solder but it's not critical and it matters that it is easy to solder by hand)

4014 LED minimodule

A cheap, small module that displays two 7-segments digits with simple multiplexing

Yann Guidon / YGDES

Yann Guidon / YGDES